- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

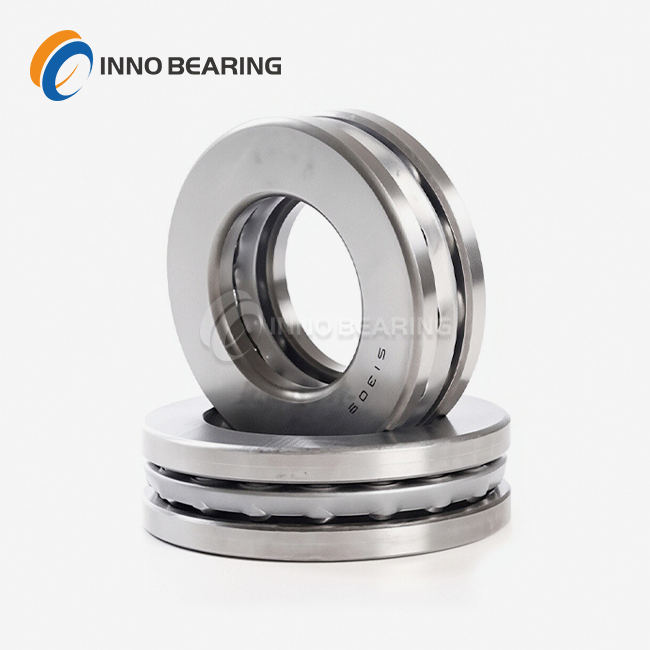

Large Thrust Ball Bearing

2.Structure Type: Shaft washer + housing washer + single-row or double-row steel balls + steel cage, the shaft washer and housing washer have a thick-wall design (wall thickness ≥8mm).

3.Size Range: Inner diameter: 100 - 500mm, outer diameter: 200 - 600mm, height: 20 - 80mm.

4.Material: Shaft washer: GCr15/GCR15SIMN/20Cr2Ni4A, housing washer: GCr15/GCR15SIMN/20Cr2Ni4A, rolling elements (steel balls): GCr15/GCR15SIMN, cage: steel / brass.

5.Accuracy: Conventional P0/P6 grades, models for large precision equipment are of P5 grade.

6.Application Fields: Large motors, mining machinery, port light-duty cranes.

7.Key Inspection Items: Axial load-bearing capacity, strength of shaft washer and housing washer (compressive strength ≥800MPa), accuracy of steel ball arrangement.

Large Thrust Ball Bearing: Precision Solutions for Heavy-Duty Machinery

When your equipment faces extreme axial loads, high temperatures, or relentless operational demands, Large Thrust ball bearings from LUOYANG INNO BEARING CO., LTD deliver unmatched reliability. Designed for heavy machinery in metallurgy, port operations, and industrial systems, our bearings combine robust construction (up to φ5000mm) with rapid customization to meet unique load, speed, and environmental challenges.

Engineered for Heavy Machinery in Demanding Environments

Our products excel in applications where axial forces dominate. From blast furnaces operating at 150°C to high-speed port cranes, our Solutions are trusted globally for:

- Metallurgical Equipment: Handle extreme heat (150°C+) and shock loads in rolling mills.

- Port Machinery: Support heavy axial loads in ship loaders and automated cranes.

- Medical Systems: Ensure precision (P4/P5-grade) in low-noise CT scanners.

Technical Excellence for Extreme Conditions

Key Specifications & Advantages

- Dimensions: Customizable inner diameter (100–5000mm), height (20–80mm), and configurations (single/double-row).

- Materials: High-purity GCr15 steel, heat-treated for 800MPa compressive strength.

- Precision: P0/P6 standard grades; P4/P5 options for low noise (≤35dB).

- Load Capacity: Static loads up to 2,500 kN; dynamic loads up to 1,000 kN.

- Testing: 12+ performance tests, including fatigue, vibration, and temperature cycling.

Agile Customization & Faster Turnarounds

Need a non-standard design? Our modular production system cuts lead times to 15–20 days (70% faster than industry averages).

Customization Process:

1. Submit technical drawings or load requirements.

2. Receive feasibility analysis within 72 hours.

3. Prototype testing with real-time updates.

Example: A Large Thrust Ball Bearing φ3000mm for a legacy crane was delivered in 18 days, matching exact load and dimensional specs.

Built to Last: Quality You Can Trust

Rigorous Quality Assurance

- Material Science: Ultra-clean steel processing minimizes impurities.

- Precision Grinding: Tolerance levels under 0.001mm.

- 3-Stage Inspections:

1. Raw material verification.

2. In-process dimensional checks.

3. Final performance validation (99.9% qualification rate).

Certifications: ISO 9001, CE, ASTM, and TÜV compliance.

Global Supply Chain for Urgent Needs

- Stock Availability: 1,000+ standard bearings ready for 48-hour dispatch.

- Regional Warehouses: EU, North America, and APAC hubs for faster delivery.

- Custom Orders: Dedicated production lines with progress tracking.

Your Partner Beyond Delivery

We provide end-to-end support to maximize uptime:

- Pre-Installation: On-site audits for legacy equipment retrofits.

- IoT Monitoring: Real-time wear analytics to predict maintenance needs.

- 24/7 Support: Troubleshooting and lubrication guidance.

FAQ

1. How do your bearings handle 500°C+ environments?

Proprietary heat treatment and alloy blends ensure thermal stability.

2. Can you customize bearings for legacy port cranes?

Yes—we’ve delivered φ3000mm+ solutions with custom load ratings in under 20 days.

3. What certifications do you hold?

ISO 9001, CE, TÜV, and ASTM, ensuring global compliance.

4. Do you offer emergency replacements?

48-hour dispatch available for stocked bearings; expedited custom production.

5. How is precision maintained during manufacturing?

Precision grinding and triple-stage QC guarantee P4/P5 grades.

Contact Us

Optimize Your Machinery Today with a Large Thrust Ball Bearing

Request a Quote or Consultation:

📧 Email: sales@inno-bearing.com

📞 WhatsApp/WeChat: +86 135 1234 5678

Submit your technical requirements and receive a tailored solution within 24 hours.

LUOYANG INNO BEARING CO., LTD—30+ Years of Mastery in Heavy-Duty Bearing Innovation.

Learn about our latest products and discounts through SMS or email