- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

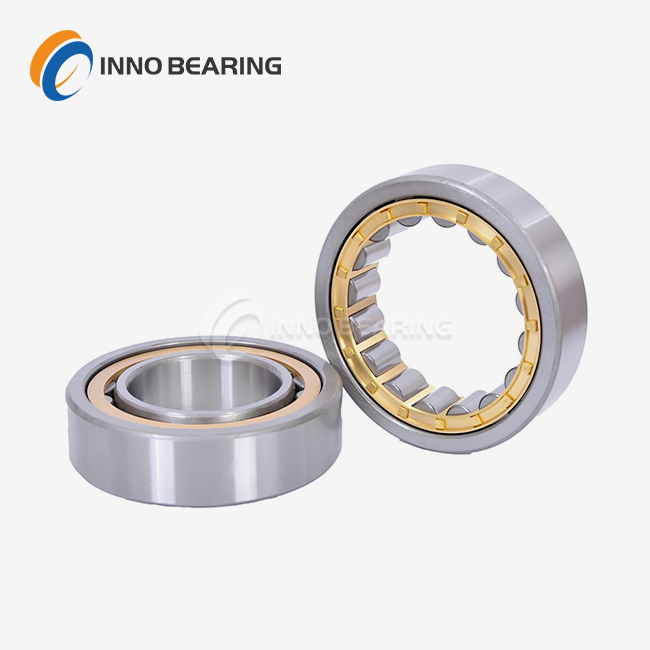

Tapered Bore Bearing

2.Structure Type: The inner ring has a tapered hole (1:12 or 1:30), the outer ring has double ribs, with double-row spherical rollers + cage, and it is open.

3.Size Range: Inner diameter 30 - 500mm, outer diameter 62 - 1000mm, width 20 - 200mm.

4.Material: Inner ring / outer ring: GCr15 bearing steel, rollers: GCr15 bearing steel, cage: stamped steel / brass.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: 1:12 taper (suitable for most shaft systems), 1:30 taper (for precise fine adjustment).

7.Application Fields: Electric motor spindles, auxiliary rolls of rolling mills, heavy-duty fans, mining machinery.

8.Key Inspection Items: Tapered hole precision, adjustable range of radial clearance, self-aligning angle.

Tapered Bore Bearing: Precision Solutions for Demanding Industries

Engineered to withstand extreme loads, high temperatures, and harsh environments, our tapered bore bearings deliver unmatched reliability for industrial applications. With 30+ years of specialized expertise, LUOYANG INNO BEARING CO., LTD provides fast 48-hour delivery for standard sizes and custom designs in 15-20 days.

Product Specifications & Applications

Key Features

-

Sizes: Standard (ID φ20mm–φ5000mm) / Fully Customizable

-

Materials: High-purity forged steel (GCr15/Si3N4)

-

Precision: ABEC-3 to P4 (medical-grade)

-

Taper Options: 1:12 (general use) or 1:30 (fine adjustment)

Top Applications

- Metallurgy: Backup rollers in rolling mills (150°C continuous operation).

- Port Machinery: Slewing rings for ship-to-shore cranes.

- Mining: Conveyor pulleys with dust-resistant seals.

Industry-Specific Benefits

For Metallurgy & Steel Plants

Our bearings feature graphite lubrication slots to prevent grease degradation at 150°C. The thermal-stable design minimizes deformation under rapid temperature changes.

For Port & Marine Equipment

Triple-layered seals and seawater-proof coatings protect against saltwater corrosion. Impact-resistant cages handle sudden axial shocks during container handling.

For Medical & Precision Machinery

Ultra-low noise (<35dB) and P4-grade accuracy ensure smooth operation in MRI machines. Non-magnetic ceramic variants eliminate interference risks.

Customization Made Simple

1. Submit your CAD drawings or specifications.

2. Review technical feasibility within 72 hours.

3. Test prototypes under real-world conditions (optional).

4. Produce with modular tooling for sizes up to φ3000mm+.

Example: A φ2500mm tapered bore bearing for a wind turbine hub was delivered in 18 days, reducing client downtime by 40%.

Quality Assurance You Can Trust

Every product undergoes:

- Raw material spectrometry (SGS-certified steel).

- 12+ performance tests (ISO 281 fatigue life, ISO 15242 vibration analysis).

- 100% final inspection for radial clearance (±0.01mm).

Result: 99.9% ex-factory qualification rate since 2020.

Fast Global Delivery

- 1,000+ standard bearings ready to ship within 48 hours.

- Regional warehouses in EU, North America, and ASEAN.

- Export-safe packaging with VCI anti-rust film.

Lifetime Technical Support

We provide:

- Free IoT monitoring software to track bearing health in real time.

- Predictive lubrication schedules tailored to your operating conditions.

- 24/7 engineering support for installation and alignment.

Why Choose Us?

✅ 30+ Years of Focus: Solely dedicated to product innovation.

✅ Cost Efficiency: Hybrid production model saves 40% vs. traditional OEMs.

✅ Full Traceability: Access lifetime quality records via blockchain-enabled logs.

FAQ

1. How do your bearings handle 300°C environments?

We use high-purity steel with graphite-infused raceways to maintain lubrication at extreme temperatures.

2. Can you customize bearings for 1000 RPM port cranes?

Yes! Our impact-resistant cages and balanced roller sets are optimized for high-speed, high-load scenarios.

3. What testing ensures heavy-load reliability?

Each bearing undergoes 3,000-hour accelerated lifespan tests under 150% rated load.

4. How do you achieve 15-20 day lead times for custom orders?

Modular tooling and pre-hardened material stocks enable rapid production scaling.

Contact Us

Need a tapered bore bearing solution? Contact our engineers at sales@inno-bearing.com for a response within 2 hours.

Learn about our latest products and discounts through SMS or email