- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

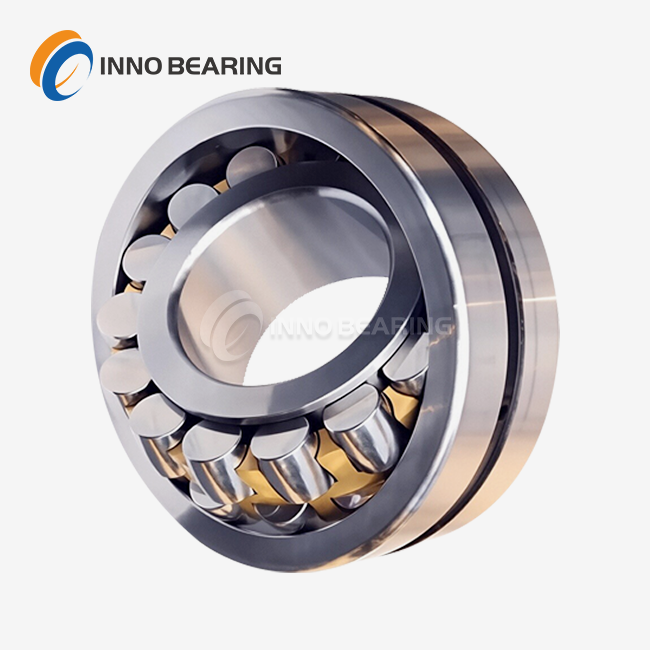

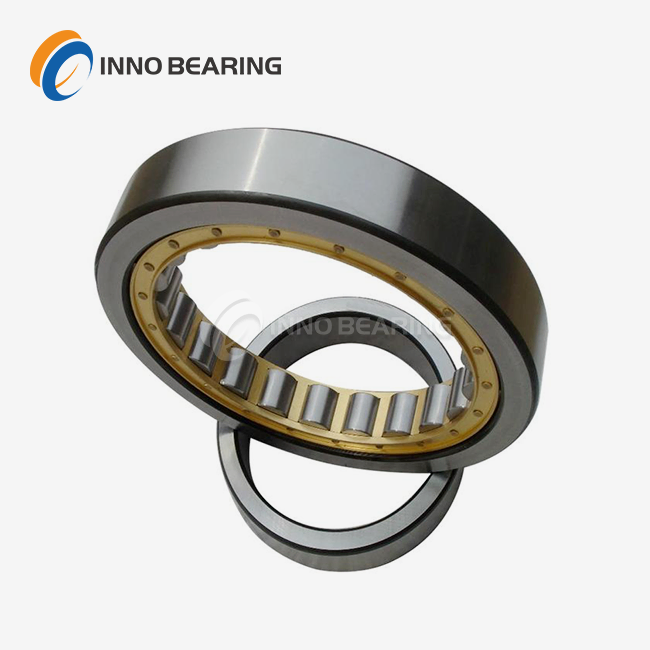

Precision Tapered Roller Bearings

2.Structure Type: The raceways of the inner ring / outer ring are super - finished, the outer ring is separable, with a single - row of rollers + cage, and it is open - type.

3.Size Range: Inner diameter 20 - 300mm, outer diameter 47 - 500mm, width 14 - 100mm.

4.Material: Inner ring/Outer ring/Rollers: GCr15/GCr15SiMn/20Cr2Ni4A, cage: stamped steel / brass.

5.Precision: P5/P4 level, ultra - precision version is P2 level.

6.Application Fields: Precision machine tool spindles, high - end automobile gearboxes, turbochargers.

7.Key Inspection Items: Taper surface fitting degree (≥98%), radial run - out (≤0.003mm), operation noise (≤45dB).

Precision Tapered Roller Bearings: Engineered for Extreme Performance & Reliability

When your machinery demands precision Tapered Roller Bearings that outperform under extreme conditions, LUOYANG INNO BEARING delivers. For 30+ years, we've specialized in manufacturing bearings that combine military-grade durability with P5/P4-level rotational accuracy (±0.001mm). Designed to withstand temperatures up to 500°C and 3x standard load capacities, our Solutions eliminate premature failures in metallurgical, wind energy, and automotive applications. Whether you need rapid 48-hour delivery of standard units or custom φ5000mm bearings, our vertically integrated production ensures unmatched quality. Discover how our contamination-resistant designs and IoT-enabled predictive maintenance can extend your equipment's lifespan by 30%+.

Why Choose Us?

1. Defy Extreme Operating Conditions

-

500°C Heat Resistance: Carburized steel rollers with ceramic hybrids maintain hardness in steel mills.

-

3x Load Capacity: Triple-layer raceway coatings handle shock loads in mining crushers.

-

Contamination Defense: Labyrinth seals with 98% particle exclusion for port machinery.

2. Sector-Specific Engineering

-

Medical Robotics: Ultra-low noise (<35dB) and smooth operation for surgical arms.

-

Wind Turbines: DNV GL-certified, corrosion-resistant designs for offshore gearboxes.

-

EV Drivetrains: 20% friction reduction via graphene-enriched lubricants.

3. Military-Grade Quality Control

- 12-stage inspections (material hardness → vibration/noise tests).

- 500-hour accelerated lifespan simulations (L10 Theory).

- 99.9% defect-free rate with digital batch traceability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Inner Diameter Range | 20mm – 5000mm |

| Precision Grades | ISO P0, P5, P4, P2 |

| Max Speed | 3,000 RPM |

| Temperature Range | -50°C to +500°C |

| Noise Level | <35dB (Standard), <28dB (EVo Series) |

Where Precision Meets Application?

- Metallurgical Machinery: Impact-resistant Precision Tapered Roller Bearings survive 300+ thermal cycles in continuous casters.

- Port Cranes: φ3000mm+ MegaLine Ultra bearings reduce slewing gear wear by 40%.

- Wind Turbines: TorqDrive Pro units achieve 200,000+ hours in high-torque gearboxes.

Customization in 4 Agile Steps

1. Requirement Analysis – Share CAD files/Specs → Get engineering feedback in 72hrs.

2. Prototyping – 15-20 days for φ3000mm+ custom bearings.

3. Real-Condition Testing – Validate performance via 500-hour simulations.

4. Bulk Production – 30% faster lead times with modular manufacturing.

Global Support, Local Speed

- 1,000+ Standard SKUs: Shipped in 48hrs via EXW/FOB/DDP.

- IoT Integration: Monitor bearing health in real-time via embedded sensors.

- Lifetime Partnership: Free AR-guided installation + predictive maintenance planning.

FAQ

Q1: How do you ensure P4 accuracy at 500°C?

Our carburizing process enhances surface hardness (≥60 HRC), while ceramic-hybrid rollers prevent thermal expansion.

Q2: Can you deliver φ4000mm custom bearings urgently?

Yes! Expedited prototyping reduces lead times to 20 days.

Q3: What certifications do your bearings hold?

ISO 9001, TS 16949, DNV GL (offshore), and IATF 16949 (automotive).

Q4: Do you offer on-site failure analysis?

Our global team dispatches engineers within 48hrs for root-cause diagnostics.

Contact Us

Ready to Upgrade Your Machinery with Precision Tapered Roller Bearings?

✉️ Email sales@inno-bearing.com for:

- Custom bearing quotes

- Free technical consultations

- Emergency replacement requests

Trusted by Leaders in Metallurgy, Renewable Energy & Automotive Sectors

| d 40~50mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 15 | 30 | 13 | 12 | 11 | 1 | 0.3 | 14 | 15 | 9000 | 13000 | 30602-1(TD-CR0529/0256) | 17 | 17 | 25 | 28 | 3 | 7 | 1 | 0.3 | 0.29 | 2.1 | 1.1 | 0.0407 | ||

| 35 | 14.8 | 15 | 11.75 | 1 | 0.3 | 21.8 | 22.4 | 9000 | 13000 | 30602(RV-70FC) | 18 | 18 | 30 | 33 | 3 | 5 | 1 | 0.3 | 0.24 | 2.5 | 1.4 | 0.0716 | |||

| 42 | 14.25 | 13 | 11 | 1 | 1 | 22.9 | 21.7 | 9000 | 13000 | 30302 | 7302E | 2FB | 23 | 23 | 35 | 36 | 3 | 5 | 1 | 1 | 0.28 | 2.1 | 1.1 | 0.0948 | |

| 17 | 40 | 13.25 | 12 | 11 | 1 | 1 | 20.7 | 22.2 | 9000 | 13000 | 30203 | 7203E | 2DB | 22 | 22 | 34 | 35 | 2 | 4 | 1 | 1 | 0.35 | 1.7 | 0.9 | 0.0781 |

| 47 | 15.25 | 14 | 12 | 1 | 1 | 28.3 | 27.4 | 8500 | 12000 | 30303 | 7303E | 2FB | 25 | 25 | 41 | 42 | 3 | 5 | 1 | 1 | 0.28 | 2.1 | 1.1 | 0.13 | |

| 47 | 20.25 | 19 | 16 | 1 | 1 | 35.4 | 36.6 | 8000 | 11000 | 32303 | 7603E | 2FD | 25 | 25 | 41 | 42 | 3 | 6 | 1 | 1 | 0.28 | 2.1 | 1.1 | 0.174 | |

| 20 | 47 | 15.25 | 14 | 12 | 1 | 1 | 28.2 | 30.9 | 8000 | 11000 | 30204 | 7204E | 2DB | 26 | 26 | 42 | 43 | 3 | 5 | 1 | 1 | 0.35 | 1.7 | 0.9 | 0.127 |

| 52 | 16.25 | 15 | 13 | 1.5 | 1.5 | 33.2 | 33.3 | 8000 | 11000 | 30304 | 7304E | 2FB | 28 | 28 | 45 | 47 | 3 | 5 | 1.5 | 1.5 | 03 | 2 | 1.1 | 0.168 | |

| 52 | 22.25 | 21 | 18 | 1.5 | 1.5 | 42.7 | 46.4 | 7500 | 10000 | 32304 | 7604E | 2FD | 28 | 28 | 45 | 47 | 3 | 6 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.231 | |

| 22 | 47 | 20 | 21 | 16 | 1 | 1 | 39.5 | 46 | 7500 | 10000 | 306/22 | 26 | 26 | 42 | 44 | 6.5 | 9 | 1 | 1 | 0.29 | 2.1 | 1.1 | 0.167 | ||

| 25 | 52 | 16.25 | 15 | 13 | 1 | 1 | 33.7 | 39.4 | 7500 | 10000 | 30205 | 7205E | 3CC | 31 | 31 | 46 | 47 | 3 | 5 | 1 | l | 0.37 | 1.6 | 0.9 | 0.157 |

| 52 | 19.25 | 18 | 16 | 1 | 1 | 39 | 48.8 | 7000 | 9500 | 32205 | 2CD | 31 | 31 | 44 | 46 | 3 | 4 | 1 | 1 | 0.36 | 1.7 | 0.9 | 0.184 | ||

| 62 | 18.25 | 17 | 13 | 1.5 | 1.5 | 40.7 | 46 | 5600 | 7500 | 31305 | 27305E | 7FB | 33 | 33 | 52 | 57 | 3 | 7 | 1.5 | 1.5 | 0.83 | 0.7 | 04 | 0.264 | |

| 62 | 18.25 | 17 | 14 | 1.5 | 1.5 | 40.7 | 46 | 5600 | 7500 | 31305X2YB2 | 33 | 33 | 52 | 57 | 3 | 7 | 1.5 | 1.5 | 0.54 | 1.1 | 0.6 | 0.267 | |||

| 62 | 18.25 | 17 | 15 | 1.5 | 1.5 | 47 | 48.3 | 6700 | 9000 | 30305 | 7305E | 2FB | 33 | 33 | 55 | 57 | 3 | 5 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.265 | |

| 62 | 18.25 | 17 | 15 | 1.5 | 1.5 | 49.1 | 48.1 | 5600 | 7500 | 30305/YB | 33 | 33 | 55 | 57 | 3 | 5 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.265 | |||

| 62 | 25.25 | 24 | 20 | 1.5 | 1.5 | 61.7 | 68.9 | 6000 | 8000 | 32305 | 7605E | 2FD | 33 | 33 | 55 | 57 | 3 | 7 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.37 | |

| 30 | 58 | 19.45 | 20 | 15.5 | 1.5 | 0.3 | 45.9 | 57.2 | 6100 | 7700 | 30606(ST3058-1) | 34 | 34 | 52 | 56 | 7 | 9 | 1.5 | 0.3 | 0.32 | 1.9 | 1 | 0.261 | ||

| 62 | 17.25 | 16 | 14 | 1 | 1 | 43.3 | 50.6 | 6300 | 8500 | 30206 | 7206E | 3DB | 36 | 36 | 56 | 57 | 3 | 5 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.232 | |

| 62 | 20 | 20 | 16 | 1 | 1 | 54.3 | 63.6 | 6300 | 8500 | 32206X2 | 36 | 36 | 56 | 59 | 8 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.277 | ||||

| 62 | 21.25 | 20 | 17 | 1 | 1 | 51.8 | 63.9 | 6300 | 8500 | 32206 | 7506E | 3DC | 36 | 36 | 56 | 57 | 3 | 6 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.285 | |

| 72 | 20.75 | 19 | 16 | 1.5 | 1.5 | 59 | 63.9 | 5600 | 7500 | 30306 | 7306E | 2FB | 38 | 38 | 64 | 66 | 3 | 7 | 1.5 | 1.5 | 0.31 | 1.9 | 1 | 0.389 | |

