- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

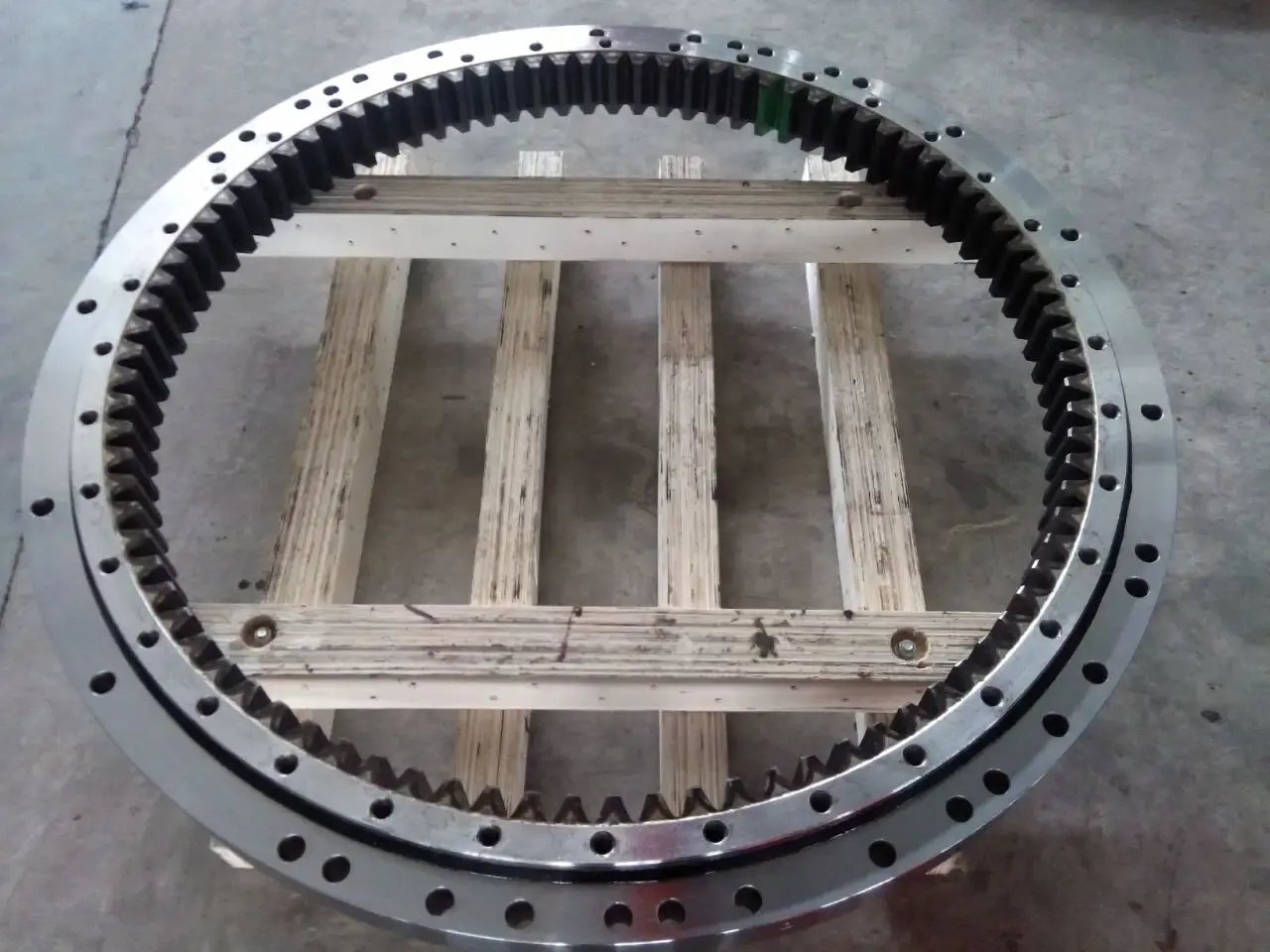

Slewing Ring Bearing

2.Structure Type: It consists of a fixed ring + a rotating ring + rolling elements + cages + seals. The rolling elements are divided into single-row or double-row according to the load. The cages prevent collisions, and the seals protect the raceways.

