- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Internal Gear Slewing Bearing

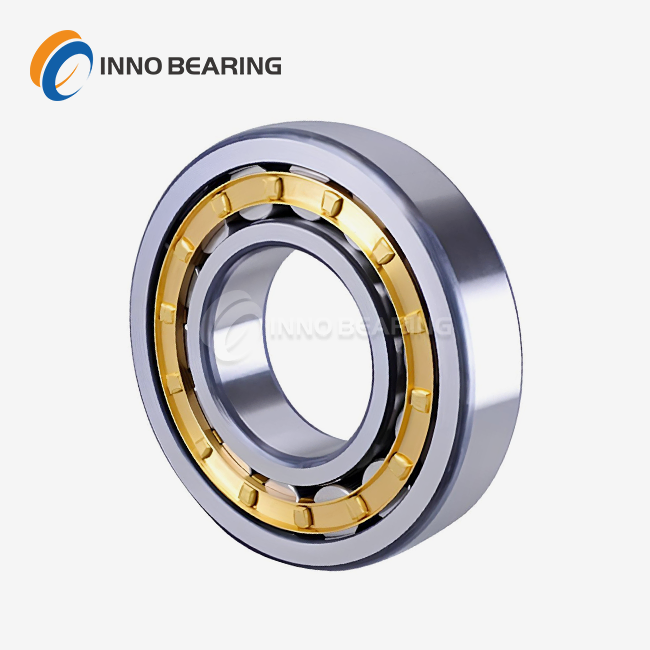

2.Structure Type: It has an annular structure. The inner side of the inner ring is machined with straight or helical teeth (module 2 - 10). The inner and outer rings have double raceways, with built-in steel balls or rollers, metal cages, and outer seals.

3.Size Range: Outer ring diameter: 500 - 3000mm, inner ring gear ring diameter: 450 - 2800mm, height: 30 - 100mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Tower cranes, portal cranes, large excavators, port loading and unloading machinery.

6.Key Inspection Items: Internal gear pitch error, tooth surface hardness, slewing accuracy.

Internal Gear Slewing Bearings: Engineered for Extreme Performance

When precision meets durability, Internal Gear Slewing Bearings deliver unmatched reliability in heavy machinery. Designed for applications where space constraints and harsh conditions collide, these bearings feature gears integrated into the inner ring, optimizing torque transmission while protecting components from dust, debris, and extreme temperatures up to 150°C. At LUOYANG INNO BEARING CO., LTD, our three decades of expertise ensure your equipment operates smoothly under axial loads up to 50,000 kN and radial forces exceeding 150,000 kN·m.

Why Choose Us?

1. Built to Withstand Industrial Demands

-

High-Temperature Resilience: Specialized alloys and ceramic coatings maintain structural integrity even in continuous casting machinery exposed to 500°C+ environments.

-

Heavy-Load Superiority: Reinforced gear teeth and triple heat-treated raceways handle shock loads common in blast furnaces and rolling mills.

-

Space-Saving Design: Internal gears minimize footprint by 15-20% compared to external gear models, ideal for compact crane slewing mechanisms.

2. Precision You Can Trust

Every product undergoes:

- P4-Grade Grinding: Achieves ±0.005mm radial runout for seamless alignment in multi-stage systems.

- AGMA 10-12 Gear Accuracy: Hardened tooth surfaces (HRC 58-62) reduce backlash to ≤0.05mm, ensuring smooth rotation in ladle turrets.

Technical Specifications

| Parameter | Specification |

|---|---|

| Diameter Range | φ300mm – φ5000mm (Customizable) |

| Material | 42CrMo/50Mn Steel with Induction Hardening |

| Load Capacity | 50,000 kN Axial, 150,000 kN·m Moment |

| Operating Temperature | -40°C to +150°C |

| Sealing | IP67 (Optional Triple-Lip Seals) |

Custom Solutions for Unique Challenges

Need a non-standard Internal Gear Slewing Bearing? Our modular production system delivers:

- 15-20 Day Lead Times: Fast-track manufacturing for φ3000mm+ custom designs.

- Integrated IoT Ports: Real-time load monitoring via embedded sensors.

- Hybrid Configurations: Combine hydraulic raceways or explosion-proof coatings for mining/oil-gas hybrids.

Where They Excel: Industry Applications?

Our bearings are proven in:

- Metallurgy: Ladle cranes, rolling mill turrets, and continuous casting systems.

- Port Machinery: Container handlers and shipyard ganties requiring reinforced gear teeth.

- Mining: Blast furnace chargers with IP67 protection against abrasive dust.

Quality Assured, Global Support

Rigorous Testing Protocol

Each product passes:

1. Gear Meshing Analysis: Simulates 10,000+ cycles under peak loads.

2. Ultrasonic Flaw Detection: Identifies micron-level material defects.

3. 500-Hour Fatigue Testing: Validates lifespan in simulated harsh conditions.

Worldwide Delivery Network

- 1,000+ Standard Bearings: Ready to ship within 48 hours from EU/NA/Asia hubs.

- Emergency Repairs: On-site retrofitting for legacy systems within 72 hours.

Your Lifetime Partner

Beyond delivery, we provide:

- Predictive Maintenance Plans: IoT-driven alerts for wear patterns.

- Certification Support: CE, API 6A, GOST R, and region-specific compliance.

- 24/7 Technical Hotline: Direct access to engineers with 10+ years’ field experience.

FAQ

Q: Can you customize bearings beyond φ5000mm?

A: Yes – our R&D team designs up to φ6000mm for ultra-large mining excavators.

Q: How do your bearings reduce downtime in port cranes?

A: Reinforced gear teeth and triple-sealed raceways extend service intervals by 40%.

Q: Do you offer condition monitoring?

A: Our SmartSeries™ includes Modbus-enabled sensors for real-time performance tracking.

Contact Us

Ready to Optimize Your Machinery?

Request a free engineering consultation to tailor an Internal Gear Slewing Bearing solution for your project.

📧 Contact Us Today: sales@inno-bearing.com

📥 Download Datasheet: [Technical Specifications PDF]

🕒 24/7 Support: Click the chat icon for immediate assistance.

LUOYANG INNO BEARING CO., LTD – Where Precision Meets Endurance.

Learn about our latest products and discounts through SMS or email