| 72 | 20.75 | 19 | 14 | 1.5 | 1.5 | 51 | 36 | 5000 | 6700 | 31306 | 27306E | 7FB | 38 | 38 | 64 | 66 | 7 | 1.5 | 1.5 | 0.82 | 0.7 | 0.4 | 0.394 | ||

| 72 | 24.5 | 24 | 17.6 | 3 | 1.5 | 53.8 | 65.9 | 5600 | 7500 | 30306X2B | 27706 | 36 | 36 | 60 | 68 | 5 | 9 | 2.5 | 1 | 0.6 | 1 | 0.56 | 0.472 | ||

| d 30~45mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 30 | 72 | 28.75 | 27 | 23 | 1.5 | 1.5 | 66.8 | 83.3 | 5300 | 7000 | 32306 | 7606E | 2FD | 38 | 38 | 64 | 66 | 4 | 8 | 1.5 | 1.5 | 0.31 | 1.9 | 1 | 0.566 |

| 72 | 28.75 | 27 | 23 | 1.5 | 15 | 66.8 | 83.3 | 5300 | 7000 | 32306AN | 37 | 38 | 59 | 66 | 4 | 6 | 1.5 | 1.5 | 31 | 1.9 | 1 | 0.587 | |||

| 32 | 75 | 29.75 | 28 | 23 | 1.5 | 1.5 | 76.9 | 60.6 | 5200 | 6900 | 323/32 | 76/32 | 39 | 39 | 68 | 71 | 3 | 6.5 | 1.5 | 1.5 | 0.55 | 1.1 | 0.6 | 0.647 | |

| 35 | 62 | 18 | 18 | 14 | 1 | 1 | 42.3 | 53.7 | 6000 | 8000 | 32007 | 3DC | 40 | 41 | 54 | 59 | 4 | 4 | 1 | 1 | 0.2 | 2.9 | 1.6 | 0.22 | |

| 65 | 18 | 18 | 14 | 3.5 | 3.5 | 41.3 | 59 | 6000 | 8000 | 30607 | 3DB | 50 | 50 | 56 | 50 | 3 | 5 | 3 | 3 | 0.38 | 1.5 | 0.8 | 0.246 | ||

| 72 | 18.25 | 17 | 15 | 1.5 | 1.5 | 54.2 | 63.7 | 5300 | 7000 | 30207 | 7207E | 3DB | 43 | 43 | 64 | 67 | 3 | 5 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.333 | |

| 72 | 24.25 | 23 | 19 | 1.5 | 1.5 | 70.6 | 89.7 | 5300 | 7000 | 32207 | 7507E | 3DC | 43 | 43 | 64 | 67 | 3 | 7 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.447 | |

| 72 | 28 | 28 | 22 | 1.5 | 1.5 | 82.6 | 102 | 5500 | 7000 | 33207 | 40 | 41 | 62 | 71 | 3 | 7 | 1.5 | 1.5 | 0.35 | 1.7 | 0.9 | 0.518 | |||

| 80 | 22.75 | 21 | 18 | 2 | 1.5 | 75.4 | 83.6 | 5000 | 6700 | 30307 | 7307E | 2FB | 44 | 44 | 71 | 75 | 3 | 7 | 2 | 1.5 | 0.31 | 1.9 | 1 | 0.518 | |

| 80 | 22.75 | 21 | 15 | 2 | 1.5 | 63.8 | 45.8 | 4500 | 6000 | 31307 | 27307E | 42 | 44 | 62 | 76 | 4 | 8 | 2 | 1.5 | 0.82 | 0.7 | 0.4 | 0.517 | ||

| 80 | 32.75 | 31 | 25 | 2 | 1.5 | 99.1 | 119.7 | 4800 | 6300 | 32307 | 7607E | 2FE | 44 | 44 | 71 | 75 | 5 | 10 | 2 | 1.5 | 31 | 1.9 | 1 | 0.766 | |

| 80 | 32.75 | 31 | 24 | 2 | 1.5 | 94.7 | 116 | 4800 | 6300 | 32307CN | 43 | 44 | 66 | 74 | 4 | 8 | 2 | 2 | 0.31 | 1.9 | 1 | 0.777 | |||

| 40 | 62 | 15.2 | 14 | 12 | 0.6 | 0.6 | 30 | 50 | 5600 | 7200 | 32908X2 | 2007908 | 46 | 46 | 57 | 58 | 3 | 5 | 0.6 | 6 | 0.28 | 2.1 | 1.1 | 0.139 | |

| 68 | 19 | 19 | 14.5 | 1 | 1 | 52.6 | 72.3 | 5300 | 7000 | 32008 | 3DB | 46 | 46 | 60 | 65 | 4 | 4.5 | 1 | 1 | 0.38 | 1.5 | 0.8 | 0.275 | ||

| 80 | 19.75 | 18 | 16 | 1.5 | 1.5 | 63 | 74.1 | 4800 | 6300 | 30208 | 7208E | 3DB | 48 | 48 | 72 | 75 | 3 | 6 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.423 | |

| 80 | 21.5 | 18 | 17.75 | 1.5 | 1.5 | 66 | 80 | 5300 | 6600 | 30608 | 7808E | 48 | 48 | 72 | 75 | 4 | 7 | 15 | 1.5 | 0.37 | 1.6 | 0.9 | 0.446 | ||

| 80 | 24.75 | 23 | 19 | 1.5 | 1.5 | 77.9 | 97.5 | 4800 | 6300 | 32208 | 7508E | 3DC | 48 | 48 | 72 | 75 | 3 | 8 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.529 | |

| 80 | 24.75 | 23 | 10 | 1.5 | 1.5 | 77.9 | 97.5 | 4800 | 6300 | 32208R | 47 | 48 | 68 | 75 | 3 | 6 | 2 | 1.5 | 0.37 | 1.6 | 0.9 | 0.549 | |||

| 90 | 25.25 | 23 | 20 | 2 | 1.5 | 90.8 | 108.7 | 4500 | 6000 | 30308 | 7308E | 2FB | 49 | 49 | 80 | 85 | 3 | 7 | 2 | 1.5 | 0.35 | 1.7 | 0.9 | 0.748 | |

| 90 | 25.25 | 23 | 17 | 2 | 1.5 | 81.5 | 96.5 | 4000 | 5300 | 31308 | 27308E | 7EB | 49 | 49 | 80 | 85 | 6 | 10 | 2 | 1.5 | 0.83 | 0.7 | 0.4 | 0.729 | |

| 90 | 35.25 | 33 | 27 | 2 | 1.5 | 115.3 | 149 | 4000 | 5300 | 32308 | 7608E | 2FD | 49 | 49 | 80 | 85 | 5 | 10 | 2 | 1.5 | 0.35 | 1.7 | 0.9 | 1 | |

| 90 | 35.25 | 33 | 26 | 2 | 1.5 | 100 | 118 | 4000 | 5300 | 32308CN | 49 | 49 | 73 | 83 | 4 | 8.5 | 2 | 2 | 0.35 | 1.7 | 0.9 | 1.02 | |||

| 45 | 85 | 20.75 | 19 | 16 | 1.5 | 1.5 | 67.6 | 84.4 | 4500 | 6000 | 30209 | 7209E | 3DB | 53 | 53 | 76 | 79 | 3 | 7 | 1.5 | 1.5 | 0.4 | 1.5 | 0.8 | 0.474 |

| 85 | 24.75 | 23 | 19 | 1.5 | 1.5 | 80.3 | 105.1 | 4500 | 6000 | 32209 | 7509E | 3DC | 53 | 53 | 76 | 79 | 3 | 8 | 1.5 | 1.5 | 0.4 | 1.5 | 0.8 | 0.585 | |

| d 45~55mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 45 | 85 | 24.75 | 23 | 19 | 1.5 | 1.5 | 72 | 60 | 4500 | 6000 | 32209R | 53 | 53 | 76 | 79 | 3 | 8 | 1.5 | 1.5 | 0.4 | |||||

| 85 | 25 | 23.5 | 20 | 1.5 | 1.5 | 77 | 93 | 4500 | 6000 | 32209/YB2 | 127509 | 53 | 53 | 76 | 79 | 3 | 8 | 15 | 1.5 | 0.4 | 1.5 | 0.8 | 0.584 | ||

| 85 | 32 | 32 | 25 | 1.5 | 1.5 | 113 | 147 | 4000 | 5300 | 33209 | 52 | 52 | 72 | 78 | 5 | 7 | 1 | 1 | 0.4 | 1.5 | 0.8 | 0.82 | |||

| 100 | 27.25 | 25 | 22 | 2 | 1.5 | 108.7 | 131.2 | 4000 | 5300 | 30309 | 7309E | 2FB | 54 | 54 | 90 | 94 | 4 | 7 | 2 | 1.5 | 0.35 | 1.7 | 0.9 | 988 | |

| 100 | 32 | 29 | 20 | 1.5 | 1.5 | 63 | 83 | 4000 | 5300 | 30309X2B | 27709 | 51 | 51 | 82 | 96 | 6 | 13 | 1.5 | 1.5 | 0.7 | 0.8 | 0.46 | 1.04 | ||

| 47 | 100 | 43 | 43 | 37 | 1.5 | 1 | 108 | 169 | 4000 | 5300 | 30647 | 7909 | 57 | 57 | 86 | 95 | 6 | 8 | 1.5 | 0.3 | 1.9 | 1.1 | 1.66 | ||

| 50 | 80 | 20 | 20 | 15.5 | 1.5 | 1.5 | 54.5 | 85 | 4500 | 6000 | 32010/YB2 | 3DC | 56 | 56 | 72 | 77 | 4 | 4.5 | 1.5 | 1.5 | 0.42 | 14 | 0.8 | 373 | |

| 80 | 20 | 20 | 15.5 | 1 | 1 | 59.1 | 85 | 4500 | 6000 | 32010 | 3DC | 56 | 56 | 72 | 77 | 4 | 4.5 | 1 | 1 | 0.42 | 1.4 | 0.8 | 0.373 | ||

| 90 | 21.75 | 20 | 17 | 1.5 | 1.5 | 76.1 | 97.4 | 4300 | 5600 | 30210 | 7210E | 3DB | 58 | 58 | 82 | 85 | 4 | 7 | 1.5 | 1.5 | 0.43 | 1.4 | 0.8 | 0.539 | |

| 90 | 24.75 | 23 | 19 | 1.5 | 1.5 | 89.4 | 120 | 4300 | 5600 | 32210 | 7510E | 3DC | 58 | 58 | 82 | 85 | 3 | 8 | 1.5 | 1.5 | 43 | 1.4 | 0.8 | 0.645 | |

| 90 | 24.75 | 23 | 19 | 1.5 | 1.5 | 77 | 65 | 4300 | 5600 | 32210R | 57 | 57 | 78 | 86 | 3 | 6 | 1.5 | 1.5 | 0.43 | 1.4 | 0.8 | 0.668 | |||

| 110 | 29.25 | 27 | 23 | 2.5 | 2 | 129.9 | 158.9 | 3600 | 4800 | 30310 | 7310E | 2FB | 60 | 60 | 98 | 103 | 4 | 8 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.3 | |

| 110 | 29.25 | 27 | 19 | 2.5 | 2 | 102 | 128 | 3200 | 4300 | 31310 | 27310E | 58 | 60 | 87 | 105 | 10.5 | 25 | 2 | 0.82 | 0.7 | 4 | 122 | |||

| 110 | 31.75 | 29.5 | 23 | 2.5 | 136 | 157 | 3200 | 4300 | 30310X2 | 60 | 60 | 98 | 103 | 4 | 8 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.35 | ||||

| 110 | 42.25 | 40 | 33 | 2.5 | 2 | 177.3 | 238.7 | 3200 | 4300 | 32310 | 7610E | 2FD | 60 | 60 | 98 | 103 | 6 | 12 | 2.1 | 2 | 0.35 | 1.7 | 9 | 1.9 | |

| 110 | 42.25 | 40.5 | 33 | 2.5 | 190 | 244 | 3200 | 4300 | AK32310 | 60 | 60 | 98 | 103 | 6 | 12 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.91 | ||||

| 50.8 | 100 | 35 | 35 | 27 | 2.5 | 2.5 | 140 | 192 | 3400 | 4500 | 33910/YB2 | 63 | 63 | 90 | 88 | 3 | 5 | 2 | 2 | 0.4 | 1.5 | 0.8 | 1.17 | ||

| 55 | 90 | 23 | 23 | 17.5 | 1.5 | 1.5 | 75.4 | 122 | 4000 | 5300 | 32011 | 2007111E | 3CE | 63 | 62 | 81 | 86 | 4 | 5.5 | 1.5 | 1.5 | 0.4 | 1.5 | 0.8 | 0.561 |

| 95 | 30 | 30 | 23 | 1.5 | 1.5 | 105 | 148 | 3800 | 5000 | 33111 | 3007711 | 3CE | 63 | 63 | 81 | 92 | 5 | 7 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.862 | |

| 100 | 22.75 | 21 | 18 | 2 | 1.5 | 90.9 | 115.7 | 3800 | 5000 | 30211 | 7211E | 3DB | 64 | 64 | 90 | 94 | 4 | 7 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 0.719 | |

| 100 | 24.75 | 23 | 18 | 2 | 1.5 | 90.1 | 111 | 3800 | 5000 | 30211 X2 | 64 | 64 | 88 | 95 | 4 | 5 | 2 | 1.5 | 0.55 | 1 | 0.6 | 0.76 | |||

| 100 | 26.75 | 25 | 21 | 2 | 1.5 | 107.5 | 143.8 | 3800 | 5000 | 32211 | 7511E | 3DC | 64 | 64 | 90 | 94 | 4 | 8 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 0.86 | |

