- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

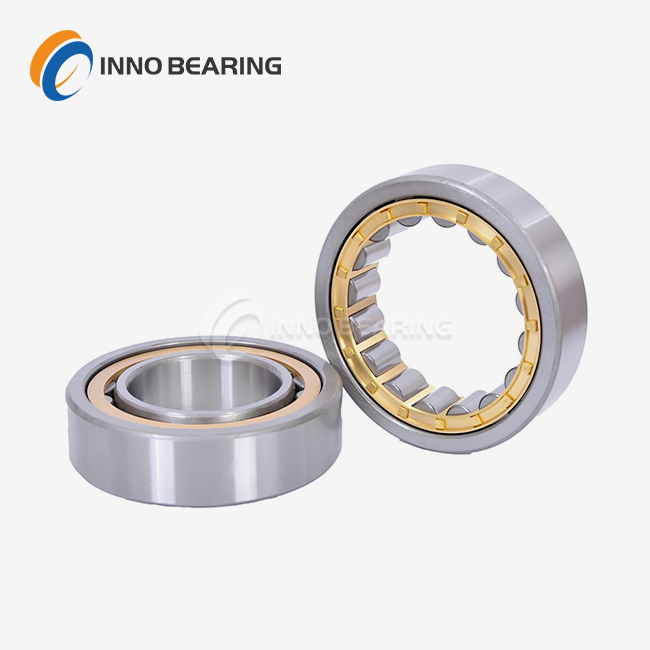

double angular contact bearing

2.Structure Type: Inner ring + outer ring (with symmetrical double angular contact raceways) + double-row steel balls + stamped steel or brass cage, capable of independently bearing bidirectional forces.

3.Size Range: Inner diameter: 20 - 400mm, outer diameter: 47 - 600mm, width: 20 - 150mm.

4.Material: Inner ring / outer ring: GCr15/GCR15SIMN, rolling elements (steel balls): GCr15/GCR15SIMN, cage: stamped steel (conventional) / brass (precision).

5.Accuracy: Conventional P0 grade, precision models are of P6/P5/P4 grades.

6.Application Fields: Small and medium-sized motors, feed shafts of machine tools, automobile transmission systems, light industrial precision equipment.

7.Key Inspection Items: Bidirectional radial clearance (0.003 - 0.008mm), conformity of steel balls fitting, stability of the cage, installation adaptability.

Double Angular Contact Bearing: Precision Engineered for Extreme Performance

When you need bearings that handle bidirectional axial and radial loads without compromising space or durability, our double angular contact bearing Solutions deliver unmatched reliability. Designed for high-load, high-speed, and high-precision applications—from medical robotics to metallurgical presses—these bearings combine 30 years of engineering expertise with cutting-edge materials to outperform industry standards.

Key Technical Advantages

- Enhanced Load Capacity: 40–60% higher axial/radial load tolerance than standard angular contact bearings.

- Extreme Environment Ready: Stable performance from -50°C to 150°C with specialized heat treatment.

- Precision Grades: P4/P2 accuracy (ISO 492-certified) for surgical robotics and CNC machinery.

- Rapid Customization: Non-standard sizes up to φ5000mm delivered in 15–20 days.

Built for Your Industry's Demands

Metallurgy & Heavy Machinery

Withstand 500°C temperatures and contamination-prone environments using carbide-free bainite-treated steel. Our bearings maintain ≤0.01% dimensional change under continuous thermal stress, reducing unplanned downtime in smelting equipment.

Port & Marine Equipment

Impact-resistant designs with brass cages and saltwater-proof seals extend service life by 30% in high-humidity crane operations.

Medical & Precision Engineering

Ultra-low noise (<15 dB) and P4-grade precision ensure error-free performance in MRI machines and robotic surgery arms.

Customization Made Simple

Configure your product in 5 steps:

- Size: Standard (φ20–φ2000mm) or custom (up to φ5000mm).

- Material: High-purity SUJ2 steel or corrosion-resistant alternatives.

- Sealing: Contact/non-contact seals for dust, moisture, or chemical resistance.

- Lubrication: Grease, oil, or solid-film options tailored to operating temperatures.

- Precision: P0 (standard) to P4 (medical-grade).

Lead Time Advantage:

- Non-standard orders: 15–20 days (vs. 70-day industry average).

- Bulk standard orders: Shipped in 48 hours from 1,000+ in-stock SKUs.

Quality You Can Trust

Every double angular contact bearing undergoes triple inspection:

- Material Testing: Hardness (60–64 HRC) and purity checks via spectrometry.

- Dimensional Accuracy: ±2μm tolerance using CNC coordinate measuring.

- Performance Validation: Vibration (<4.5 dB), lifespan (100,000+ hours L10), and load distribution tests.

Result: 99.9% ex-factory qualification rate (ISO 9001-certified processes).

Beyond the Bearing: Lifetime Support

- Pre-Sales Engineering: Get load/speed analysis reports within 24 hours.

- Installation: On-site technicians or AR-guided remote assistance.

- Predictive Maintenance: IoT sensors monitor wear, auto-scheduling lubrication.

Why Partner with Us?

- ✅ 30 Years of Expertise: 500+ custom projects delivered since 2020.

- ✅ Global Reach: Warehouses in Asia, Europe, and North America.

- ✅ Transparent Processes: Real-time order tracking and lifecycle analytics.

Ready to Optimize Your Equipment?

[Request a Quote] | [Download Catalog] | [Upload Custom Design]

Urgent need? Get an engineer's callback within 2 hours.

FAQ

Q: How do your bearings handle φ3000mm+ custom sizes so quickly?

A: Modular manufacturing cuts production time by 70%. We pre-machine components for common configurations, enabling rapid assembly.

Q: What ensures P4 precision in medical-grade bearings?

A: Precision grinding, high-purity steel, and triple-stage QC—validating noise, vibration, and radial runout (±0.002mm).

Q: Can I get bearings for high-impact port cranes?

A: Yes! Our brass cages and tempered steel absorb shocks, extending lifespan by 30% in heavy-load scenarios.

Contact Us

Contact Our Engineers Today for a double angular contact bearing

Email: sales@inno-bearing.com

Learn about our latest products and discounts through SMS or email