- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

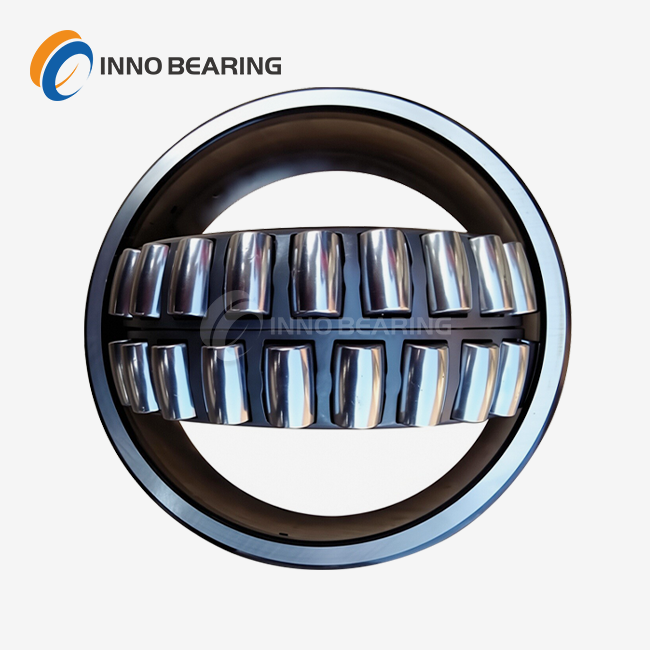

roller bearing slewing ring

2.Structure Type: It has a thick-wall annular shape. The inner and outer rings have double raceways, with built-in single-row or multi-row cylindrical or tapered rollers, steel cages, heavy-duty seals, and the mounting holes have anti-loosening designs.

3.Size Range: Outer ring diameter: 500 - 3000mm, inner ring diameter: 450 - 2850mm, height: 25 - 100mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Port cranes, metallurgical equipment, large wind power main units, heavy-duty mining machinery.

6.Key Inspection Items: Roller assembly clearance, anti-overturning moment, dust-proof performance of seals.

High-Performance Roller Bearing Slewing Rings for Heavy Industrial Machinery

Engineered for Extreme Loads, Precision, and Longevity in Metallurgy, Mining, and Port Equipment

When your machinery faces relentless heavy loads, abrasive dust, or scorching temperatures, a roller bearing slewing ring isn't just a component—it's your operational lifeline. At LUOYANG INNO BEARING CO., LTD, we've spent 30+ years perfecting slewing rings that outlast industry standards, combining unmatched load capacity (up to 15,000kN axial) with precision engineering for industries where downtime isn't an option.

Precision-Built for Harsh Environments

Technical Specifications & Customization

- Size Range: Standard (φ500mm–φ3000mm) / Custom (up to φ5000mm)

- Load Capacity: Radial (up to 10,000kN), Axial (up to 15,000kN)

- Materials: High-purity 50Mn/42CrMo steel rollers, nitrile/FKM seals

- Precision: ISO P5-P6 grades (standard), P4 for medical/robotics

- Temperature Resistance: -40℃ to +150℃ (custom heat-treated options)

Customize Your Solution:

- Flange designs for retrofitting legacy equipment

- IoT-ready sensor ports for predictive maintenance

- Multi-row tapered rollers for compact, high-load applications

Optimized Solutions for Critical Industrial Scenarios

Metallurgy: Surviving the Furnace

Our high-temperature roller bearing slewing rings handle molten metal ladle cranes (150℃ continuous operation) with low-deformation alloy steel and carburized raceways.

Port Machinery: Defying Impacts

Port cranes demand wear-resistant slewing rings—our hardened rollers and shock-absorbing raceway geometry extend service life by 20% in high-impact container handling.

Mining: Conquering Corrosion

Sealed against abrasive dust and moisture, our mining-grade slewing rings use zinc-nickel coatings and multi-labyrinth seals to cut premature failures by 35%.

Rigorous Processes for Reliable Performance

Manufacturing Excellence:

1. Forging: Ultra-dense alloy steel billets reduce internal voids.

2. Heat Treatment: Carburizing/nitriding for surface hardness ≥60 HRC.

3. Grinding: Raceway roughness ≤0.4μm Ra for smooth rotation.

Quality Assurance:

- 100% raw material spectrometry checks

- 3D coordinate inspection (±0.005mm accuracy)

- 12+ performance tests (vibration, noise, lifespan)

Fast Delivery, Lifelong Partnership

- Standard Orders: 1,000+ SKUs ship in 48 hours globally.

- Custom Projects: φ3000mm+ slewing rings delivered in 25 days.

- 24/7 Support: Installation guidance, IoT maintenance alerts, retrofit mapping.

Why Choose Us?

✅ No Subcontracting: Full control over forging, machining, and QA.

✅ Material Science Edge: 15% higher fatigue strength vs. standard bearings.

✅ Agile Scalability: Produce 50+ custom projects simultaneously.

FAQ

1. How do your slewing rings handle 150°C in metallurgy?

We use SAE 4320 steel with carburized surfaces and high-temp grease.

2. What's your lead time for φ5000mm custom slewing rings?

20 days max—30% faster via modular production and dedicated project tracking.

3. Can you retrofit outdated machinery?

Yes! Send legacy bearing specs or invite our engineers for on-site mapping.

4. Do you provide load simulation reports?

Absolutely—FEA-based load distribution analysis comes standard with every custom order.

Contact Us

Request a Roller Bearing Slewing Ring Solution Tailored to Your Machinery

📧 Email Our Engineers: sales@inno-bearing.com

🔧 Get a Custom Quote in 8 Hours

📦 Explore 1,000+ Standard SKUs

Engineered to endure. Built to outperform. Trusted by global heavy industry leaders since 1993.

Learn about our latest products and discounts through SMS or email