- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

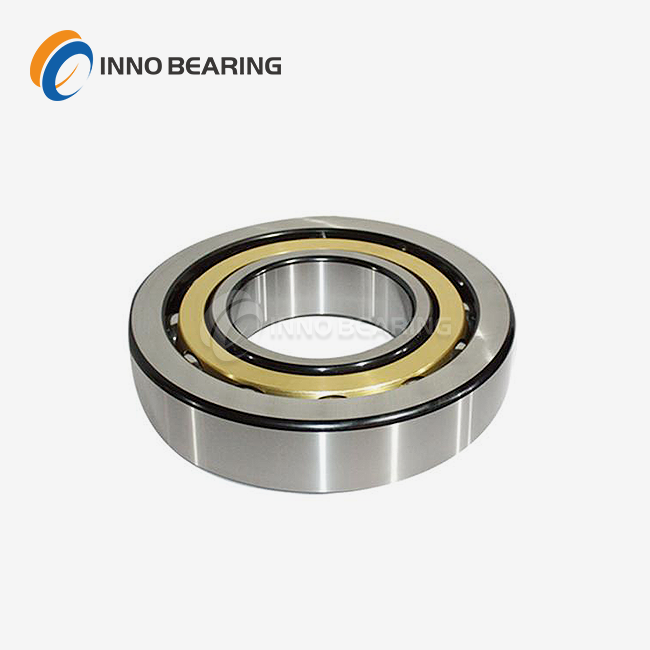

Deep Groove Ball Bearings - Double Rows

2.Structure Type: Inner ring + outer ring (with double circular arc raceways) + double-row steel balls + steel cage. An isolation ring is set in the middle to prevent collisions.

3.Size Range: Inner diameter: 20 - 800mm, outer diameter: 47 - 1000mm, width: 18 - 200mm.

4.Material: Inner ring / outer ring / isolation ring: GCr15/GCR15SIMN/20Cr2Ni4A, rolling elements (steel balls): GCr15/GCR15SIMN, cage: steel (for heavy load) / brass (for high-speed).

5.Accuracy: Conventional P0/P6 grades, heavy-duty precision models are of P5 grade.

6.Sealing: Open type / 2RS (double-sided rubber seal) / 2Z (double-sided iron seal).

7.Application Fields: Heavy-duty motors, mining machinery, port cranes, large water pumps.

8.Key Inspection Items: Consistency of double-row steel ball clearance, radial load-bearing capacity, dust-proof performance of seals.

Deep Groove Ball Bearings - Double Rows: Precision Engineered for Extreme Performance

When heavy machinery demands unmatched durability and precision, Deep groove ball bearings - Double Rows deliver. Designed to handle 1.8–2.2x higher radial loads than single-row alternatives, these bearings excel in space-constrained, high-stress environments like mining equipment, medical devices, and port cranes. At LUOYANG INNO BEARING CO., LTD, we combine 30+ years of manufacturing expertise with advanced material science to create bearings that thrive under extreme temperatures, heavy impacts, and corrosive conditions.

Technical Excellence: Built to Withstand Demanding Conditions

Key Specifications

-

Dimensions: Inner Diameter (20–800mm) | Outer Diameter (47–1000mm) | Width (18–200mm)

-

Load Capacity: Radial load up to 1,200kN | Axial load support in both directions

-

Materials: High-purity GCr15 steel for raceways | Ceramic hybrid cages (300°C+ resistance) | Brass/steel cages for speed/stability

-

Precision: P0/P6 standard | P5/P4 grades for heavy-duty/medical applications

-

Sealing: Open, 2RS (double rubber seals), or 2Z (steel shields)

Industry-Specific Enhancements

- Metallurgy: Heat-treated bearings withstand 500°C+ temperatures in rolling mills.

- Port Machinery: Triple-labyrinth seals block saltwater ingress, extending service life by 40%.

- Medical Imaging: P4-grade accuracy and <35dB noise ensure vibration-free MRI operations.

Why Choose Our Double Row Deep Groove Ball Bearings?

Rapid Customization for Unique Challenges

Need a non-standard size like φ3000mm for a port crane? Our modular production system delivers custom product in 15–20 days – 70% faster than industry averages.

Material Innovation

High-purity steel paired with cryogenic heat treatment boosts wear resistance by 200%, while our ShockArmor series absorbs 50kN+ impact loads in port machinery.

Global Availability, Local Speed

With 1,000+ standard bearings in stock and regional warehouses worldwide, we ship 48-hour emergency orders and guarantee 7-day delivery to EU/NA/Asia hubs.

Full Lifecycle Support

From IoT-based wear monitoring to recycling programs, our services reduce downtime and operational costs by up to 30%.

Proven Applications Across Industries

High-Temperature Rolling Mills

A steel plant replaced failing single-row bearings with our HTX Series Deep Groove Ball Bearings - Double Rows, achieving zero downtime in 500°C casting rollers for 18+ months.

Coastal Port Cranes

ShockArmor bearings with manganese steel raceways reduced corrosion-related replacements by 60% in a Middle Eastern port's 50-ton cranes.

Medical Imaging Systems

SilentPro Series P4-grade bearings eliminated micro-vibrations in MRI scanners, improving diagnostic accuracy for a European hospital group.

Quality Assured, Performance Validated

Every bearing undergoes:

- Material Screening: Spectrometer checks for steel purity.

- In-Process Checks: CMM machines verify micron-level tolerances.

- Final Validation: 12+ tests simulate real-world conditions (e.g., 200,000-hour salt spray testing).

Certifications: ISO 9001 (quality), ISO 14001 (environmental), and industry-specific standards like ISO 13485 for medical applications.

FAQ

Q: Can you customize bearings for high-dust environments?

A: Yes! Our 2RS-sealed product integrate multi-lip rubber seals to block 99.8% of particulates.

Q: What's the minimum order quantity (MOQ) for custom sizes?

A: MOQ starts at 50 units for non-standard designs.

Q: How do I extend bearing life in port machinery?

A: Opt for our triple-labyrinth sealed ShockArmor series and schedule bi-annual IoT condition checks.

Q: Do you provide installation support?

A: Our engineers offer remote/on-site guidance, including alignment checks and lubrication plans.

Contact Us

Let's Solve Your Bearing Challenges Together

Need a Deep Groove Ball Bearings - Double Rows that survives extreme heat, heavy loads, or saltwater corrosion? Share your requirements, and we'll deliver a solution in days, not weeks.

📧 Contact Us Today: sales@inno-bearing.com

🔧 Custom Quotes: Delivered within 24 hours.

🌍 Global Support: Regional experts in your time zone.

Learn about our latest products and discounts through SMS or email