- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

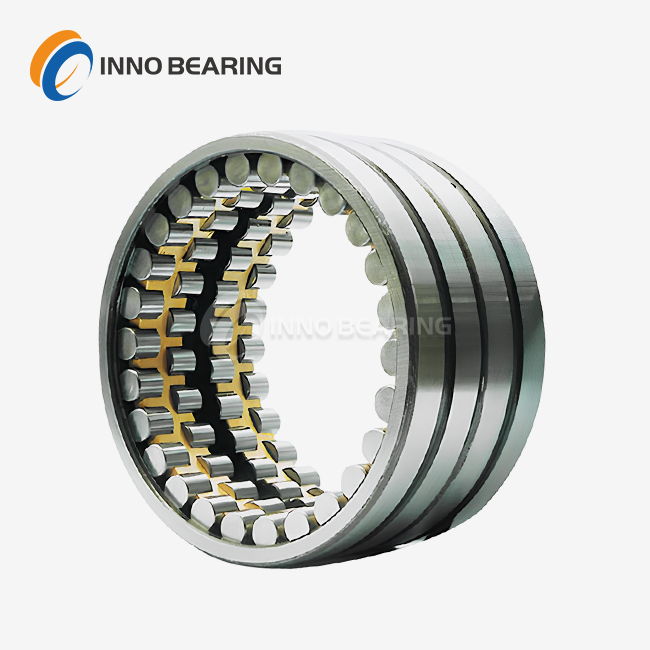

Crossed Cylindrical Roller Bearings

2.Structure Type: The inner and outer rings can be integrated or split, with V-shaped raceways. The crossed rollers are equipped with brass or engineering plastic cages, and there is no seal (suitable for clean environments).

3.Size Range: Outer ring diameter: 50 - 1200mm, inner ring diameter: 30 - 1150mm, height: 10 - 70mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Semiconductor equipment (wafer transfer arms), precision robots (joint bearings), inspection instruments (high-precision turntables).

6.Key Inspection Items: Radial accuracy (≤0.005mm), parallelism of rollers, surface roughness of raceways.

Crossed Cylindrical Roller Bearings: Precision Engineered for Demanding Applications

When your machinery demands uncompromising accuracy and durability, Crossed Cylindrical roller bearings deliver. At LUOYANG INNO BEARING CO., LTD, we combine 30+ years of engineering expertise with advanced manufacturing to produce bearings that excel in high-load, high-precision environments. Whether you’re designing medical robots requiring sub-micron accuracy or heavy-duty port cranes needing φ3000mm+ custom Solutions, our bearings ensure smooth, reliable motion.

Why Choose Us?

Key Specifications & Advantages

-

Precision Performance: Achieve ≤0.005mm radial accuracy (ISO P4/P5 grades) for applications like semiconductor wafer handlers or CNC machining centers.

-

Extreme Load Capacity: Support up to 850kN static loads in harsh conditions, from -50°C to +150°C.

-

Flexible Sizing: Standard sizes (φ50mm–φ2000mm) or custom designs up to φ5000mm.

-

Proven Reliability: 99.9% defect-free rate through triple-stage inspections and 12+ performance tests per batch.

Industry-Tailored Solutions

- Robotics & Automation: Ultra-quiet models (≤35dB noise) with brass cages for precision joint movements.

- Medical Imaging: Cleanroom-manufactured bearings with MRI-safe materials and zero lubricant leakage.

- Heavy Machinery: Heat-treated 42CrMo alloy rollers withstand 500+ cycles at 150°C in steel mills.

- EV Drivetrains: EMI-shielded designs integrate seamlessly with LiDAR/radar systems.

Customization Capabilities: Precision Meets Flexibility

Need a Crossed Cylindrical Roller Bearings non-standard solution? Our modular production system accelerates turnaround:

- Legacy Equipment Upgrades: Retrofit outdated systems with 100% dimensionally compatible bearings.

- Material Innovations: Opt for ceramic hybrids (30% lighter) or nitrile rubber seals for corrosive environments.

- Fast-Track Orders: Receive oversized bearings (e.g., φ3000mm port crane units) in 20 days.

Rigorous Quality Assurance

Every bearing undergoes:

1. Material Testing: X-ray inspection for subsurface defects; HRC 60+ hardness verification.

2. Performance Validation: 10,000+ hour lifespan simulations and vibration analysis.

3. Post-Shipment Support: IoT-enabled wear monitoring for predictive maintenance.

Global Support & Rapid Delivery

- 48-Hour Shipping: 200+ standard models ready from regional hubs.

- Technical Collaboration: Free legacy system audits and 24/7 troubleshooting.

- Certified Compliance: ISO 9001, IATF 16949, AS9100, and RoHS/REACH documentation.

FAQ

1. Can you customize bearings for φ3000mm+ port cranes?

Yes! Our modular system delivers oversized products in 20 days with P4-grade precision.

2. How do you ensure quiet operation (≤35dB) for medical robots?

We use polished raceways (≤0.1μm roughness) and engineering plastic cages to minimize vibration.

3. What materials handle 500°C+ temperatures in steel mills?

42CrMo alloy rollers with specialized heat treatment endure extreme thermal cycling.

4. Do you provide IoT integration for predictive maintenance?

Yes—smart bearings can monitor load, temperature, and wear in real time.

5. How fast can you deliver urgent orders?

Standard sizes ship in 48 hours; custom designs prioritized for 15-day turnaround.

Contact Us

Need a High-Performance Bearing Solution?

📧 Contact our engineers at sales@inno-bearing.com for:

- Compatibility checks within 4 hours (upload drawings).

- Volume discounts on orders ≥100 units.

- Emergency production slots for critical projects.

Engineer confidence into every rotation with precision Crossed Cylindrical Roller Bearings built for your toughest challenges.

Learn about our latest products and discounts through SMS or email