Our Cup Tapered Roller Bearing withstands 24/7 operation in 500°C environments with integrated cooling compatibility, and a mining client reduced unplanned downtime by 40% after switching to our shock-resistant design.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

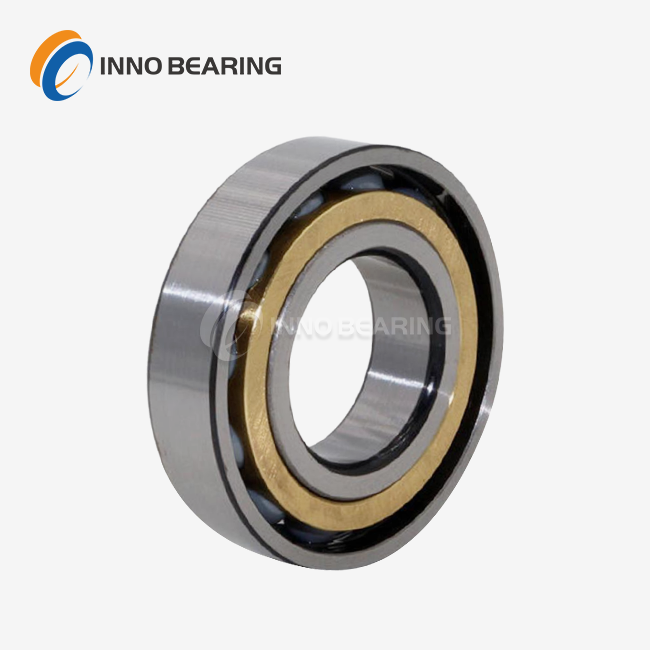

Cup Tapered Roller Bearing

2.Structure Type: The outer ring has a tapered raceway (high - precision), the inner ring is separable (conventional precision), with a single - row of rollers + cage.

3.Size Range: Inner diameter 15 - 500mm, outer diameter 32 - 1000mm, width 10 - 200mm.

4.Material: Inner ring/Outer ring/Rollers: GCr15/GCr15SiMn/20Cr2Ni4A, cage: stamped steel / brass.

5.Precision: The outer ring is P5 level, and the inner ring is P6 level.

6.Application Fields: Machine tool spindle bearing seats, automobile hub bearing seats.

7.Key Inspection Items: Outer - ring dimensional accuracy, taper surface fitting degree, bearing seat fit clearance.

High-Performance Cup Tapered Roller Bearings for Extreme Industrial Applications

Customizable Solutions for Heavy Loads (Up to 5000kN), High Temperatures (500°C+), and Ultra-Low Noise (<35dB)

When your machinery demands precision under pressure, Cup Tapered Roller Bearings deliver unmatched performance. Designed to handle combined radial and axial loads, these bearings excel in harsh environments—from scorching steel mills to high-precision medical imaging systems. At LUOYANG INNO BEARING CO., LTD, we engineer solutions that endure extreme temperatures, shock loads, and corrosive conditions while maintaining optimal efficiency. With over 30 years of expertise, our bearings are trusted by industries where downtime isn't an option.

Why Choose Us?

1. Built for Extreme Conditions

-

Material: High-purity GCr15/GCr15SiMn steel with advanced heat treatment for 20% longer fatigue life.

-

Precision: Achieve P4/P5 grades (ISO 492) for medical equipment and heavy machinery.

-

Load Capacity: Support dynamic loads up to 5000kN and static loads to 8000kN.

-

Temperature Range: Operate seamlessly from -50°C to +500°C.

2. Industry-Specific Engineering

-

Metallurgy: Graphite-lubricated cages prevent seizure in continuous 500°C operations.

-

Ports & Mining: Triple-labyrinth seals and 20Cr2Ni4A steel combat saltwater corrosion and dust ingress (IP6X rated).

-

Medical: Electropolished surfaces and ceramic hybrids reduce noise to <35dB, ideal for MRI systems.

