- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

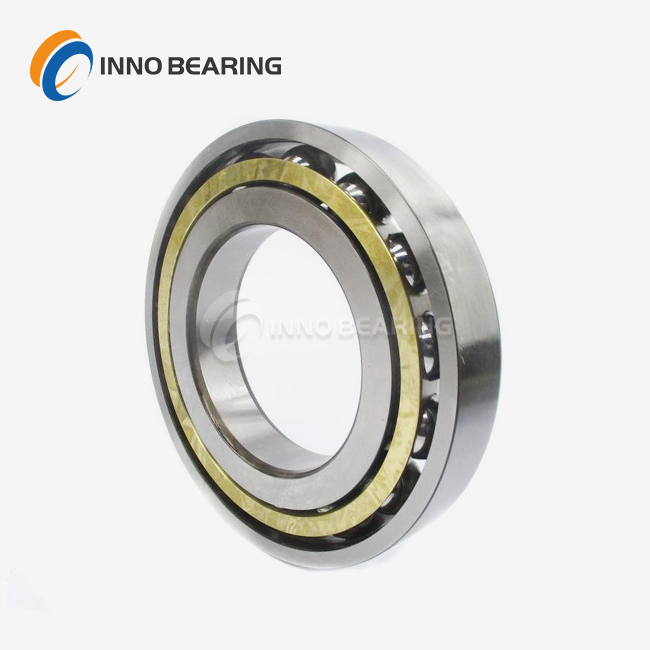

Turntable Bearings

2.Structure Type: It has an annular shape (some are split for easy installation), made of thick-wall 50Mn steel, with single or double-row steel balls or rollers, dust-proof seals, and the flatness of the mounting surface is ≤0.1mm/m. Some are equipped with locating pin holes.

3.Size Range: Outer ring diameter: 200 - 5000mm, inner ring diameter: 160 - 4800mm, height: 20 - 180mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Machine tool turntables (vertical lathes), radar turntables, exhibition display equipment (rotating display stands), heavy logistics turntables.

6.Key Inspection Items: Flatness of the turntable, running noise of rolling elements, flatness of the mounting surface.

High-Precision Turntable Bearings for Extreme Industrial Demands – Customized to Your Machinery, Delivered in 15-20 Days

Engineered for Heavy Loads (Up to 10,000kN), High Temperatures (150°C), and 35dB Ultra-Low Noise – Trusted by Metallurgy & Port Machinery Leaders

Turntable bearings, also known as slewing rings, are the backbone of rotating machinery across industries. At LUOYANG INNO BEARING CO., LTD, we specialize in crafting products that outperform in extreme conditions—whether it's a 150°C metallurgical kiln or a saltwater-exposed port crane. With 30+ years of engineering expertise, our Solutions combine precision, durability, and rapid customization to keep your operations running smoothly.

Product Overview

| Parameter | Specifications | |

|---|---|---|

| Diameter Range | φ200mm – φ5000mm | |

| Load Capacity | Static: Up to 10,000kN; Dynamic: 5,000kN | |

| Rotational Accuracy | P4/P5 Grade (ISO 194) | |

| Temperature Tolerance | -60°C to 150°C | |

| Noise Levels | ≤35dB (tested at 20 RPM) | |

| Material Standards | 50Mn, 42CrMo, GCr15 Bearing Steel |

Industries We Serve

- Heavy Machinery: Port cranes, mining excavators, steelmaking equipment.

- Precision Systems: Medical robotics, radar platforms, CNC machine tools.

- Renewable Energy: Wind turbine yaw/pitch systems.

Why Choose Us?

✅ Fast Custom Manufacturing

Need a non-standard φ3000mm slewing ring? Get it in 15–20 days—30% faster than industry averages. Our modular production system ensures quick turnaround without compromising precision.

✅ Built to Withstand Extremes

Our bearings use high-purity 50Mn steel and specialized heat treatment for 2x wear resistance. Tested under 8,000kN axial loads and 150°C heat, they deliver 50% longer service life than conventional designs.

✅ Zero-Defect Precision

Every bearing undergoes 12-point inspections, including vibration analysis and load-cycle testing. Achieve ≤0.1mm/m mounting surface flatness for seamless integration.

Technical Excellence for Demanding Applications

1. Heavy-Load Slewing Rings

Designed for port cranes and mining equipment, our heavy-duty turntable bearings feature:

-

Double-row roller designs for 10,000kN static loads.

-

IP67-rated seals to block dust, moisture, and salt corrosion.

-

Optional internal/external gears for torque transmission.

2. High-Temperature Solutions

For metallurgical kilns and steel plants, we offer:

-

42CrMo alloy cores hardened to HRC 58–62.

-

Custom lubrication ports for continuous 500°C operation.

-

0.01mm/m rotational accuracy under thermal expansion.

3. Precision Micro Bearings

Ideal for robotics and medical systems:

- Cross-roller designs with <0.001° backlash.

- Polymer-composite cages for 30% weight reduction.

- IoT-enabled variants with embedded wear sensors.

Quality Assurance You Can Trust

- Material Traceability: Full mill certifications for 50Mn/42CrMo steel.

- Process Control: Hardness checks, grinding accuracy monitoring (≤5μm variance).

- Final Validation: 72-hour load testing, noise/vibration analysis, and 3D surface scanning.

Global Support & Rapid Delivery

- 1,000+ Standard Bearings: Ready for 48-hour global shipping.

- Custom Orders: 15–20 day lead time, even for φ5000mm designs.

- Technical Assistance: On-site installation guidance and 24/7 remote diagnostics.

FAQs

1. Can you make products larger than φ5000mm?

Yes! Our modular design approach allows custom solutions up to φ8000mm. Structural integrity is ensured via FEA simulation and material stress testing.

2. How do you achieve faster lead times?

We use pre-machined modules and agile production lines to cut machining steps by 40%.

3. Do your bearings work in saltwater environments?

Absolutely. Specify our Sealed-for-Life series with fluororubber seals and anti-corrosion coatings.

4. What certifications do you hold?

We comply with ISO 9001, CE, and AS9100 (aerospace). Material certs include EN 10204 3.1.

5. Can I get IoT-enabled bearings?

Yes! Our smart slewing rings come with embedded sensors for real-time load/temperature monitoring.

Contact Us

Ready to Upgrade Your Machinery?

📩 Contact Us Today!

Email: sales@inno-bearing.com

Get a custom quote within 4 hours or download our free engineering guide for installation best practices.

Why INNO?

- 30+ years in precision bearing engineering.

- 99.9% defect-free rate since 2020.

- Dedicated lifecycle management & recycling programs.

Turntable bearings are critical to your equipment's performance—trust a partner who engineers reliability into every rotation.

Learn about our latest products and discounts through SMS or email