- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

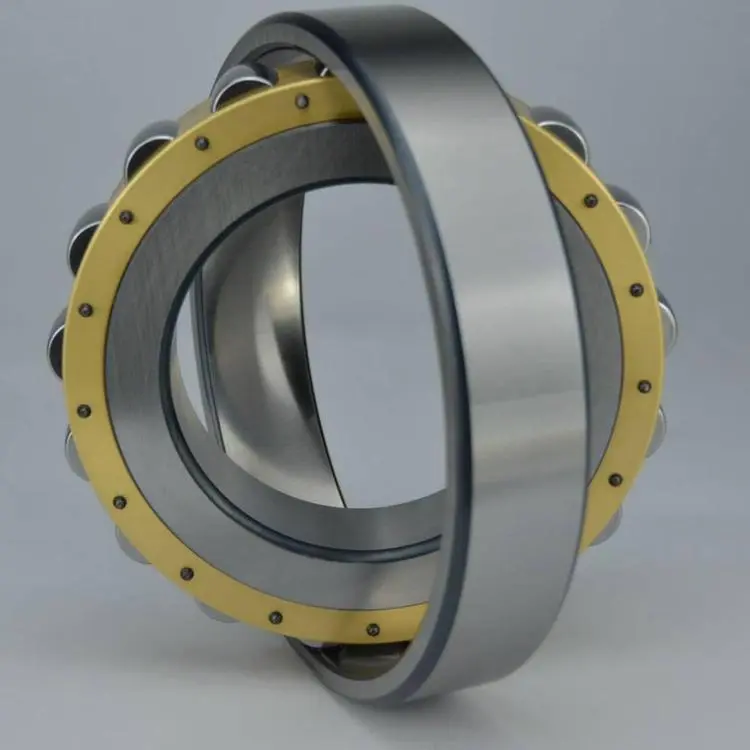

Nu Cylindrical Roller Bearing

2.Structure Type: The outer ring has double ribs, the inner ring is separable, with a single row of rollers + cage, and it is open - type / with dust cover.

3.Size Range: Inner diameter 20 - 500mm, outer diameter 47 - 1000mm, width 14 - 200mm.

4.Material: Inner ring / outer ring / rollers: GCr15/GCR15SIMN/20Cr2Ni4A, cage: stamped steel / brass.

5.Precision: P0/P6 level, high-speed version is P5 level.

6.Application Fields: Electric motors, machine tool spindles, reducers, automobile gearboxes.

7.Key Inspection Items: Radial clearance, roller parallelism, rotational flexibility.

Nu Cylindrical Roller Bearing Overview

When your operations demand reliability under extreme conditions, Nu Cylindrical roller bearings deliver unmatched performance. Designed for industries like metallurgy, port machinery, and mining, these bearings excel in high-stress environments with temperatures up to 150°C, heavy radial loads exceeding 200kN, and corrosive settings. With a separable inner ring and optimized cage design, they ensure smooth operation at high speeds while minimizing maintenance downtime.

Technical Specifications

- Dimensions: ID 20mm–5000mm (standard & custom sizes)

- Temperature Range: -30°C to +150°C (heat-treated steel variants available)

- Precision Grades: P0 to P4 (ISO 15242-1 compliant)

- Noise Level: <35dB at 1500 RPM

- Load Capacity: Up to 1,500kN static radial load

- Materials: GCr15, 20Cr2Ni4A steel, brass/stamped steel cages

- Lubrication: Grease, oil, or custom solutions for harsh environments

Why Choose Us?

30+ Years of Industrial Expertise

Our in-house R&D team and vertically integrated production ensure consistent quality. From raw material selection to final assembly, every Nu Cylindrical Roller Bearing undergoes 12+ performance tests, including vibration analysis and thermal stress simulations.

Rapid Customization

Need non-standard sizes? Our modular design process slashes lead times by 30%. For example, a φ3000mm bearing for a rolling mill can be delivered in 15–20 days—ideal for urgent project timelines.

Built to Last in Extreme Conditions

High-purity chromium steel and specialized heat treatment extend bearing lifespan by 3x in high-temperature applications like blast furnaces. Oxidation-resistant coatings further enhance durability.

Global Availability

1,000+ standard bearings are stocked in regional warehouses (EU, NA, Asia) for 48-hour dispatch. Custom orders ship via expedited logistics with DDP incoterms support.

Where NU Cylindrical Roller Bearions Excel?

1. Metallurgy: Backup bearings in rolling mills handling 500°C heat and radial shocks.

2. Port Machinery: Corrosion-resistant variants with IP69K seals for crane slewing rings.

3. Mining: Shock-proof designs (50J impact resistance) for crushers and conveyors.

4. Medical Equipment: P4-grade precision bearings with <35dB noise for imaging devices.

Customization Made Simple

1. Share Requirements: Submit load, speed, and environmental details.

2. 3D Modeling & Review: Get technical feedback within 24 hours.

3. Prototype Testing: Optional pre-production validation.

4. Bulk Production: 15–20 days for most non-standard orders.

Quality Assurance

- Material Checks: Spectrometer testing ensures 99.95% steel purity.

- Precision Grinding: Tolerance control ≤0.002mm.

- Final Validation: Lifespan testing (10,000+ hours), thermal cycling, and vibration analysis.

FAQ

Q: Can you deliver a φ3200mm product in 18 days?

A: Yes. Our modular production system prioritizes urgent requests without compromising quality.

Q: How do your bearings handle saltwater corrosion?

A: We use super duplex steel and triple-lip seals for 1,000+ hours of salt spray resistance (ASTM B117 certified).

Q: What certifications do your bearings have?

A: ISO 9001, ASTM A295, and EN 10204 3.1 material traceability. Industry-specific certs like MSHA and ATEX are available.

Contact Us

Ready to Upgrade Your Equipment with Nu Cylindrical Roller Bearing?

Contact Us Today!

Email your specifications to sales@inno-bearing.com for a free technical review and competitive quote within 24 hours.

LUOYANG INNO BEARING CO., LTD—Powering Industries with Precision Since 1993.

Learn about our latest products and discounts through SMS or email