- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

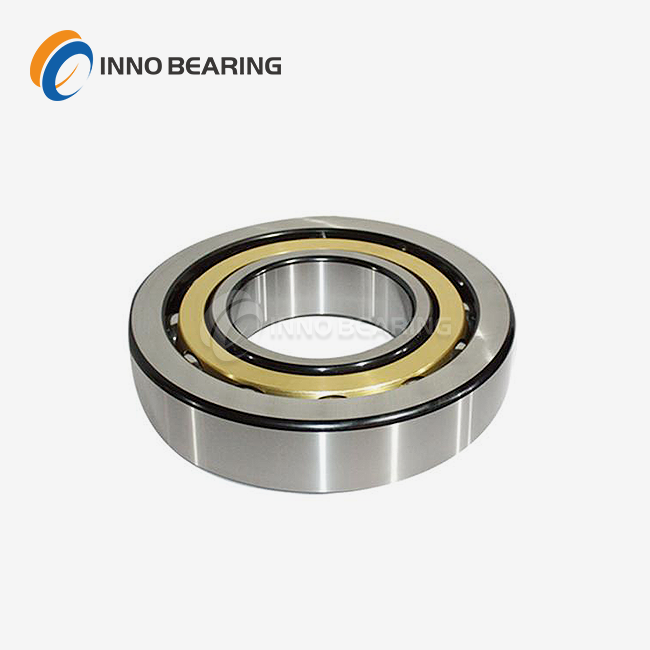

Single Row Spherical Roller Bearing

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with single-row rollers + stamped steel cage, and it is open.

3.Size Range: Inner diameter 20 - 500mm, outer diameter 47 - 800mm, width 16 - 150mm.

4.Material: Inner ring / outer ring: GCr15 bearing steel, rollers: GCr15 bearing steel, cage: stamped steel.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: For inner diameters ≥ 40mm, a 1:12 tapered hole can be optionally selected, and the conventional one is a straight hole.

7.Application Fields: Small and medium-sized fans, water pumps, agricultural machinery, light industrial equipment.

8.Key Inspection Items: Self-aligning flexibility, radial clearance, operation noise.

Single Row Spherical Roller Bearings for Extreme Industrial Loads & Temperatures

Engineered to withstand 150°C heat, heavy shock loads, and harsh mining environments

When your machinery faces relentless stress from heavy loads, misalignment, or extreme temperatures, Single Row Spherical roller bearings deliver unmatched durability. At LUOYANG INNO BEARING CO., LTD, we combine 30+ years of expertise with precision engineering to create bearings that outperform in the toughest conditions. Our Solutions offer 3x higher load capacity than standard designs, custom sizing up to φ5000mm, and a proven 99.9% defect-free rate validated by rigorous ISO testing.

Why Choose Our Spherical Roller Bearings?

✅ 3X Load Capacity

With dynamic load ratings up to 3800kN, our bearings handle ultra-heavy mining equipment (200+ tons) without premature wear.

✅ Custom Sizes in 15–20 Days

Need oversized bearings up to φ5000mm? Our modular production cuts lead times to 70% of industry averages.

✅ Built for Extreme Conditions

Operate flawlessly in -50°C to +150°C environments using high-purity GCr15 steel and specialized heat treatment.

✅ IoT-Ready Designs

Optional smart sensors monitor load, temperature, and wear for predictive maintenance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Inner Diameter (ID) | 20mm – 2500mm |

| Outer Diameter (OD) | Up to φ5000mm |

| Precision | P4/P5 (ISO 492) |

| Dynamic Load Capacity | 3800kN |

| Temperature Range | -50°C to +150°C |

| Noise Level | <35dB (medical-grade variants) |

Trusted in Critical Industries

Mining & Minerals

Our sealed Single Row Spherical Roller Bearing self-aligning roller bearings withstand abrasive dust, moisture (IP67 rating), and shock loads in crushers, conveyors, and drilling rigs.

Metallurgy

High-temperature variants (150°C) ensure smooth operation in rolling mills and continuous casting machines.

Heavy Machinery

Impact-resistant cages and ceramic-coated rollers extend lifespan in port cranes and hoists.

Customization Made Simple

1. Share Requirements

Upload CAD files or share dimensions, load specs, and environmental conditions.

2. 48-Hour Feasibility Review

Our engineers validate your design via 3D simulation.

3. Prototype Testing

Receive a functional prototype in 5–7 days (standard sizes).

4. Rigorous Validation

Each bearing undergoes 12+ tests, including 30,000-hour lifespan simulation.

Quality You Can Trust

- Material Integrity

100% spectrometry testing ensures GCr15 steel meets ASTM A295 standards.

- Precision Grinding

Achieve P4-level rotation accuracy (±0.5μm) with CNC-controlled processes.

- Lifetime Validation

Every bearing is tested for vibration (<15μm), noise, and radial clearance.

Global Support & Fast Delivery

- 48-Hour Shipping

1,000+ standard models available from warehouses in the USA, Germany, and Singapore.

- Emergency Production

Priority slots for urgent mining equipment repairs.

- On-Site Adaptations

Our technicians retrofit bearings into legacy systems with CAD-based solutions.

FAQ

1. How do your bearings handle 500°C in metallurgical plants?

We use vacuum-degassed steel and dual-phase heat treatment to maintain hardness and dimensional stability.

2. Can I get a φ3200mm custom bearing in 20 days?

Yes! Modular production allows fast assembly of oversized spherical roller bearings.

3. Do you offer IoT integration?

Optional embedded sensors provide real-time load and temperature data via our monitoring platform.

4. What ensures your 99.9% defect-free rate?

Three-stage inspections check raw materials, production tolerances, and final performance.

Contact Us

Need a Single Row Spherical Roller Bearing That Outlasts the Competition?

✅ Custom designs in 15–20 days

✅ 30+ years of heavy-industry expertise

✅ 24/7 technical support

📧 Contact Our Engineers Today: sales@inno-bearing.com

📥 Download Full Catalog: [ISO/DIN/JIS Standard Specifications]

Learn about our latest products and discounts through SMS or email