| 100 | 35 | 35 | 27 | 2 | 1.5 | 3800 | 5000 | 33211 | 0.4 | 1.5 | 0.8 | 1.22 | |||||||||||||

| 120 | 31.5 | 29 | 21 | 2.5 | 129.9 | 158 | 2800 | 3800 | 31311 | 27311E | 7FB | 65 | 65 | 103 | 114 | 8 | 14 | 2.1 | 2 | 0.83 | 0.7 | 0.4 | 1.56 | ||

| 120 | 31.5 | 29 | 21 | 4 | 3 | 113 | 90 | 2800 | 3800 | 31311/YB2 | 70 | 65 | 104 | 112 | 4 | 6.5 | 1.8 | 1.8 | 0.82 | 0.7 | 0.4 | 1.56 | |||

| d 55~65mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 55 | 120 | 31.5 | 29 | 25 | 2.5 | 2 | 153.1 | 189.7 | 3200 | 4300 | 30311 | 7311 | 2FB | 65 | 65 | 106 | 114 | 4 | 9 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 163 |

| 120 | 31.5 | 29 | 21 | 2.5 | 2 | 16 | 191 | 3200 | 4300 | 30311R | 65 | 65 | 106 | 114 | 4 | 9 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.69 | |||

| 120 | 45.5 | 43 | 35 | 2.5 | 2 | 202.8 | 274.3 | 3000 | 4000 | 32311 | 7611E | 2FD | 65 | 65 | 106 | 114 | 8 | 14 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 2.33 | |

| 120 | 45.5 | 43 | 35 | 7 | 2 | 203 | 256 | 3000 | 4000 | 32311/YB2 | 66 | 65 | 99 | 111 | 5 | 10.5 | 1.8 | 1.8 | 0.35 | 1.7 | 0.9 | 2.34 | |||

| 125 | 37 | 36 | 25 | 3 | 2 | 158 | 209 | 3000 | 4000 | 31611 | 3DB | 69 | 69 | 107 | 111 | 4 | 11 | 2.5 | 2.5 | 0.73 | 0.8 | 0.4 | 2.11 | ||

| 130 | 36 | 33 | 22 | 3 | 2.5 | 170 | 184 | 2800 | 3800 | 30611 | 2FB | 69 | 69 | 111 | 116 | 4 | 11 | 2.5 | 2.5 | 0.82 | 0.7 | 0.4 | 2.11 | ||

| 60 | 85 | 17.3 | 16 | 14 | 1 | 1 | 56 | 83 | 4000 | 5300 | 32912X2 | 2007912 | 67 | 67 | 78 | 81 | 5 | 1 | 1 | 0.38 | 1.6 | 0.9 | 0.24 | ||

| 95 | 23 | 23 | 17.5 | 1.5 | 1.5 | 79.8 | 125 | 3800 | 5000 | 32012 | 2007112E | 3CE | 67 | 67 | 85 | 91 | A | 5.5 | 1.5 | 1.5 | 0.43 | 1.4 | 0.7 | 0.592 | |

| 110 | 23.75 | 22 | 19 | 2 | 1.5 | 102.9 | 131.5 | 3400 | 4500 | 30212 | 7212E | 69 | 69 | 100 | 104 | 5 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 0.906 | |||

| 110 | 29.75 | 28 | 24 | 2 | 1.5 | 132.2 | 181.5 | 3400 | 4500 | 32212 | 7512E | 3EB | 69 | 69 | 100 | 104 | 4 | 8 | 2 | 1.5 | 04 | 1.5 | 0.8 | 1.18 | |

| 110 | 34.1 | 30 | 20 | 2 | 2 | 82 | 61 | 5810 | 7270 | 3-706 | 70 | 70 | 100 | 104 | 5 | 14 | 2 | 2 | 0.43 | 1.4 | 0.7 | 1.25 | |||

| 130 | 33.5 | 31 | 26 | 3 | 2.5 | 175 | 203 | 3000 | 4000 | 30312 | 7312E | 2FB | 71 | 71 | 116 | 123 | 4 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2 | |

| 130 | 33.5 | 31 | 26 | 3 | 2.5 | 175 | 203 | 3000 | 4000 | 30312R | 71 | 71 | 116 | 123 | 4 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.06 | |||

| 130 | 33.5 | 31 | 22 | 3 | 2.5 | 145.4 | 176.8 | 2600 | 3600 | 31312 | 27312E | 7FB | 71 | 71 | 112 | 123 | 8 | 14 | 2.5 | 2.1 | 0.83 | 0.72 | 0.4 | 2.02 | |

| 130 | 48.5 | 46 | 37 | 3 | 2.5 | 226.3 | 306.1 | 2600 | 3600 | 32312 | 7612E | 7FD | 71 | 71 | 116 | 123 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 2.91 | |

| 62 | 100 | 21.5 | 21 | 16.5 | 1.5 | 1.5 | 70 | 104 | 3900 | 4900 | 306/62 | 7912 | 68 | 71 | 91 | 96.9 | 4 | 6 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.597 | |

| 65 | 100 | 23 | 23 | 17.5 | 1.5 | 1.5 | 84.5 | 131 | 3400 | 4500 | 32013 | 3DC | 72 | 72 | 90 | 97 | 4 | 5.5 | 1.5 | 1.5 | 046 | 1.3 | 0.7 | 0.631 | |

| 110 | 34 | 34 | 26.5 | 1.5 | 1.5 | 125 | 202 | 3200 | 4300 | 33113 | 75 | 75 | 100 | 104 | 4 | 5 | 1.5 | 1.5 | 0.39 | 1.5 | 0.8 | 1.27 | |||

| 120 | 24.75 | 23 | 20 | 2 | 1.5 | 120 | 154.2 | 3000 | 4000 | 30213 | 7213E | 3EB | 74 | 74 | 108 | 114 | 5 | 7 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 1.13 | |

| 120 | 32.75 | 31 | 27 | 2 | 1.5 | 163 | 212 | 3000 | 4000 | 32213 | 7513E | 3EC | 74 | 74 | 108 | 114 | 4 | 8 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 1.54 | |

| 120 | 41 | 41 | 32 | 2 | 1.5 | 184 | 257 | 2800 | 3800 | 33213 | 3007213 | 3EE | 74 | 76 | 104 | 111 | 6 | 12 | 2 | 1.5 | 0.39 | 1.5 | 0.8 | 2.01 | |

| 120 | 41 | 41 | 32 | 2 | 1.5 | 183 | 280 | 2800 | 3800 | 33213TN1 | 74 | 77 | 106 | 114 | 5 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 1.91 | ||||

| 130 | 45 | 43 | 35 | 7 | 2 | 207 | 306 | 2600 | 3600 | 30613 | 70 | 75 | 100 | 104 | 4 | 8 | 3 | 1.5 | 0.33 | 1.5 | 0.8 | 2.64 | |||

| 140 | 36 | 33 | 28 | 3 | 2.5 | 195.7 | 244.4 | 2600 | 3600 | 30313 | 7313E | 7GB | 76 | 76 | 125 | 132 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.45 | |

| 140 | 36 | 33 | 28 | 6 | 2.5 | 206 | 243 | 2600 | 3600 | 30313/YB2 | 76 | 76 | 125 | 132 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.44 | |||

| 140 | 40 | 39 | 26 | 3 | 2.5 | 204 | 246 | 2600 | 3600 | 30313X2B | 76 | 76 | 125 | 132 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.68 | |||

| d 60~80mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 60 | 140 | 36 | 33 | 23 | 3 | 2.5 | 165.7 | 202.6 | 2200 | 3200 | 31313 | 27313E | 7GB | 76 | 76 | 120 | 132 | 10 | 16 | 2.5 | 2.1 | 0.83 | 0.7 | 0.4 | 2.39 |

| 140 | 40 | 38 | 27 | 3 | 2.5 | 187 | 247 | 2600 | 3600 | 31613? | 3DB | 79 | 79 | 122 | 126 | 6 | 13 | 2.5 | 2.5 | 0.73 | 0.8 | 0.4 | 2.74 | ||

| 140 | 51 | 48 | 39 | 3 | 2.5 | 259.3 | 353.6 | 2400 | 3400 | 32313 | 7613E | 2GD | 76 | 76 | 125 | 132 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 3.35 | |

| 140 | 51 | 48 | 39 | 3 | 2.5 | 230 | 206 | 2400 | 3400 | 32313R | 76 | 76 | 125 | 132 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 3.63 | |||

| 70 | 120 | 33 | 33 | 27 | 2 | 2 | 151 | 217 | 3000 | 4000 | 33114X2 | 7814E | 3DE | 77 | 77 | 110 | 115 | 5 | 10 | 2 | 2 | 0.28 | 2.2 | 1.2 | 1.46 |

| 120 | 33 | 33 | 27 | 2 | 2 | 173 | 246 | 3000 | 4000 | 33114X2/YA | 77 | 77 | 110 | 115 | 5 | 10 | 2 | 2 | 0.28 | 2.2 | 1.2 | 1.55 | |||

| 125 | 26.25 | 24 | 21 | 1.5 | 132 | 174.3 | 3000 | 4000 | 30214 | 7214E | 3EB | 79 | 79 | 114 | 119 | 5 | 7 | 2 | 1.5 | 0.42 | 1.4 | 0.8 | 1.26 | ||

| 125 | 33.25 | 31 | 27 | 2 | 1.5 | 168.1 | 238 | 2800 | 3800 | 32214 | 7514E | 3EC | 79 | 79 | 114 | 119 | 4 | 8 | 2 | 1.5 | 42 | 1.4 | 0.8 | 1.65 | |

| 150 | 38 | 35 | 30 | 3 | 2.5 | 218.8 | 274.7 | 2400 | 3400 | 30314 | 7314E | 2GB | 81 | 81 | 135 | 142 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 9 | 2.99 | |

| 150 | 38 | 35 | 30 | 9 | 2.5 | 230 | 275 | 2400 | 3400 | 30314/YB2 | 81 | 81 | 135 | 142 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.97 | |||

| 70 | 150 | 38 | 35 | 25 | 5 | 2.5 | 197 | 232 | 2000 | 3000 | 31314 | 82 | 89 | 130 | 141 | 5 | 8 | 4 | 2.5 | 0.82 | 0.7 | 0.4 | 2.91 | ||

| 150 | 38 | 35 | 25 | 5 | 2.5 | 197 | 232 | 2000 | 3000 | 31314/YB2 | 82 | 89 | 130 | 141 | 5 | 8 | 4 | 2.5 | 0.82 | 0.7 | 0.4 | 2.91 | |||

| 150 | 54 | 51 | 42 | 3 | 2.5 | 298.8 | 413.4 | 2200 | 3200 | 32314 | 7614E | 2GD | 81 | 81 | 135 | 142 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 4.43 | |

| 75 | 130 | 27.25 | 25 | 22 | 2 | 1.5 | 137.7 | 186.9 | 2800 | 3800 | 30215 | 7215E | 4DB | 84 | 84 | 119 | 124 | 5 | 7 | 2 | 1.5 | 0.44 | 1.4 | 0.8 | 1.38 |

| 130 | 33.25 | 31 | 27 | 2 | 1.5 | 169.5 | 244.1 | 2600 | 3600 | 32215 | 7515 | 4DC | 84 | 84 | 119 | 124 | 4 | 8 | 2 | 1.5 | 44 | 1.4 | 0.8 | 1.74 | |

| 135 | 44 | 45 | 35 | 2 | 2 | 175 | 274 | 3000 | 3800 | 30615/YB2 | 82 | 85 | 119 | 131 | 5 | 11 | 2 | 2 | 0.28 | 2.2 | 1.2 | 2.57 | |||

| 135 | 44.5 | 45 | 36.5 | 2 | 228 | 339 | 3000 | 3800 | 30615 | 82 | 85 | 119 | 131 | 5 | 11 | 2 | 2 | 0.28 | 2.2 | 1.2 | 2.69 | ||||

| 135 | 44.5 | 45 | 36.5 | 2 | 2 | 240 | 370 | 3000 | 3800 | 30615/YA | 86 | 86 | 120 | 125 | 5 | 11 | 2 | 2 | 0.24 | 2.5 | 1.4 | 2.76 | |||

| 160 | 40 | 37 | 26 | 3 | 2.5 | 219 | 259 | 1900 | 2800 | 31315 | 87 | 91 | 127 | 148 | 6 | 14 | 2 | 2 | 0.83 | 0.72 | 0.4 | 3.5 | |||

| 160 | 40 | 37 | 31 | 3 | 2.5 | 250.3 | 318.6 | 2200 | 3200 | 30315 | 7315E | 2GB | 86 | 86 | 143 | 152 | 5 | 11 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 3.58 | |

| 160 | 58 | 55 | 45 | 3 | 2.5 | 358 | 472 | 2000 | 3000 | 32315 | 7615E | 2GD | 86 | 86 | 143 | 152 | 10 | 16 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 5.32 | |

| 170 | 61.5 | 58 | 48 | 3 | 2.5 | 406 | 543 | 1900 | 2800 | T6GD075 | 90 | 90 | 152 | 162 | 10 | 16 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 6.64 | |||

| 80 | 110 | 20 | 20 | 16 | 1 | 1 | 72.8 | 123 | 32916 | 0.538 | |||||||||||||||

| 125 | 29 | 29 | 22 | 1.5 | 1.5 | 136 | 209 | 2600 | 3600 | 32016 | 3EB | 87 | 89 | 112 | 120 | 6 | 7 | 1 | 1 | 0.42 | 1.6 | 0.8 | 1.27 | ||

