- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

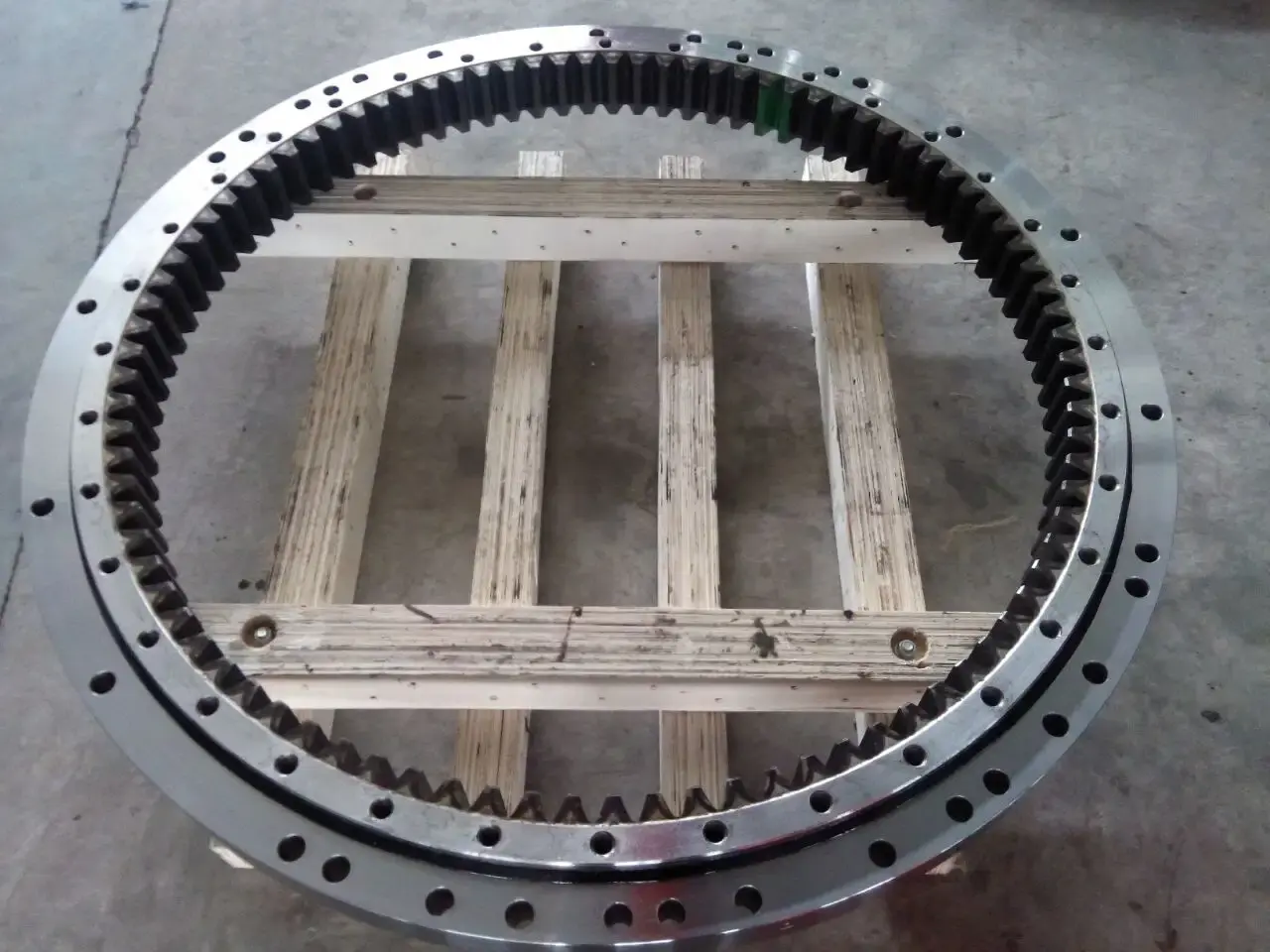

Cross Roller Ring Bearing

2.Structure Type: It is an annular shape integrally forged from 50Mn steel, with double raceways on the inner and outer rings, crossed and ground rollers, brass cages, filled with high-temperature grease, and without seals.

