- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

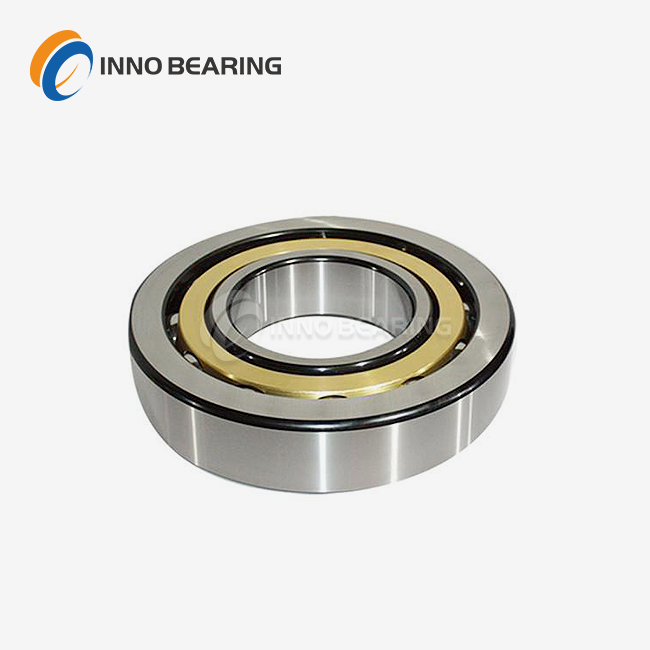

Split self-aligning roller bearing

2.Structure Type: The inner ring and outer ring are axially split (with bolt connections), with double-row spherical rollers + steel cage, and metal seals to prevent impurities.

3.Size Range: Inner diameter ranging from 100mm to 2000mm, outer diameter ranging from 200mm to 3000mm, width ranging from 50mm to 300mm.

4.Material: Inner ring / outer ring: GCr15SiMn (heavy-load with integral forging and then split), GCr15 bearing steel (conventional), rollers: GCr15 bearing steel, cage: steel.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: Optionally with a 1:12 tapered hole (suitable for shaft diameters ranging from 100mm to 2000mm).

7.Application Fields: Large rolling mill roll shafts, mining machinery spindles, port super-heavy-duty equipment.

8.Key Inspection Items: Fitting degree of the split surface, bolt connection strength, radial load-bearing capacity, sealing integrity.

Split Self-Aligning Roller Bearings for Heavy Industrial Applications

High-Load Capacity • Customizable Designs • 48-Hour Rapid Delivery

Optimized for Heavy-Duty Performance & Easy Maintenance

Split self-aligning roller bearings are engineered to solve critical challenges in heavy machinery. These bearings compensate for shaft misalignment (up to ±3°) while handling extreme radial/axial loads (500kN+), making them ideal for metallurgy, port equipment, and mining. Unlike traditional solid bearings, their split design allows quick installation and replacement without dismantling adjacent components—saving hours of downtime.

Key Features That Set Our Bearings Apart

1. Split Design for Simplified Maintenance

Installing large bearings on oversized shafts (φ300mm–φ5000mm) is now effortless. Our products feature precision-machined bolt connections, enabling hassle-free assembly in confined spaces.

2. Self-Aligning Capability (±2.5°–3°)

Misalignment from thermal expansion or mounting errors? Our bearings automatically adjust, reducing vibration and uneven wear by up to 40%.

3. Extended Service Life Under Extreme Conditions

Crafted from high-purity GCr15 steel and subjected to advanced heat treatment, our bearings achieve 50% longer fatigue life than standard models. They operate reliably in temperatures from -20°C to +150°C.

4. Tailored Solutions for Unique Demands

Need non-standard dimensions (e.g., φ5000mm+), ceramic-coated rollers, or stainless-steel cages? We deliver custom split self-aligning bearings in 8–12 weeks—30% faster than competitors.

5. Rapid Delivery, Global Reach

With 1,000+ standard bearings in stock and regional warehouses, we ship urgent orders within 48 hours.

Critical Applications Where Our Bearings Excel

| Industry | Use Case | Key Benefit |

|---|---|---|

| Steel Mills | Rolling mill roll necks | High-temperature stability (150°C) |

| Port Cranes | Slewing mechanisms | Corrosion-resistant coatings |

| Mining Crushers | Rotating shafts | Shock load resistance (up to 2,000 kN) |

| Cement Plants | Kiln support rollers | Dust-proof sealing for abrasive environments |

Technical Specifications at a Glance

- Dimensions: ID 100mm–5000mm | OD up to 6500mm | Width 50–300mm

- Precision: P4/P5 accuracy with noise <35dB

- Materials: GCr15SiMn, SAE 52100, or M50 alloy for extreme heat

- Certifications: ISO 9001, CE, API 6A, EN 10204 3.1 traceability

Why Partner With Us?

✅ 30+ Years of Split Bearing Expertise

Our R&D team optimizes every component of the Split self-aligning roller bearing—from split-surface tolerances (≤0.02mm) to bolt torque specifications—for reliability.

✅ End-to-End Engineering Support

Get free misalignment analysis, CAD simulations, and IoT-enabled predictive maintenance plans.

✅ Lifecycle Cost Savings

Reduce downtime by 45% with bearings designed for 50,000+ hours of continuous operation.

Your Success, Our Priority

Pre-Sales Support

-

Load capacity verification

-

Material selection guidance

Post-Sales Assurance

- 24/7 technical hotline

- On-site installation supervision

- Custom lubrication schedules

FAQ

1. How does the split design simplify bearing replacement in port cranes?

Our products bolt together around the shaft, eliminating the need to remove machinery components—cutting replacement time by 60%.

2. What certifications validate your bearings’ shock resistance?

We provide ISO 15243 fatigue test reports and API 6A certifications, with dynamic load ratings exceeding 2,000 kN.

3. Can you make bearings larger than φ5000mm?

Yes! We specialize in ultra-large split self-aligning bearings up to φ6500mm, using modular forging techniques.

4. How do your bearings handle 500°C furnace environments?

We use M50 high-temperature alloy and ceramic coatings to minimize thermal expansion—ensuring stable operation.

5. Do you offer IoT-enabled bearings?

Yes. Integrated sensors monitor vibration and temperature, alerting you to maintenance needs before failures occur.

Contact Us

Need a Reliable Split self-aligning roller bearing Solution for Heavy Machinery?

📧 Email our engineers at sales@inno-bearing.com for:

- Urgent 48-hour delivery quotes

- Custom bearing design consultations

Learn about our latest products and discounts through SMS or email