| 130 | 32 | 31 | 25 | 1 | 3.5 | 140 | 233 | 2500 | 3500 | 30616/YB2 | 86 | 86 | 119 | 124 | 5 | 7 | 1 | 0.38 | 1.6 | 0.8 | 1.56 | ||||

| 140 | 28.25 | 26 | 22 | 2.5 | 2 | 160.1 | 213.6 | 2400 | 3400 | 30216 | 7216E | 3EB | 90 | 90 | 127 | 134 | 5 | 8 | 1 | 2 | 0.42 | 1.4 | 0.8 | 1.84 | |

| d 80~95mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 80 | 140 | 35.25 | 33 | 28 | 2.5 | 2 | 198 | 280.1 | 2400 | 3400 | 32216 | 7516E | 3EC | 90 | 90 | 127 | 134 | 5 | 8 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 2.03 |

| 140 | 35.5 | 33 | 28 | 2 | 2 | 160 | 241 | 2400 | 3400 | 32216/YB2 | 7516 | 90 | 90 | 127 | 134 | 5 | 8 | 2 | 2 | 0.4 | 1.5 | 0.8 | 2.15 | ||

| 140 | 45 | 45 | 36.5 | 2.5 | 2 | 233 | 214 | 2200 | 3200 | 30616 | 87 | 90 | 127 | 136 | 5 | 11 | 2.1 | 2 | 0.28 | 2.2 | 1.2 | 2.81 | |||

| 170 | 42.5 | 39 | 33 | 3 | 2.5 | 286 | 343 | 2000 | 3000 | 30316 | 7316E | 2GB | 92 | 92 | 152 | 162 | 7 | 12 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 4.5 | |

| 170 | 61.5 | 58 | 48 | 3 | 2.5 | 400 | 532 | 1900 | 2800 | 32316 | 7616E | 2GD | 92 | 92 | 152 | 162 | 10 | 16 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 6.39 | |

| 85 | 140 | 77.07 | 38.5 | 69.14 | 2 | 0.6 | B3-748L | 95 | 95 | 130 | 2 | 2 | 0.33 | 1.8 | 1 | 3.32 | |||||||||

| 150 | 30.5 | 28 | 24 | 2.5 | 2 | 180 | 242.5 | 2200 | 3200 | 30217 | 7217E | 3EB | 95 | 95 | 136 | 144 | 5 | 9 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 2.06 | |

| 150 | 38.5 | 36 | 30 | 2.5 | 2 | 220 | 323 | 2200 | 3200 | 32217 | 7517E | 3EC | 95 | 95 | 136 | 144 | 5 | 11 | 2.1 | 2 | 042 | 1.4 | 0.8 | 2.67 | |

| 150 | 49 | 49 | 37 | 2.5 | 2 | 272 | 409 | 2000 | 3000 | 33217 | 3007217 | 3EE | 95 | 95 | 136 | 145 | 7 | 12 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 3.57 | |

| 180 | 44.5 | 41 | 34 | 4 | 3 | 304.5 | 392.4 | 1900 | 2800 | 30317 | 7317E | 3GB | 97 | 97 | 161 | 171 | 8 | 14 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 5.305 | |

| 180 | 44.5 | 41 | 28 | 4 | 3 | 266 | 320 | 1800 | 2600 | 31317 | 99 | 103 | 143 | 169 | 6 | 6.5 | 2.5 | 2.5 | 0.83 | 0.72 | 0.4 | 4.6 | |||

| 180 | 63.5 | 60 | 49 | 4 | 3 | 434 | 580 | 1800 | 2600 | 32317 | 7617E | 2GD | 98 | 98 | 161 | 171 | 12 | 18 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 6.81 | |

| 90 | 140 | 32 | 32 | 24 | 2 | 1.5 | 159 | 245 | 2200 | 3200 | 32018 | 3EB | 99 | 100 | 125 | 134 | 6 | 8 | 2 | 1.5 | 0.42 | 1.4 | 0.8 | 1.7 | |

| 140 | 32.4 | 30 | 26 | 2 | 1.5 | 160 | 257 | 2200 | 3200 | 32018X2/YA | 2007118 | 99 | 99 | 128 | 134 | 5 | 8 | 2 | 1.5 | 0.34 | 1.8 | 1 | 1.66 | ||

| 140 | 32.4 | 30 | 26 | 2 | 1.5 | 130 | 210 | 2200 | 3200 | 32018 RX2 | 99 | 100 | 125 | 134 | 6 | 8 | 2 | 2 | 0.34 | 1.7 | 0.9 | 1.7 | |||

| 150 | 45 | 45 | 35 | 2.5 | 2 | 231 | 396 | 2000 | 3000 | 33118TN1 | 102 | 102 | 134 | 138 | 5 | 10 | 2 | 2 | 0.4 | 1.5 | 0.8 | 2.97 | |||

| 160 | 32.5 | 30 | 26 | 2.5 | 2 | 199.7 | 270.5 | 2000 | 3000 | 30218 | 7218E | 3FB | 100 | 100 | 145 | 153 | 5 | 9 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 2.558 | |

| 160 | 42.5 | 40 | 34 | 2.5 | 2 | 269.1 | 396.9 | 2000 | 3000 | 32218 | 7518E | 3FC | 100 | 100 | 145 | 153 | 5 | 11 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 3.33 | |

| 190 | 46.5 | 43 | 36 | 4 | 3 | 341.7 | 445.7 | 1800 | 2600 | 30318 | 7318E | 2GB | 103 | 103 | 170 | 181 | 8 | 14 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 6.144 | |

| 190 | 67.5 | 64 | 53 | 4 | 3 | 4,777 | 690.8 | 1700 | 2400 | 32318 | 7618E | 2GD | 103 | 103 | 170 | 181 | 12 | 18 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 8.76 | |

| 95 | 145 | 32 | 32 | 24 | 2 | 1.5 | 162 | 255 | 2200 | 3200 | 32019 | 3EB | 104 | 105 | 130 | 140 | 6 | 8 | 2 | 1.5 | 0.45 | 1.3 | 0.7 | 177 | |

| 145 | 32.4 | 30 | 26 | 2 | 1.5 | 226.1 | 310.2 | 2200 | 3200 | 32019X2/YA | 2007119 | 104 | 104 | 133 | 139 | 5 | 8 | 2 | 1.5 | 0.36 | 1.7 | 0.9 | 1.7 | ||

| 160 | 47 | 47 | 38 | 3 | 2.5 | 251 | 420 | 3970 | 4970 | 30619 | 3FB | 109 | 109 | 145 | 146 | 5 | 9 | 2.5 | 2.5 | 0.29 | 2 | 1.1 | 3.7 | ||

| 170 | 34.5 | 32 | 27 | 3 | 2.5 | 226.1 | 310.2 | 1900 | 2800 | 30219 | 7219E | 3FB | 106 | 106 | 157 | 163 | 5 | 10 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 3.269 | |

| 170 | 45.5 | 43 | 37 | 3 | 2.5 | 313 | 443 | 1900 | 2800 | 32219 | 7519E | 3FC | 106 | 106 | 157 | 163 | 5 | 11 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 4.216 | |

| 170 | 58 | 58 | 44 | 3 | 2.5 | 1900 | 2800 | 33219 | 106 | 106 | 157 | 163 | 5 | 11 | 2.5 | 2.1 | |||||||||

| d 95~120mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 95 | 200 | 49.5 | 45 | 38 | 4 | 3 | 368.6 | 483 | 1800 | 2600 | 30319 | 7319E | 2GB | 109 | 109 | 180 | 191 | 8 | 14 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 7.13 |

| 200 | 71.5 | 67 | 55 | 4 | 3 | 515.5 | 745.8 | 1700 | 2400 | 32319 | 7619E | 2GD | 109 | 109 | 180 | 191 | 14 | 20 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 10.73 | |

| 100 | 130 | 57 | 56 | 35 | 11 | 2 | 238 | 327 | LY-3026 | 2.99 | |||||||||||||||

| 150 | 32 | 32 | 24 | 2 | 1.5 | 165 | 265 | 2000 | 3000 | 32020 | 3EB | 109 | 109 | 134 | 144 | 6 | 8 | 2 | 2 | 0.46 | 1.3 | 0.7 | 1.84 | ||

| 150 | 32.4 | 30 | 26 | 2 | 1.5 | 163 | 266 | 2000 | 3000 | 32020YB2 | 2007120 | 109 | 109 | 138 | 144 | 5 | 8 | 2 | 1.5 | 0.37 | 1.6 | 0.9 | 1.79 | ||

| 150 | 32.4 | 30 | 26 | 2 | 1.5 | 150 | 261 | 2000 | 3000 | 32020 RX2 | 109 | 109 | 134 | 144 | 6 | 8 | 2 | 1.5 | 0.37 | 1.6 | 0.9 | 1.8 | |||

| 165 | 47 | 46 | 39 | 3 | 305 | 486 | 1900 | 2800 | 33120X2 | 111 | 111 | 145 | 160 | 5 | 10 | 2.5 | 2.5 | 0.32 | 1.9 | 1 | 3.93 | ||||

| 180 | 37 | 34 | 29 | 3 | 2.5 | 253.3 | 35L6 | 1900 | 2800 | 30220 | 7220E | 3FB | 111 | 111 | 162 | 172 | 5 | 10 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 3.73 | |

| 180 | 49 | 46 | 39 | 3 | 2.5 | 340.2 | 513.7 | 1800 | 2600 | 32220 | 7520E | 3FC | 111 | 11 | 162 | 172 | 5 | 14 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 5.12 | |

| 180 | 63 | 63 | 48 | 3 | 3 | 1700 | 2400 | 33220/YB2 | 111 | 111 | 162 | 2.5 | 2.5 | ||||||||||||

| 215 | 51.5 | 47 | 39 | 4 | 3 | 406 | 532.3 | 1700 | 2400 | 30320 | 7320E | 2GB | 116 | 116 | 194 | 205 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 8.69 | |

| 215 | 77.5 | 73 | 60 | 4 | 3 | 599.5 | 881.9 | 1600 | 2200 | 32320 | 7620E | 2GD | 116 | 116 | 194 | 205 | 14 | 20 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 12.96 | |

| 105 | 160 | 35 | 35 | 26 | 2.5 | 2 | 194 | 311 | 1900 | 2800 | 32021 | 3EB | 115 | 116 | 143 | 154 | 6 | 9 | 2 | 2 | 0.44 | 1.3 | 0.7 | 2.38 | |

| 160 | 43 | 43 | 34 | 2.5 | 2 | 240 | 398 | 1900 | 2800 | 33021 | 3EB | 115 | 116 | 143 | 154 | 6 | 9 | 2 | 2 | 0.46 | 1.3 | 0.7 | 2.94 | ||

| 190 | 39 | 36 | 30 | 3 | 2.5 | 284.6 | 400 | 1800 | 2600 | 30221 | 7221E | 2FB | 116 | 116 | 172 | 182 | 6 | 11 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 4.936 | |

| 190 | 53 | 50 | 43 | 3 | 2.5 | 380.1 | 581.2 | 1800 | 2600 | 32221 | 7521E | 3FC | 116 | 116 | 172 | 182 | 6 | 12 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 6.495 | |

| 225 | 53.5 | 49 | 41 | 4 | 3 | 432.6 | 568.1 | 1600 | 2200 | 30321 | 7321E | 2GB | 120 | 120 | 202 | 215 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 9.912 | |

| 225 | 81.5 | 77 | 63 | 4 | 3 | 646.4 | 955.6 | 1500 | 2000 | 32321 | 7621E | 2GD | 123 | 123 | 202 | 215 | 14 | 20 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 14.458 | |

| 110 | 170 | 38 | 38 | 29 | 2.5 | 2 | 202 | 354 | 1800 | 2800 | 32022 | 3DC | 120 | 122 | 152 | 163 | 7 | 9 | 2 | 0.43 | 1.4 | 0.7 | 3.01 | ||

| 170 | 47 | 47 | 37 | 2.5 | 266 | 464 | 1800 | 2800 | 33022 | 3EB | 120 | 122 | 152 | 163 | 7 | 9 | 2 | 2 | 0.29 | 2.1 | 1.1 | 3.76 | |||

| 200 | 41 | 38 | 32 | 3 | 2.5 | 314.1 | 445.1 | 1700 | 2400 | 30222 | 7222E | 3FB | 121 | 121 | 181 | 192 | 6 | 11 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 5.422 | |

| 200 | 56 | 53 | 46 | 3 | 2.5 | 430.7 | 668.6 | 1700 | 2400 | 32222 | 7522E | 3FC | 121 | 121 | 181 | 192 | 6 | 12 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 7.86 | |

| 240 | 54.5 | 50 | 42 | 4 | 3 | 471.6 | 619.1 | 1600 | 2200 | 30322 | 7322E | 2GB | 124 | 124 | 215 | 230 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 11.45 | |

| 240 | 84.5 | 80 | 65 | 4 | 3 | 722.8 | 1076 | 1400 | 1900 | 32322 | 7622E | 2GD | 127 | 127 | 215 | 230 | 18 | 25 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 18.78 | |

| 120 | 180 | 38 | 38 | 29 | 2.5 | 2 | 230 | 394 | 1700 | 2400 | 32024/YA | 2007124K | 130 | 131 | 161 | 173 | 7 | 9 | 2 | 2 | 0.37 | 1.6 | 0.9 | 3.07 | |

| d 105~150mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 105 | 180 | 38.4 | 36 | 31 | 2.5 | 2 | 230 | 394 | 1700 | 2400 | 32024X2R | 130 | 131 | 161 | 173 | 7 | 9 | 2 | 2 | 0.37 | 1.6 | 0.9 | 3.14 | ||