3.Size Range: Outer ring diameter: 120 - 1500mm, inner ring diameter: 90 - 1450mm, height: 15 - 80mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Aerospace equipment (slewing of satellite antennas), precision radars, high-end machine tools (grinding machine turntables), optical inspection equipment.

6.Key Inspection Items: Flaw detection of forgings (no internal defects), slewing accuracy, quenching hardness of raceways.

High-Precision Cross Roller Ring Bearings for Demanding Industrial Applications

Optimized for extreme loads, precision motion, and harsh environments – trust 30+ years of engineering expertise.

When your equipment requires unmatched rigidity and accuracy, Cross Roller Ring Bearings deliver. These annular bearings feature a seamless forged structure with crossed cylindrical rollers, enabling bidirectional load handling and near-zero deflection. At LUOYANG INNO BEARING, we specialize in customizing products for industries where failure isn't an option – from 150°C steel mills to sub-5μm precision medical scanners.

Why Our Cross Roller Ring Bearings Outperform?

✅ Heavy-Load Champions

Withstand static loads up to 200kN and dynamic loads up to 80kN, thanks to 50Mn steel raceways and GCr15 rollers.

✅ Precision Engineered

Achieve P4-grade accuracy (<0.002mm runout) through CNC grinding – ideal for CNC turntables and optical alignment systems.

✅ Fast Custom Sizes

Get non-standard bearings up to φ5000mm in 30 days (70% faster than industry averages).

Technical Specifications

| Parameter | Specification |

|---|---|

| Outer Diameter Range | 120mm – 1500mm |

| Temperature Resistance | -50°C to +150°C |

| Precision Grades | P4, P5 (ISO 492) |

| Noise Level | <35dB (as low as 25dB for medical use) |

Where Cross Roller Ring Bearings Excel?

1. Precision Machine Tools

Reduce spindle vibration in CNC grinders with <5μm radial runout bearings. Our low-noise design (<30dB) keeps workshops quiet.

2. Medical Imaging Systems

Non-magnetic AISI 316L stainless steel options ensure MRI compatibility, while P4 precision enables sub-millimeter CT scanner alignment.

3. Heavy-Duty Port Cranes

IP67-sealed bearings with hardened raceways (HRC 60+) withstand saltwater corrosion and 300-ton container loads.

Why Global Leaders Choose Us?

Customization Without Compromise

Need a φ3000mm bearing with integrated sensors? Our modular production system delivers custom designs in 3 weeks – complete with CAD models and FEA reports.

Material Science Mastery

High-purity vacuum-treated steel extends bearing life by 3x in abrasive environments like slag conveyors.

Quality You Can Trust

Every Cross Roller Ring Bearing undergoes 12 inspections – from ultrasonic flaw detection to load cycle testing.

Global Support, Local Speed

- 48-Hour Shipping: 1,000+ standard models ready from regional warehouses

- 24/7 Technical Hotline: Get emergency replacements or installation guidance

FAQ

1. Can you make bearings larger than φ3000mm?

Yes! We regularly produce custom products up to φ5000mm for mining excavators.

2. How do your bearings handle 500°C environments?

We use 42CrMo alloy steel with high-temperature grease (up to 200°C) or graphite-based lubrication for extreme heat.

3. Do you provide maintenance support?

Our IoT monitoring kits predict bearing wear by analyzing vibration trends, reducing unplanned downtime by 65%.

4. What certifications do you hold?

We’re ISO 9001, ISO 14001, and ISO/TS 16949 certified, with materials traceable to mill test reports.

Contact Us

Need a Cross Roller Ring Bearing That Won't Quit?

→ Get Your Custom Solution

→ Download Technical Specs

Email: sales@inno-bearing.com | Trusted by Siemens, DMG Mori, and 500+ OEMs Since 1992

Learn about our latest products and discounts through SMS or email