- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

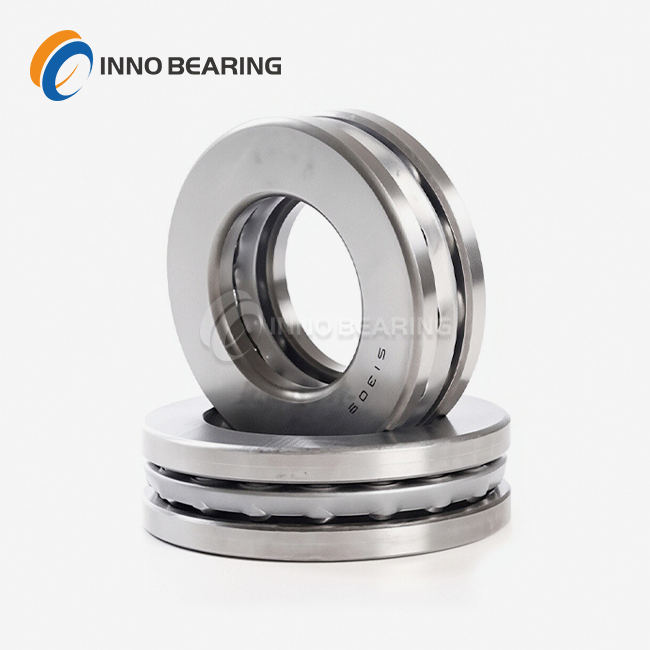

Crossed Roller Slewing Bearing

2.Structure Type: It has an annular shape. The inner and outer rings have double raceways, with crossed cylindrical rollers and nylon cages. Some are equipped with dust-proof seals, and mounting holes are reserved.

3.Size Range: Outer ring diameter: 80 - 2000mm, inner ring diameter: 60 - 1850mm, height: 10 - 80mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Precision machine tools, robot joints, radar antennas, inspection equipment.

6.Key Inspection Items: Radial runout, accuracy of roller arrangement.

Precision Crossed Roller Slewing Bearings for Extreme Environments – Custom-Built in 30 Days with 30+ Years Expertise

Need a robust rotational solution? Get Your Custom Design Now →

---

Engineered for Demanding Applications

Crossed Roller Slewing Bearings are your ultimate solution for precision rotation under combined loads. With cylindrical rollers arranged in a 90° cross pattern, these bearings handle axial, radial, and moment loads simultaneously—perfect for robotics, medical scanners, and heavy machinery.

Key Features:

- High Rigidity: Supports bidirectional loads up to 200 kN·m.

- Temperature Resilience: Operates reliably from -60°C to 150°C.

- P4 Precision: <5μm runout for surgical robotics and CNC equipment.

- Compact Design: 10–80mm height saves space in tight installations.

---

Where Crossed Roller Slewing Bearings Excel

1. Metallurgy & Heavy Machinery

Withstand furnace temperatures (150°C+) and heavy loads in rolling mills. Our heat-treated 42CrMo steel ensures 2x longer lifespan than standard bearings.

2. Port Cranes & Offshore Equipment

IP67 seals and 1,200-hour salt spray resistance prevent corrosion in coastal environments.

3. Medical Robotics & Imaging Systems

Achieve whisper-quiet operation (<60dB) with P6-grade accuracy for MRI machines and surgical arms.

---

Built to Your Exact Needs

Customization Workflow:

1. Consultation: Share load, speed, and environmental requirements.

2. Material Selection: Choose between GCr15SiMn for shock resistance or nitrile rubber seals for oil exposure.

3. Modular Production: 30 days for diameters up to 3,000mm.

4. Rigorous Testing: 12-step checks including vibration analysis and lifespan simulations.

Why Our Crossed Roller Bearings Outperform:

✅ 30% Faster Turnaround: Modular manufacturing slashes lead times.

✅ ±1μm Accuracy Guarantee: Nanopolishing for robotics and optics.

✅ Global Compliance: ISO 9001, CE, and RoHS-certified materials.

---

Quality Assured at Every Step

| Stage | Control Measures | |

|---|---|---|

| Raw Materials | 100% traceable high-purity steel | |

| Heat Treatment | HRC 58-62 hardness via vacuum quenching | |

| Final Inspection | 3D profilometry, noise testing <35dB |

99.9% defect-free rate backed by 18-month warranty.

Ready to Ship or Customize

Standard Bearings:

- 1,000+ Types In Stock: From φ80mm to φ2000mm.

- 48-Hour Dispatch: Shipped globally via DDP/DAP.

Need Non-Standard Sizes?

We produce up to φ5000mm with mounting holes, seals, or special coatings.

---

Beyond the Sale: Lifetime Support

- IoT Monitoring: Real-time vibration/temperature alerts via embedded sensors.

- 24/7 Technical Help: Troubleshoot installation or maintenance issues.

- Recycling Program: Eco-friendly disposal of worn bearings.

---

Why Engineers Choose Us

| Factor | LUOYANG INNO | Industry Average | |

|---|---|---|---|

| Lead Time (Non-Std) | 15–20 days | 25–35 days | |

| Precision Grade | P4 (ISO 492) | P5 | |

| Salt Spray Resistance | 1,200 hours | 500 hours |

---

FAQ

Q: Can you make 3,000mm+ Crossed Roller Slewing Bearings for steel plants?

Yes! Our modular process delivers φ5000mm bearings in 20 days with 150°C resilience.

Q: How do you ensure low noise in medical-grade bearings?

Precision grinding and P6 tolerances reduce noise to <60dB—ideal for MRI systems.

Q: What certifications do your Crossed Roller Bearings have?

ISO 9001, CE, and material test reports are provided. Medical orders include ISO 13485 compliance.

Q: Do you offer emergency replacements?

We keep 1,000+ standard types in stock for 48-hour global delivery.

---

Start Your Project

Limited Weekly Engineering Slots Available

Email sales@inno-bearing.com for:

✅ Custom design consultation

✅ Instant stock availability

✅ Expedited production requests

Your precision. Our expertise. Let’s rotate forward.

Learn about our latest products and discounts through SMS or email