- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

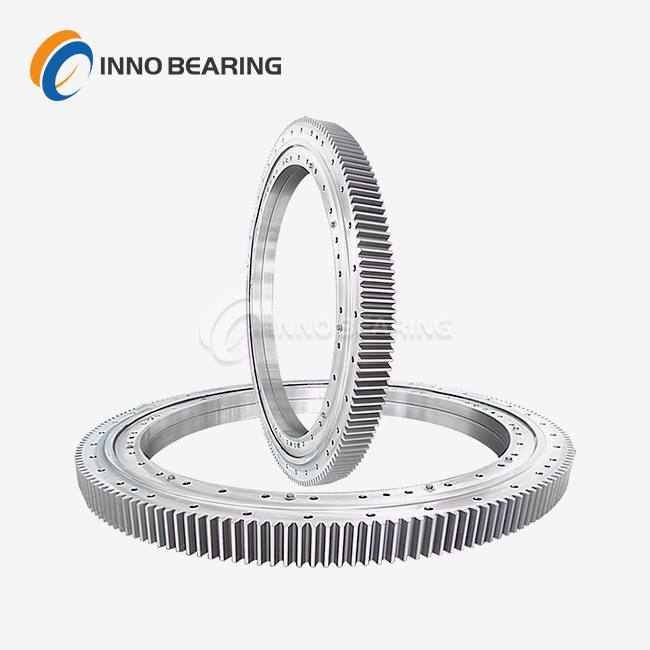

Slewing Bearings

INNO & LYCRH is professional slewing bearings supplier and factory in China, specialized in providing customized low price slewing bearings. To buy or wholesale cheap slewing bearings from our factory. For quotation, contact us now.

Manufacturing Capability

INNO's manufacturing capability is rooted in three decades of precision engineering heritage from the LYC Group. We operate dedicated facilities that produce large-diameter (up to φ5000mm), high-precision slewing bearings, engineered to withstand the extreme demands of mining, heavy construction, renewable energy, and offshore operations.

We specialize in customized-to-order solutions. Our integrated process, from design to final validation, is structured to deliver components that meet precise specifications for load, accuracy, and service life.

| Technical Capability | Your Project Benefit |

|---|---|

| Max. Diameter: φ5000mm | Solves ultra-large component needs for mining, port, and offshore equipment. A viable alternative to imported solutions. |

| Precision Grades: P0(G), P6(E), P5(D) | Match precision to application: • P0: Cost-effective for excavators, material handlers. • P6/E: Smooth operation for cranes, mid-sized wind systems. • P5/D: High-precision for rotary tables, test equipment. |

| Deep Non-Standard Customization | Our engineers design based on your drawings, load data, and conditions (dust, humidity, temp.), optimizing gears, seals, and mounts. |

| Import Substitution & Repair | • Substitution: Localized alternatives to SKF/IMO/Rothe Erde, with better lead time/cost. • Repair: Professional remanufacturing extends bearing life at 30%-60% of new cost. |

Product Series

Our product is categorized based on load type, structural design, and industry application to help you quickly identify the appropriate technical direction.

| Product Series | Structural Features | Typical Load Advantages | Example Applications |

|---|---|---|---|

| Single row roller slewing bearings | Compact design, lightweight | Capable of simultaneously withstanding axial force, radial force, and tilting moment | Truck cranes, mobile cranes, medium-sized stacker/reclaimer rotary platforms |

| Double row ball slewing bearings | Increased raceway contact points | Significantly higher load capacity and resistance to overturning moment than single-row designs | Tower cranes, portal harbor cranes, medium excavators |

| Three-row roller slewing bearings | Three roller rows are designed to withstand separate loads. | Ultra-high load capacity, can withstand loads from all directions independently. | Large mining excavators (e.g., electric shovels), offshore cranes, heavy-lift wind turbine installation vessels |

Learn about our latest products and discounts through SMS or email