Every Four Row Cylindrical Roller Bearing undergoes 12+ quality tests, including vibration analysis and lifespan simulation, to meet P4-grade tolerances.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

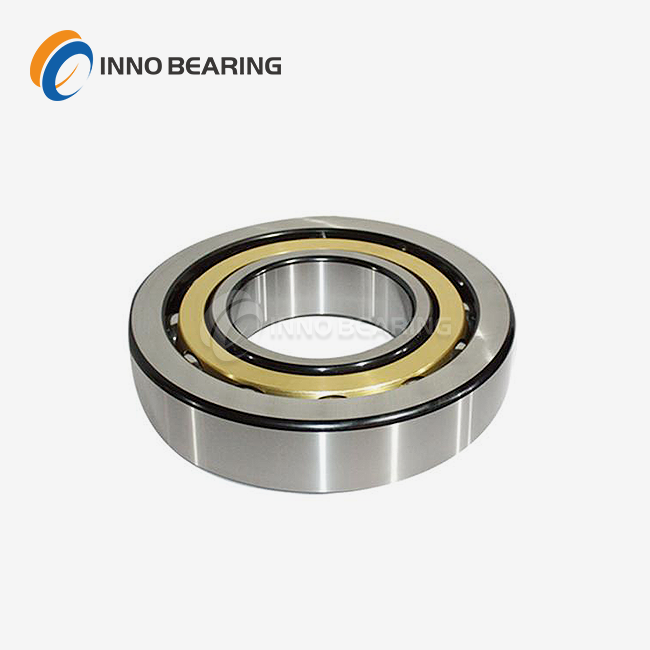

Four Row Cylindrical Roller Bearing

2.Structure Type: Integrally forged inner ring/outer ring, four-row rollers + cage, multiple spacer rings, metal seal.

3.Dimension Range: Inner diameter: 100-2000mm, Outer diameter: 200-3000mm, Width: 80-500mm

4.Material: Inner ring/Outer ring/Rollers: GCr15/GCr15SiMn/20Cr2Ni4A; Cage: Stamped steel/brass

5.Accuracy: Class P0/P6, Class P5 for special requirements

6.Application Fields: Rolling mill work rolls/support rolls, mining machinery spindles, port ultra-heavy cranes

7.Key Inspection Items: Forging flaw detection (UT/MT), clearance consistency of four-row rollers, radial load capacity (≥10000kN)

High-Capacity Four Row Cylindrical Roller Bearings for Extreme Industrial Environments (150°C/Heavy Loads)

Customized Solutions for metallurgical, mining, and port machinery with 48-hour standard delivery and ISO-certified durability.

Engineered for Extreme Performance

When your equipment faces relentless heavy loads, high temperatures, or shock impacts, our Four Row Cylindrical roller bearings deliver unmatched stability. Designed with four rows of precision-ground rollers and reinforced spacer rings, these bearings distribute stress evenly, achieving 3.5x higher radial load capacity than single-row designs. Whether you're operating rolling mills at 150°C or port cranes lifting 1,000+ tons, our solutions ensure minimal downtime and maximum productivity.

Core Specifications

- Dimensions: Inner Diameter 100mm–5000mm (custom sizes available)

- Load Capacity: Radial up to 12,000kN | Axial up to 3,500kN

- Temperature Range: -50°C to +150°C (high-purity steel + advanced heat treatment)

- Precision: P4/P5 grades for smooth operation under heavy loads

- Lubrication: Pre-lubricated with high-temperature grease or IoT-enabled oil systems

Where They Excel?

Metallurgy

Withstand scorching 150°C environments in rolling mills, backed by carburized steel that resists thermal deformation.

Mining

Absorb shock loads ≥2.5x nominal capacity in crushers, thanks to double-crowned rollers and brass cages.

Ports

Operate at ≤35dB noise levels in crane trolleys, using corrosion-resistant coatings for saltwater environments.

Why Choose Us?

✅ Precision Manufacturing

✅ Rapid Customization

Get non-standard bearings up to φ5000mm in 15-20 days – 70% faster than industry averages.

✅ Built to Endure

99.9% of bearings pass ex-factory inspections for wear resistance, load capacity, and thermal stability.

✅ Always Supported

From IoT-based performance monitoring to 24/7 technical guidance, we optimize your bearing’s lifecycle.

Trusted Compliance & Testing

- Material Certificates: Traceable GCr15/SAE 52100 steel with oxygen content ≤12ppm.

- Load Testing: Validated radial/axial load thresholds via hydraulic rigs.

- Compatibility Guides: Detailed dimension charts for retrofitting legacy equipment.

Fast Global Delivery

- Regional Stocks: 1,000+ standard units available in EU/NA/Asia hubs.

- Secure Packaging: Anti-rust vacuum seals + steel-reinforced crates for oversized bearings.

- Lead Times: 48 hours for standard sizes | 15-20 days for custom φ3000mm+ orders.

Get Your Solution Now

[Request Technical Datasheet] – Specify your industry and application.

[Get Custom Quote in 4 Hours] – Upload your bearing requirements.

Prefer direct support? Chat live with our engineers (GMT/EST/CST).

FAQ

1. How do your bearings handle 150°C temperatures?

We use carburizing heat treatment on ultra-clean steel, enhancing thermal stability without compromising load capacity.

2. Can you make bearings over φ5000mm?

Yes. Our modular production system allows custom outer diameters up to φ5000mm with a 20-day lead time.

3. How is the 99.9% quality rate achieved?

Raw materials are tested via UT/MT, followed by in-process checks on roller alignment, hardness, and clearance consistency.

4. Do you support legacy machinery upgrades?

Our retrofit kits include pre-machined spacer rings and installation guides tailored to your equipment’s specs.

5. What lubrication options exist for mining?

Choose graphite-based grease for high temperatures or automated oil systems with IoT viscosity sensors.

Contact Us

Need a reliable partner for Four Row Cylindrical Roller Bearing heavy-duty bearings?

Email our engineers at sales@inno-bearing.com – responses within 4 hours.

Learn about our latest products and discounts through SMS or email