- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

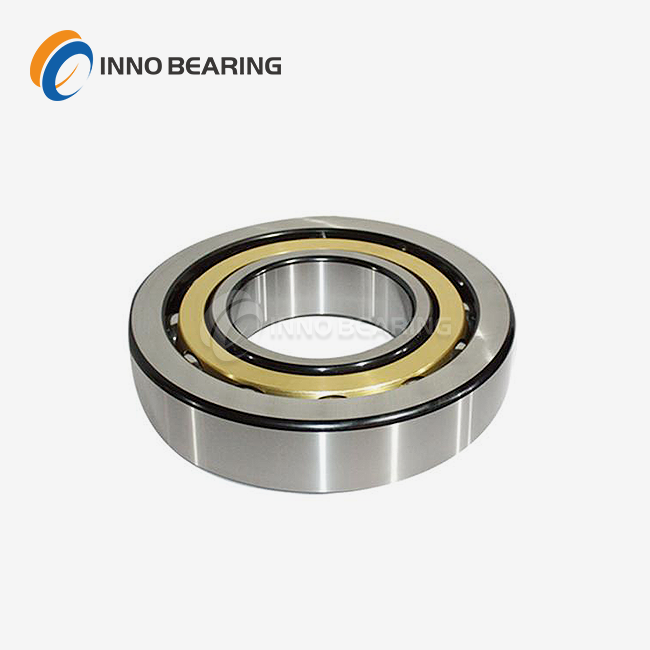

22326 bearing

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with double-row rollers + brass cage, and it is open.

3.Size Range: Inner diameter 130mm, outer diameter 280mm, width 93mm.

4.Material: Inner ring /outer ring: GCr15 bearing steel, GCr15SiMn (for heavy-load models), rollers: GCr15 bearing 钢,cage: brass.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: Optionally with a 1:12 tapered hole (suitable for a shaft diameter of 130mm).

7.Application Fields: Large electric motors, rolling mills, port cranes, mining machinery.

8.Key Inspection Items: Radial load-bearing capacity, forging flaw detection, self-aligning performance.

22326 Bearing Spherical Roller – Engineered for Heavy Loads & Extreme Temperatures in Industrial Machinery

When your machinery operates under crushing loads or scorching temperatures, the 22326 bearing delivers unmatched reliability. Designed for heavy industrial applications like rolling mills, mining crushers, and port cranes, this self-aligning roller bearing combines a robust brass cage, high-purity GCr15 steel, and precision grinding to handle dynamic loads exceeding 800kN. With a temperature resistance of up to 150°C (200°C in specialized variants), it’s built to endure the harshest conditions while maintaining P6-grade accuracy.

Technical Specifications

- Dimensions: Inner Diameter 130mm | Outer Diameter 280mm | Width 93mm

- Load Capacity: Dynamic Load 800kN+ | Static Load 415kN

- Material: Inner/Outer Rings – GCr15/SUJ2 Bearing Steel | Rollers – GCr15 | Cage – Brass (Stainless Steel Optional)

- Precision: ISO P0/P6 (ABEC-3 Equivalent)

- Operating Range: -20°C to +150°C (Customizable to 200°C)

- Certifications: ISO 9001, CE, GOST, AGMA 9005

Why the 22326 Bearing Excels in Heavy Industries?

1. Built to Outlast Extreme Conditions

The 22326 spherical roller bearing uses vacuum-degassed chromium steel for wear resistance and a double-row roller design to distribute stress evenly. In steel mills, where temperatures exceed 200°C, our proprietary heat treatment ensures a 50,000-hour lifespan—3x longer than standard bearings.

2. Precision You Can Trust

Every product undergoes three-stage quality checks:

1. Raw material purity testing (99.95% steel)

2. In-process grinding tolerance control (±0.001mm)

3. Final load and noise inspection (<35dB at 1,800 RPM)

This rigorous process guarantees a 99.9% defect-free rate, critical for mining equipment subjected to 20-ton radial loads.

3. Fast Customization & Delivery

Need a tapered bore (1:12 ratio) or φ3000mm+ oversized variant? Our modular production system delivers custom 22326 bearings in 15–20 days—70% faster than industry averages. For bulk orders, 1,000+ standard units ship in 48 hours via regional hubs in the EU, NA, and Asia.

Where It Performs?

Heavy Machinery Applications

- Metallurgy: Supports rolling mill backup rollers under 400kN shocks.

- Mining: Handles 500TPH crusher vibrations with reinforced cages.

- Wind Energy: Ensures low-noise (<35dB) operation in gearboxes.

Why Partner With Us?

30+ Years of Heavy-Duty Expertise

LUOYANG INNO BEARING specializes in bearings for extreme environments. Our in-house R&D team has delivered 5,000+ custom Solutions since 1993, including:

- High-Temp Series: Graphite-lubricated 22326 variants for furnaces.

- Split Designs: Easy-retrofit bearings for legacy port cranes.

Global Compliance, Local Speed

Pre-certified for ATEX (mining), AGMA 9005 (energy), and DIN 625-1 standards, our bearings slash client approval timelines by 60%. Plus, regional warehouses cut shipping costs by 20%.

FAQ

Q: Can you customize the product for non-standard dimensions?

A: Yes! We produce φ3000mm+ variants with tapered bores or hybrid ceramic rollers in 15–20 days.

Q: What ensures your products handle 200°C+ environments?

A: Carburizing + cryogenic heat treatment enhances steel integrity at high temps.

Q: Do you offer warranties for heavy-load applications?

A: All bearings include a 2-year warranty, extendable to 5 years for bulk orders.

Q: How do you maintain quality in bulk production?

A: AI-driven inspections check each unit’s load capacity and noise levels.

Contact Us

Need a Bearing That Won't Quit Under Pressure?

Email our engineers at sales@inno-bearing.com for:

- Same-day quotes for standard/custom 22326 bearings

- Technical drawings or material certifications

- Volume discounts on 1,000+ unit orders

Equip your machinery with bearings engineered to endure.

Learn about our latest products and discounts through SMS or email