3. Rapid Global Delivery

- Stock Availability: 1,000+ standard SKUs ready to ship within 48 hours.

- Custom Orders: Modular production cuts lead times by 30% (e.g., φ3000mm bearings in 15–20 days).

Technical Specifications

| Parameter | Standard Range | Customizable Options |

|---|---|---|

| Inner Diameter (ID) | 15–500 mm | Up to 5000 mm |

| Outer Diameter (OD) | 32–1000 mm | Up to 5000 mm |

| Width | 10–200 mm | Tailored to application |

| Max RPM | 3,000 | Optimized for high-speed |

| Lubrication | Grease/Oil | Solid-film (high-temp) |

Where Cup Tapered Roller Bearings Excel?

Steel Mill Rolling Mills

Port Crane Slewing Rings

Impact-resistant variants handle 200kN dynamic loads—proven in 50+ port cranes across Southeast Asia.

Medical Imaging Gantries

Non-magnetic, low-noise bearings comply with IEC 60601 standards for MRI and CT scanners.

Trusted by 500+ Global Clients

- 12M+ Bearings Produced Annually: Across 3 automated ISO 9001-certified plants.

- End-to-End Support: From CAD modeling to on-site installation.

- 100% Testing: Every bearing undergoes vibration, hardness, and fatigue life checks.

FAQ

1. Can your bearings handle OD >5000mm with P4 precision?

Yes! We've delivered φ5200mm non-standard bearings for hydropower turbines, maintaining P4 precision through proprietary grinding techniques.

2. How do you achieve <35dB noise levels?

Precision-ground rollers + brass cages minimize friction. Medical-grade bearings are further polished to Ra 0.05μm.

3. What’s your lead time for urgent orders?

Standard sizes ship in 48 hours. Expedited custom orders save 7 days via our modular assembly lines.

4. Do you support legacy machinery retrofits?

Our engineers provide free fitment analysis and CAD adaptations for outdated equipment.

Contact Us

Need a Cup Tapered Roller Bearing That Outlasts Your Equipment?

📧 Contact our engineers today: sales@inno-bearing.com

✅ 48-hour delivery | 30-day returns | Lifetime technical support

| d 40~50mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 15 | 30 | 13 | 12 | 11 | 1 | 0.3 | 14 | 15 | 9000 | 13000 | 30602-1(TD-CR0529/0256) | 17 | 17 | 25 | 28 | 3 | 7 | 1 | 0.3 | 0.29 | 2.1 | 1.1 | 0.0407 | ||

| 35 | 14.8 | 15 | 11.75 | 1 | 0.3 | 21.8 | 22.4 | 9000 | 13000 | 30602(RV-70FC) | 18 | 18 | 30 | 33 | 3 | 5 | 1 | 0.3 | 0.24 | 2.5 | 1.4 | 0.0716 | |||

| 42 | 14.25 | 13 | 11 | 1 | 1 | 22.9 | 21.7 | 9000 | 13000 | 30302 | 7302E | 2FB | 23 | 23 | 35 | 36 | 3 | 5 | 1 | 1 | 0.28 | 2.1 | 1.1 | 0.0948 | |

| 17 | 40 | 13.25 | 12 | 11 | 1 | 1 | 20.7 | 22.2 | 9000 | 13000 | 30203 | 7203E | 2DB | 22 | 22 | 34 | 35 | 2 | 4 | 1 | 1 | 0.35 | 1.7 | 0.9 | 0.0781 |

| 47 | 15.25 | 14 | 12 | 1 | 1 | 28.3 | 27.4 | 8500 | 12000 | 30303 | 7303E | 2FB | 25 | 25 | 41 | 42 | 3 | 5 | 1 | 1 | 0.28 | 2.1 | 1.1 | 0.13 | |

