- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

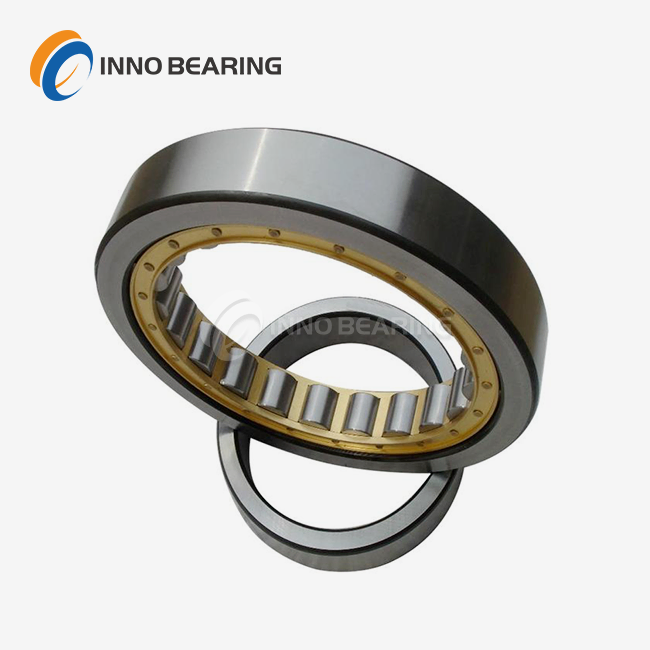

spherical bearing manufacturers

2.Product Range: Covering 222 series (double-row), 231/232 series (self-aligning roller), sealed models / tapered hole models, and providing matching bearing housings.

3.Size Coverage: Inner diameter 20 - 2000mm, outer diameter 47 - 3000mm.

4.Material Standard: Inner ring / outer ring is GCr15 bearing steel, rollers are GCr15 bearing steel, cage is stamped steel / brass, and 42CrMo can be selected for heavy-load models.

5.Precision Level: Conventional P0/P6 level, precision version is P5 level.

6.Common Inner Tapered Hole: Can provide 1:12 or 1:30 tapered holes as required, suitable for shaft diameters of 30 - 1000mm.

7.Service Fields: Construction machinery, electric motors, rolling mills, port equipment, wind power.

8.Key Guarantees: Material flaw detection, random inspection of dimensions, sealing performance testing, after-sales technical support.

High-Performance Spherical Bearings for Heavy Machinery – Engineered for Extreme Loads & Temperatures (150°C+)

Customized Solutions for Metallurgical & Port Machinery | 30+ Years Expertise | Global 48-Hour Delivery

Why Partner with Leading Spherical Bearing Manufacturers?

When your machinery operates in extreme conditions – like 150°C+ heat or saltwater environments – you need bearings that won't fail. As trusted spherical bearing manufacturers, we combine three decades of engineering expertise with cutting-edge materials to deliver reliability where others fall short. Whether you're retrofitting legacy port cranes or designing next-gen medical robots, our solutions adapt to your toughest challenges.

Product Highlights

1. Extreme Environment Mastery

-

High-Temperature Stability: 150°C operational range (200°C with ceramic coatings).

-

Heavy-Load Capacity: Static loads up to 2,000kN for metallurgical rolling mills.

-

Saltwater Resistance: PTFE-coated variants survive 10,000+ hours in port/marine settings.

2. Custom-Built Precision

-

Non-Standard Designs: Manufacture spherical bearings up to φ5000mm OD with 15–20 day lead times.

-

Legacy Compatibility: Reverse-engineer bearings for outdated machinery using 3D scanning.

3. Cross-Industry Validation

- Metallurgy: Bearings for continuous casters with 2x industry-average lifespan.

- Medical: P4-grade precision (±0.002mm) and ultra-low noise (<35dB) for surgical robots.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | GCr15 bearing steel / 42CrMo alloy |

| Precision | P0/P6 (standard), P4/P5 (high-precision) |

| Load Capacity | 1,200kN–2,000kN static; 500kN–1,500kN dynamic |

| Temperature Range | -20°C to +150°C (expandable to 200°C) |

| Certifications | ISO 9001, CE, ASTM F2094, REACH/ROHS |

How We Outperform Other Spherical Bearing Manufacturers?

1. Integrated R&D & Testing

-

Full-cycle design validation using FEA simulations and thermal analysis.

-

12+ performance tests per batch, including fatigue (ISO 281) and salt spray (ASTM B117).

2. Agile Global Supply Chain

-

1,000+ Standard Bearings: Ready for dispatch within 48 hours.

-

Regional Warehouses: EU, North America, and Asia-Pacific hubs.

3. Lifecycle Optimization

-

IoT-enabled wear monitoring predicts maintenance needs 3–6 months in advance.

- Material recycling programs reduce your total cost of ownership by up to 25%.

Application Scenarios

Case 1: Port Crane Modernization

A European port upgraded 12 ship-loading cranes with our corrosion-resistant spherical bearings from leading spherical bearing manufacturers. Result: Zero unplanned downtime in 18 months despite daily saltwater exposure.

Case 2: Steel Mill Overhaul

Replaced 142 bearings in a hot strip mill with high-temperature models. Operational lifespan increased from 9 to 22 months.

Quality Assurance Process

1. Material Inspection: Spectrometry checks for Cr-Ni-Mo alloy purity.

2. In-Process Checks: Laser-guided dimensional verification (±0.01mm).

3. Final Validation: 72-hour load testing under simulated operational stress.

FAQ

1. How do you achieve 500°C heat resistance?

Our spherical bearings use high-purity steel alloys and ceramic coatings to maintain structural integrity in metallurgical furnaces.

2. Can you customize bearings for legacy equipment?

Yes. We use 3D scanning and reverse engineering to recreate obsolete designs in 7–10 days.

3. What certifications do you hold?

We’re ISO 9001, CE, and REACH certified, with region-specific compliance (ATEX, GOST).

Contact Us

Ready to Upgrade Your Machinery with spherical bearing manufacturers?

📩 Contact Us Today

Email: sales@inno-bearing.com

📞 Response Time: 24 hours for quotes | 48 hours for technical support.

Download Our Technical Dossier → Material specs, case studies, and compliance guides.

Learn about our latest products and discounts through SMS or email