- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

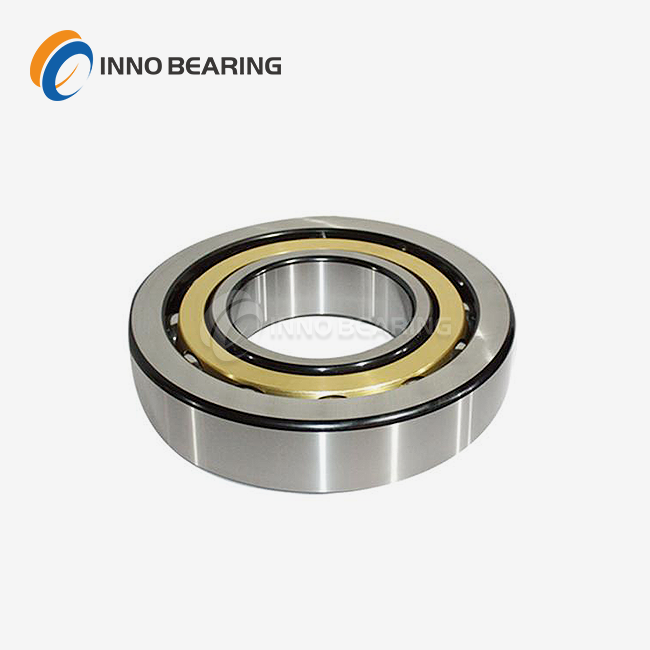

Double Row Angular Contact Ball Bearing

2.Structure Type: Inner ring + outer ring (with double angular contact raceways) + double-row steel balls + brass cage. An isolation ring is set in the middle to prevent steel ball collisions.

3.Size Range: Inner diameter: 20 - 500mm, outer diameter: 47 - 800mm, width: 20 - 180mm.

4.Material: Inner ring / outer ring / isolation ring: GCr15/GCR15SIMN, rolling elements (steel balls): GCr15/GCR15SIMN, cage: brass.

5.Accuracy: Conventional P0 grade, precision models are of P6/P5/P4 grades.

6.Application Fields: Machine tool spindles (bidirectional positioning), large motors, transmission ends of port cranes, precision reducers.

7.Key Inspection Items: Consistency of double-row steel ball clearance (deviation ≤ 0.002mm), accuracy of bidirectional contact angles, radial runout, running stability.

Double Row Angular Contact Ball Bearings for Extreme Load & Precision Scenarios

30+ Years Expertise | Custom Sizes up to φ5000mm | 15-Day Rapid Turnkey Solutions

When your equipment demands bidirectional load handling and space-efficient precision, Double Row Angular contact ball bearings deliver unmatched performance. Designed with two rows of balls and optimized contact angles, these bearings eliminate the need for paired bearing arrangements while handling combined axial/radial loads. At LUOYANG INNO, we’ve refined our manufacturing processes over three decades to create solutions that thrive in metallurgy, wind energy, robotics, and more – even under 500°C temperatures or extreme vibrations.

Why Choose Us?

✅ Bidirectional Load Mastery

Withstand radial loads up to 380kN and axial loads up to 210kN thanks to our precision-ground raceways and GCr15 steel construction. The double row design provides 2.3x higher moment stiffness than single-row alternatives, critical for port crane slewing rings or CNC machine tool spindles.

✅ Tailored for Your Industry

- Wind Turbines: DNV GL-certified φ2000-5000mm bearings with CrN anti-corrosion coating

- Medical Robotics: Noise-optimized (<25dB) P4-grade units with NSF H1 grease

- Steel Mills: 500°C-rated variants using Si3N4 hybrid ceramic balls

✅ Rapid Customization

Need non-standard dimensions? We produce Double row angular contact ball bearings from 10mm to 5000mm ID within 15-20 days – 30% faster than industry benchmarks. Our modular production system adapts to your exact needs:

| Parameter | Standard Range | Custom Capacity |

|---|---|---|

| Inner Diameter | 20-500mm | Up to 5000mm |

| Contact Angle | 25°/30°/40° | Any angle ±0.5° |

| Cage Material | Brass | PEEK/Stainless Steel |

Built for Demanding Applications

Wind Turbine Yaw/Pitch Systems

Our offshore-grade angular contact bearings feature:

-

Triple-labyrinth seals with IP69K protection

-

500,000+ hour L10 lifespan at 2.5MW+ loads

-

-40°C to 120°C operational range

Automotive Robotic Arms

Enable 0.003mm repeatability in EV production lines with:

-

P2 ultra-precision grinding (Ra ≤0.1μm)

-

Integrated torque sensors for collision detection

-

Cleanroom-compatible packaging

High-Speed Spindles

Achieve 8,000 RPM in machining centers via:

- Preloaded configurations eliminating axial play

- Oil-air lubrication compatibility

- Dynamic balancing to G1 grade

6 Reasons Engineers Trust INNO Bearings

Material Science Leadership

Vacuum-degassed steel (O₂ ≤15ppm) extends fatigue life by 60% vs. standard grades.

Precision Grinding

3D measurement systems ensure ≤0.002mm clearance consistency between double rows.

Accelerated Testing

Every batch undergoes 200-hour accelerated lifespan simulations at 150% rated load.

Global Logistics

48-hour shipping from regional hubs in EU/NA/Asia + emergency air freight options.

Smart Monitoring

Retrofit-ready sensors track temperature, vibration, and load trends via IoT platform.

Lifecycle Support

From installation torque specs (PDF guides) to end-of-life recycling Certificates.

FAQ

Q: Can you match legacy bearing dimensions in aging equipment?

A: Yes – share drawings or samples. We’ll reverse-engineer replacements with modern materials.

Q: How do you prevent lubricant leakage in vertical installations?

A: We modify cage designs and apply PTFE-reinforced seals – tested to 10,000+ tilt cycles.

Q: What documentation accompanies orders?

A: ISO 9001/14001 certificates, material test reports, 3D STEP files, and load charts.

Q: Minimum order quantity for custom designs?

A: MOQ 1 piece for prototyping. Volume discounts apply at 50+ units.

Contact Us

Ready to Optimize Your Bearing Performance with a Double Row Angular Contact Ball Bearing?

Contact our engineering team at sales@inno-bearing.com for:

- Free load capacity calculations

- Industry-specific material recommendations

- CAD models & installation simulations

Response within 2 working hours – 24/7 emergency support available.

Learn about our latest products and discounts through SMS or email