| 47 | 20.25 | 19 | 16 | 1 | 1 | 35.4 | 36.6 | 8000 | 11000 | 32303 | 7603E | 2FD | 25 | 25 | 41 | 42 | 3 | 6 | 1 | 1 | 0.28 | 2.1 | 1.1 | 0.174 | |

| 20 | 47 | 15.25 | 14 | 12 | 1 | 1 | 28.2 | 30.9 | 8000 | 11000 | 30204 | 7204E | 2DB | 26 | 26 | 42 | 43 | 3 | 5 | 1 | 1 | 0.35 | 1.7 | 0.9 | 0.127 |

| 52 | 16.25 | 15 | 13 | 1.5 | 1.5 | 33.2 | 33.3 | 8000 | 11000 | 30304 | 7304E | 2FB | 28 | 28 | 45 | 47 | 3 | 5 | 1.5 | 1.5 | 03 | 2 | 1.1 | 0.168 | |

| 52 | 22.25 | 21 | 18 | 1.5 | 1.5 | 42.7 | 46.4 | 7500 | 10000 | 32304 | 7604E | 2FD | 28 | 28 | 45 | 47 | 3 | 6 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.231 | |

| 22 | 47 | 20 | 21 | 16 | 1 | 1 | 39.5 | 46 | 7500 | 10000 | 306/22 | 26 | 26 | 42 | 44 | 6.5 | 9 | 1 | 1 | 0.29 | 2.1 | 1.1 | 0.167 | ||

| 25 | 52 | 16.25 | 15 | 13 | 1 | 1 | 33.7 | 39.4 | 7500 | 10000 | 30205 | 7205E | 3CC | 31 | 31 | 46 | 47 | 3 | 5 | 1 | l | 0.37 | 1.6 | 0.9 | 0.157 |

| 52 | 19.25 | 18 | 16 | 1 | 1 | 39 | 48.8 | 7000 | 9500 | 32205 | 2CD | 31 | 31 | 44 | 46 | 3 | 4 | 1 | 1 | 0.36 | 1.7 | 0.9 | 0.184 | ||

| 62 | 18.25 | 17 | 13 | 1.5 | 1.5 | 40.7 | 46 | 5600 | 7500 | 31305 | 27305E | 7FB | 33 | 33 | 52 | 57 | 3 | 7 | 1.5 | 1.5 | 0.83 | 0.7 | 04 | 0.264 | |

| 62 | 18.25 | 17 | 14 | 1.5 | 1.5 | 40.7 | 46 | 5600 | 7500 | 31305X2YB2 | 33 | 33 | 52 | 57 | 3 | 7 | 1.5 | 1.5 | 0.54 | 1.1 | 0.6 | 0.267 | |||

| 62 | 18.25 | 17 | 15 | 1.5 | 1.5 | 47 | 48.3 | 6700 | 9000 | 30305 | 7305E | 2FB | 33 | 33 | 55 | 57 | 3 | 5 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.265 | |

| 62 | 18.25 | 17 | 15 | 1.5 | 1.5 | 49.1 | 48.1 | 5600 | 7500 | 30305/YB | 33 | 33 | 55 | 57 | 3 | 5 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.265 | |||

| 62 | 25.25 | 24 | 20 | 1.5 | 1.5 | 61.7 | 68.9 | 6000 | 8000 | 32305 | 7605E | 2FD | 33 | 33 | 55 | 57 | 3 | 7 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.37 | |

| 30 | 58 | 19.45 | 20 | 15.5 | 1.5 | 0.3 | 45.9 | 57.2 | 6100 | 7700 | 30606(ST3058-1) | 34 | 34 | 52 | 56 | 7 | 9 | 1.5 | 0.3 | 0.32 | 1.9 | 1 | 0.261 | ||

| 62 | 17.25 | 16 | 14 | 1 | 1 | 43.3 | 50.6 | 6300 | 8500 | 30206 | 7206E | 3DB | 36 | 36 | 56 | 57 | 3 | 5 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.232 | |

