- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

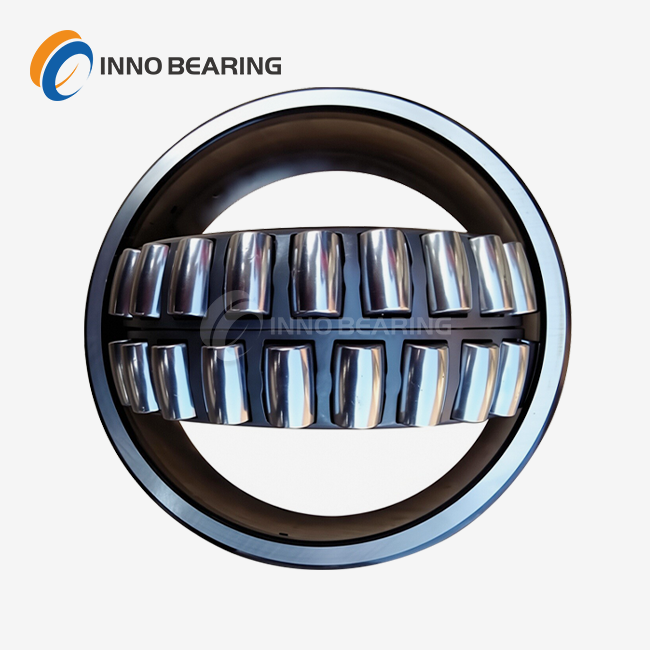

roller slewing ring

2.Structure Type: It has a thick-wall annular shape. The inner and outer rings are made of alloy structural steel, with built-in single-row or multi-row rollers, steel cages, heavy-duty seals to prevent impurities, and the mounting holes have anti-loosening designs.

3.Size Range: Outer ring diameter: 500 - 3000mm, inner ring diameter: 450 - 2850mm, height: 25 - 100mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Port cranes, metallurgical equipment, large wind power main units, heavy-duty mining machinery.

6.Key Inspection Items: Roller assembly clearance, anti-overturning moment performance, dust-proof performance of seals.

High-Performance Roller Slewing Rings for Heavy-Duty Machinery – Custom Engineered for Harsh Conditions

ISO-Certified Manufacturer with 30+ Years of Expertise in Metallurgy, Port, and Construction Applications

When your heavy machinery demands reliability under extreme stress, roller slewing rings deliver unmatched performance. These robust bearings use cylindrical or tapered rollers—instead of balls—to handle higher loads, resist impacts, and endure harsh environments like steel mills, port cranes, and mining sites. At LUOYANG INNO BEARING CO., LTD, we’ve spent three decades perfecting slewing ring designs that combine precision engineering with industry-specific durability.

Why Choose Us?

✅ Heavy-Load Champions

Built with GCr15 bearing steel rollers and 42CrMo alloy rings, our roller-type Slewing Bearings support radial/axial loads up to 5,000 kN. Ideal for port cranes lifting 100+ tons or mining excavators operating in abrasive conditions.

✅ Customization in Days, Not Months

Need a non-standard design? Submit your CAD file, and our engineers will provide feasibility feedback within 24 hours. Modular production slashes lead times by 30%—even φ3000mm slewing rings ship in 25 days.

✅ Built for Extreme Conditions

- High-temperature resistance (500°C) with Inconel-coated rollers

- Saltwater-proof IP68 seals surviving 2,000+ hours of salt spray

- Precision grinding ensures ≤0.05mm/m radial runout

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Outer Diameter Range | 300mm – 5000mm |

| Material | 50Mn/42CrMo Steel, GCr15SiMn Rollers |

| Load Capacity | Up to 10,000 kN (Customizable) |

| Temperature Resistance | -30°C to +150°C |

| Certifications | ISO 9001, CE, FEM 9.511, API 8C |

Where Our Roller Slewing Rings Excel?

🏗️ Metallurgical Equipment

Survive molten metal environments with our high-temperature slewing rings:

-

Special heat treatment prevents warping at 150°C

-

42CrMo4 steel cores resist thermal fatigue

🚢 Port Machinery

Keep container cranes running with corrosion-resistant designs:

-

Fluororubber seals block saltwater ingress

-

100% final inspection verifies 5,000-hour lifespan

🌪️ Wind Turbines

Ensure smooth yaw/pitch control in turbines:

- Multi-row roller designs handle uneven loads

- IoT-ready models enable predictive maintenance

6 Reasons Engineers Trust Us

1. 30+ Years of Vertical Expertise

We control every step—from steel sourcing (EN 10204-3.1 certified) to final grinding of roller slewing ring—ensuring 99.9% defect-free bearings.

2. Rapid Response to Emergencies

1,000+ standard slewing rings ship in 48 hours. Urgent custom orders get dedicated project tracking.

3. Precision You Can Measure

Our triple QC checks:

- Raw material hardness (≥58 HRC)

- In-process dimensional accuracy (±0.01mm)

- 100% load testing with traceable reports

4. Global Support Network

Regional warehouses + 24/7 technical assistance in English, Russian, and Spanish.

5. Sustainability Focus

ROHS-compliant materials and energy-efficient production processes.

6. Lifetime Cost Savings

Predictive maintenance plans extend bearing life by 40%, reducing downtime costs by $8,000/hour.

FAQ

❓ Can you make a φ4000mm product in 3 weeks?

Yes! Our modular production system delivers oversized custom bearings in 15-25 days—70% faster than industry averages.

❓ How do you prevent seal failure in dusty mines?

We use triple-lip nitrile rubber seals + grease purging ports, tested to retain 99.7% of particles in ISO 12103-1 dust tests.

❓ Do you assist with installation?

Absolutely. Every order includes:

- CAD models with tolerance specs

- Step-by-step installation videos

- Optional on-site technician support

Contact Us

Ready to Upgrade Your Roller Slewing Ring Machinery's Backbone?

📩 Contact Our Engineers Today

Email: sales@inno-bearing.com

LUOYANG INNO BEARING CO., LTD — Where Heavy-Duty Meets Precision.

Learn about our latest products and discounts through SMS or email