- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

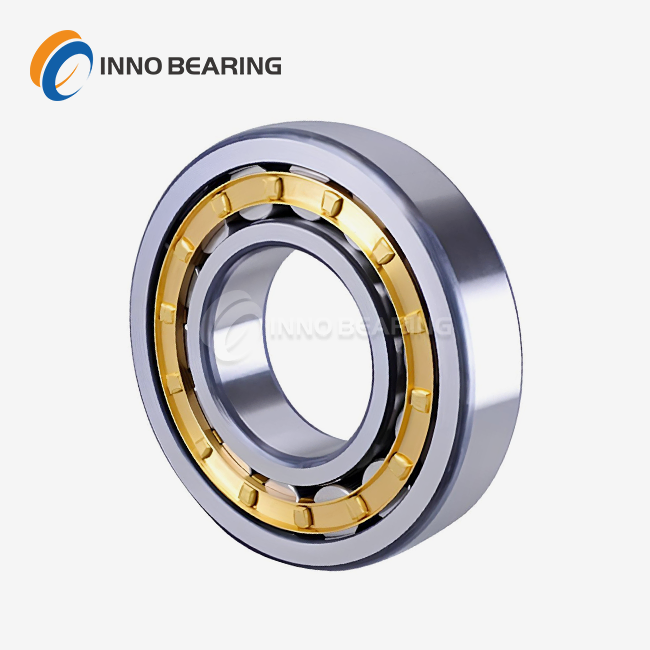

Rolling Mill Bearing

2.Structure Type: Four-row/double-row rollers, integrally forged inner ring/outer ring, cage, metal labyrinth seal (anti-iron chips/cooling water).

3.Dimension Range: Inner diameter: 100-1500mm, Outer diameter: 200-2000mm, Width: 80-500mm

4.Material: Inner ring/Outer ring/Rollers: GCr15/GCr15SiMn/20Cr2Ni4A; Cage: Stamped steel/brass

5.Accuracy: Class P0/P6, Class P5 for precision roll systems of cold rolling mills

6.Application Fields: Hot rolling mills, cold rolling mills, section steel rolling mills, work rolls/support rolls of strip rolling mills

7.Key Inspection Items: Impact resistance, high-temperature resistance, seal protection against iron chips/cooling water, forging flaw detection

High-Temperature & Heavy-Load Rolling Mill Bearings Built for Metallurgical Demands (Up to 300 Tons, 150°C)

30+ Years of Precision Engineering for Rolling Mills – Customizable, Durable, Fast-Delivery Solutions.

Built to Endure Extreme Conditions

Rolling Mill Bearings are the backbone of metallurgical equipment, designed to operate under relentless stress. At LUOYANG INNO BEARING CO., LTD, we engineer bearings that thrive in temperatures up to 500°C and handle loads exceeding 300 tons. With over three decades of expertise, our solutions are trusted by steel mills worldwide to minimize downtime and maximize productivity.

What Makes Our Rolling Mill Bearings Unique?

1. Engineered for Metallurgical Challenges

-

Temperature Resistance: Operate reliably from -50°C to 150°C, even in continuous casting lines.

-

Heavy-Load Capacity: Support up to 300+ tons with forged steel construction (GCr15/GCr15SiMn).

-

Precision Performance: Achieve P5-level accuracy for cold rolling mills, reducing vibration by 40%.

2. Robust Design for Harsh Environments

- Sealed Against Contaminants: Metal labyrinth seals block iron chips and cooling water ingress.

- Impact-Resistant Structure: Four-row tapered rollers and integrally forged rings for 50,000+ service hours.

Available Sizes: Inner Diameter 100–1500mm | Outer Diameter 200–5000mm

Custom Solutions for Your Rolling Mill

1. Tailored to Your Specifications

We manufacture non-standard Rolling Mill Bearings up to φ5000mm, with:

-

Custom coatings (e.g., ceramic layers for 150°C environments).

-

Modified cage designs (stamped steel or brass) for high-speed applications.

-

Legacy equipment retrofitting with 3D-scanned compatibility checks.

2. Faster Turnaround, Lower Costs

Our modular production cuts lead times by 30%. For example:

-

φ3000mm bearings delivered in 15–20 days (vs. industry-standard 30+ days).

- 48-hour shipping for 1,000+ standard types from regional warehouses.

Quality Built into Every Bearing

12+ Rigorous Tests Ensure Reliability:

1. Flaw Detection: Ultrasonic testing for forging defects.

2. Lifespan Simulation: 1,000-hour accelerated wear testing.

3. Seal Integrity: Pressure tests against water/coolant ingress.

Result: 99.9% defect-free rate post-installation.

Global Support, Local Speed

- Regional Warehouses: Stocking 10,000+ units in Asia, Europe, and North America.

- 24/7 Technical Assistance: On-call engineers for installation guidance or emergency replacements.

- IoT Predictive Maintenance: Real-time vibration/temperature alerts via embedded sensors.

Why Partner With Us?

✅ 30+ Years of Metallurgical Focus

✅ φ5000mm+ Large-Bearing Production

✅ 48-Hour Delivery for Urgent Orders

✅ Lifetime TCO Reduction Programs

FAQ

1. Can your bearings withstand 500°C in steel rolling mills?

Yes! Our high-purity steel alloys and heat-resistant coatings ensure stable performance up to 500°C.

2. What's the lead time for a φ4000mm custom bearing?

Typically 18–22 days, including design validation and precision grinding.

3. Do you assist with legacy mill retrofits?

Absolutely. We provide CAD modeling and on-site measurements for seamless integration.

Contact Us

Ready to Upgrade Your Rolling Mill Bearing?

Contact our engineers today for a free consultation:

📧 Email: sales@inno-bearing.com

📞 Request a Quote: Specify dimensions, operating conditions, and annual volume.

Optimized for performance. Backed by science. Delivered on time.

Learn about our latest products and discounts through SMS or email