| 62 | 20 | 20 | 16 | 1 | 1 | 54.3 | 63.6 | 6300 | 8500 | 32206X2 | 36 | 36 | 56 | 59 | 8 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.277 | ||||

| 62 | 21.25 | 20 | 17 | 1 | 1 | 51.8 | 63.9 | 6300 | 8500 | 32206 | 7506E | 3DC | 36 | 36 | 56 | 57 | 3 | 6 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.285 | |

| 72 | 20.75 | 19 | 16 | 1.5 | 1.5 | 59 | 63.9 | 5600 | 7500 | 30306 | 7306E | 2FB | 38 | 38 | 64 | 66 | 3 | 7 | 1.5 | 1.5 | 0.31 | 1.9 | 1 | 0.389 | |

| 72 | 20.75 | 19 | 14 | 1.5 | 1.5 | 51 | 36 | 5000 | 6700 | 31306 | 27306E | 7FB | 38 | 38 | 64 | 66 | 7 | 1.5 | 1.5 | 0.82 | 0.7 | 0.4 | 0.394 | ||

| 72 | 24.5 | 24 | 17.6 | 3 | 1.5 | 53.8 | 65.9 | 5600 | 7500 | 30306X2B | 27706 | 36 | 36 | 60 | 68 | 5 | 9 | 2.5 | 1 | 0.6 | 1 | 0.56 | 0.472 | ||

| d 30~45mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 30 | 72 | 28.75 | 27 | 23 | 1.5 | 1.5 | 66.8 | 83.3 | 5300 | 7000 | 32306 | 7606E | 2FD | 38 | 38 | 64 | 66 | 4 | 8 | 1.5 | 1.5 | 0.31 | 1.9 | 1 | 0.566 |

| 72 | 28.75 | 27 | 23 | 1.5 | 15 | 66.8 | 83.3 | 5300 | 7000 | 32306AN | 37 | 38 | 59 | 66 | 4 | 6 | 1.5 | 1.5 | 31 | 1.9 | 1 | 0.587 | |||

| 32 | 75 | 29.75 | 28 | 23 | 1.5 | 1.5 | 76.9 | 60.6 | 5200 | 6900 | 323/32 | 76/32 | 39 | 39 | 68 | 71 | 3 | 6.5 | 1.5 | 1.5 | 0.55 | 1.1 | 0.6 | 0.647 | |

| 35 | 62 | 18 | 18 | 14 | 1 | 1 | 42.3 | 53.7 | 6000 | 8000 | 32007 | 3DC | 40 | 41 | 54 | 59 | 4 | 4 | 1 | 1 | 0.2 | 2.9 | 1.6 | 0.22 | |

| 65 | 18 | 18 | 14 | 3.5 | 3.5 | 41.3 | 59 | 6000 | 8000 | 30607 | 3DB | 50 | 50 | 56 | 50 | 3 | 5 | 3 | 3 | 0.38 | 1.5 | 0.8 | 0.246 | ||

| 72 | 18.25 | 17 | 15 | 1.5 | 1.5 | 54.2 | 63.7 | 5300 | 7000 | 30207 | 7207E | 3DB | 43 | 43 | 64 | 67 | 3 | 5 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.333 | |

| 72 | 24.25 | 23 | 19 | 1.5 | 1.5 | 70.6 | 89.7 | 5300 | 7000 | 32207 | 7507E | 3DC | 43 | 43 | 64 | 67 | 3 | 7 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.447 | |

| 72 | 28 | 28 | 22 | 1.5 | 1.5 | 82.6 | 102 | 5500 | 7000 | 33207 | 40 | 41 | 62 | 71 | 3 | 7 | 1.5 | 1.5 | 0.35 | 1.7 | 0.9 | 0.518 | |||

| 80 | 22.75 | 21 | 18 | 2 | 1.5 | 75.4 | 83.6 | 5000 | 6700 | 30307 | 7307E | 2FB | 44 | 44 | 71 | 75 | 3 | 7 | 2 | 1.5 | 0.31 | 1.9 | 1 | 0.518 | |

