- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

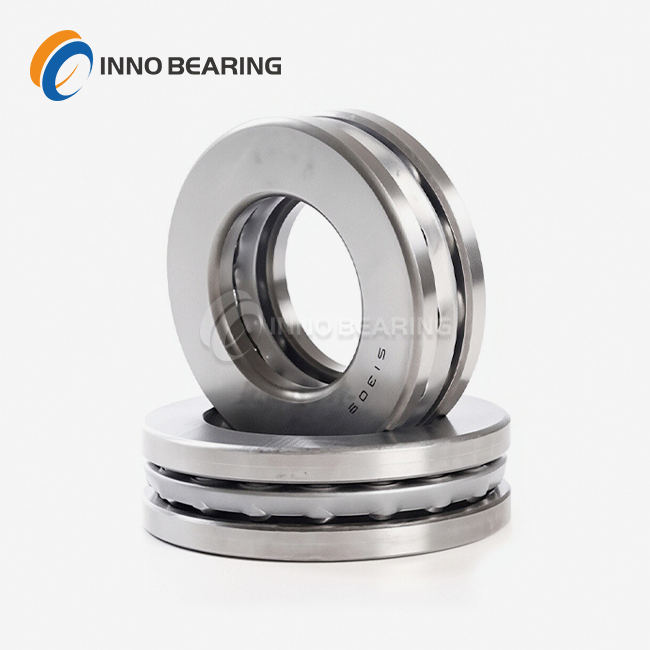

Four-Point Contact Ball Slewing Bearings

2.Structure Type: It has an annular integrated structure. The inner and outer rings have double raceways, with four-point contact steel ball groups + cages. Some are equipped with seals, and mounting holes are reserved.

3.Size Range: Outer ring diameter: 300 - 3000mm, inner ring diameter: 250 - 2800mm, height: 15 - 120mm.

4.Material: Inner ring /outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile,fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Construction machinery, wind power equipment, machine tools, port machinery.

6.Key Inspection Items: Dimensional accuracy, slewing resistance, sealing and waterproof performance.

Four-Point Contact Ball Slewing Bearings for Heavy-Duty Industrial Performance

Engineered to handle extreme axial/radial loads and harsh environments, LUOYANG INNO's Four-Point Contact Ball Slewing Bearings deliver unmatched durability for metallurgical plants, port cranes, and heavy machinery. With 30+ years of precision manufacturing expertise, we produce bearings up to φ5000mm that withstand 500℃ temperatures, 10,000 kN loads, and 35dB ultra-quiet operation.

Core Specifications: Precision Built for Demanding Applications

- Diameter Range: φ200mm – φ5000mm (standard & custom sizes)

- Load Capacity: Axial up to 10,000 kN | Radial up to 6,500 kN

- Temperature Resistance: -30℃ to +150℃ (ideal for molten metal handling)

- Material: 42CrMo/50Mn steel with 58-62 HRC hardness

- Precision: P4/P5 grading (ISO 492) | Radial runout ≤0.05mm

- Noise Level: ≤35dB (suitable for medical imaging equipment)

Why Choose Our Four-Point Contact Ball Slewing Bearings?

1. Heavy-Duty Reliability Under Extreme Conditions

Our bearings excel where others fail:

-

Metallurgical Equipment: Survive 500℃ molten metal splashes and shock loads with specialized heat-treated raceways.

-

Port Cranes: Saltwater-resistant coatings and 100,000+ rotation cycles reduce unplanned downtime by 40%.

-

Mining Machinery: Pre-lubricated, triple-sealed designs prevent dust ingress in abrasive environments.

2. Custom Engineering for Unique Challenges

Need non-standard sizes or load configurations? We deliver:

-

Fast Prototyping: Legacy equipment retrofits with 3D scanning & dimensional mapping in 24h.

-

Material Optimization: Impact-resistant GCr15SiMn steel for mining or corrosion-resistant options for marine use.

-

Integrated Gear Machining: ±0.01mm accuracy gear teeth cut directly onto bearing raceways.

3. Zero-Compromise Quality Assurance

Every Four-Point Contact Ball Slewing Bearings undergoes rigorous checks:

- Triple Inspection System: UT/MT material tests, in-process alignment checks, final vibration/lifespan validation.

- 12+ Tested Parameters: Hardness (58-62 HRC), torque consistency, waterproof sealing (IP67 rating).

- Full Traceability: Mill certificates & heat-treatment records provided with every order.

Accelerated Delivery – Even for Custom Orders

- Stock Availability: 1,000+ standard bearings ready to ship globally in 48h.

- Custom Production: φ3000mm bearings delivered in 15-20 days (30% faster than competitors).

- Regional Hubs: Emergency replacements shipped from EU/NA/Asia warehouses within 72h.

Technical Support That Extends Bearing Lifespan

- Predictive Maintenance: IoT sensors monitor real-time load, temperature, and lubrication needs.

- Failure Analysis: Free inspection of worn bearings to identify root causes (abrasion, misalignment, etc.).

- 24/7 Engineering Support: Multilingual technicians guide installation, alignment, and maintenance.

FAQ

Q: How do your bearings handle repeated 500℃ thermal shocks in steel mills?

A: Our metallurgy-grade series uses 50Mn steel with cryogenic hardening, maintaining structural integrity through 100+ thermal cycles.

Q: Can you customize bearings beyond φ5000mm?

A: Yes – our in-house forging shop produces up to φ6000mm. Submit specs for a feasibility review.

Q: What certifications do your bearings hold?

A: ISO 9001, CE, DNV-GL, and OSHA compliance. Industry-specific certs available upon request.

Q: Do you offer on-site installation support?

A: Global engineers provide alignment checks, load testing, and operator training worldwide.

Contact Us

Ready to Solve Your Heavy-Duty Rotation Challenges?

Submit your Four-Point Contact Ball Slewing Bearings requirements (loads, dimensions, environment) to sales@inno-bearing.com for a free quote + technical proposal within 6 hours.

Learn about our latest products and discounts through SMS or email