- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

ball bearing slewing ring

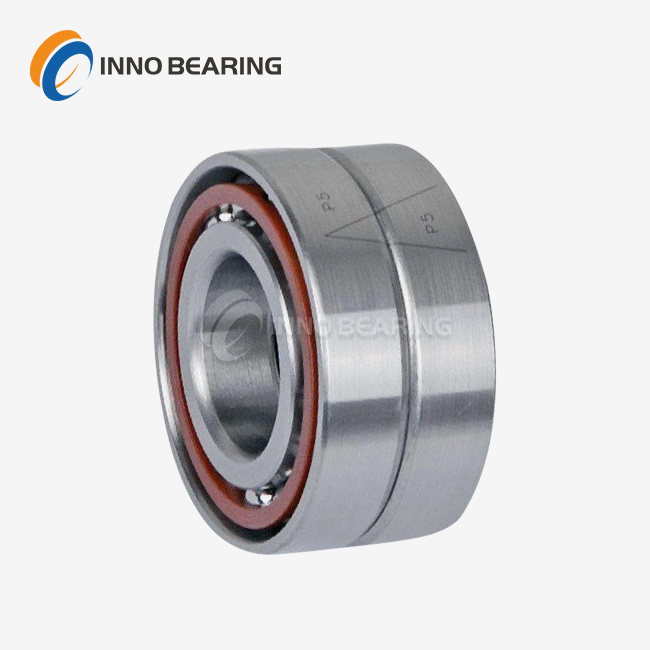

2.Structure Type: It has an annular shape. The inner and outer rings have single or double arc raceways, with built-in single-row or double-row steel balls, nylon or steel cages, rubber seals on both sides, and evenly distributed mounting holes.

3.Size Range: Outer ring diameter: 300 - 2500mm, inner ring diameter: 250 - 2350mm, height: 15 - 80mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Small excavators, amusement equipment, light logistics turntables, ordinary machine tools.

6.Key Inspection Items: Steel ball clearance, slewing flexibility, sealing and waterproof performance.

Why Choose Our Ball Bearing Slewing Rings?

If you're searching for a ball bearing slewing ring that combines durability, precision, and rapid customization, you’ve found your solution. Designed for heavy machinery, port equipment, and metallurgical systems, our slewing rings deliver unmatched performance in extreme conditions—whether it’s 150°C furnace environments or heavy-load crane operations. With 30+ years of R&D expertise, we engineer every component to reduce downtime and extend service life.

Core Advantages

✅ 30+ Years of Specialized Engineering

We’ve perfected slewing ring design for high-load, high-temperature, and high-impact applications. Our in-house production of large-diameter rings (up to φ5000mm) ensures precision and reliability.

✅ 15–20 Days for Oversized Custom Orders

Need a φ3000mm+ product? Our modular production system delivers custom Solutions 30% faster than industry averages.

✅ Built to Endure Extreme Stress

Metallurgical-grade materials (50Mn/42CrMo steel) and specialized heat treatment ensure resistance to wear, corrosion, and thermal deformation.

✅ Global Inventory & 48-Hour Delivery

With 1,000+ standard slewing rings in stock and regional logistics hubs, we minimize delays for urgent orders.

Technical Excellence

| Parameter | Specification |

|---|---|

| Diameter Range | 200mm – 5000mm (custom sizes available) |

| Temperature Resistance | -30°C to 150°C (metallurgical grade) |

| Load Capacity | Up to 10,000 kN static/dynamic loads |

| Materials | 50Mn/42CrMo steel, GCr15 bearing steel |

| Precision | Runout tolerance ≤0.05mm |

| Certifications | ISO 9001, CE, ASTM A988, DNV-GL, UL |

Where Our Ball Bearing Slewing Rings Excel?

1. Metallurgical Equipment

Withstand 150°C furnace environments and heavy tilting loads in ladle cranes.

2. Port Machinery

Saltwater-resistant coatings and impact-proof designs for ship-to-shore cranes.

3. Heavy Mining Equipment

High-load bearings for tunnel boring machines and excavators.

4. Renewable Energy Systems

Low-noise (<35dB) operation for solar trackers and wind turbine yaw systems.

Quality Assurance: Zero Compromise

Every ball bearing slewing ring undergoes:

1. Material Inspection: Spectrometer checks for steel purity.

2. In-Process Testing: Raceway grinding accuracy ≤0.01mm.

3. 12-Parameter Final Check: Vibration, fatigue, and lifespan validation.

Result: 99.9% defect-free performance.

Global Supply Chain, Local Speed

- Standard Orders: 48-hour delivery from regional hubs (EU, North America, Asia).

- Custom Projects: Dedicated engineering teams for urgent large-scale orders.

FAQ

1. How do you achieve a 15–20-day lead time for φ3000mm+ slewing rings?

Our modular production system pre-fabricates components, reducing assembly time by 40%.

2. Can your slewing rings handle heavy impacts in port machinery?

Yes! Impact-resistant steel (GCr15SiMn) and reinforced cages absorb shock loads.

3. Do you provide IoT-driven maintenance support?

Absolutely. We offer predictive maintenance plans with real-time wear monitoring.

4. What certifications do your products hold?

We meet ISO 9001, CE, and industry-specific standards like ASTM A988 for metallurgy.

Contact Us

Ready to Upgrade Your Machinery with ball bearing slewing ring?

Request a Quote or Consult Our Engineers Today!

✅ Custom solutions in 15–20 days

✅ 24/7 technical support

✅ Global compliance guaranteed

📧 Contact Us: sales@inno-bearing.com

📥 Download: [Technical Brochure]

LUOYANG INNO BEARING CO., LTD – Where Precision Meets Durability.

Learn about our latest products and discounts through SMS or email