| 80 | 22.75 | 21 | 15 | 2 | 1.5 | 63.8 | 45.8 | 4500 | 6000 | 31307 | 27307E | 42 | 44 | 62 | 76 | 4 | 8 | 2 | 1.5 | 0.82 | 0.7 | 0.4 | 0.517 | ||

| 80 | 32.75 | 31 | 25 | 2 | 1.5 | 99.1 | 119.7 | 4800 | 6300 | 32307 | 7607E | 2FE | 44 | 44 | 71 | 75 | 5 | 10 | 2 | 1.5 | 31 | 1.9 | 1 | 0.766 | |

| 80 | 32.75 | 31 | 24 | 2 | 1.5 | 94.7 | 116 | 4800 | 6300 | 32307CN | 43 | 44 | 66 | 74 | 4 | 8 | 2 | 2 | 0.31 | 1.9 | 1 | 0.777 | |||

| 40 | 62 | 15.2 | 14 | 12 | 0.6 | 0.6 | 30 | 50 | 5600 | 7200 | 32908X2 | 2007908 | 46 | 46 | 57 | 58 | 3 | 5 | 0.6 | 6 | 0.28 | 2.1 | 1.1 | 0.139 | |

| 68 | 19 | 19 | 14.5 | 1 | 1 | 52.6 | 72.3 | 5300 | 7000 | 32008 | 3DB | 46 | 46 | 60 | 65 | 4 | 4.5 | 1 | 1 | 0.38 | 1.5 | 0.8 | 0.275 | ||

| 80 | 19.75 | 18 | 16 | 1.5 | 1.5 | 63 | 74.1 | 4800 | 6300 | 30208 | 7208E | 3DB | 48 | 48 | 72 | 75 | 3 | 6 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.423 | |

| 80 | 21.5 | 18 | 17.75 | 1.5 | 1.5 | 66 | 80 | 5300 | 6600 | 30608 | 7808E | 48 | 48 | 72 | 75 | 4 | 7 | 15 | 1.5 | 0.37 | 1.6 | 0.9 | 0.446 | ||

| 80 | 24.75 | 23 | 19 | 1.5 | 1.5 | 77.9 | 97.5 | 4800 | 6300 | 32208 | 7508E | 3DC | 48 | 48 | 72 | 75 | 3 | 8 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.529 | |

| 80 | 24.75 | 23 | 10 | 1.5 | 1.5 | 77.9 | 97.5 | 4800 | 6300 | 32208R | 47 | 48 | 68 | 75 | 3 | 6 | 2 | 1.5 | 0.37 | 1.6 | 0.9 | 0.549 | |||

| 90 | 25.25 | 23 | 20 | 2 | 1.5 | 90.8 | 108.7 | 4500 | 6000 | 30308 | 7308E | 2FB | 49 | 49 | 80 | 85 | 3 | 7 | 2 | 1.5 | 0.35 | 1.7 | 0.9 | 0.748 | |

| 90 | 25.25 | 23 | 17 | 2 | 1.5 | 81.5 | 96.5 | 4000 | 5300 | 31308 | 27308E | 7EB | 49 | 49 | 80 | 85 | 6 | 10 | 2 | 1.5 | 0.83 | 0.7 | 0.4 | 0.729 | |

| 90 | 35.25 | 33 | 27 | 2 | 1.5 | 115.3 | 149 | 4000 | 5300 | 32308 | 7608E | 2FD | 49 | 49 | 80 | 85 | 5 | 10 | 2 | 1.5 | 0.35 | 1.7 | 0.9 | 1 | |

| 90 | 35.25 | 33 | 26 | 2 | 1.5 | 100 | 118 | 4000 | 5300 | 32308CN | 49 | 49 | 73 | 83 | 4 | 8.5 | 2 | 2 | 0.35 | 1.7 | 0.9 | 1.02 | |||

