- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

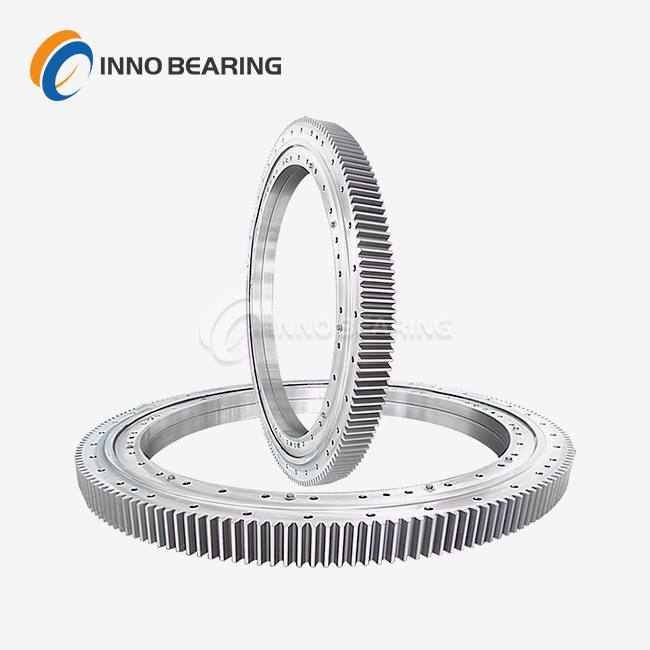

Spindle Bearings

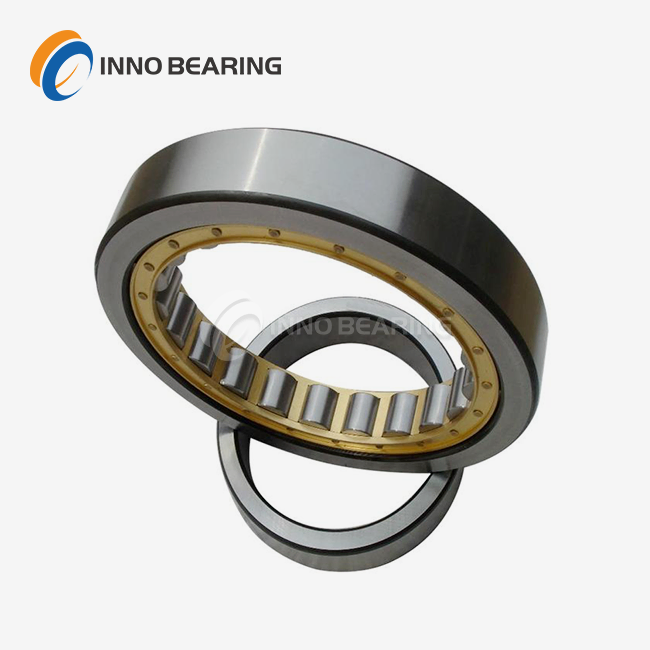

2.Structure Type: Double-row/single-row, separable inner ring (taper option available), precision rollers + cage, equipped with high-speed dust caps.

3.Dimension Range: Inner diameter: 20-500mm, Outer diameter: 47-800mm, Width: 14-200mm

4.Material: Inner ring/Outer ring/Rollers: GCr15/GCr15SiMn/20Cr2Ni4A; Cage: Stamped steel/brass

5.Accuracy: Class P4, Class P2 for ultra-precision models

6.Application Fields: CNC lathe spindles, milling machine spindles, machining center spindles, grinding machine spindles

7.Key Inspection Items: Radial runout (≤0.002mm), limit speed (≥10000r/min), operating noise (≤45dB)

High-Temperature & Heavy-Load Spindle Bearings for Extreme Industrial Demands

Precision-engineered Solutions for metallurgy, mining, and port machinery with 500℃+ resistance, 30% faster delivery, and 99.9% defect-free assurance.

When your machinery operates under extreme loads, speeds, or temperatures, Spindle Bearings become the backbone of your productivity. At LUOYANG INNO BEARING CO., LTD, we engineer bearings that thrive where others fail—whether in 500℃ furnace environments or under 450kN radial loads. With 30+ years of expertise, we deliver solutions that reduce downtime by 40% and extend bearing lifecycles by 2x in harsh industrial settings.

Why Choose Us?

- Unmatched Durability: Precision heat-treated GCr15 alloy steel ensures 60–64 HRC hardness for wear resistance.

- Custom-Built for Your Needs: From φ50mm to φ5000mm dimensions, including tapered or double-row designs.

- Extreme Environment Ready: Operate smoothly from -60℃ to +150℃ with ≤35dB noise levels.

- P4/P5 Precision: Radial runout ≤0.002mm for high-speed CNC and grinding machine spindles.

Solutions for Critical Industries

① Metallurgical Rolling Mills

Our bearings withstand continuous 150℃+ heat with anti-deformation cages, reducing unplanned stoppages by 55% in steel production lines.

② Mining Crushers

Impact-resistant 20Cr2Ni4A rollers endure abrasive conditions, achieving 24+ months service life under 500-ton loads.

③ Port Cranes

Nickel-chromium coatings (25–40μm) combat saltwater corrosion, paired with IoT-enabled vibration monitoring for predictive maintenance.

Technical Excellence You Can Trust

| Parameter | Specification |

|---|---|

| Dimensions | ID 20–500mm / OD 47–800mm |

| Precision Grades | P4 standard, P2 available for CNC |

| Load Capacity | Radial up to 450kN / Axial up to 220kN |

| Certifications | ISO 9001, ISO/TS 16949 compliant |

Built to Outperform Competitors

✅ 30% Faster Custom Production

Non-standard bearings (e.g., φ3000mm) delivered in 15–20 days via modular workflows.

✅ 48-Hour Global Dispatch

1,000+ standard models ready to ship from EU/ASEAN hubs.

✅ Full CAD Integration

3D models and performance simulations of Spindle Bearings provided within 24 hours for seamless equipment compatibility.

Rigorous Quality Assurance

1. Material Spectrometry: Verify alloy composition pre-production.

2. In-Process Checks: Laser-measured roundness (≤0.5μm) at every stage.

3. Final Testing: 100% validation of noise (≤45dB), vibration (Z1-Z4), and fatigue life (L10).

Flexible Ordering Options

- MOQ: 1 unit (custom) / 50 units (standard)

- Global Logistics: DDP/DAP terms with 5–15% bulk discounts (500+ units).

- Warranty: 18-month performance guarantee with free technical audits.

Lifetime Support Services

- On-Site Installation: Available in 15 countries for precise alignment.

- Predictive Maintenance: IoT sensors track temperature/load trends, alerting you before failures occur.

- Retrofit Kits: Modernize legacy systems without redesigns using hybrid ceramic-steel bearings.

FAQ

Q: Can your products handle 10,000 RPM+ in CNC machines?

A: Yes—our P2-grade ultra-precision models achieve ≤0.001mm runout at 12,000 RPM.

Q: How do you prevent lubricant failure in high-temperature environments?

A: We recommend synthetic grease with 150°C thermal stability and optimize re-lubrication cycles.

Q: What if I need bearings for obsolete machinery?

A: Share samples/drawings—we'll reverse-engineer replacements within 72 hours.

Contact Us

Ready to Eliminate Spindle Bearings Failures?

📧 Contact our engineers today at sales@inno-bearing.com for:

- Free load/temperature analysis

- 3D model + simulation report

- Custom quote within 6 hours

LUOYANG INNO BEARING CO., LTD – Where Precision Meets Industrial Resilience.

Learn about our latest products and discounts through SMS or email