- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

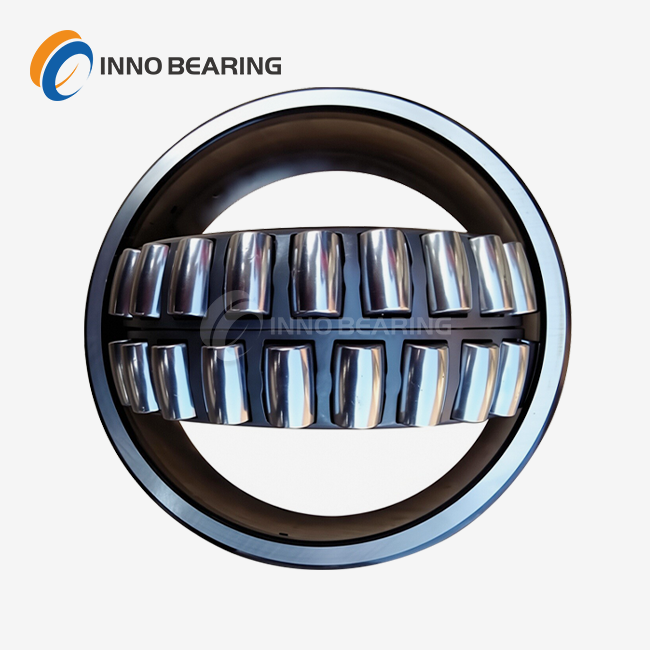

Spherical Roller Thrust Bearings

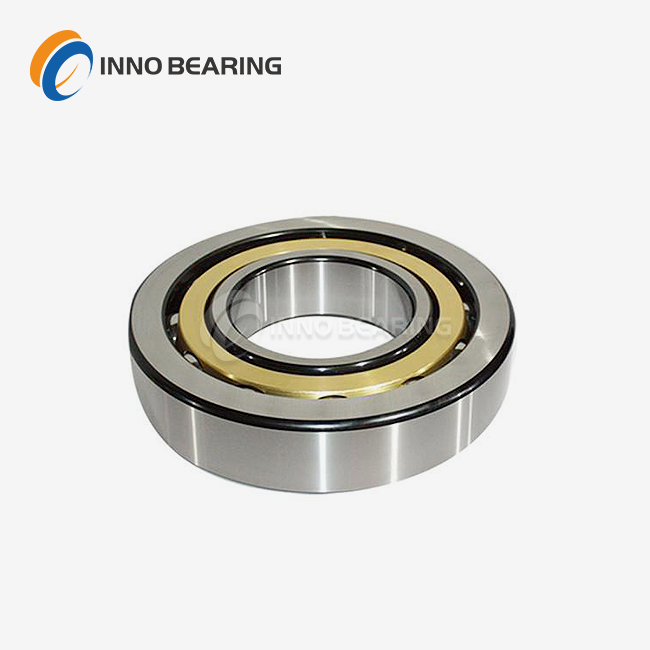

2.Structure Type: Shaft washer + housing washer (with spherical raceway) + spherical rollers + cage, open structure.

3.Size Range: Inner diameter: 50 - 800mm, outer diameter: 100 - 1000mm, height: 25 - 150mm.

4.Material: Shaft washer: GCr15/GCR15SIMN/20Cr2Ni4A, housing washer: GCr15/GCR15SIMN/20Cr2Ni4A, rolling elements (spherical rollers): GCr15/GCR15SIMN, cage: steel / brass.

5.Accuracy: Conventional P0/P6 grades, models for large equipment are of P5 grade.

6.Application Fields: Axial support of large motors, mining machinery, port cranes, wind power equipment.

7.Key Inspection Items: Aligning angle (±1.5°), smoothness of spherical raceway, axial load-bearing capacity.

High-Capacity Spherical Roller Thrust Bearings for Extreme Industrial Demands

Engineered for Heavy Loads (up to 2,500 kN), High-Temperature Resistance (150°C+), and Customized Precision. Fast Global Delivery in 15–20 Days.

When your equipment faces relentless axial forces, misalignment challenges, or extreme temperatures, Spherical Roller Thrust bearings deliver unmatched performance. Designed to handle heavy axial loads while compensating for angular misalignment (±1.5°), these bearings are the backbone of industries like metallurgy, mining, and renewable energy. With LUOYANG INNO BEARING's 30+ years of expertise, we combine advanced material science, ISO 9001-certified manufacturing, and rapid customization to keep your operations running smoothly—even in the harshest conditions.

Why Choose Us?

1. Built for Extreme Conditions

-

Heavy Load Mastery: Support axial loads up to 2,500 kN and radial loads up to 1,200 kN—ideal for mining crushers and port cranes.

-

High-Temperature Resilience: Operate reliably in environments up to 150°C (e.g., steel mill rolling mills).

-

Precision Alignment: Self-aligning design compensates for shaft deflections, reducing wear and downtime.

2. Customization at Speed

Need a non-standard size (up to φ5000mm) or specialized coating? Our modular production system delivers tailored Solutions in 15–20 days—70% faster than industry averages.

3. Material Excellence

We use high-purity steel and precision grinding to achieve 3x longer lifespan in abrasive environments. Optional solid-film lubrication ensures performance in dusty or corrosive settings.

Technical Specifications

| Parameter | Details |

|---|---|

| Load Capacity | Axial: 2,500 kN,Radial: 1,200 kN |

| Temperature Range | -50°C to +150°C |

| Precision Grades | P0/P6 (standard), P5/P4 (custom) |

| Materials | GCr15, GCR15SIMN, or 20Cr2Ni4A steel |

| Lubrication | Grease, oil, or solid-film coatings |

Where They Excel?

1. Metallurgy & Mining

Withstand shock loads in rolling mills and continuous operation in 150°C furnaces with Spherical Roller Thrust Bearings.

2. Wind Turbines & Hydropower

Corrosion-resistant designs (IP69K) for saltwater environments and 100,000+ hour lifespans.

3. Port Machinery & Heavy Trucks

P4-grade precision reduces noise (<35dB) in automated cranes, while compact designs save space in transport systems.

Quality Assured, Globally Trusted

- Triple-Stage QC: Raw material spectroscopy → In-process CMM checks → Final load/vibration testing.

- Certifications: ISO 9001, CE, ASTM, and industry-specific standards.

- 99.9% Qualification Rate: Validated through lifespan testing (e.g., 10,000+ hours at 3,000 RPM).

Ready When You Are

- 1,000+ Standard Bearings: Shipped in 48 hours.

- Urgent Custom Orders: φ3000mm+ bearings delivered in 15 days.

- 24/7 Support: On-site installation guidance and IoT-driven predictive maintenance.

FAQ

Q: Can you replicate legacy bearing dimensions?

A: Yes! Share your drawings, and we’ll reverse-engineer replacements with modern materials.

Q: How to extend bearing life in high-dust environments?

A: Pair solid-film lubrication with our IoT health monitoring for quarterly maintenance alerts.

Q: Do your bearings comply with EU regulations?

A: Absolutely—REACH and ROHS certifications are standard.

Contact Us

Need Spherical Roller Thrust Bearings That Match Your Ambition?

Reach our engineers at sales@inno-bearing.com for free technical consultations or urgent quotes.

LUOYANG INNO BEARING: Powering Industries, One Rotation at a Time.

Learn about our latest products and discounts through SMS or email