- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

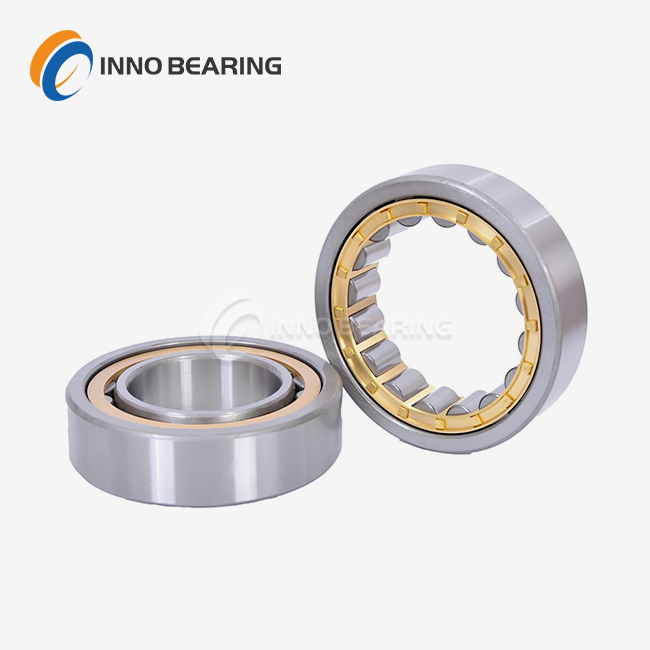

thin section angular contact bearings

2.Structure Type: Thin-wall inner ring + thin-wall outer ring (with angular contact raceway) + small-diameter steel balls + engineering plastic cage, without redundant structural protrusions, and with a compact size.

3.Size Range: Inner diameter: 15 - 200mm, outer diameter: 32 - 250mm, width: 5 - 20mm (wall thickness 2 - 5mm).

4.Material: Inner ring / outer ring: GCr15 (thin-wall forgings), rolling elements (steel balls): GCr15, cage: engineering plastic (lightweight and wear-resistant).

5.Accuracy: Conventional P0 grade, precision models are of P6/P5/P4 grades.

6.Application Fields: Robot joints, medical equipment (surgical robots), micro-motors, transmission systems of drones, precision instruments.

7.Key Inspection Items: Deformation amount of thin walls (≤ 0.003mm), radial clearance (0.002 - 0.005mm), conformity of steel balls fitting, installation adaptability.

Precision Thin Section Angular Contact Bearings for Extreme Performance

When space, weight, and precision matter, thin section angular contact bearings deliver unmatched performance in demanding applications. With over 30 years of expertise, LUOYANG INNO BEARING CO., LTD specializes in crafting ultra-slim bearings (wall thickness ≤5mm) that excel in robotics, medical systems, aerospace, and high-temperature industrial machinery. Our P4-grade precision models achieve noise levels below 35dB and withstand temperatures up to 500°C, ensuring reliability where standard bearings fail.

Why Choose Us?

Engineered for Precision & Durability

-

Space-Saving Design: Wall thickness as low as 2mm, ideal for compact robotic joints or surgical tools.

-

High-Temperature Resistance: Advanced heat treatment enables stable operation in metallurgical furnaces (up to 500°C).

-

Ultra-Low Noise: <35dB operation for MRI machines and semiconductor manufacturing.

-

Material Excellence: GCr15 steel rings with engineering plastic cages for reduced friction and wear.

Industry-Tailored Solutions

-

Medical Robotics: ABEC 7/9 precision, cleanroom-manufactured bearings with <0.5μm axial runout.

-

Port Machinery: IP67-sealed units resist saltwater corrosion in cranes and hoists.

-

Aerospace: Hybrid ceramic bearings capable of 1M RPM for satellite guidance systems.

Rapid Customization

Need non-standard dimensions (e.g., OD >5000mm) or hybrid materials? Our thin section angular contact bearings modular production delivers prototypes in 5-7 days and full batches in 15-20 days – 70% faster than industry averages.

Technical Specifications

| Parameter | Details |

|---|---|

| Inner Diameter | 15mm – 200mm |

| Outer Diameter | 32mm – 250mm |

| Dynamic Load | Up to 120kN (customizable) |

| Accuracy Grades | P0 (standard) to P4 (ultra-precise) |

| Temperature Range | -60°C to +500°C |

Trusted by Global Industries

Case 1: Medical Imaging Systems

A leading OEM reduced MRI noise by 40% using our vacuum-lubricated bearings with <18dB operation.

Case 2: Steel Mill Conveyors

Custom 500°C-resistant bearings increased service intervals by 300% in a hot-rolling furnace.

Quality Assured, Delivery Guaranteed

- Rigorous Testing: 100% dimensional checks, 24h overloading trials, and ISO 15242-1 vibration tests.

- Global Stock: 1,000+ standard models ready for 48-hour shipping.

- Lifetime Support: IoT-based wear monitoring and predictive maintenance planning.

FAQ

Q: Can you customize bearings for legacy equipment?

A: Yes! We offer reverse engineering and on-site measurements to adapt to older machinery.

Q: What’s the MOQ for custom orders?

A: We accept orders as small as 50 units without compromising quality.

Q: How do you ensure corrosion resistance?

A: Stainless steel variants with IP67 sealing are available for harsh environments.

Contact Us

Need a Precision Solution?

Contact our engineers today at sales@inno-bearing.com for tailored thin section angular contact bearings that optimize your machinery’s performance.

Learn about our latest products and discounts through SMS or email