| 45 | 85 | 20.75 | 19 | 16 | 1.5 | 1.5 | 67.6 | 84.4 | 4500 | 6000 | 30209 | 7209E | 3DB | 53 | 53 | 76 | 79 | 3 | 7 | 1.5 | 1.5 | 0.4 | 1.5 | 0.8 | 0.474 |

| 85 | 24.75 | 23 | 19 | 1.5 | 1.5 | 80.3 | 105.1 | 4500 | 6000 | 32209 | 7509E | 3DC | 53 | 53 | 76 | 79 | 3 | 8 | 1.5 | 1.5 | 0.4 | 1.5 | 0.8 | 0.585 | |

| d 45~55mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 45 | 85 | 24.75 | 23 | 19 | 1.5 | 1.5 | 72 | 60 | 4500 | 6000 | 32209R | 53 | 53 | 76 | 79 | 3 | 8 | 1.5 | 1.5 | 0.4 | |||||

| 85 | 25 | 23.5 | 20 | 1.5 | 1.5 | 77 | 93 | 4500 | 6000 | 32209/YB2 | 127509 | 53 | 53 | 76 | 79 | 3 | 8 | 15 | 1.5 | 0.4 | 1.5 | 0.8 | 0.584 | ||

| 85 | 32 | 32 | 25 | 1.5 | 1.5 | 113 | 147 | 4000 | 5300 | 33209 | 52 | 52 | 72 | 78 | 5 | 7 | 1 | 1 | 0.4 | 1.5 | 0.8 | 0.82 | |||

| 100 | 27.25 | 25 | 22 | 2 | 1.5 | 108.7 | 131.2 | 4000 | 5300 | 30309 | 7309E | 2FB | 54 | 54 | 90 | 94 | 4 | 7 | 2 | 1.5 | 0.35 | 1.7 | 0.9 | 988 | |

| 100 | 32 | 29 | 20 | 1.5 | 1.5 | 63 | 83 | 4000 | 5300 | 30309X2B | 27709 | 51 | 51 | 82 | 96 | 6 | 13 | 1.5 | 1.5 | 0.7 | 0.8 | 0.46 | 1.04 | ||

| 47 | 100 | 43 | 43 | 37 | 1.5 | 1 | 108 | 169 | 4000 | 5300 | 30647 | 7909 | 57 | 57 | 86 | 95 | 6 | 8 | 1.5 | 0.3 | 1.9 | 1.1 | 1.66 | ||

| 50 | 80 | 20 | 20 | 15.5 | 1.5 | 1.5 | 54.5 | 85 | 4500 | 6000 | 32010/YB2 | 3DC | 56 | 56 | 72 | 77 | 4 | 4.5 | 1.5 | 1.5 | 0.42 | 14 | 0.8 | 373 | |

| 80 | 20 | 20 | 15.5 | 1 | 1 | 59.1 | 85 | 4500 | 6000 | 32010 | 3DC | 56 | 56 | 72 | 77 | 4 | 4.5 | 1 | 1 | 0.42 | 1.4 | 0.8 | 0.373 | ||

| 90 | 21.75 | 20 | 17 | 1.5 | 1.5 | 76.1 | 97.4 | 4300 | 5600 | 30210 | 7210E | 3DB | 58 | 58 | 82 | 85 | 4 | 7 | 1.5 | 1.5 | 0.43 | 1.4 | 0.8 | 0.539 | |

| 90 | 24.75 | 23 | 19 | 1.5 | 1.5 | 89.4 | 120 | 4300 | 5600 | 32210 | 7510E | 3DC | 58 | 58 | 82 | 85 | 3 | 8 | 1.5 | 1.5 | 43 | 1.4 | 0.8 | 0.645 | |

| 90 | 24.75 | 23 | 19 | 1.5 | 1.5 | 77 | 65 | 4300 | 5600 | 32210R | 57 | 57 | 78 | 86 | 3 | 6 | 1.5 | 1.5 | 0.43 | 1.4 | 0.8 | 0.668 | |||

