- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

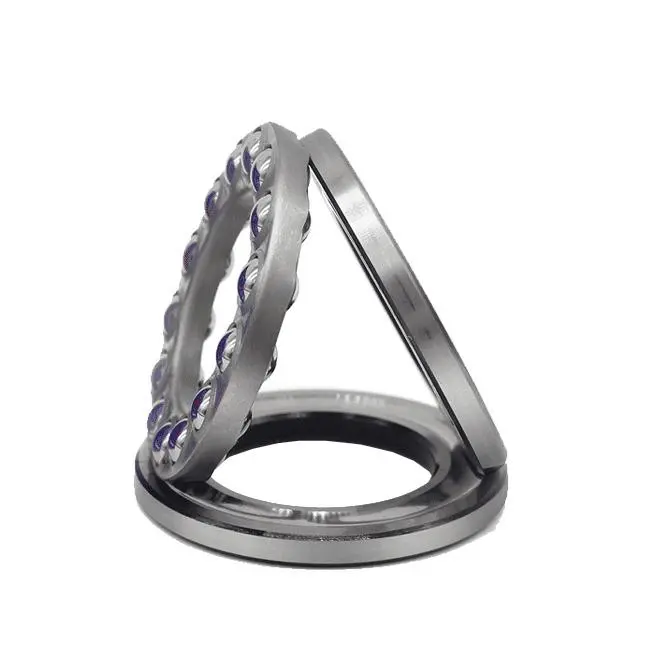

Angular Contact Thrust Ball Bearing

2.Structure Type: Shaft washer + housing washer + angular contact steel balls + cage, open type or with fluororubber dust cover.

3.Size Range: Inner diameter: 15 - 200mm, outer diameter: 40 - 250mm, height: 12 - 40mm.

4.Material: Shaft washer: GCr15/GCR15SIMN/20Cr2Ni4A, housing washer: GCr15/GCR15SIMN/20Cr2Ni4A, rolling elements (angular contact steel balls): GCr15/GCR15SIMN, cage: brass (precision model) / stamped steel.

5.Accuracy: Conventional P5 grade, ultra-precision model is of P4 grade.

6.Application Fields: Spindles of precision machine tools, turbochargers, high-end motors.

7.Key Inspection Items: Accuracy of contact angle, radial and axial load-bearing capacities, rotational accuracy (radial runout ≤0.005mm).

Angular Contact Thrust Ball Bearing: Precision & Durability for Demanding Applications

When your machinery requires bearings that handle axial loads and high-speed rotations without compromising precision, our Angular Contact Thrust ball bearings deliver unmatched performance. Designed with a 15°/25° contact angle, these bearings support combined axial and radial loads, making them ideal for precision machine tool spindles, turbochargers, and high-end motors. With material upgrades like GCr15SIMN steel and P4-grade accuracy, they ensure longevity even in extreme conditions.

Product Overview

- Design: Shaft washer + housing washer + angular contact steel balls + cage (open or fluororubber dust-covered).

- Size Range: Inner diameter 15–200mm, outer diameter 40–250mm, height 12–40mm (customizable up to φ5000mm).

- Materials: High-purity steel (GCr15/20Cr2Ni4A), brass/stamped steel cages, optional ceramic hybrid balls.

- Accuracy: Standard P5 grade; ultra-precision models achieve P4-grade (radial runout ≤0.005mm).

- Key Tests: Contact angle accuracy, axial/radial load capacity, rotational stability, and noise levels (<35dB).

Where Our Bearings Excel?

1. High-Speed Industrial Automation

-

Reduce downtime in robotic arms and CNC machines with P4-grade precision and low-noise operation.

-

Ceramic hybrid options cut weight by 25% and withstand temperatures up to 150°C.

2. Wind Energy & Heavy Machinery

-

Tapered roller designs handle 450+ kN loads in port cranes and wind turbine pitch systems.

-

Diamond-like carbon (DLC) coatings enhance wear resistance in abrasive environments.

3. Aerospace & Medical Devices

- Achieve ±0.001mm tolerances for aircraft landing gear and medical imaging equipment.

- REACH/ROHS-compliant materials meet EU sustainability mandates.

Customization Made Simple

Need non-standard sizes or materials? Here’s how we adapt:

1. Analysis: Share your operational conditions (loads, speed, temperature).

2. CAD Mapping: Our engineers design bearings with 3D simulations for optimal performance.

3. Prototyping: Test a sample within 7 days.

4. Bulk Production: 90% of custom orders ship in 15–20 days—30% faster than competitors.

Popular Customizations:

- Non-standard bore diameters (e.g., legacy aerospace systems).

- Pre-lubricated or sealed designs for dusty environments.

- IoT-ready bearings with embedded sensors for real-time health monitoring.

Quality You Can Trust

Every Angular Contact Thrust Ball Bearing undergoes:

- 12+ performance tests (vibration, lifespan, load capacity).

- 100% finished-product inspection.

- Material purity checks (high-purity steel with ≥60 HRC hardness).

Certifications: ISO 9001, IATF 16949, AS9100 (aerospace), DNV-GL (offshore).

Fast-Track Delivery & Pricing

- Standard Bearings: 1,000+ SKUs ready for 48-hour shipping.

- Bulk Orders: Tiered pricing for 100–5,000+ units.

- Urgent Projects: Expedited 15-day production for large custom batches.

Technical Support & Resources

- 24/7 Engineering Support: Get installation guidance or troubleshoot issues via email or live chat.

- Free Downloads: Access 3D CAD models, maintenance checklists, and lubrication guides.

Why Choose LUOYANG INNO?

- ✅ 30+ Years of Expertise: Specializing in precision bearings since 1992.

- ✅ 30% Faster Lead Times: Agile production for urgent orders.

- ✅ 99.9% Defect-Free Rate: Rigorous quality checks ensure reliability.

- ✅ Global Warehouses: 48-hour delivery across Asia, Europe, and North America.

- ✅ Lifetime Support: Predictive maintenance plans to extend bearing life.

FAQ

Q1: How do your bearings maintain P4 precision at 500°C?

We use heat-stable materials like GCr15SIMN and advanced heat treatment to minimize thermal expansion.

Q2: Can you make bearings larger than φ5000mm?

Yes! Our modular production system supports sizes up to φ5000mm with a 20-day lead time.

Q3: What tests ensure low noise (<35dB) in medical devices?

Each bearing undergoes vibration spectrum analysis and noise profiling in soundproof chambers.

Q4: How do you achieve 30% faster lead times?

Self-owned factories and regional warehouses eliminate third-party delays.

Q5: Do you provide installation support?

Our engineers offer free on-site guidance or video consultations for complex integrations.

Contact Us

Need a Custom Angular Contact Thrust Ball Bearing Solution?

Email our engineers at sales@inno-bearing.com for a response within 4 hours.

Download Technical Specs | Get a Custom Design Proposal

Learn about our latest products and discounts through SMS or email