| 180 | 38.4 | 36 | 31 | 2.5 | 2 | 230 | 394 | 1700 | 2400 | 32024X2/YA | 2007124 | 130 | 130 | 166 | 174 | 6 | 9 | 2.1 | 2 | 0.37 | 1.6 | 0.9 | 3 | ||

| 215 | 43.5 | 40 | 34 | 3 | 2.5 | 335.8 | 487.2 | 1600 | 2200 | 30224 | 7224E | 4FB | 131 | 131 | 196 | 207 | 7 | 12 | 2.5 | 2.1 | 0.44 | 1.4 | 0.8 | 6.125 | |

| 215 | 61.5 | 58 | 50 | 3 | 2.5 | 492 | 741 | 1600 | 2200 | 32224 | 7524E | 4FD | 131 | 131 | 196 | 207 | 8 | 12 | 2.5 | 2.1 | 0.44 | 1.4 | 0.8 | 9.25 | |

| 260 | 59.5 | 55 | 46 | 4 | 3 | 562 | 754.3 | 1500 | 2000 | 30324 | 7324E | 2GB | 137 | 137 | 235 | 250 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 13.7 | |

| 260 | 90.5 | 86 | 69 | 4 | 3 | 824.8 | 1239 | 1300 | 1800 | 32324 | 7624E | 2GD | 138 | 138 | 235 | 250 | 18 | 25 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 21.7 | |

| 120 | 180 | 48 | 48 | 38 | 2.5 | 2 | 283 | 514 | 1700 | 2400 | 33024 | 130 | 131 | 161 | 173 | 7 | 12 | 2 | 2 | 0.31 | 1.9 | 1 | 4.09 | ||

| 130 | 200 | 45 | 45 | 34 | 2.5 | 2 | 309 | 513 | 1600 | 2200 | 32026 | 3EB | 140 | 144 | 178 | 192 | 8 | 11 | 2 | 2 | 0.43 | 1.3 | 0.7 | 4.9 | |

| 230 | 43.75 | 40 | 34 | 4 | 3 | 364.3 | 525.6 | 1500 | 2000 | 30226 | 7226E | 4FB | 142 | 142 | 208 | 222 | 7 | 12 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 7.24 | |

| 230 | 44.5 | 40 | 34 | 4 | 3 | 351 | 466 | 1500 | 2000 | 30226X2 | 7226 | 4FB | 142 | 142 | 208 | 222 | 7 | 12 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 7.25 | |

| 230 | 67.75 | 64 | 54 | 4 | 3 | 561 | 855 | 1500 | 2000 | 32226 | 7526E | 4FD | 142 | 142 | 208 | 222 | 10 | 16 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 11.37 | |

| 280 | 63.75 | 58 | 49 | 5 | 4 | 639.3 | 864.5 | 1300 | 1800 | 30326 | 7326E | 2GB | 148 | 148 | 250 | 267 | 14 | 18 | 4 | 3 | 0.35 | 1.7 | 0.9 | 17.1 | |

| 140 | 190 | 32 | 32 | 25 | 2 | 1.5 | 207 | 390 | 1600 | 2200 | 32928/YB | 146 | 146 | 177 | 187 | 4 | 8 | 2 | 1.5 | 0.36 | 1.7 | 0.9 | 2.49 | ||

| 210 | 45 | 45 | 34 | 2.5 | 2 | 314 | 533 | 1600 | 2200 | 32028 | 3EB | 150 | 153 | 187 | 202 | 8 | 11 | 2 | 2 | 0.46 | 1.3 | 0.7 | 5.14 | ||

| 210 | 45.5 | 42 | 36 | 2.5 | 2 | 285 | 460 | 1600 | 2200 | 32028X2 | 2007128 | 150 | 153 | 187 | 202 | 8 | 11 | 2 | 2 | 0.37 | 1.6 | 0.9 | 5.1 | ||

| 210 | 45.5 | 42 | 36 | 2.5 | 2 | 259 | 460 | 1600 | 2200 | 32028X2LYA | 2007128L | 150 | 153 | 187 | 202 | 8 | 11 | 2 | 2 | 0.37 | 1.6 | 0.9 | 5.72 | ||

| 250 | 45.75 | 42 | 36 | 4 | 3 | 407.3 | 589.4 | 1400 | 1900 | 30228 | 7228E | 4FB | 153 | 153 | 226 | 241 | 7 | 12 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 8.892 | |

| 250 | 71.75 | 68 | 58 | 4 | 3 | 657 | 1020 | 1400 | 1900 | 32228 | 7528E | 4FD | 153 | 153 | 226 | 241 | 10 | 16 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 14.68 | |

| 300 | 67.75 | 62 | 53 | 5 | 4 | 721.8 | 985.5 | 1200 | 1700 | 30328 | 7328E | 2GB | 159 | 159 | 270 | 288 | 14 | 18 | 4 | 3 | 0.35 | 1.7 | 0.9 | 21.7 | |

| 150 | 225 | 48 | 48 | 36 | 3 | 2.5 | 361 | 621 | 1500 | 2000 | 32030 | 3EB | 164 | 162 | 200 | 216 | 8 | 12 | 2.5 | 2.5 | 0.46 | 1.3 | 0.7 | 6.38 | |

| 225 | 48 | 48 | 36 | 8 | 2.5 | 365 | 630 | 1500 | 2000 | 32030/YB | 164 | 174 | 200 | 216 | 8 | 12 | 7 | 2.5 | 0.46 | 1.3 | 0.7 | 6.29 | |||

| 270 | 49 | 45 | 38 | 4 | 3 | 495 | 687 | 1300 | 1800 | 30230 | 7230E | 4GB | 164 | 164 | 248 | 260 | 8 | 14 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 10.3 | |

| 270 | 77 | 73 | 60 | 4 | 3 | 718 | 1191 | 1200 | 1700 | 32230 | 7530E | 4GD | 164 | 164 | 248 | 260 | 14 | 20 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 18.2 | |

| 320 | 115 | 108 | 90 | 5 | 4 | 1010 | 1580 | 950 | 1400 | 32330 | 7630 | 172 | 172 | 287 | 305 | 20 | 30 | 4 | 3 | 0.31 | 1.9 | 1.1 | 37.1 | ||

| d 160~220mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 160 | 240 | 51 | 51 | 38 | 3 | 2.5 | 346 | 346 | 1300 | 1800 | 32032/YA4 | 2007132K | 4GD | 172 | 175 | 213 | 231 | 8 | 13 | 2.5 | 2.5 | 0.37 | 1.6 | 0.9 | 7.16 |

| 240 | 51.5 | 48 | 41 | 3 | 2.5 | 380 | 634 | 1300 | 1800 | 32032X2 | 172 | 175 | 213 | 231 | 8 | 13 | 2 | 2 | 0.46 | 1.3 | 0.7 | 7.41 | |||

| 290 | 52 | 48 | 40 | 4 | 3 | 556 | 774 | 1100 | 1600 | 30232 | 7232E | 4GB | 175 | 175 | 265 | 279 | 8 | 14 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 12.9 | |

| 290 | 84 | 80 | 67 | 4 | 3 | 852.6 | 1446 | 1000 | 1400 | 32232 | 7532E | 4GD | 175 | 175 | 265 | 279 | 14 | 20 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 21.1 | |

| 170 | 260 | 57 | 57 | 43 | 3 | 2.5 | 473 | 815 | 1200 | 1700 | 32034 | 3EB | 182 | 187 | 230 | 249 | 10 | 14 | 2.5 | 2.5 | 0.44 | 1.4 | 0.8 | 10.2 | |

| 360 | 127 | 120 | 100 | 5 | 4 | 1280 | 2080 | 850 | 1100 | 32334 | 7634 | 192 | 192 | 326 | 344 | 20 | 30 | 4 | 3 | 0.36 | 1.7 | 0.9 | 58.3 | ||

| 180 | 280 | 64 | 64 | 48 | 3 | 2.5 | 611 | 1070 | 1100 | 1600 | 32036 | 2007136 | 192 | 199 | 247 | 268 | 10 | 16 | 2.5 | 2.5 | 0.28 | 2.1 | 1.2 | 14 | |

| 280 | 64.5 | 60 | 52 | 3 | 2.5 | 550 | 928 | 1100 | 1600 | 32036X2 | 4GD | 192 | 199 | 247 | 267 | 10 | 16 | 2.5 | 2.5 | 0.28 | 2.1 | 1.2 | 13.5 | ||

| 320 | 91 | 86 | 71 | 5 | 4 | 998.1 | 1727 | 950 | 1400 | 32236 | 7536E | 4GD | 196 | 196 | 292 | 308 | 18 | 25 | 4 | 3 | 0.45 | 1.3 | 0.7 | 29.8 | |

| 190 | 260 | 45 | 45 | 34 | 2.5 | 2 | 335 | 699 | 1100 | 1600 | 32938 | 202 | 202 | 231 | 248 | 8 | 11 | 2 | 2 | 0.48 | 1.25 | 0.7 | 6.76 | ||

| 290 | 64 | 64 | 48 | 3 | 2.5 | 605 | 1070 | 1000 | 1500 | 32038 | 202 | 202 | 268 | 282 | 8 | 0.29 | 1.1 | 14.1 | |||||||

| 290 | 64.5 | 60 | 52 | 3 | 2.5 | 511 | 970 | 1000 | 1500 | 32038X2/YA | 2007138 | 14 | 2.5 | 2.1 | 2.1 | ||||||||||

| 290 | 64.5 | 60 | 52 | 3 | 2.5 | 511 | 970 | 1000 | 1500 | 32038X2/HNYA | 2007138N | 202 | 209 | 257 | 279 | 10 | 16 | 2.5 | 2.5 | 0.29 | 2.1 | 1.1 | 14.1 | ||

| 290 | 64.5 | 60 | 52 | 3 | 2.5 | 511 | 970 | 1000 | 1500 | 32038X2NYA | 2007138N | 202 | 209 | 257 | 279 | 10 | 16 | 2.5 | 2.5 | 0.29 | 2.1 | 1.1 | 14.1 | ||

| 340 | 97 | 92 | 75 | 5 | 4 | 1117 | 1920 | 900 | 1300 | 32238 | 7538E | 4GD | 208 | 208 | 309 | 328 | 18 | 25 | 4 | 3 | 0.44 | 1.4 | 0.8 | 36.1 | |

| 200 | 300 | 55 | 51 | 45 | 5 | 4 | 519 | 909 | LY-3023 | 13.8 | |||||||||||||||

| 310 | 70 | 70 | 53 | 3 | 2.5 | 703 | 1240 | 950 | 1400 | 32040 | 222 | 212 | 273 | 297 | 11 | 17 | 2.5 | 2 | 0.43 | 1.4 | 0.8 | 18.6 | |||

| 310 | 70.5 | 70 | 53.5 | 3 | 2.5 | 950 | 1400 | 950 | 1400 | 32040X2 | 222 | 212 | 273 | 297 | 11 | 17 | 2.5 | 2 | 0.43 | 1.4 | 0.8 | 18.7 | |||

| 360 | 104 | 98 | 82 | 5 | 4 | 1309 | 2204 | 900 | 1300 | 32240 | 7540E | 3GD | 231 | 218 | 302 | 340 | 11 | 22 | 4 | 3 | 0.41 | 1.5 | 0.8 | 43.2 | |

| 205 | 485 | 117.5 | 95.2 | 73 | 4 | 4 | 1418 | 1750 | 770 | 960 | 30641 | 7841 | 247 | 279 | 410 | 454 | 20 | 30 | 3 | 3 | 0.87 | 0.7 | 0.4 | 90.8 | |

| 220 | 340 | 76.5 | 72 | 62 | 4 | 3 | 726 | 1380 | 900 | 1300 | 32044X2 | 2007144 | 234 | 234 | 314 | 331 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 22.2 | |

| 400 | 73 | 65 | 54 | 4 | 770 | 1160 | 850 | 1200 | 31244X2 | 35.4 | |||||||||||||||

| 400 | 73 | 65 | 54 | 4 | 3 | 941 | 1330 | 850 | 1200 | 30244X2 | 7244 | 244 | 244 | 367 | 385 | 14 | 20 | 3 | 2.5 | 0.37 | 1.6 | 0.9 | 35.4 | ||

| d 220~300mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 220 | 400 | 115 | 108 | 90 | 4 | 3 | 1530 | 2565 | 800 | 1100 | 32244 | 7544 | 244 | 244 | 367 | 385 | 20 | 30 | 3 | 2.5 | 0.39 | 1.5 | 0.8 | 48.1 | |

| 400 | 115 | 108 | 90 | 4 | 3 | 1230 | 2280 | 800 | 1100 | 32244X2 | 238 | 238 | 381 | 382 | 12 | 24 | 3 | 3 | 0.39 | 1.5 | 0.8 | 48.1 | |||

| 460 | 154 | 145 | 122 | 5 | 5 | 2130 | 3390 | 750 | 1000 | 32344 | 260 | 260 | 408 | 430 | 20 | 35 | 4 | 4 | 0.37 | 1.6 | 0.9 | 40.6 | |||

| 240 | 320 | 51.5 | 48 | 41 | 3 | 2.5 | 407 | 804 | 900 | 1300 | 32948/YB2 | 10.7 | |||||||||||||

| 320 | 52.5 | 52.5 | 39 | 3 | 2.5 | 473 | 975 | 900 | 1300 | 32948X2 | 10.9 | ||||||||||||||

| 360 | 76 | 76 | 57 | 4 | 3 | 709 | 1560 | 850 | 1200 | 32048 | 254 | 261 | 318 | 346 | 12 | 19 | 3 | 3 | 0.36 | 25.8 | |||||

