Full-scale manufacturing of Angular Contact Ball Bearings in 15–20 days, even for oversized bearings up to φ5000mm.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

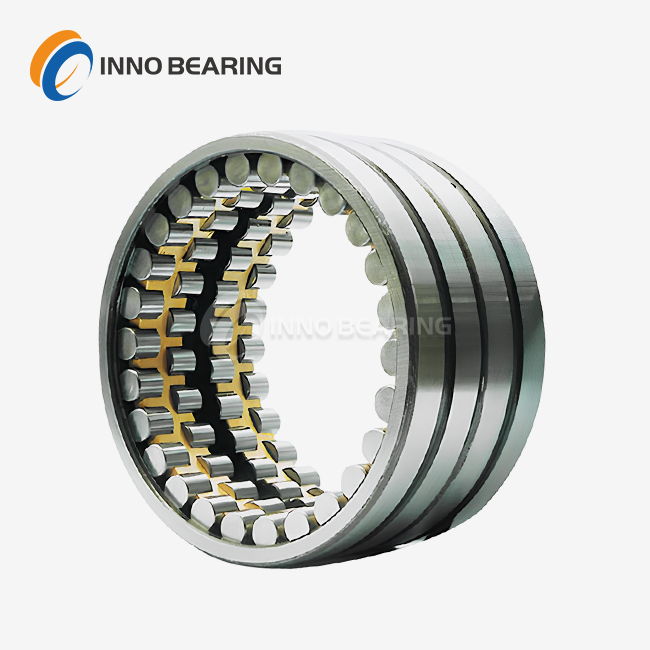

Angular Contact Ball Bearing

2.Structure Type: Inner ring + outer ring (thick-wall angular contact raceway, quenching depth ≥ 5mm) + large-diameter steel balls + steel cage, with strong impact resistance.

3.Size Range: Inner diameter: 30 - 600mm, outer diameter: 72 - 1000mm, width: 20 - 200mm.

4.Material: Inner ring / outer ring: GCr15/GCR15SIMN, rolling elements (steel balls): GCr15/GCR15SIMN, cage: steel (impact-resistant).

5.Accuracy: Conventional P0 grade, precision models are of P6/P5/P4 grades.

6.Application Fields: Spindles of heavy-duty machine tools, transmission ends of port cranes, mining machinery, large reducers.

7.Key Inspection Items: Hardness of the raceway (HRC60 - 65), axial load-bearing capacity (≥ 80kN), radial runout, integrity of steel balls.

Angular Contact Ball Bearing: Precision Performance for Demanding Applications

Technical Specifications

- Axial/Radial Load Capacity: Up to 300kN

- Temperature Range: -40°C to 500°C

- Precision Grades: P0 (ABEC-1) to P4 (ABEC-7)

- Noise Levels: <35dB (as low as 20dB for medical models)

- Sizes: Inner Diameter 30–600mm | Outer Diameter 72–1000mm

- Stock Availability: 1,000+ standard models ready for 48-hour global delivery

Angular contact ball bearings excel where precision, durability, and load capacity matter. Engineered with a 40° contact angle and reinforced raceways, our bearings handle medium-to-heavy axial/radial loads in extreme conditions.

Where Angular Contact Ball Bearings Deliver Results?

Metallurgical Machinery

Our high-temperature bearings (500°C+) withstand continuous operation in steel rolling mills, with axial load capacities exceeding 200kN.

Port Equipment

Impact-resistant models (IK10-rated) power crane slewing rings, surviving salt spray (1,000+ hours) and heavy shocks in container terminals.

Medical Devices

P4-grade low-noise bearings (<25dB) ensure smooth MRI scanner rotations, using biocompatible materials compatible with autoclave sterilization.

Custom-Built Angular Contact Bearings in 35 Days

Requirement Analysis

Define your needs:

-

Load profiles (axial/radial)

-

Operating environment (temperature, corrosion risks)

-

Precision tolerances (±0.001mm achievable)

Prototype Development

Receive testable samples within 15 days for:

-

Dimensional verification

-

Load testing

-

Environmental simulation

Bulk Production

Built to Last: Materials & Quality

| Component | Specification | |

|---|---|---|

| Raceways | GCr15 steel, HRC60–65 hardness | |

| Steel Balls | GCr15SiMn, oxide inclusion ≤0.5μm | |

| Cages | Impact-resistant steel |

Quality Assurance

- 100% dimensional inspection

- 99.9% defect-free rate

- 50,000-hour accelerated lifespan testing

Global Supply Chain Advantages

- Fast Shipping: 48-hour delivery to EU/US/Asia hubs

- Smart Packaging: Modular crates reduce damage risk

- Trade Compliance: Pre-cleared shipments to 60+ countries

Technical Support That Follows Your Purchase

- Bearing Failure Analysis: 72-hour diagnostic reports

- Retrofitting Services: Upgrade legacy equipment bearings

- IoT Monitoring: Real-time vibration alerts via mobile app

Why Engineers Trust Our Angular Contact Ball Bearings?

✅ 30+ Years Specialization: Focused R&D since 1992

✅ 40% Cost Savings: In-house tooling eliminates third-party fees

✅ 200+ Success Cases: Proven in mining drills, CNC spindles, and CT scanners

FAQ

Q: What certifications do your bearings hold?

A: ISO 9001, IATF 16949, CE, FDA 510(k), and GOST-R. Sector-specific certs available on request.

Q: Can I order just 1 custom bearing?

A: Yes – we accept MOQ 1 for prototypes and special applications.

Q: How long is the warranty?

A: 12–36 months based on application severity.

Contact Us

Global Compliance & Local Support

Our Angular Contact Ball Bearings meet ISO, DIN, and ANSI standards. Regional engineers in Germany, Texas, and Osaka provide onsite troubleshooting.

Need a Precision Solution? Contact Us at sales@inno-bearing.com for bearing specifications within 4 hours.

Learn about our latest products and discounts through SMS or email