- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

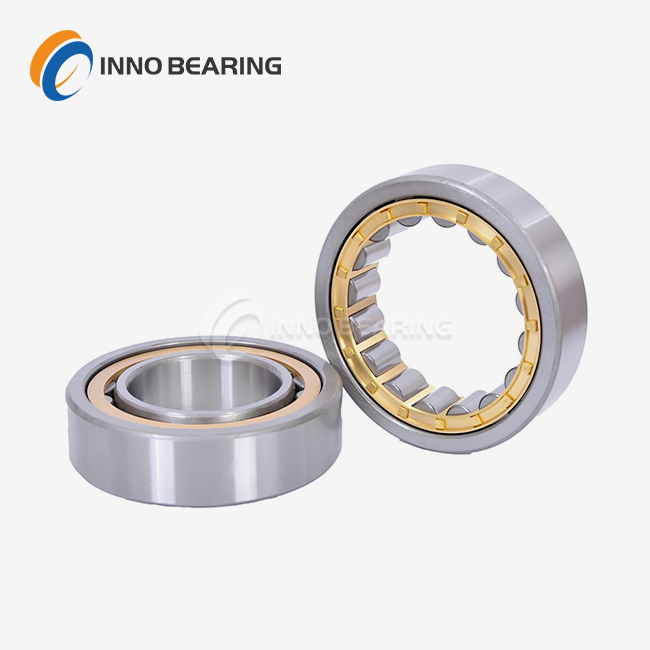

Thrust Bearing

2.Structure Type: Shaft washer + housing washer + rolling elements (steel balls or rollers) + cage, open type or with seals.

3.Size Range: Inner diameter: 10 - 600mm, outer diameter: 30 - 800mm, height: 8 - 100mm.

4.Material: Shaft washer: GCr15/GCR15SIMN/20Cr2Ni4A, housing washer: GCr15/GCR15SIMN/20Cr2Ni4A, rolling elements: GCr15/GCR15SIMN, cage: stamped steel / brass.

5.Accuracy: Conventional P0/P6 grades, precision models are of P5 grade.

6.Application Fields: Axial support of machine tools, motors, construction machinery, mining equipment.

7.Key Inspection Items: Axial load-bearing capacity, rotational flexibility, integrity of rolling elements.

Thrust Bearings: Precision Axial Load Solutions for Industrial Excellence

When your machinery requires reliable axial load support, LUOYANG INNO BEARING's Thrust bearings deliver unmatched durability and precision. With over 30 years of expertise, we engineer products tailored to withstand extreme conditions—from 500°C metallurgical kilns to saltwater-heavy offshore environments. Our modular production system ensures rapid delivery of standard (≤φ5000mm) and custom designs, backed by cross-industry validation in wind energy, medical tech, and heavy machinery.

Technical Specifications & Product Range

Core Features:

- Dimensions: Standard (φ50mm–φ5000mm) | Custom sizes up to φ8000mm

- Load Capacity: Axial static loads up to 1,200kN | Combined radial/axial configurations

- Temperature Range: -50°C to 150°C (material-specific)

- Precision Grades: P0 (standard) to P4 (ultra-low-noise medical grade)

- Materials: GCr15 steel, 20Cr2Ni4A alloys, ceramic hybrids

Design Variations:

- Ball Thrust Bearings: Ideal for moderate loads (e.g., automotive steering)

- Roller Thrust Bearings: Optimized for heavy loads (e.g., crane slewing rings)

- Sealed/Open Types: IP69K-rated seals for corrosive environments

Customization Process: From Concept to Installation

1. Requirement Analysis

Share your load profiles, RPM, and environmental challenges. We’ll simulate scenarios using CAD tools.

2. Prototyping & Validation

Receive 3D models for approval within 72 hours. Test prototypes under real-world conditions.

3. Modular Manufacturing

Our pre-machined components reduce production time by 70% vs. traditional methods.

4. Rigorous Testing

Every thrust bearing undergoes vibration analysis, lifespan simulations, and noise level checks.

Quality Assurance & Certifications

- Material Traceability: 100% raw steel purity checks via spectrometry

- Production Standards: ISO 9001, IATF 16949, GL Wind Certification

- Defect Prevention: 99.9% defect-free rate achieved through precision grinding and heat treatment

Industry-Specific Thrust Bearing Solutions

Wind Turbine Systems

-

Offshore-Grade Bearings: ZrN-coated rollers + polymer seals survive 1,000+ salt-spray hours

-

IoT-Enabled Monitoring: Embedded sensors predict maintenance needs, reducing downtime by 30%

Steel Production Mills

-

150°C-Ready Designs: Heat-treated alloy cages handle rolling mill axial shocks

Medical Imaging Equipment

- P4-Grade Precision: <35dB operation ensures MRI compatibility

Fast-Track Logistics & Support

- 48-Hour Global Shipping: 1,000+ standard units in stock

- Bulk Order Optimization: Save 15% on 500+ unit orders with consolidated shipments

- Custom Lead Times: 15 days for φ3000mm+ bearings

Why Partner With LUOYANG INNO BEARING?

1. 30+ Years of Axial Load Expertise: Focused solely on product innovation

2. Dual-Channel Supply Chain: Self-produced cores + vetted partners ensure quality control

3. Lifecycle ROI: Precision grinding extends service life by 20% vs. industry averages

FAQ

Q: Can you replicate discontinued products for legacy equipment?

A: Yes! We reverse-engineer old units using 3D scanning and material analysis.

Q: How do your bearings handle saltwater corrosion?

A: Offshore-grade models use ZrN coatings and IP69K seals, tested per ASTM B117 standards.

Q: What’s your lead time for φ4000mm custom products?

A: 18 days on average—50% faster than competitors via modular assembly.

Contact Us

Need a Thrust Bearing That Outperforms?

Contact our engineers at sales@inno-bearing.com for load analysis or urgent quotes.

Engineered for axial excellence. Built to outlast.

Learn about our latest products and discounts through SMS or email