| 440 | 127 | 120 | 100 | 4 | 4 | 1843 | 3183 | 750 | 1000 | 32248 | 7548E | 262 | 262 | 393 | 425 | 20 | 30 | 3 | 3 | 0.44 | 1.4 | 0.8 | 81.3 | ||

| 500 | 165 | 155 | 132 | 5 | 5 | 2660 | 4290 | 670 | 900 | 32348 | 272 | 272 | 440 | 470 | 20 | 35 | 4 | 4 | 0.37 | 1.6 | 0.9 | 148 | |||

| 241 | 360 | 76 | 76 | 57 | 4 | 3 | 709 | 1560 | 850 | 1200 | 32048/YA2 | 254 | 261 | 318 | 346 | 12 | 19 | 3 | 3 | 0.36 | 25.6 | ||||

| 255 | 560 | 123.8 | 104.8 | 70 | 6 | 6 | 1816 | 2380 | 620 | 770 | 30651 | 7851 | 300 | 338 | 480 | 523 | 30 | 40 | 5 | 5 | 0.87 | 0.7 | 0.4 | 129 | |

| 260 | 360 | 64.5 | 60 | 52 | 3 | 2.5 | 654 | 1290 | 800 | 1100 | 32952X2 | 18.6 | |||||||||||||

| 400 | 87 | 87 | 65 | 5 | 4 | 1110 | 2120 | 700 | 950 | 32052 | 277 | 277 | 370 | 384 | 10 | 16 | 4 | 3 | 0.43 | 1.4 | 0.8 | 38.3 | |||

| 400 | 87.7 | 82 | 71 | 5 | 4 | 917 | 1849 | 800 | 1100 | 32052X2 | 2007152 | 277 | 277 | 370 | 386 | 12 | 18 | 4 | 3 | 0.3 | 2 | 1.1 | 36.9 | ||

| 540 | 114 | 102 | 85 | 6 | 6 | 2014 | 2898 | 670 | 900 | 30352X2 | 7352 | 301 | 301 | 490 | 506 | 20 | 30 | 5 | 5 | 0.23 | 2.6 | 1.4 | 111 | ||

| 280 | 350 | 36 | 33 | 26 | 2 | 2 | 259 | 614 | 870 | 1100 | 30656 | 1007856 | 295 | 295 | 336 | 342 | 6 | 9 | 2 | 2 | 0.43 | 1.4 | 0.8 | 6.33 | |

| 380 | 63.5 | 63.5 | 48 | 3 | 2.5 | 601 | 1430 | 800 | 1000 | 32956 | 2007956 4EC | 298 | 298 | 348 | 368 | 11 | 16 | 2.5 | 2.1 | 0.43 | 1.4 | 0.8 | 19.8 | ||

| 380 | 64.5 | 60 | 52 | 3 | 2.5 | 601 | 1430 | 800 | 1000 | 32956/YB2 | 2007956K | 300 | 325 | 348 | 368 | 11 | 16 | 2.5 | 2.1 | 0.29 | 2.1 | 1.1 | 19.8 | ||

| 300 | 420 | 76.5 | 72 | 60.5 | 4 | 3 | 998 | 2128 | 700 | 950 | 32960/YB2 | 2007960 | 317 | 317 | 394 | 408 | 10 | 16 | 3 | 2.5 | 0.28 | 2.1 | 1.2 | 28.7 | |

| 460 | 100 | 100 | 74 | 5 | 4 | 1470 | 2840 | 560 | 700 | 32060 | 320 | 320 | 425 | 445 | 20 | 30 | 4 | 3 | 0.43 | 1.4 | 0.8 | 57.2 | |||

| 460 | 100.7 | 95 | 82 | 5 | 4 | 803 | 1722 | 560 | 700 | 32060/YB2 | 2007160 | 320 | 320 | 425 | 445 | 14 | 20 | 4 | 3 | 0.31 | 1.9 | 1.1 | 55.9 | ||

| 440 | 73 | 70 | 55 | 4 | 3 | 959 | 2062 | 570 | 600 | 30660 | 7860 | 318 | 318 | 406 | 426 | 14 | 20 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 30.7 | ||

| 500 | 95 | 90 | 70 | 4 | 4 | 1225 | 2207 | 530 | 670 | 31160X2 | 1007760 | 327 | 327 | 460 | 480 | 20 | 30 | 3 | 3 | 0.32 | 1.9 | 1 | 67.7 | ||

| 540 | 149 | 140 | 115 | 6 | 5 | 2740 | 4780 | 530 | 670 | 32260/HC YA | 330 | 330 | 485 | 515 | 20 | 35 | 5 | 4 | 0.43 | 1.4 | 0.8 | 143 | |||

| d 304.8~460mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 304.8 | 546.1 | 171.1 | 171.1 | 140.1 | 8 | 8 | 2660 | 3020 | 530 | 670 | 306/304.8/HC | 316 | 316 | 534 | 8 | 8 | 0.34 | 175 | |||||||

| 320 | 440 | 76.5 | 72 | 62 | 4 | 3 | 607 | 1375 | 650 | 870 | 32964 | 2007964 | 335 | 335 | 412 | 427 | 10 | 16 | 3 | 2.5 | 0.3 | 2 | 1.1 | 44.7 | |

| 480 | 100.7 | 95 | 82 | 5 | 4 | 1463 | 2945 | 630 | 850 | 32064/YB2 | 2007164 | 340 | 340 | 440 | 468 | 14 | 20 | 4 | 3 | 0.42 | 1.4 | 0.8 | 59 | ||

| 330.2 | 482.64 | 87 | 75 | 68 | 3 | 3 | 863 | 1526 | 530 | 670 | 306/330.2 | 7766 | 351 | 351 | 449 | 462 | 20 | 30 | 2.5 | 2.5 | 0.31 | 1.9 | 1.1 | 37.2 | |

| 340 | 460 | 76.5 | 72 | 62 | 4 | 3 | 611 | 1428 | 530 | 670 | 32968/YB2 | 2007968 | 356 | 356 | 432 | 448 | 10 | 16 | 3 | 2.5 | 0.31 | 1.9 | 1.1 | 34.3 | |

| 520 | 86 | 82 | 64 | 4 | 3 | 807 | 1540 | 500 | 630 | 32068X2 | 7168 | 360 | 360 | 486 | 501 | 18 | 25 | 3 | 3 | 0.29 | 2.1 | 1.1 | 57 | ||

| 520 | 100 | 95 | 75 | 5 | 5 | 1510 | 2940 | 30668 | 73.4 | ||||||||||||||||

| 360 | 480 | 76.5 | 72 | 62 | 4 | 3 | 634 | 1526 | 500 | 630 | 32972/YB2 | 2007972 | 376 | 376 | 452 | 468 | 10 | 16 | 3 | 2.5 | 0.33 | 1.8 | 1 | 35.9 | |

| 540 | 86 | 82 | 64 | 4 | 4 | 919 | 1848 | 480 | 600 | 31072X2 | 7172 | 380 | 380 | 504 | 522 | 18 | 25 | 3 | 3 | 0.3 | 2 | 1.1 | 60.5 | ||

| 380 | 520 | 66.5 | 65 | 46.5 | 3 | 3 | 529 | 1138 | 480 | 600 | 31976X2 | 1007976 | 402 | 402 | 486 | 505 | 15 | 20 | 2.5 | 2.5 | 0.42 | 1.4 | 0.8 | 37.5 | |

| 620 | 112 | 106 | 76 | 4 | 4 | 909 | 1708 | 400 | 500 | 31176X2 | 1007776 | 420 | 420 | 534 | 560 | 10 | 40 | 3 | 3 | 0.46 | 1.3 | 0.7 | 114 | ||

| 400 | 540 | 70 | 65 | 48 | 5 | 4 | 811 | 1658 | 980 | 1220 | 31980 | 422 | 422 | 499 | 518 | 16 | 16 | 4 | 4 | 0.44 | 1.3 | 0.7 | 40.6 | ||

| 600 | 95 | 90 | 67 | 4 | 4 | 1040 | 2128 | 400 | 500 | 31080X2 | 7180 | 420 | 420 | 560 | 580 | 20 | 30 | 3 | 3 | 0.39 | 1.5 | 0.8 | 84 | ||

| 420 | 560 | 70 | 65 | 51 | 3 | 3 | 630 | 1383 | 400 | 500 | 31984X2 | 1007984 | 440 | 440 | 532 | 546 | 15 | 20 | 2.5 | 2.5 | 0.3 | 1.9 | 1.1 | 42.4 | |

| 620 | 95 | 90 | 70 | 4 | 4 | 1132 | 2422 | 380 | 480 | 31084X2 | 7184 | 448 | 448 | 579 | 601 | 20 | 30 | 3 | 3 | 0.4 | 1.5 | 0.8 | 88 | ||

| 700 | 130 | 122 | 92 | 6 | 6 | 1620 | 2800 | 310 | 420 | 31184X2 | 107784 | 490 | 490 | 606 | 646 | 15 | 40 | 5 | 5 | 0.32 | 19 | 1 | 183 | ||

| 440 | 620 | 95 | 90 | 67 | 2.3 | 5 | 1440 | 2930 | 340 | 650 | 32988 XI/P5 | 465 | 465 | 585 | 592 | 20 | 30 | 2 | 4 | 0.41 | 1.5 | 0.8 | 79.4 | ||

| 650 | 96.4 | 94 | 67 | 6 | 4 | 1193 | 2422 | 360 | 450 | 31088X2 | 7188 | 469 | 469 | 606 | 629 | 20 | 30 | 5 | 3 | 0.43 | 1.4 | 0.8 | 99 | ||

| 460 | 620 | 80 | 74 | 58 | 3 | 3 | 836 | 1843 | 380 | 480 | 31992X2 | 1007992 | 480 | 480 | 590 | 605 | 18 | 25 | 2.5 | 2.5 | 0.4 | 1.5 | 0.8 | 59.8 | |

| 660 | 115 | 110 | 90 | 5 | 4 | 1960 | 4650 | 32996X3 | |||||||||||||||||

| d 460~1800mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 460 | 680 | 105 | 100 | 78 | 6 | 6 | 1680 | 3550 | 330 | 450 | 31092X2 | 7192 | 516 | 516 | 610 | 640 | 8 | 34 | 5 | 5 | 0.3 | 1.9 | 1.1 | 118 | |

| 480 | 650 | 84.2 | 78 | 60 | 4 | 4 | 854 | 1918 | 340 | 430 | 31996X2 | 1007996 | 502 | 502 | 613 | 633 | 18 | 25 | 3 | 3 | 0.42 | 1.4 | 0.8 | 71 | |

| 500 | 720 | 110 | 100 | 82 | 6 | 6 | 1459 | 3192 | 280 | 360 | 310/500X2 | 71/500 | 530 | 530 | 674 | 700 | 20 | 30 | 5 | 5 | 0.33 | 1.8 | 1 | 135 | |

| 530 | 670 | 100.5 | 95 | 82 | 5 | 3 | 1850 | 4800 | 329/530X2 | 552 | 552 | 637 | 658 | 20 | 30 | 4 | 3 | 0.38 | 81.3 | ||||||

| 710 | 88 | 82 | 62 | 4 | 4 | 1001 | 2380 | 280 | 360 | 319/530X2 | 10079/530 | 554 | 554 | 672 | 693 | 20 | 30 | 3 | 3 | 0.41 | 1.5 | 0.8 | 94.8 | ||

| 560 | 750 | 92.5 | 85 | 64 | 4 | 4 | 1001 | 2576 | 240 | 320 | 319/560X2 | 10079/560 | 586 | 586 | 708 | 731 | 20 | 30 | 3 | 3 | 0.44 | 1.4 | 0.8 | 104 | |

| 820 | 121 | 115 | 84 | 6 | 6 | 1887 | 4046 | 220 | 300 | 310/560X2 | 71/560 | 594 | 594 | 768 | 795 | 30 | 40 | 5 | 5 | 0.39 | 1.5 | 0.8 | 191 | ||

| 600 | 870 | 124 | 118 | 89 | 6 | 6 | 2020 | 4438 | 180 | 240 | 310/600X2 | 71/600 | 630 | 630 | 821 | 845 | 30 | 40 | 5 | 5 | 0.41 | 1.5 | 1.6 | 235 | |

| 630 | 920 | 135 | 128 | 94 | 7.5 | 7.5 | 2315 | 5222 | 170 | 220 | 310/630X2 | 71/630 | 669 | 669 | 858 | 891 | 30 | 40 | 6 | 6 | 0.42 | 1.4 | 0.8 | 278 | |

| 710 | 950 | 114 | 106 | 80 | 6 | 6 | 1765 | 4494 | 150 | 190 | 319710X2 | 10079710 | 743 | 743 | 895 | 925 | 25 | 35 | 5 | 5 | 0.46 | 1.3 | 0.7 | 210.24 | |

| 800 | 990 | 57 | 55 | 45 | 5 | 5 | 907 | 2644 | 150 | 190 | 308800 RYB2P6 | 822 | 822 | 930 | 968 | 25 | 35 | 4 | 4 | 0.39 | 1.5 | 0.8 | 96.3 | ||

| 1060 | 122 | 115 | 89 | 6 | 6 | 2132 | 5530 | 130 | 170 | 319/800 X2 | 10079/800 | 838 | 838 | 1005 | 1031 | 25 | 35 | 5 | 5 | 0.35 | 1.7 | 0.9 | 275 | ||

