- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

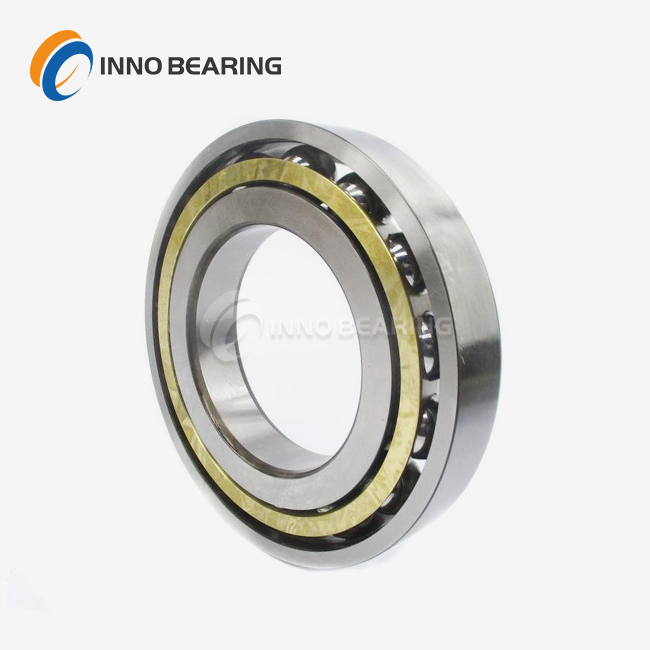

single row ball slewing bearing

2.Structure Type: It consists of an inner ring, an outer ring, a single row of high-precision steel balls, cages and seals. The inner and outer rings are equipped with a single arc raceway, with nitrile rubber sealing covers on both sides, and the outer ring has through mounting holes.

3.Size Range: Outer ring diameter: 150 - 1800mm, inner ring diameter: 120 - 1650mm, height: 12 - 60mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Small construction machinery (mini excavators), amusement equipment (merry-go-rounds), light logistics equipment (turntable conveyors).

6.Key Inspection Items: Steel ball clearance, position accuracy of mounting holes, no cracks on the appearance.

High-Performance Single Row Ball Slewing Bearings for Extreme Industrial Applications

Engineered for Heavy Loads (Up to 1,500 kN·m), High Temperatures (500°C+), and Rapid Customization – Delivered in 15–20 Days.

When your machinery faces extreme loads, corrosive environments, or non-standard design challenges, LUOYANG INNO's single row ball slewing bearing delivers unmatched reliability. Built with 30+ years of engineering expertise, these bearings combine robust construction (50Mn/42CrMo steel), precision P5-grade performance, and rapid customization to keep heavy machinery running smoothly in mining, metallurgy, and port operations. Whether you need a standard model shipped in 48 hours or a φ5000mm custom solution, we ensure minimal downtime and maximum durability.

Why Choose Us?

✅ Proven Heavy-Duty Performance

- Withstand axial/radial loads up to 1,500 kN·m and temperatures from -50°C to +150°C.

- Ideal for high-impact environments like mining excavators and port cranes.

✅ Fast Customization & Delivery

- Custom designs up to φ5000mm approved in ≤3 days.

- 70% faster lead times: Non-standard bearings (e.g., φ3000mm) delivered in 25-30 days.

✅ Rigorous Quality Assurance

- 99.9% defect-free rate via 3-stage inspections: Material checks → Process control → Final load/noise testing.

✅ Global Technical Support

- On-site installation guidance, IoT-driven predictive maintenance, and 24/7 engineering consultations.

Technical Specifications

| Parameter | Specification |

|---|---|

| Outer Ring Diameter | 150mm – 1800mm (Custom up to 5000mm) |

| Dynamic Load Capacity | Up to 1,500 kN·m |

| Material | 50Mn, 42CrMo Steel / GCr15 Bearing Balls |

| Precision Grade | ISO P6 (Noise <60dB) |

| Sealing | Nitrile/Fluororubber (IP65 Rated) |

Industry-Specific Solutions

🏗️ Mining & Construction Machinery

-

Reinforced raceways and heat-treated steel (HRC 58-62) prevent deformation under repetitive impacts.

🚢 Port Cranes & Logistics Systems

- Triple-sealed single row ball slewing bearing designs resist saltwater corrosion while ensuring smooth 360° rotation.

Customization Made Simple

1. Share Requirements: Provide load, dimensions, and environmental conditions.

2. Prototype & Approve: Receive CAD models and simulation results within 72 hours.

3. Production & Delivery: Track real-time quality data and expect fast shipping.

Trusted by 500+ Manufacturers Globally

Our bearings meet ISO 9001, CE, and ATEX standards, with regional warehouses ensuring timely delivery across Europe, Asia, and the Americas.

FAQ

1. How do your bearings handle extreme temperatures in metallurgical applications?

We use graphite cages to stabilize performance up to 120°C.

2. Can you customize a product for φ3000mm+ sizes?

Yes! Submit your specs, and we'll deliver CAD designs in 3 days.

3. What materials ensure wear resistance in mining environments?

42CrMo steel cores + specialized heat treatment (HRC 58-62) combat abrasion.

4. How does your quality control guarantee 99.9% defect-free bearings?

Every unit undergoes spectral analysis, precision grinding checks, and final load testing.

5. Do you offer IoT-based maintenance for Slewing Bearings?

Yes – our smart sensors predict failures, reducing unplanned downtime by 40%.

Contact Us

Ready to Optimize Your Single Row Ball Slewing Bearing Machinery?

📩 Request a Custom Quote – Get tailored specifications within 24 hours.

📥 Download Technical Datasheet – Detailed performance metrics (PDF).

Contact Us Today: Email sales@inno-bearing.com for engineering support or urgent orders.

Learn about our latest products and discounts through SMS or email