- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

sealed spherical roller bearings

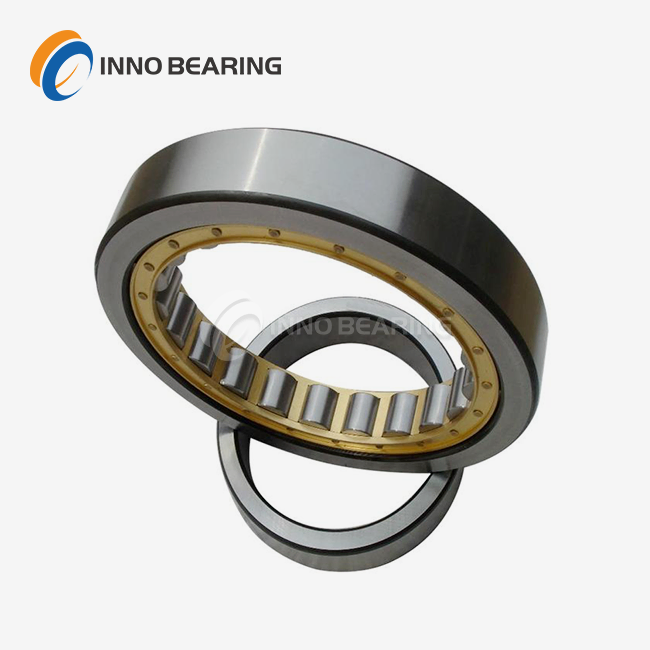

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with double-row rollers + stamped steel cage, and there are nitrile rubber sealing rings (2RS) on both sides.

3.Size Range: Inner diameter 30 - 500mm, outer diameter 62 - 800mm, width 20 - 150mm.

4.Material: Inner ring / outer ring: GCr15 bearing steel, rollers: GCr15 bearing steel, cage: stamped steel, seals: nitrile rubber / fluororubber.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: For inner diameters ≥ 50mm, a 1:12 tapered hole can be optionally selected, and most of the small inner diameters are straight holes.

7.Application Fields: Agricultural machinery, mining machinery (with dust), automobile chassis (in humid conditions), water pumps.

8.Key Inspection Items: Sealing protection performance, self-aligning flexibility, radial clearance.

High-Performance Sealed Spherical Roller Bearings for Extreme Industrial Environments

Engineered for 150°C Operations | IP6X Dust/Water Protection | 30% Faster Customization

In harsh industrial environments where dust, moisture, and heavy loads threaten equipment longevity, sealed Spherical roller bearings are the ultimate defense. At LUOYANG INNO BEARING, we specialize in designing double-row self-aligning bearings with advanced sealing systems that outperform standard models. With IP54 to IP65 protection, our bearings thrive in cement plants, mining sites, and metallurgical furnaces—saving you costly downtime and maintenance.

Why Our Sealed Bearings Outperform Competitors?

- Multi-Layer Sealing: Nitrile rubber or fluoropolymer seals block contaminants while retaining lubrication.

- Heavy-Duty Resilience: GCr15 steel construction handles radial loads up to 450kN.

- Self-Aligning Design: ±2.5° misalignment compensation for high-vibration applications.

- Temperature Mastery: Operate smoothly from -20°C to 150°C (higher ranges customizable).

Key Specifications

| Parameter | Details |

|---|---|

| Inner Diameter | 30mm – 500mm (custom up to 3000mm) |

| Sealing Standard | IP54/IP65 (IP69K optional) |

| Precision Grade | ISO P0/P6 (P4/P5 available) |

| Material | GCr15 steel, nitride-treated options |

| Lubrication | High-temperature grease compatible |

Where Our Sealed Spherical Roller Bearings Excel?

✅ Mining Crushers: IP65 seals prevent rock dust ingress in high-vibration zones.

✅ Steel Mill Conveyors: Withstand 150°C+ temperatures and molten debris.

✅ Agricultural Machinery: Waterproof seals endure muddy conditions.

✅ Port Cranes: Saltwater-resistant fluoropolymer seals reduce corrosion.

5 Reasons Industrial Leaders Choose Us

1. 30+ Years of Sealed Bearing Expertise

Our R&D team has engineered sealed Spherical Roller Bearings Solutions for 500+ projects in mining, cement, and energy sectors since 1995.

2. No-Surprise Customization

Modify bore sizes (tapered or straight), seal layers, or cage materials in 15 days—30% faster than industry averages.

3. Reliability Validated by Data

Every unit undergoes:

- IP6X dust/water resistance tests

- 500-hour accelerated lifespan simulations

- Vibration analysis (<35dB noise certification)

4. Global Compliance Ready

Bearings meet ISO 9001, CE, and MSHA standards. Medical-grade options (ISO 13485) available.

5. Agile Delivery, Zero Compromise

1,000+ sealed bearings in stock for 48-hour shipping. Custom φ3000mm orders delivered in 20 days.

Trust Through Transparency

Our Quality Control Process:

1. Material Hardness Testing (HRC 60-64)

2. In-Process Seal Compression Checks

3. 100% Post-Assembly RPM/Leakage Tests

“Why You?” Here's How We Stack Up

| Feature | INNO Bearing | Industry Average |

|---|---|---|

| Max Seal Layers | 3-5 | 1-2 |

| Lead Time (φ1000mm) | 12 days | 20+ days |

| Temp Limit (Standard) | 200°C | 150°C |

| Warranty Support | 3-year technical cover | 1-year limited |

FAQs

Q: Can you integrate sensors into sealed bearings for condition monitoring?

A: Yes! We embed temperature/vibration sensors without compromising IP ratings.

Q: How do your bearings reduce maintenance costs?

A: Our seals retain grease 3x longer, cutting relubrication cycles by 40%.

Q: Do you supply medical-grade sealed bearings?

A: Absolutely—ISO 13485-compliant units with ultra-clean seals are available.

Q: What if I need bearings for acidic environments?

A: Specify our PTFE-coated seals and stainless steel cages for chemical resistance.

Contact Us

Ready to Eliminate Bearing Failures?

Email our engineers at sales@inno-bearing.com for a customized solution. Share your operating conditions (temperature, load, contaminants), and we’ll reply with technical drawings within 24 hours.

LUOYANG INNO BEARING – Where Sealed Spherical Roller Bearings Meet Uncompromising Reliability.

Learn about our latest products and discounts through SMS or email