| 900 | 1180 | 124 | 122 | 87 | 6 | 6 | 2173 | 5782 | 95 | 130 | 319/900X2 | 10079900 | 940 | 940 | 1117 | 1146 | 30 | 40 | 5 | 5 | 0.39 | 1.5 | 0.8 | 330 | |

| 1280 | 190 | 170 | 135 | 7.5 | 7.5 | 5615 | 13913 | 95 | 130 | 320900X2 | 71/900 | 944 | 944 | 1194 | 1246 | 45 | 60 | 6 | 6 | 0.54 | 1.1 | 0.6 | 703 | ||

| 950 1800 |

1250 | 140 | 132 | 100 | 7.5 | 7.5 | 3930 | 10427 | 80 | 100 | 319950X2 | 10079950 | 994 | 994 | 1191 | 1220 | 30 | 40 | 6 | 6 | 0.33 | 1.8 | 1 | 428 | |

| 2300 | 260 | 218 | 180 | 15 | 15 | 10810 | 34000 | 306/1800 | 1824 | 1824 | 2191 | 2276 | 30 | 40 | 15 | 15 | 0.67 | 0.9 | 0.5 | 2339 | |||||

| d 17.462~31.75mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 17.462 | 39.878 | 13.84 | 14.61 | 10.67 | 1.3 | 1.3 | 21.2 | 20.8 | 9000 | 13000 | LMI1749LMI1710 | LM1749LMII710 | 21.5 | 23 | 34 | 37 | 2 | 3 | 1 | 1.3 | 0.29 | 2.1 | 1.15 | 0.083 | |

| 19.05 | 45.237 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 27.5 | 27.5 | 8500 | 12000 | LMI⁹49LMI910 | LM1949LMII910 | 23.5 | 25 | 39.5 | 41.5 | 2 | 4 | 1 | 1.3 | 0.3 | 2 | 1.I | 0.124 | |

| 21.43 | 50.005 | 17.53 | 18.29 | 13.97 | 1.3 | 1.3 | 36.9 | 38 | 8000 | 11000 | M12649M12610 | MI2M649MI2610 | 25.4 | 27.5 | 44 | 46 | 2 | 4 | 1 | 1.3 | 0.28 | 2.16 | 1.19 | 0.169 | |

| 21.986 | 45.237 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 26.9 | 33.6 | 9270 | 11590 | LMI2749LM12710 | 26 | 27.5 | 39.5 | 42 | 3 | 4 | 1 | 1.3 | 0.31 | 2 | 1.1 | 0.115 | ||

| 45.974 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 27.5 | 31 | 8000 | 11000 | LM12749LMI2711 | LMZ749LMI27I1 | 26 | 27.5 | 40 | 42.5 | 3 | 4 | 1 | 1.3 | 0.3 | 2.02 | 1.11 | 0.12 | ||

| 22 | 45.237 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 27.5 | 31 | 8000 | 11000 | LMIZ749LMI12710 | LMLZ749LM12710 | 26 | 28 | 39.5 | 41.5 | 2 | 4 | 1 | 1.3 | 0.3 | 2.02 | 1.11 | 0.115 | |

| 49.225 | 11 | 1 | 16.4 | 18.4 | LR306302 | (内组件) | 0.071 | ||||||||||||||||||

| 25.4 | 50.005 | 13.5 | 14.26 | 9.525 | 1 | 1 | 27 | 29 | 7500 | 10000 | 710007196 | 71000197 | 29.5 | 30.5 | 44.5 | 47 | 3 | 5 | 1 | 1 | 0.4 | 149 | 0.82 | 0.119 | |

| 50.292 | 14.22 | 14.73 | 10.67 | 1.3 | 1.3 | 26 | 30 | 7500 | 10000 | L4643L44610 | 14643L4610 | 29.5 | 31.5 | 44.5 | 47 | 3 | 5 | 1 | 1.3 | 0.37 | 1.6 | 0.88 | 0.127 | ||

| 26.988 | 50.292 | 14.22 | 14.73 | 10.67 | 3.5 | 1.3 | 26 | 32.2 | 7500 | 10000 | L44649L44610 | 14649L4610 | 31 | 37.5 | 44.5 | 47 | 3 | 5 | 3 | 1.3 | 0.37 | 1.6 | 0.88 | 0.12 | |

| 29 | 50.292 | 14.22 | 14.73 | 10.67 | 3.5 | 1.3 | 26 | 33 | 7000 | 9500 | L4549L45410 | 14549L45410 | 33 | 39.5 | 44.5 | 48 | 3 | 5 | 3 | 1.3 | 0.37 | 1.62 | 0.89 | 0.113 | |

| 58 | 17 | 4 | 16.4 | 18.4 | LR3063302YB | (内组件) | 0.248 | ||||||||||||||||||

| 30.162 | 64.292 | 21.43 | 21.43 | 16.67 | 1.5 | 1.5 | 48 | 66.5 | 6750 | 8430 | M86649M86610 | 38.2 | 41 | 54 | 61 | 3 | 5 | 3 | 1.3 | 0.55 | 1.1 | 0.6 | 0.331 | ||

| 31.75 | 59.131 | 15.88 | 16.76 | 11.81 | 3.6 | 1.3 | 34.7 | 43 | 6300 | 7500 | LM67048LM67010 | LM6748LM67H0 | 36 | 42.5 | 52 | 56 | 3 | 5 | 3 | 1.3 | 0.41 | 1.46 | 0.8 | 0.18 | |

| 59.131 | 15.88 | 16.76 | 11.81 | 3.6 | 1.3 | 32.8 | 43 | 10410 | 13010 | LM67048LM67010 | 36 | 42.5 | 52 | 56 | 3.5 | S | 3 | 1.3 | 0.41 | 1.46 | 0.8 | 0.18 | |||

| 62 | 18.16 | 19.05 | 14.29 | 3.5 | 1.3 | 45.8 | 60.1 | 6300 | 8500 | 1512315245 | 36 | 42.5 | 52 | 56 | 3.5 | 5 | 3.5 | 1.3 | 0.35 | 1.71 | 0.94 | 0.244 | |||

| 68.262 | 22.23 | 22.23 | 17.46 | 3.5 | 1.5 | 53.1 | 64.8 | 247502420 | 38.5 | 39 | 59 | 63 | 5.5 | 3 | 3.5 | 1.5 | 0.42 | 1.44 | 0.382 | ||||||

| 69.012 | 19.85 | 19.58 | 15.88 | 3.5 | 1.3 | 51.2 | 65.4 | 9060 | 11320 | 14125A/14276 | 37.5 | 44 | 60 | 63 | 3 | 5 | 3.5 | 1.3 | 0.38 | 1.57 | 0.86 | 0.353 | |||

| d 34.925~50.8mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 34.925 | 65.088 | 18.03 | 18.29 | 13.97 | 3.6 | 1.3 | 47.3 | 58.2 | 5600 | 7500 | LM48548LM4510 | LM48548LM48510 | 40 | 46 | 58 | 61 | 3 | 5 | 3 | 1.3 | 0.38 | 1.59 | 0.88 | 0.252 | |

| 80.167 | 29.37 | 30.39 | 23.81 | 3.5 | 3.2 | 91.9 | 106 | 5000 | 6700 | 35793320 | 3793320 | 41.5 | 48 | 70 | 74.8 | 3 | 5 | 3 | 2.5 | 0.27 | 2.19 | 1.21 | 0.742 | ||

| 34.987 | 59.131 | 15.88 | 16.76 | 11.94 | 3.6 | 1.3 | 32.2 | 47.3 | L68149L68110 | 39 | 45.5 | 52 | 56 | 3 | 4 | 3 | 1.3 | 0.42 | 1.44 | 0.79 | 0.169 | ||||

| 59.975 | 15.88 | 16.76 | 11.94 | 3.6 | 1.3 | 32.2 | 47.3 | 6710 | 8390 | L68149L68I1 | 39 | 45.5 | 53 | 56 | 3 | 4 | 3 | 1.3 | 0.42 | 1.44 | 0.79 | 0.177 | |||

| 37.987 | 62.975 | 17 | 17 | 13.5 | 3.6 | 1.3 | 40 | 55 | 5600 | 7500 | JL69349JL69310 | JL693416310 | 41 | 47 | 56 | 60 | 4 | 6 | 3 | 1.3 | 0.42 | 1.44 | 0.79 | 0.186 | |

| 38.1 | 76.2 | 23.81 | 25.65 | 19.05 | 3.5 | 3.2 | 74.8 | 93 | 5000 | 6700 | 2788R2720 | 278R2720 | 43 | 50 | 65 | 72 | 4 | 6 | 3 | 2.5 | 0.3 | 2.03 | 1.12 | 0.501 | |

| 39.688 | 73.025 | 25.65 | 22.1 | 21.34 | 0.8 | 2.3 | 66 | 86.5 | 5000 | 6700 | M201047M291011 | M201047M2DH011 | 44 | 51 | 66 | 70 | 4 | 6 | 0.8 | 2.1 | 0.32 | 1.85 | 1.02 | 0.432 | |

| 41.275 | 73.431 | 19.56 | 19.81 | 14.73 | 3.5 | 0.8 | 55 | 73.9 | 4800 | 6300 | LM501349LMS901310 | LM601349LMS0138 | 46.5 | 53 | 67 | 70 | 3.5 | 6 | 3.5 | 0.8 | 0.4 | 1.5 | 0.8 | 0.336 | |

| 82.55 | 26.54 | 25.65 | 20.19 | 3.5 | 3.3 | 76.3 | 105 | MS02048M82011F | 51 | 57 | 70 | 79 | 3 | 6 | 3.5 | 3.3 | 0.55 | 1.1 | 0.617 | ||||||

| 88.9 | 30.16 | 29.37 | 23.02 | 3.5 | 3.3 | 95.2 | 127 | 4300 | 5600 | FHDMS13146FH8B19 | FHM906146FH895LI0 | 53 | 53.5 | 70 | 84 | 4 | 7 | 3 | 2.5 | 0.54 | 1.1 | 0.6 | 0.882 | ||

| 44.45 | 82.931 | 23.81 | 25.4 | 19.05 | 3.5 | 0.8 | 80.9 | 106 | 4500 | 6000 | 25882550 | 258025) | 50 | 56 | 72 | 78 | 4 | 6 | 3 | 0.8 | 0.32 | 1.85 | 1.02 | 0.57 | |

| 45.23 | 79.985 | 19.84 | 20.64 | 15.08 | 2 | 1.3 | 55.1 | 70.8 | 4800 | 6300 | 1788717831 | 178717831 | 50 | 56 | 72 | 78 | 4 | 6 | 2 | 1.3 | 0.37 | 1.64 | 0.9 | 0.402 | |

| 45.242 | 73.431 | 19.56 | 19.81 | 15.75 | 3.5 | 0.8 | 53.9 | 69.5 | 4800 | 6300 | LM02949LMI02910 | LMI299LM102910 | 50 | 57 | 68 | 70 | 3 | 5 | 3 | 0.8 | 0.31 | 1.97 | 1.08 | 0.3 | |

| 77.788 | 21.43 | 19.84 | 16.67 | 3.5 | 0.8 | 52.2 | 73.7 | 8110 | 10140 | LM1603049LM6L3012 | 50 | 57 | 70 | 74 | 3.5 | 5 | 3.5 | 0.8 | 0.43 | 141 | 0.77 | 0.385 | |||

| 45.618 | 82.931 | 23.81 | 25.4 | 19.05 | 3.5 | 0.8 | 80.9 | 106 | 4500 | 6000 | 2559025520 | 259025530 | 50 | 56 | 72 | 78 | 4 | 6 | 3 | 8 | 0.33 | 1.8 | 1 | 0.554 | |

| 82.931 | 26.99 | 25.4 | 22.23 | 3.5 | 2.3 | 80.9 | 106 | 4500 | 6000 | 2559025523 | 25902524 | 50 | 56 | 72 | 78 | 4 | 6 | 3 | 2.1 | 0.33 | 1.8 | 1 | 0.603 | ||

| 50 | 82 | 21.5 | 21.5 | 17 | 3 | 0.6 | 66.9 | 94.1 | 4840 | 6060 | JLM10948JLM109 | 0 | 55 | 60 | 76 | 78 | 4 | 6 | 3 | 0.6 | 0.31 | 1.97 | 1.08 | 0.429 | |

| 50.8 | 82.55 | 21.59 | 22.23 | 16.51 | 3.5 | 1.3 | 60.8 | 94.1 | 4790 | 5990 | LM104949LM10491 | 55 | 62 | 75 | 78 | 4 | 6 | 3.5 | 1.3 | 0.31 | 1.97 | 1.08 | 0.426 | ||

| d 52.388~89.975mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 52.388 | 92.075 | 24.61 | 25.4 | 19.85 | 3.5 | 0.8 | 82 | 108 | 4000 | 5300 | 2858428521 | 28842821 | 59 | 69 | 83 | 87 | 4 | 7 | 0.8 | 38 | 159 | 0.87 | 0.695 | ||

| 54.488 | 104.78 | 36.51 | 36.51 | 28.58 | 2 | 3.3 | 139 | 192 | HM8/748HMS0010 | 63 | 73 | 89 | 100 | 4 | 7 | 2 | 3.3 | 49 | 1.23 | 1.38 | |||||

| 54.5 | 104.78 | 36.51 | 36.51 | 28.58 | 2 | 3.3 | 139 | 192 | LY-3035 | 1.38 | |||||||||||||||

| 55 | 90 | 23 | 26 | 18.5 | 3.5 | 0.5 | 84 | 110 | 3800 | 5000 | IMSAEJLAE9M89 | ANS0648ELMS5W680 | 61 | 69 | 78 | 87 | 7 | 8 | 3 | 0.5 | 4 | 149 | 0.82 | 0.586 | |