3.Size Range: Outer ring diameter: 100 - 4000mm, inner ring diameter: 80 - 3800mm, height: 8 - 150mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Construction machinery, wind power, machine tools, amusement equipment, port machinery.

6.Key Inspection Items: Dimensional accuracy, slewing flexibility, running noise of rolling elements.

High-Performance Slewing Ring Bearings for Heavy-Duty Applications – Customized & Bulk Supply Solutions

30+ Years Expertise in Manufacturing Precision Bearings for Metallurgical, Port Machinery, and Extreme Environments – ISO-Certified, Rapid Global Delivery

Engineered to Withstand Extreme Demands

Slewing Ring Bearings are the backbone of heavy machinery, enabling seamless 360° rotation under massive loads. At LUOYANG INNO BEARING, we specialize in crafting bearings that thrive in harsh conditions—from scorching metallurgical furnaces to corrosive port environments. With over three decades of expertise, our products combine unmatched durability (150°C heat resistance, ≤35dB noise) with precision engineering to minimize downtime and maximize productivity.

Why Choose Us?

1. Tailored Solutions for Every Challenge

-

Custom Sizes: From compact 100mm to massive 4000mm diameters.

-

Material Excellence: 42CrMo/50Mn alloy steel, hardened for 15% longer lifespan.

-

Load Mastery: Axial loads up to 15,000kN, radial loads to 9,000kN.

2. Built for Your Industry

-

Metallurgy: Ceramic-coated bearings withstand 150°C+ temperatures in rolling mills.

-

Port Machinery: IP67 seals combat salt spray; 20-year fatigue life.

-

Medical/Energy: Ultra-low noise (<35dB) for MRI machines and solar trackers.

3. Speed Without Compromise

- 30% faster production via modular manufacturing.

- Urgent orders? Get φ3000mm+ custom slewing rings in 15–20 days.

Technical Excellence, Delivered

| Feature | Specification |

|---|---|

| Precision | ISO 492 P5–P2 (runout ≤0.05mm) |

| Sealing | Triple-lip seals + corrosion-resistant grease |

| Custom Options | Flanges, gear teeth, IoT sensor ports |

| Certifications | ISO 9001, CE, API 6A, DNV-GL |

Your Assurance of Quality

Every slewing ring bearing undergoes 12+ rigorous tests:

1. Material Integrity: Spectrographic analysis for traceability.

2. Performance Validation: 500,000+ cycle fatigue testing.

3. Noise Control: ≤35dB verified in soundproof chambers.

Result: 99.9% defect-free rate at delivery.

Global Support, Local Speed

- 48-Hour Dispatch: 2,000+ standard models shipped from EU/NA/Asia hubs.

- Bulk Order Benefits: MOQ 10 units for custom designs; volume discounts.

- Lifetime Support: Free CAD models, on-site installation guides, 24/7 multilingual tech help.

Trusted by Industry Leaders

- 85% repeat business from global manufacturers.

- Zero Downtime Guarantee: 72-hour emergency replacements.

- Cost Savings: 15–25% lower TCO through optimized lifecycle management.

Ready to Elevate Your Machinery?

✅ Get a Custom Quote (1-hour response)

✅ Download Catalog (Specs & Bulk Pricing)

FAQs

1. How do your bearings handle 500°C temperatures?

We use ceramic-coated raceways and water-cooled designs, tested in real furnace conditions.

2. Can you deliver a φ3000mm custom bearing in 15 days?

Yes! Our modular production system cuts lead times by 30% without sacrificing quality.

3. What ensures noise levels stay below 35dB?

Precision grinding and advanced cage designs reduce vibration. Each unit is acoustically tested.

4. Do you support retrofitting older machines?

Absolutely. We provide 3D scanning and CAD redesign for seamless upgrades.

Contact Us

📧 Email: sales@inno-bearing.com

🌐 Global Slewing Ring Bearing Support: 24/7 engineering assistance in English, German, Spanish & Japanese.

Learn about our latest products and discounts through SMS or email