- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

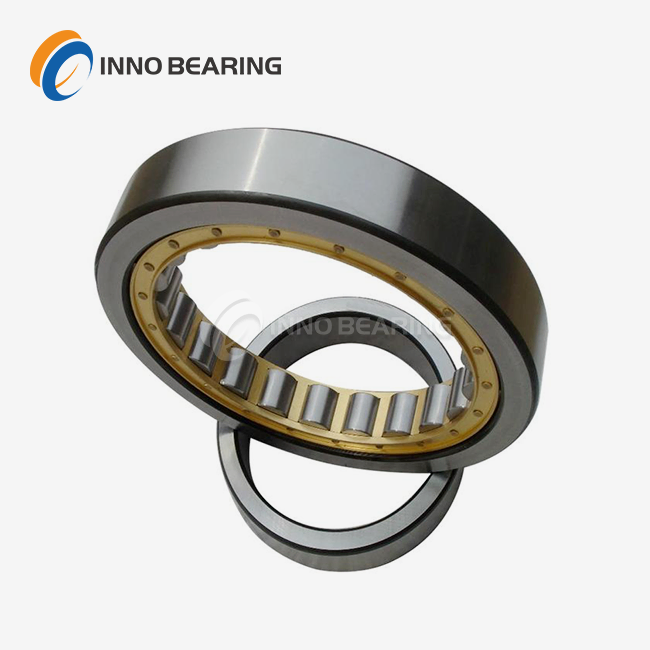

Cylindrical Bearing

2.Structure Type: The inner ring / outer ring have ribs, with a single row of rollers + cage, and it is open - type / sealed, and the inner ring / outer ring are separable.

3.Size Range: Inner diameter 10 - 1000mm, outer diameter 26 - 2000mm, width 8 - 300mm.

4.Material: Inner ring / outer ring / rollers: GCr15/GCR15SIMN/20Cr2Ni4A, cage: stamped steel / brass.

5.Precision: P0/P6 level, precision version is P5 level.

6.Application Fields: Electric motors, machine tools, reducers, automobiles, construction machinery.

7.Key Inspection Items: Radial clearance, roller parallelism, dimensional accuracy.

High-Performance Cylindrical Bearings for Heavy-Duty & Precision Applications

30+ Years of Expertise in Customized Solutions for Metallurgy, Port, and Medical Industries

Cylindrical bearings are engineered to handle heavy radial loads while maintaining high rotational speeds, making them indispensable in industries where durability and precision matter. At LUOYANG INNO, we specialize in crafting Cylindrical roller bearings that excel in extreme conditions—from scorching metallurgical mills to high-speed port cranes and noise-sensitive medical devices. With over three decades of expertise, we deliver tailored solutions that balance performance, longevity, and cost-efficiency.

Why Choose Us?

✅ Industry-Specific Engineering

From φ10mm miniaturized bearings for medical robotics to φ5000mm heavy-duty variants for port logistics, our designs are optimized for:

- Metallurgy: Withstand temperatures up to 150°C and radial loads exceeding 800kN.

- Port Machinery: IP66-sealed bearings resist saltwater corrosion and abrasive dust.

- Medical Devices: P4-grade precision (≤2μm runout) and noise levels below 40 dB(A).

✅ Rigorous Quality Assurance

Every cylindrical roller bearing undergoes triple inspections:

1. Raw material spectrometry for steel purity.

2. Real-time dimensional accuracy checks during production.

3. 100% final testing for noise, vibration, and load capacity.

✅ Agile Production & Delivery

- 1,000+ standard SKUs shipped within 48 hours.

- Custom designs produced 70% faster than industry averages.

Technical Specifications

| Parameter | Details |

|---|---|

| Sizes | ID 10–1000mm, OD 26–2000mm, Width 8–300mm |

| Materials | GCr15 steel, brass/stamped steel cages |

| Precision | P0/P6 (standard), P5 (high-precision) |

| Load Capacity | Up to 800kN radial load |

| Temperature Range | -30°C to +150°C |

Built for Demanding Applications

🏭 Metallurgy & Heavy Machinery

Our HT-Series cylindrical bearings use carburized steel cores and advanced heat treatment to prevent deformation under 100+ ton loads. Ideal for rolling mills and forging presses.

🚢 Port & Offshore Equipment

SHX-Series bearings feature integrated seals and 60–65 HRC hardness to survive 10,000+ hours in abrasive, high-vibration environments like container cranes.

🏥 Medical Imaging Systems

NanoPro-Series bearings achieve P4-grade precision with ceramic hybrid rollers, eliminating vibration interference in MRI/CT scanners.

Customization Made Simple

1. Share Requirements: Load, speed, environmental conditions.

2. Simulate & Prototype: CAD models delivered in 72 hours.

3. Produce & Certify: Full documentation for ISO 13485 (medical) or DNV-GL (marine).

Quality Control Process

1. Material Testing: Spectrometers verify steel purity and hardness.

2. Production Monitoring: Automated systems check roller parallelism (±0.002mm).

3. Final Validation: Load tested at 120% rated capacity; noise levels measured in anechoic chambers.

Fast Global Delivery

- 🌍 12 regional hubs stock φ20–2000mm standard bearings.

- 📦 Priority air shipping available for urgent orders.

FAQs

Q: What's the minimum order quantity for custom products?

A: No MOQ! We support prototyping even for single-unit validation.

Q: How do you ensure medical-grade bearing cleanliness?

A: Medical bearings are assembled in ISO Class 5 cleanrooms with biocompatible greases.

Q: Can you modify existing bearing designs?

A: Yes! Send us your CAD files—we'll optimize seals, cages, or materials in ≤48 hours.

Contact Us

Trusted by Industries Worldwide

🛡️ 12-month warranty on all Cylindrical Bearing.

🔧 24/7 technical support with failure analysis reports.

📩 Need a Bearing That Outperforms?

Email our engineers at sales@inno-bearing.com for free technical consultations or custom quotes.

Optimized for radial loads, speed, and reliability—your machinery deserves INNO precision.

Learn about our latest products and discounts through SMS or email