- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Double-Direction Angular Contact Thrust Ball Bearings

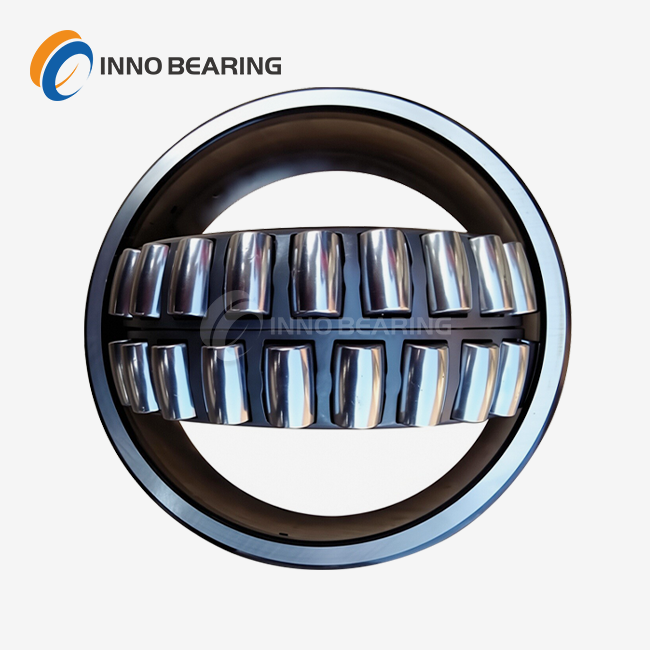

2.Structure Type: Intermediate washer + double shaft washers + double-row angular contact steel balls + brass cage, the intermediate washer has double raceways.

3.Size Range: Inner diameter: 20 - 200mm, outer diameter: 50 - 280mm, height: 18 - 50mm.

4.Material: Shaft washer: GCr15/GCR15SIMN/20Cr2Ni4A, intermediate washer: GCr15/GCR15SIMN/20Cr2Ni4A, rolling elements (angular contact steel balls): GCr15/GCR15SIMN, cage: brass.

5.Accuracy: Conventional P5 grade, ultra-precision model is of P4 grade.

6.Application Fields: Spindles of high-end machine tools, precision inspection equipment, aerospace auxiliary equipment.

7.Key Inspection Items: Bidirectional accuracy of contact angle, rotational accuracy, axial clearance (≤0.01mm).

Double-Direction Angular Contact Thrust Ball Bearings | High-Capacity Custom Solutions for Heavy-Duty Industrial Applications

When your machinery demands reliable bidirectional axial load management under extreme conditions, our Double-Direction Angular Contact Thrust ball bearings deliver unmatched precision and durability. Engineered for industries like metallurgy, aerospace, and heavy machinery, these bearings combine high-purity materials, customizable designs (up to φ5000mm), and ISO-certified quality to optimize performance in the most demanding environments.

Why Choose Us?

Precision Engineering for Extreme Loads

Designed with dual-row angular contact steel balls and a brass cage, these bearings handle bidirectional axial loads and slight radial forces without requiring complex pairing. Their intermediate washer with dual raceways ensures even stress distribution, making them ideal for:

-

High-speed machine tool spindles requiring ≤0.01mm axial clearance.

-

Port cranes exposed to shock loads up to 500 kN.

-

Steel rolling mills operating at 200°C+ with minimal lubrication degradation.

Built to Last in Harsh Environments

We use GCr15/GCR15SIMN steel for shaft and intermediate washers, paired with heat-treated angular contact balls, to achieve:

-

Wear resistance: 30% longer lifespan than standard bearings in dusty mining setups.

-

Impact resistance: Stable performance under 50G acceleration in agricultural machinery.

-

Temperature resilience: Consistent operation from -30°C to +150°C.

Customization Without Compromise

Need non-standard dimensions or enhanced load capacity? We adjust:

- Size: Inner diameter (20–200mm), outer diameter (50–280mm standard; up to φ5000mm custom).

- Material: Upgrade to 20Cr2Ni4A alloy for corrosive offshore wind turbine applications.

- Precision: P4-grade options for aerospace auxiliary systems requiring ≤35dB noise levels.

Where Our Bearings Excel?

Heavy Industry Solutions

-

Metallurgy: Bearings for continuous casting machines with high-temperature stability (150°C+).

-

Mining: Corrosion-resistant designs for underground conveyors handling 10,000+ hourly cycles.

-

Port Machinery: Low-noise, high-impact units for crane slewing rings (≤40dB).

Precision-Driven Sectors

- Aerospace: Vacuum-grade lubrication for satellite components exposed to -60°C to 150°C swings.

- Medical Equipment: Ultra-precise P4-grade bearings for MRI scanner positioning systems.

- EV Manufacturing: Lightweight aluminum cages for 20,000 RPM+ drivetrains.

Quality You Can Trust

Our three-stage quality control ensures every Double-Direction Angular Contact Thrust Ball Bearings meets strict benchmarks:

1. Raw Material Inspection: Spectrometer testing for steel purity.

2. In-Process Checks: Laser measurement of contact angles (±0.5° tolerance).

3. Final Validation: Vibration/noise testing (≤35dB), lifespan simulations.

Certifications: ISO 9001, IATF 16949, AS9100.

Order with Confidence

Fast Global Delivery

-

Standard units: Shipped within 48 hours from regional hubs (NA/EMEA/APAC).

-

Custom orders: 15–20-day lead time for φ3000mm+ designs.

End-to-End Support

- Pre-Sales: 3D CAD modeling, load simulation reports.

- Post-Sales: IoT-driven maintenance alerts, 24/7 technical support.

FAQ

Q: Can you customize bearings for φ5000mm mining equipment?

A: Yes! We adjust outer diameters, load capacities, and materials to match your specs.

Q: What certifications do your bearings hold?

A: We’re ISO 9001-certified and comply with industry-specific standards like GL Wind and AS9100.

Q: How do you ensure precision in medical-grade applications?

A: P4-grade bearings undergo extra grinding for ≤0.002mm axial clearance.

Contact Us

Need a Custom Solution with Double-Direction Angular Contact Thrust Ball Bearings?

📧 Contact our engineers at sales@inno-bearing.com for a tailored quote.

📥 Download the Technical Datasheet → [Insert Link]

Learn about our latest products and discounts through SMS or email