- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

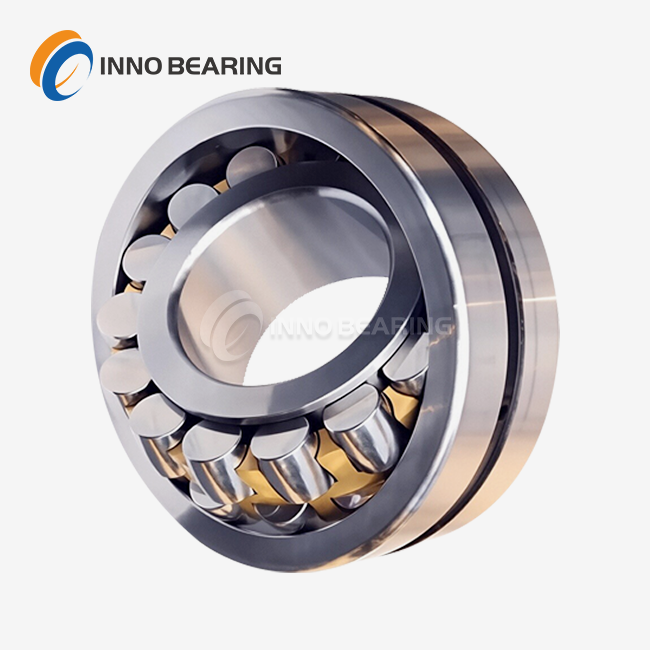

Thrust Ball Bearing

2.Structure Type: Unidirectional type (shaft washer + housing washer + single-row steel balls), bidirectional type (intermediate washer + double shaft washers + double-row steel balls), the cage separates the steel balls.

3.Size Range: Inner diameter: 10 - 300mm, outer diameter: 30 - 400mm, height: 8 - 50mm.

4.Material: Shaft washer: GCr15/GCR15SIMN/20Cr2Ni4A, housing washer: GCr15/GCR15SIMN/20Cr2Ni4A, intermediate washer: GCr15/GCR15SIMN/20Cr2Ni4A, rolling elements (steel balls): GCr15/GCR15SIMN, cage: stamped steel / brass.

5.Accuracy: Conventional P0/P6 grades, precision models are of P5 grade.

6.Application Fields: Machine tool spindles, water pumps, small motors, office equipment.

7.Key Inspection Items: Clearance between steel balls, flatness of shaft washer and housing washer, accuracy of rolling element arrangement.

High-Temp, Heavy-Load Thrust Ball Bearings Built for Metallurgical Machinery – Precision Engineered to Withstand 500°C+ & 30% Faster Delivery

Solve axial load challenges in extreme conditions with LUOYANG INNO BEARING's Thrust ball bearings. Designed for metallurgical machinery, our bearings handle temperatures exceeding 500°C, heavy axial loads, and corrosive environments while ensuring precision and longevity. With 1,000+ standard models in stock and custom Solutions delivered 30% faster than competitors, we keep your operations running smoothly.

Why Choose Us?

- Extreme Durability: 25% higher load capacity than industry standards, built to endure 150°C+ environments.

- 48-Hour Global Delivery: Immediate shipping for 1,000+ standard models.

- Tailored Solutions: Custom dimensions (up to φ5000mm OD), materials, and sealing for harsh applications.

- Lifetime Support: IoT-driven maintenance alerts and installation guidance to minimize downtime.

Technical Specifications

| Parameter | Specification |

|---|---|

| Inner Diameter | 10 – 300mm |

| Outer Diameter | 30 – 400mm (Custom up to φ5000mm) |

| Axial Load Capacity | Up to 200 kN (Customizable for higher loads) |

| Temperature Limit | 150°C+ (HT Series with ceramic hybrids) |

| Noise Level | <35dB for medical-grade precision |

Materials

- Raceways: GCr15/GCR15SIMN/20Cr2Ni4A steel, heat-treated for wear resistance.

- Balls: GCr15 or ceramic hybrids for high-temperature stability.

- Cages: Stamped steel or brass for reduced friction.

Where Our Thrust Ball Bearings Excel?

✅ Rolling Mill Gearboxes

Withstand heavy axial loads up to 200 kN, preventing premature failure in steel processing.

✅ Smelting Furnace Conveyors

Ceramic hybrid balls and heat-resistant lubrication ensure smooth operation at 150°C+.

✅ Heavy Press Machinery

Impact-resistant design reduces deformation under sudden load spikes.

Customization Made Simple

1. Share Requirements: Submit load, speed, temperature, and dimensions.

2. Get a 3D Model: Receive CAD designs and material recommendations in 72 hours.

3. Test Prototypes (Optional): Validate performance with real-condition testing.

4. Fast Production: Bulk orders ready in 15–20 days – 30% faster than industry averages.

Rigorous Quality Assurance

Every thrust ball bearing undergoes:

- 12+ Performance Tests: Lifespan simulation, vibration analysis, and thermal cycling.

- Material Inspections: Spectrometer checks for alloy consistency.

- Precision Grinding: Raceways polished to ≤0.001mm tolerance.

Result: 99.9% defect-free rate from raw material to final packaging.

Global Supply Chain Advantage

- Regional Warehouses: Stock available in EU, Asia, and North America.

- Urgent Orders: Priority production slots for emergency replacements.

- Transparent Tracking: Monitor your order from factory to facility.

Your Support Team – Before and After Purchase

- Pre-Installation Analysis: Optimize bearing selection based on machinery conditions.

- Predictive Maintenance: IoT sensors alert you to lubrication needs or wear patterns.

- 24/7 Technical Hotline: Resolve operational hiccups in real time.

Ready to Upgrade Your Machinery?

📥 Download Full Catalog

Explore 1,000+ standard product specs for metallurgical, medical, and industrial use.

✉️ Request a Custom Quote

Get a tailored solution design and pricing within 72 hours.

FAQ

Q: How do your bearings handle 500°C+ temperatures?

A: We use martensitic steel raceways and ceramic hybrid balls, paired with heat-resistant greases.

Q: Can you make bearings larger than φ3000mm?

A: Yes! Our XL Series supports OD up to φ5000mm, ideal for rolling mills.

Q: What ensures faster delivery for custom orders?

A: Modular production lines and pre-engineered components cut lead times by 30%.

Q: Do you assist with installation?

A: Absolutely – we provide step-by-step guides and live video support.

Contact Us

Contact Our thrust ball bearing Experts Today

🌐 www.inno-bearing.com

Learn about our latest products and discounts through SMS or email