- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

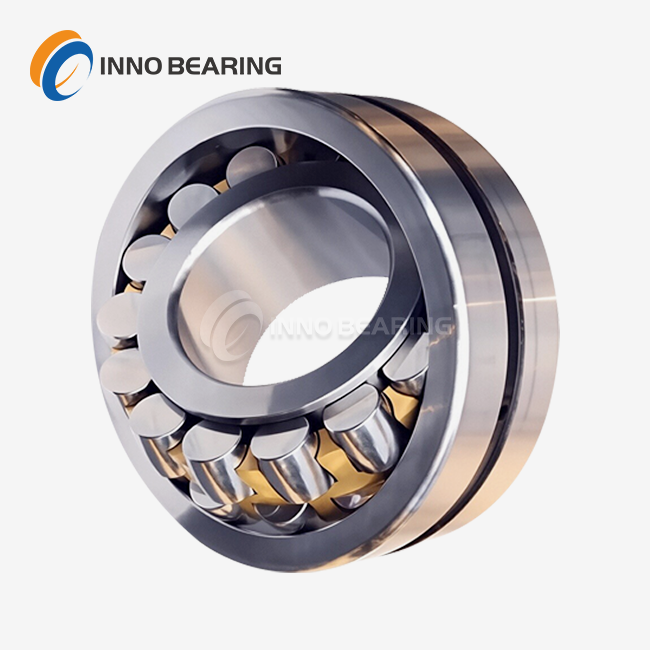

22334 bearing

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with double-row rollers + steel cage, and it is open.

3.Size Range: Inner diameter 170mm, outer diameter 360mm, width 120mm.

4.Material: Inner ring / outer ring: GCr15SiMn (heavy-load with integral forging), GCr15 bearing steel (conventional), rollers: GCr15 bearing steel, cage: steel.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: The standard configuration is a 1:12 tapered hole (suitable for a shaft diameter of 170mm).

7.Application Fields: Extra-large rolling mills, port super-heavy-duty machinery, offshore wind power equipment.

8.Key Inspection Items: Forging flaw detection, radial load-bearing capacity (≥6000kN), tapered hole precision.

22334 Bearing: High-Capacity Solution for Extreme Load Applications

When your heavy machinery faces extreme loads and harsh conditions, the 22334 bearing delivers unmatched durability. As a self-aligning roller bearing designed for extra-heavy-duty use, it combines robust construction with precision engineering. Whether you're operating rolling mills, port cranes, or offshore wind systems, this bearing ensures reliable performance under 150°C temperatures and dynamic loads exceeding 6000kN.

Core Advantages

Built for Demanding Environments

-

150°C Heat Resistance: Forged from GCr15SiMn steel with carbide coating, our 22334 handles metallurgical furnace temperatures

-

20% Higher Load Capacity: Double-row rollers and optimized raceway geometry outperform ISO dynamic load standards

-

50,000+ Hour Lifespan: Precision grinding reduces friction wear, even under continuous 20kN radial loads

Rapid Availability

- 48-Hour Global Shipping: Pre-stocked φ170-360mm units ready for urgent needs

- Custom Sizes in 15 Days: Non-standard variants up to φ5000mm (70% faster than industry average)

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions (ID/OD/Width) | 170mm / 360mm / 120mm |

| Material | GCr15SiMn Steel (Raceways), Steel Cage |

| Precision Grade | P0/P6 (P4 Optional) |

| Load Capacity | 220kN Dynamic / 480kN Static |

| Temperature Range | -20°C to +150°C |

Where It Excels

Heavy Industry Champions

1. Steel Production

- Withstands rolling mill vibrations equivalent to 6.5 magnitude earthquakes

- 12-stage heat treatment prevents micro-cracks in continuous casting systems

2. Port Machinery

- IP68 sealing protects against saltwater corrosion in container cranes

- Embedded IoT sensors enable predictive maintenance (vibration <35dB)

3. Energy Sector

- Custom ceramic hybrids for wind turbine pitch control systems

- 99.9% defect-free rate validated by 12+ performance tests

Why Partner With Us

30+ Years of 22334 bearing Load-Bearing Expertise

- Integrated Production: 90% components made in-house for quality control

- Smart Customization:

- Redesign raceways within 72 hours for unique load profiles

- Modify cage designs for automated lubrication systems

- Global Support Network:

- On-site installation audits by certified engineers

- IoT-driven maintenance plans reduce downtime by 40%

- Quality Assurance:

- 3-stage inspection process (material/in-process/final)

- ABMA-compliant testing with load simulation up to 8000kN

Global Logistics Network

Regional Stock Availability

- Europe: 200+ units (Germany warehouse)

- Americas: 150+ units (Chicago hub)

- Asia-Pacific: Custom orders shipped within 15 days

FAQs

Q: How do you prevent premature wear in abrasive environments?

Our ESA-86G steel undergoes deep cryogenic treatment (-190°C) to enhance surface hardness by 3HRC.

Q: Can I get samples before bulk orders?

Yes - request φ170-500mm test units through our expedited sampling program (7-day lead time).

Q: What certifications do your products have?

All units meet ISO 9001 and ANSI/ABMA standards, with material traceability per EN 10204 3.2.

Q: How does your IoT monitoring work?

Embedded sensors track temperature/vibration trends, sending alerts when parameters exceed safe thresholds.

Q: What's your minimum custom order quantity?

We accept orders as low as 50 units for non-standard dimensions.

Contact Us

Optimize your heavy machinery today with the 22334 bearing - contact our engineers at sales@inno-bearing.com for load analysis and custom Solutions.

Learn about our latest products and discounts through SMS or email