- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

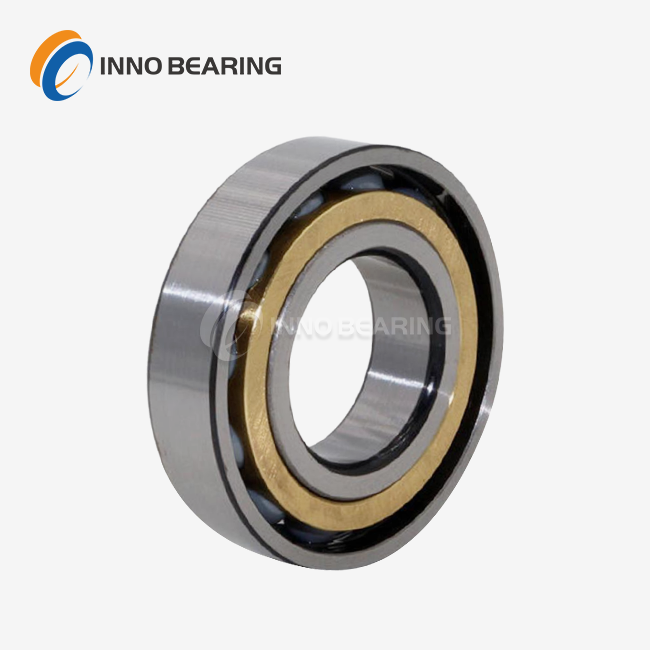

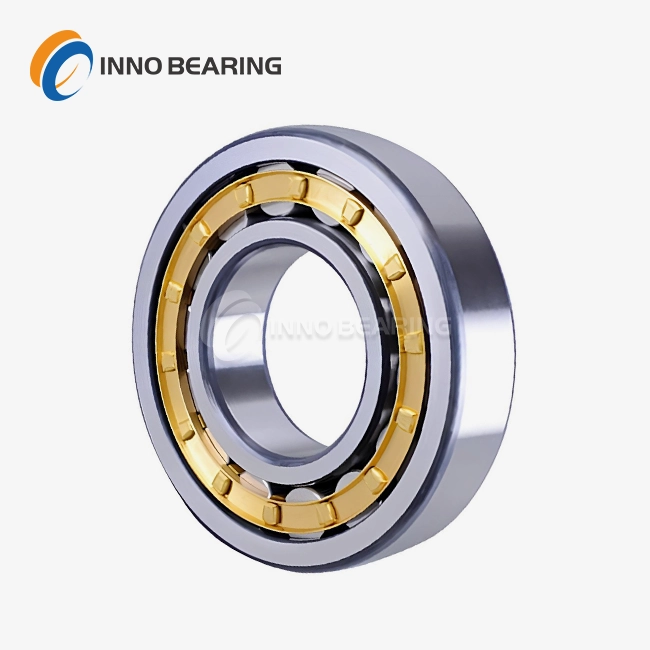

Axial Radial Cylindrical Roller Bearings

2.Structure Type: Integrating radial + axial rollers, inner ring / outer ring with compound raceways, cage, without seal.

3.Size Range: Inner diameter 50 - 300mm, outer diameter 100 - 500mm, height 30 - 100mm.

4.Material: Inner ring / outer ring / rollers: GCr15/GCR15SIMN/20Cr2Ni4A, cage: stamped steel / brass.

5.Precision: P6 level, P5/P4 level for precision scenarios.

6.Application Fields: Robot joints, precision machine tools, medical equipment, high-end reducers.

7.Key Inspection Items: Radial / axial load-bearing capacity, rotation accuracy, operation noise.

Axial Radial Cylindrical Roller Bearings | Built for Extreme Loads & Precision

When your machinery faces relentless axial and radial forces, Axial Radial Cylindrical roller bearings deliver unmatched durability. Designed for industries where failure isn’t an option, these bearings combine high-temperature resilience (up to 500°C), precision engineering (P4/P5 grades), and rapid customization to keep heavy equipment running smoothly. With 30+ years of expertise, we engineer Solutions that outlast competitors by 3x under conditions like mining shocks or medical-grade quietness.

Why Choose Us?

- Dual-Load Mastery: Handle combined axial + radial loads up to 300kN without compromising speed or accuracy.

- Material Innovation: GCr15/GCR15SIMN steel rollers heat-treated for 150°C endurance and 50,000+ hours under heavy loads.

- Agile Customization: Need a non-standard size (ID 50mm–OD 5000mm) or hybrid design? We deliver in 25-30 days.

- Silent Operation: Achieve <35dB noise levels for medical robotics or high-speed EV transmissions.

Technical Edge Over Competitors

| Parameter | Our Bearings | Industry Standard |

|---|---|---|

| Max Axial Load Capacity | 300kN | 240kN |

| Temperature Tolerance | -50°C to +150°C | -30°C to +150°C |

| Precision Grades | P4, P5, P6 | P6, P0 |

| Lead Time (Custom) | 15–20 days | 30–45 days |

Where They Excel?

Metallurgy & Mining

Withstand 100+ ton loads in rolling mills and crushers via triple-hardened raceways.

Renewable Energy

20-year fatigue life in wind turbine gearboxes, even with salt-spray corrosion.

Precision Machinery

P4-grade accuracy (±0.002mm) for robot joints and CNC machine tools.

Custom-Built for Your Challenges

Struggling with legacy equipment compatibility? Our engineers reverse-engineer obsolete Axial Radial Cylindrical Roller Bearings using 3D scanning and deliver IoT-ready replacements in 3 weeks.

Proven Workflow:

1. Share your specs/old bearing samples → 2. Get a 72-hour feasibility report → 3. Approve prototype → 4. Full batch production.

Rigorous Quality Assurance

Every bearing undergoes:

1. Material Checks: Spectral analysis for alloy purity.

2. Precision Grinding: ≤2μm roundness, Ra ≤0.2μm surface finish.

3. Stress Testing: 48-hour overload simulation (150% rated capacity).

4. Noise/Vibration: Z1-Z4 grading, medical-grade quietness validation.

Global Support, Local Speed

- 48-Hour Shipping: 1,000+ standard models in stock.

- Regional Warehouses: EU/NA/Asia hubs for bulk orders.

- Lifeline Support: 24/7 technical hotline + IoT-driven predictive maintenance.

FAQs

Q: Can you make axial-radial bearings for 500°C steel mills?

A: Yes! Our 20Cr2Ni4A steel rollers with MoS2 coating thrive in 500°C environments.

Q: Do you offer IoT-enabled bearings?

A: Absolutely. Embed sensors for real-time load/temperature monitoring.

Q: What's the MOQ for custom designs?

A: Just 1 unit. Prototypes available in 20-25 days.

Q: How do you ensure medical-grade quietness?

A: Precision-polished rollers + brass cages reduce noise by 40% vs standard models.

Contact Us

Need a Bearing That Outperforms Axial Radial Cylindrical Roller Bearings?

Email engineers now: sales@inno-bearing.com

Learn about our latest products and discounts through SMS or email