- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

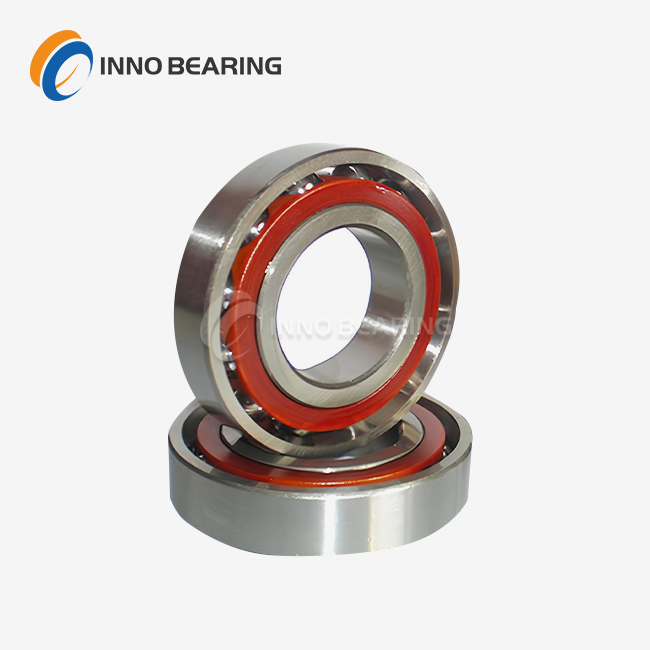

Large Cylindrical Roller Bearing

2.Structure Type: Outer ring with double ribs (partially split type), separable inner ring, single-row/double-row rollers + cage, metal seal.

3.Dimension Range: Inner diameter: 300-2000mm, Outer diameter: 500-3000mm, Width: 80-500mm

4.Material: Inner ring/Outer ring/Rollers: GCr15/GCr15SiMn/20Cr2Ni4A; Cage: Stamped steel/brass

5.Accuracy: Class P0/P6, Class P5 for large-sized precision equipment

6.Application Fields: Large motor rotors, rolling mill roll shafts, mining machinery spindles, offshore wind power equipment

7.Key Inspection Items: Forging flaw detection, dimensional accuracy (tolerance for large-sized parts), radial load capacity

High-Performance Large Cylindrical Roller Bearings for Extreme Industrial Demands

Engineered for metallurgy, port, and mining machinery – with customization up to φ5000mm, 150℃+ heat resistance, and rapid 15-20 day lead times.

Powering Heavy Industries with Precision and Reliability

Large Cylindrical roller bearings are the backbone of heavy-load machinery, designed to handle radial forces up to 300 tons while operating in extreme temperatures and abrasive environments. At LUOYANG INNO, we specialize in manufacturing bearings with inner diameters from 300mm to 2000mm, optimized for applications like rolling mills, mining crushers, and offshore wind turbines. Our modular design and full-cycle R&D ensure these bearings deliver 50,000+ hours of reliable performance, even under 150℃ conditions.

Key Features & Applications

Built for Demanding Environments

-

Heavy-Load Capacity: Reinforced rollers and cages withstand dynamic loads up to 1,200 kN/mm².

-

High-Temperature Resistance: Materials like GCr15SiMn and 20Cr2Ni4A retain hardness at 150℃+.

-

Corrosion/Dust Protection: Optional metal seals and stainless steel coatings for port/marine use.

-

Precision Grades: P5/P6 accuracy (radial runout ≤0.02mm) for medical equipment and precision gearboxes.

Top Applications:

- Rolling mill roll shafts in steel plants

- Mining conveyor drive systems

- Offshore wind turbine yaw mechanisms

Technical Specifications

| Parameter | Specification |

|---|---|

| Inner Diameter (ID) | 300mm – 2000mm |

| Outer Diameter (OD) | 500mm – 3000mm |

| Width | 80mm – 500mm |

| Material | GCr15/GCr15SiMn rings; brass/stamped steel cages |

| Precision | P0/P6 (standard); P5 (custom orders) |

| Temperature Tolerance | -30℃ to +150℃ (higher upon request) |

Why Choose LUOYANG INNO?

✅ 30+ Years of Expertise: Self-produced critical components for quality control.

✅ Rapid Customization: 15-20 day lead times for non-standard designs (φ3000mm+).

✅ 12-Point Quality Testing: 99.9% defect-free rate via vibration, lifespan, and load tests.

✅ Global Stock Availability: 1,000+ standard models ship within 48 hours.

✅ Lifetime Technical Support: From CAD modeling to IoT-driven maintenance plans.

Industry-Specific Solutions

Case 1: Metallurgy

A steel plant reduced bearing replacements by 40% after switching to our Large Cylindrical Roller Bearings with high-temperature cylindrical roller bearings and anti-deformation rollers.

Case 2: Port Machinery

Ship loaders using our sealed bearings reported 30% longer service life in saltwater environments.

Case 3: Mining

Vibrating screens equipped with our impact-resistant bearings achieved 20% higher uptime.

Quality Assurance & Compliance

- ISO 9001, CE, and ASTM F2097 certifications

- Raw material checks via spectrometry

- 3-stage inspections (pre-production, in-process, final)

- SGS-validated lifespan testing

Global Logistics Network

| Order Type | Lead Time | Delivery Scope |

|---|---|---|

| Standard Bearings | 48 hours | Worldwide via regional warehouses |

| Custom Designs | 15-20 days | Tailored to your location |

FAQ

1. How do your bearings handle 500℃+ temperatures?

We use heat-treated alloys like 20Cr2Ni4A and ceramic-coated rollers to maintain structural integrity.

2. Can I get a φ2500mm bearing in 18 days?

Yes! Our modular production system cuts lead times to 70% of industry averages.

3. What certifications do you provide?

All bearings include ISO 9001 and material test reports. CE, ATEX, and OSHA compliance are optional.

4. Do you offer installation support?

Our engineers provide on-site guidance or video tutorials for seamless integration.

Contact Us

Need Large Cylindrical Roller Bearings That Outperforms?

📧 Email sales@inno-bearing.com for a free consultation. Get technical drawings and a quote within 24 hours!

Optimized for heavy-load, high-temperature, and corrosive environments – LUOYANG INNO Bearings redefine durability.

Learn about our latest products and discounts through SMS or email