- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

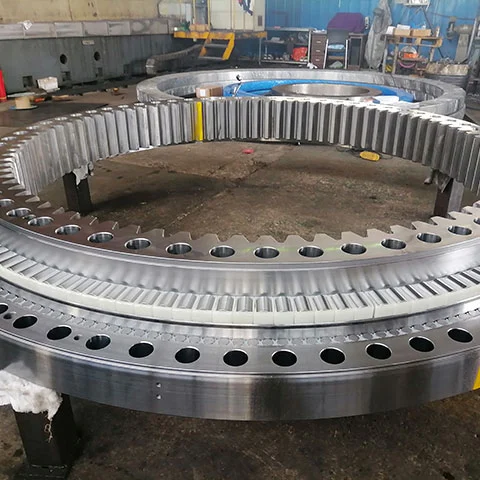

large slewing bearings

2.Structure Type: It has a thick-wall forged annular shape. The inner and outer rings are made of 42CrMo steel, with built-in double-row or triple-row rollers, heavy-duty seals, and the mounting holes are suitable for large bolts.

3.Size Range: Outer ring diameter: 2000 - 6000mm, inner ring diameter: 1850 - 5800mm, height: 80 - 200mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Large port cranes, mining machinery, wind power main units, heavy-duty crawler cranes.

6.Key Inspection Items: Flaw detection of forgings, anti-overturning moment, impurity-proof performance of seals.

Large Slewing Bearings (Up to φ5000mm) for Heavy-Duty Industrial Applications

Engineered for Extreme Loads, High Temperatures & Rapid Delivery

When your projects demand reliability under punishing conditions, large Slewing Bearings from LUOYANG INNO BEARING CO., LTD deliver unmatched performance. With over 30 years of expertise, we design and manufacture bearings up to 5,000mm in diameter, combining forged alloy steel, precision engineering, and industry-specific adaptations. Whether you need standard bearings for port cranes or custom Solutions for mining equipment, we reduce lead times to 70% of industry averages while ensuring 99.9% defect-free quality.

---

Why Choose Our Large Slewing Bearings?

1. Built to Withstand the Toughest Environments

- Material Excellence: Inner/outer rings forged from 42CrMo or 50Mn steel, hardened to HRC 55-60 for wear resistance.

- Extreme Load Capacity: Axial/radial loads up to 10,000 kN, tested under dynamic forces exceeding ISO 281 standards.

- Temperature Resilience: Operate seamlessly from -30°C to 150°C with thermal deformation resistance.

2. Customization Without Compromise

Need a non-standard design? We specialize in:

- Integrated Gear Teeth: Reduce assembly time for crane slewing mechanisms.

- Corrosion-Resistant Coatings: Ideal for offshore or saltwater environments.

- IoT-Ready Designs: Embed sensors for real-time load/temperature monitoring.

3. Rapid Production & Global Delivery

- Fast-Track Orders: φ3000mm custom bearings delivered in 15-20 days.

- Regional Warehouses: 48-hour dispatch for 1,000+ standard bearings in the EU, North America, and Asia.

---

Industry-Proven Performance

Metallurgy & Steel Plants

Our large slewing bearings handle 500℃ furnace rotations with zero thermal warping, backed by induction-hardened rollers and high-temp grease.

Port Machinery & Offshore Cranes

Salt-spray tested for 1,000+ hours, these bearings prevent corrosion while supporting 50-ton loads in container handlers and ship loaders.

Mining & Heavy Construction

Reinforced structures absorb shock loads up to 3,000 kNm, while triple-lip seals block abrasive dust in excavators and tunnel boring machines.

---

Quality You Can Trust

Triple-Stage Inspection Process

1. Material Testing: Spectral analysis verifies steel grade and purity.

2. Precision Machining: Coordinate Measuring Machines (CMM) ensure ±0.01mm accuracy.

3. 100% Load Testing: Simulate 10+ years of operation in 72-hour endurance trials.

Result: 99.9% ex-factory qualification rate validated by 12+ metrics, including vibration (<35dB) and fatigue life.

---

Technical Support & Services

- Free Engineering Consultations: Get 3D models and FEM simulations for custom designs.

- Lifetime Monitoring: IoT-enabled predictive maintenance reduces downtime by 50%.

- 24/7 Global Support: On-site installation guidance and emergency troubleshooting.

---

---

FAQ: Large Slewing Bearings

1. Can you produce bearings larger than φ5000mm?

Yes! We engineer non-standard large slewing bearings up to φ6000mm using modular forging techniques.

2. How do you ensure corrosion resistance in port environments?

We apply zinc-nickel coatings and use fluororubber seals, tested for 1,000+ hours in salt-spray chambers.

3. What’s the lead time for a φ4000mm custom bearing?

Just 18-22 days – 30% faster than industry standards due to our agile production lines.

4. Do you provide load test reports?

Yes. Every bearing includes a certificate with dynamic/static load data and torque values.

5. Can your bearings integrate with IoT systems?

Absolutely. We embed sensors for real-time health monitoring via our cloud platform.

---

Get Your Custom Solution Today

Request a Quote: Share your specs, and receive technical drawings within 24 hours.

Download Catalog: Explore 500+ standard models with CAD files and case studies.

📧 Contact Our Engineers: sales@inno-bearing.com

🌍 Global Warehouses: Fast shipping from the EU, USA, and Asia.

---

LUOYANG INNO BEARING CO., LTD – Where Precision Meets Endurance.

Learn about our latest products and discounts through SMS or email