| 55.562 | 97.63 | 24.61 | 24.61 | 19.45 | 3.5 | 0.8 | 80.9 | 71 | 4160 | 5200 | 2868028622 | 62 | 68 | 88 | 92 | 4 | 5 | 3.5 | 0.8 | 4 | 149 | 0.82 | 0.754 | ||

| 60.325 | 101.6 | 25.4 | 25.4 | 1985 | 5 | 3.3 | 85.8 | 125 | 3600 | 4800 | 289852893 | 29K52901 | 68 | 80 | 88 | 97 | 5 | 9 | 3 | 2.5 | 43 | 14 | 0.78 | 0.798 | |

| 63.5 | 107.95 | 25.4 | 25.4 | 19.05 | 1.5 | 3.3 | 83.5 | 76.4 | 295862950 | 915 | |||||||||||||||

| 12224 | 38.1 | 38.35 | 29.72 | 7 | 1.5 | 172 | 245 | 3400 | 4300 | FN212047HM212010 | HBCID4THNZ1200 | 73 | 80 | 110 | 116 | A | 6 | 6 | 1.5 | 0.34 | 178 | 0.98 | 1.94 | ||

| 122.24 | 38.1 | 38.35 | 29.72 | 1 | 3.3 | 172 | 245 | 3400 | 4300 | HNI212N47HM21201 | HMCI3N4THM213I1 | 73 | 80 | 110 | 116 | 4 | 6 | 6 | 2.5 | 0.34 | 178 | 0.98 | 1.93 | ||

| 66.675 | 107.95 | 25.4 | 25.4 | 19.05 | 3.5 | 0.8 | 85.8 | 125 | 3600 | 4800 | 295029522 | H29902622 | 75 | 87 | 94 | 103 | 4 | 10 | 3 | 0.8 | 0.46 | 13 | 0.72 | 0.854 | |

| 122.24 | 38.1 | 38.35 | 29.72 | 3.5 | 1.5 | 159 | 146 | 3400 | 4200 | HN212049HN212010 | HBCI3M49HM212010 | 75.5 | 82 | 110 | 116 | 4 | 6 | 3 | 1.5 | 0.34 | 178 | 0.98 | 1.85 | ||

| 122.24 | 38.1 | 38.35 | 29.72 | 3.5 | 3.3 | 159 | 146 | 3400 | 4200 | HNI212049HM21201 | HMCI12049EDNL12011 | 75.5 | 82 | 110 | 116 | 4 | 5 | 3 | 3 | 0.34 | 178 | 0.98 | 1.85 | ||

| 68.262 | 161.93 | 49.21 | 46.04 | 31.75 | 3.5 | 3.3 | 256 | 304 | 2690 | 3360 | 9278922 | 904 | 97 | 138 | 153 | 4.5 | 12 | 3.5 | 3 | 71 | 85 | 0.46 | 4.46 | ||

| 69.85 | 146.05 | 41.28 | 39.69 | 25.4 | 3.6 | 3.4 | 192 | 239 | 2880 | 3610 | H9189H9L810 | 82 | 95 | 124 | 138 | 5.5 | 11 | 3.5 | 3 | 78 | 77 | 0.42 | 2.92 | ||

| 84.976 | 125.41 | 25.4 | 25.4 | 19.85 | 5 | 1.5 | 110 | 183 | 2970 | 3710 | 276527620 | 91 | 100 | 115 | 120 | 5 | 6 | 5 | 1.5 | 42 | 144 | 0.79 | 1 | ||

| 88.9 | 152.4 | 39.69 | 39.69 | 30.16 | 6 | 3.51 | 229 | 362 | 2550 | 3190 | HD51845HM518410 | 102 | 109 | 135 | 139 | 6 | 10 | 5 | 3.5 | 4 | 149 | 0.82 | 2.9 | ||

| 89.975 | 146.98 | 40 | 40 | 32.5 | 7 | 3.5 | 229 | 355 | 2200 | 3200 | HM218248HM218210 | HB2I8248HMI820 | 95 | 111 | 132 | 140 | 5 | 7 | 6 | 2.5 | 0.33 | 18 | 1 | 2.52 | |

| d 95.25~146.05mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 95.25 | 152.4 | 39.69 | 36.32 | 30.16 | 5 | 3.3 | 185.3 | 289.7 | 2480 | 3100 | 594A/592A | 104 | 113 | 135 | 144 | 4 | 10 | 5 | 3 | 0.44 | 1.36 | 0.75 | 2.55 | ||

| 99.974 | 156.98 | 42 | 42 | 34 | 8 | 3.5 | 243 | 391 | 2380 | 2970 | HM220149/HM220110 | 109 | 123 | 142 | 151 | 5.5 | 9 | 7 | 3.5 | 0.33 | 1.9 | 0.99 | 2.92 | ||

| 99.975 | 212.73 | 66.68 | 66.68 | 53.98 | 3.5 | 3.3 | 556 | 783 | 1900 | 2380 | HH224334/HH224310 | 120 | 124 | 192 | 202 | 7 | 12 | 3 | 3 | 0.33 | 1.84 | 0.99 | 11.3 | ||

| 101.6 | 180.98 | 47.63 | 48.01 | 38.1 | 3.5 | 3.3 | 288 | 436 | 780772 | 113 | 119 | 161 | 168 | 5 | 10 | 3.5 | 3 | 0.39 | 1.56 | 5.02 | |||||

| 104.78 | 180.98 | 47.63 | 48.01 | 38.1 | 7 | 3.3 | 258 | 375 | 2000 | 2600 | 7872 | 116 | 129 | 161 | 168 | 5 | 10 | 7 | 3.3 | 0.39 | 1.56 | 0.86 | 4.66 | ||

| 107.95 | 161.93 | 34.93 | 34.93 | 26.99 | 3.5 | 3.3 | 164 | 280 | 2000 | 2800 | 48190/48120 | 116 | 122 | 146 | 156 | 3.5 | 8 | 3.5 | 3.3 | 0.51 | 1.2 | 0.65 | 2.42 | ||

| 109.54 | 158.75 | 23.02 | 21.44 | 15.88 | 5 | 3.3 | 103 | 167 | 37431A/37625 | 116 | 126 | 143 | 152 | 3.5 | 7 | 5 | 3.3 | 0.61 | 0.99 | 1.31 | |||||

| 114.3 | 152.4 | 21.43 | 21.43 | 16.67 | 1.5 | 1.5 | 89 | 178 | 2000 | 2800 | L623149/L623110 | 120 | 123 | 143 | 147 | 3.5 | 6 | 15 | 1.5 | 0.41 | 1.5 | 0.8 | 1.05 | ||

| 212.73 | 66.68 | 66.68 | 53.98 | 7 | 3.3 | 570 | 810 | 1700 | 2200 | HH224346/HH224310 | 131 | 143 | 192 | 202 | 7 | 12 | 7 | 3.3 | 0.33 | 1.84 | 1 | 10 | |||

| 117.48 | 180.98 | 34.93 | 31.75 | 25.4 | 3.5 | 3.3 | 174 | 254 | 1800 | 2400 | 68462/68712 | 125 | 132 | 163 | 172 | 2 | 8 | 3.5 | 3.3 | 0.5 | 1.21 | 0.66 | 2.78 | ||

| 120 | 174.63 | 35.72 | 36.51 | 27.78 | 3.5 | 1.5 | 212 | 385 | 1900 | 2600 | M224748/M224710 | 129 | 135 | 163 | 168 | 3.5 | 15 | 0.33 | 1.8 | 0.99 | 2.78 | ||||

| 123.83 | 182.56 | 39.69 | 38.1 | 33.34 | 3.5 | 3.3 | 228 | 445 | 1800 | 2400 | 48286/48220 | 133 | 139 | 168 | 176 | 4.5 | 7 | 3.5 | 3.3 | 0.31 | 1.97 | 1.1 | 3.51 | ||

| 130.18 | 203.2 | 46.04 | 46.04 | 38.1 | 3.5 | 3.3 | 315 | 560 | 1700 | 2200 | 67389/67320 | 141 | 146 | 183 | 191 | 3.5 | 3.3 | 0.34 | 1.7 | 0.96 | 5.57 | ||||

| 142.88 | 200.03 | 41.28 | 39.69 | 34.13 | 3.5 | 3.3 | 242 | 500 | 1710 | 2130 | 4868548620 | 151 | 158 | 185 | 193 | 3.5 | 7 | 35 | 3.3 | 0.34 | 1.78 | 0.97 | 3.84 | ||

| 146.05 | 254 | 66.68 | 6668 | 47.63 | 7 | 3.3 | 530 | 867 | 99575199100 | 162 | 175 | 227 | 238 | 8 | 135 | 7 | 3.3 | 0.41 | 1.47 | 13.2 | |||||

| d 152.4~762mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 152.4 | 254 | 66.68 | 66.68 | 47.63 | 7 | 3.3 | 515 | 830 | 1300 | 1800 | 9960099100 | 9960091600 | 170 | 181 | 227 | 238 | 8 | 13.5 | 7 | 3.3 | 0.41 | 1.47 | 0.81 | 12.29 | |

| 165.1 | 247.65 | 47.63 | 47.63 | 38.1 | 3.5 | 3.3 | 345 | 705 | 1300 | 1700 | 67786720 | 179 | 185 | 229 | 240 | 5 | 8 | 3.5 | 3.3 | 0.44 | 1.36 | 0.75 | 8.16 | ||

| 174.63 | 24765 | 47.63 | 47.63 | 38.1 | 3.5 | 3.3 | 345 | 705 | 1300 | 1700 | 6778767720 | 185 | 192 | 229 | 240 | 5 | 8 | 3.5 | 3.3 | 0.44 | 1.4 | 0.75 | 7.21 | ||

| 180 | 250 | 47 | 45 | 37 | 3 | 2.5 | 338 | 682 | 1300 | 1630 | JM736149JM736110 | 190 | 196 | 232 | 243 | 5.5 | 10 | 3 | 2.5 | 0.48 | 1.25 | 0.69 | 6.72 | ||

| 190 | 260 | 46 | 44 | 36.5 | 3 | 2.5 | 370 | 730 | 1100 | 1600 | JM738249JM738210 | 200 | 206 | 242 | 252 | 5.5 | 9.5 | 3 | 2.5 | 0.48 | 1.3 | 0.69 | 6.93 | ||

| 206.38 | 282.58 | 46.04 | 46.04 | 36.51 | 3.5 | 3.3 | 365 | 800 | 100 | 1400 | 6798567920 | 219 | 224 | 260 | 275 | 5 | 8 | 3.5 | 3.3 | 0.51 | 1.2 | 65 | 8.48 | ||

| 254 | 358.78 | 71.44 | 71.44 | 53.98 | 3.5 | 3.3 | 694 | 1550 | 830 | 1040 | M249749M249710 | 270 | 274 | 335 | 343 | 75 | 135 | 35 | 3.3 | 0.33 | 1.8 | 1 | 21.7 | ||

| 304.8 | 444.5 | 63.5 | 61.91 | 39.69 | 6 | 1.1 | 685 | 1140 | 510 | 640 | EE291201291749 | 3-736 | 340 | 370 | 403 | 422 | 8 | 28 | 2 | 1 | 0.38 | 1.6 | 0.87 | 25.1 | |

| 546.1 | 171.1 | 171.1 | 140.1 | 6 | 6 | 2800 | 5800 | 490 | 600 | 3063048 | 7961 | 355 | 400 | 500 | 515 | 8 | 28 | 5 | 0.34 | 1.8 | 17.5 | ||||

| 393.7 | 546.1 | 76.2 | 61.12 | 55.56 | 6 | 6 | 860 | 1343 | 500 | 630 | EE234154234215 | 7979 | 416 | 437 | 508 | 532 | 18 | 25 | 6 | 5 | 0.48 | 1.2 | 0.7 | 44.8 | |

| 431.8 | 571.5 | 52.38 | 874.612 | 74.612 | 3.3 | 3.3 | 1080 | 2470 | 380 | 480 | LM869448J/LM869410J | 453 | 457 | 537 | 549 | 5 | 16 | 3.3 | 3.3 | 0.55 | 1.1 | 0.6 | 48.2 | ||

| 609.6 | 787.4 | 93.66 | 93.66 | 69.85 | 6 | 6 | 2010 | 5060 | 340 | 450 | EE649240649310 | 3-734 | 655 | 690 | 725 | 760 | 10 | 25 | 6 | 5 | 0.37 | 1.6 | 0.9 | 110 | |

| 685.8 | 876.3 | 93.66 | 92.08 | 69.85 | 6.4 | 6.4 | 1980 | 5150 | 300 | 400 | EE65527065345 | EF655270655345 | 714 | 723 | 831 | 843 | 13 | 25 | 5 | 5 | 0.42 | 1.4 | 0.8 | 133 | |

| 759.93 | 889 | 88.9 | 88.9 | 72 | 3.3 | 3.3 | 1910 | 6130 | LI8448L183410 | 780 | 783 | 864 | 873 | 12.5 | 19 | 3.3 | 3.3 | 0.31 | 1.97 | 89.9 | |||||

| 762 | 889 | 88.9 | 88.9 | 72 | 3.3 | 3.3 | 1910 | 6130 | LI83449L183410 | 780 | 783 | 864 | 872 | 12.5 | 19 | 3.3 | 3.3 | 0.31 | 1.97 | 88.2 | |||||

Learn about our latest products and discounts through SMS or email