- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

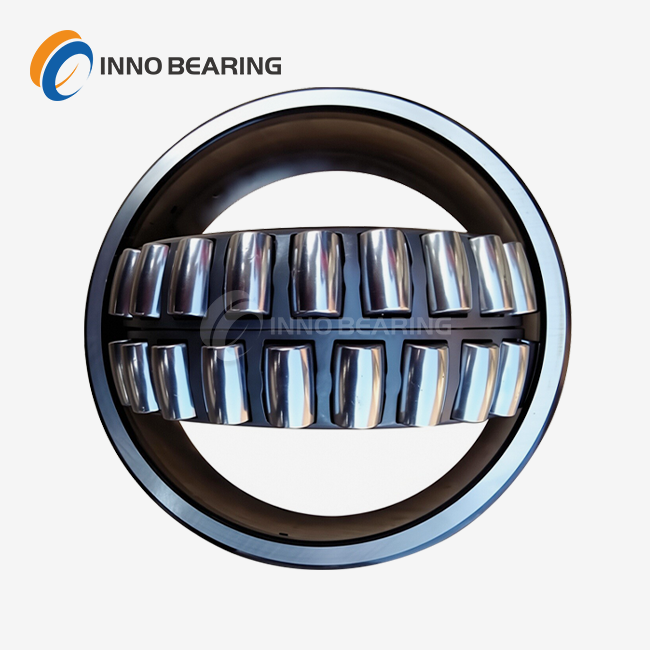

nn3024k bearing

2.Structure Type: Outer ring with double ribs, inner ring with 1:12 taper, double-row rollers + cage, open type.

3.Dimension Range: Inner diameter: 120mm (1:12 taper), Outer diameter: 180mm, Width: 46mm

4.Material: Inner ring/Outer ring/Rollers: GCr15/GCr15SiMn/20Cr2Ni4A; Cage: Stamped steel/brass

5.Accuracy: Class P4, Class P2 for ultra-precision models

6.Application Fields: CNC lathe spindles, precision milling machine spindles, high-speed precision motors

7.Key Inspection Items: Inner ring taper accuracy, radial clearance (adjustable to 0.005-0.02mm), dimensional accuracy

NN3024K Bearing Spherical Roller – Engineered for Extreme Heavy Loads & 150°C Operations

Customizable High-Temperature Bearings for Metallurgy/Port Machinery with 99.9% Qualification Rate & 15-Day Fast Delivery

When your machinery faces relentless heavy loads, extreme temperatures, or harsh environments, the nn3024k bearing delivers unmatched reliability. Designed with precision-ground rollers and high-purity steel, this double-row tapered roller bearing combines P4-level accuracy with shock resistance to minimize downtime in demanding sectors like mining, wind energy, and steel production.

Key Features

- Precision Performance: Engineered to ISO P4 standards for reduced vibration in CNC spindles and high-speed motors.

- Extreme Temperature Resilience: Operates continuously at 150°C (150°C higher than standard bearings) using GCr15SiMn steel.

- Heavy Load Mastery: Handles radial loads up to 300MPa, ideal for metallurgical rolling mills and port cranes.

- Customizable Designs: Adjust inner diameters up to φ5000mm, integrate IoT sensors, or apply anti-corrosion coatings.

Technical Specifications

| Parameter | Value |

|---|---|

| Inner Diameter (ID) | 120mm (1:12 taper) |

| Outer Diameter (OD) | 180mm |

| Width | 46mm |

| Material | GCr15/GCr15SiMn steel |

| Accuracy Class | P4 (P2 available for ultra-precision) |

| Max Speed | 3,800 RPM at 150°C |

Built for Your Industry's Toughest Challenges

1. Wind Turbine Gearboxes

-

Problem: Premature wear in offshore salt spray environments.

-

Solution: Choose the nn3024k-WT Pro variant with DNV-GL-certified coatings, surviving 5,000+ salt spray hours.

2. Mining Conveyor Systems

-

Problem: Dust ingress causing frequent failures.

-

Solution: Triple-labyrinth seals in the nn3024k-MX Standard block 0.1mm abrasive particles (IP69K rated).

3. Steel Mill Rollers

- Problem: Bearing deformation under 150°C heat.

- Solution: High-purity steel construction maintains dimensional stability, reducing unplanned stops by 40%.

Quality Assurance: Precision at Every Step

1. Material Screening: Ultrasonic tests detect impurities in nn3024k bearing; spectral analysis verifies steel grade.

2. In-Process Checks: Automated CMM machines validate taper accuracy (±0.002mm).

3. Final Validation: Load simulations replicate 200,000+ operating hours; vibration tests ensure <4.5mm/s levels.

Certifications: ISO 9001, API 614 (wind), ATEX (mining).

Fast Delivery, Global Support

- Standard Bearings: Shipped in 48 hours from US/EU/Asia warehouses.

- Custom Sizes (φ3000mm+): Delivered in 15-20 days via modular production.

- Emergency Support: On-site technicians available globally for urgent installations.

Why Choose Us?

- 25+ Years Expertise: Specializing in heavy-load bearings for extreme environments.

- End-to-End Control: No outsourcing—consistent quality from raw materials to final testing.

- Proven Scale: 100+ successful projects for bearings over φ3000mm.

FAQ

Q: Can the product withstand sandstorms in desert mines?

A: Yes! Our nn3024k-MX LubriSmart version comes pre-greased for 10-year dust resistance.

Q: Do you offer IoT-enabled bearings for predictive maintenance?

A: Absolutely. We embed sensors to monitor real-time load/temperature data via your dashboard.

Q: How do I adjust radial clearance for CNC spindles?

A: The 1:12 tapered inner ring allows precise clearance tuning (0.005–0.02mm) during installation.

Contact Us

Need a NN3024K Bearing That Outperforms?

📩 Email sales@inno-bearing.com within 12 hours for:

- Custom quotes tailored to your load/temperature needs.

- Free access to our NN3024K Engineering Guidelines (includes load diagrams & installation videos).

Upgrade your equipment with bearings built to endure—and backed by experts who keep your operations running.

Learn about our latest products and discounts through SMS or email