| 110 | 29.25 | 27 | 23 | 2.5 | 2 | 129.9 | 158.9 | 3600 | 4800 | 30310 | 7310E | 2FB | 60 | 60 | 98 | 103 | 4 | 8 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.3 | |

| 110 | 29.25 | 27 | 19 | 2.5 | 2 | 102 | 128 | 3200 | 4300 | 31310 | 27310E | 58 | 60 | 87 | 105 | 10.5 | 25 | 2 | 0.82 | 0.7 | 4 | 122 | |||

| 110 | 31.75 | 29.5 | 23 | 2.5 | 136 | 157 | 3200 | 4300 | 30310X2 | 60 | 60 | 98 | 103 | 4 | 8 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.35 | ||||

| 110 | 42.25 | 40 | 33 | 2.5 | 2 | 177.3 | 238.7 | 3200 | 4300 | 32310 | 7610E | 2FD | 60 | 60 | 98 | 103 | 6 | 12 | 2.1 | 2 | 0.35 | 1.7 | 9 | 1.9 | |

| 110 | 42.25 | 40.5 | 33 | 2.5 | 190 | 244 | 3200 | 4300 | AK32310 | 60 | 60 | 98 | 103 | 6 | 12 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.91 | ||||

| 50.8 | 100 | 35 | 35 | 27 | 2.5 | 2.5 | 140 | 192 | 3400 | 4500 | 33910/YB2 | 63 | 63 | 90 | 88 | 3 | 5 | 2 | 2 | 0.4 | 1.5 | 0.8 | 1.17 | ||

| 55 | 90 | 23 | 23 | 17.5 | 1.5 | 1.5 | 75.4 | 122 | 4000 | 5300 | 32011 | 2007111E | 3CE | 63 | 62 | 81 | 86 | 4 | 5.5 | 1.5 | 1.5 | 0.4 | 1.5 | 0.8 | 0.561 |

| 95 | 30 | 30 | 23 | 1.5 | 1.5 | 105 | 148 | 3800 | 5000 | 33111 | 3007711 | 3CE | 63 | 63 | 81 | 92 | 5 | 7 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.862 | |

| 100 | 22.75 | 21 | 18 | 2 | 1.5 | 90.9 | 115.7 | 3800 | 5000 | 30211 | 7211E | 3DB | 64 | 64 | 90 | 94 | 4 | 7 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 0.719 | |

| 100 | 24.75 | 23 | 18 | 2 | 1.5 | 90.1 | 111 | 3800 | 5000 | 30211 X2 | 64 | 64 | 88 | 95 | 4 | 5 | 2 | 1.5 | 0.55 | 1 | 0.6 | 0.76 | |||

| 100 | 26.75 | 25 | 21 | 2 | 1.5 | 107.5 | 143.8 | 3800 | 5000 | 32211 | 7511E | 3DC | 64 | 64 | 90 | 94 | 4 | 8 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 0.86 | |

| 100 | 35 | 35 | 27 | 2 | 1.5 | 3800 | 5000 | 33211 | 0.4 | 1.5 | 0.8 | 1.22 | |||||||||||||

| 120 | 31.5 | 29 | 21 | 2.5 | 129.9 | 158 | 2800 | 3800 | 31311 | 27311E | 7FB | 65 | 65 | 103 | 114 | 8 | 14 | 2.1 | 2 | 0.83 | 0.7 | 0.4 | 1.56 | ||

| 120 | 31.5 | 29 | 21 | 4 | 3 | 113 | 90 | 2800 | 3800 | 31311/YB2 | 70 | 65 | 104 | 112 | 4 | 6.5 | 1.8 | 1.8 | 0.82 | 0.7 | 0.4 | 1.56 | |||

| d 55~65mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 55 | 120 | 31.5 | 29 | 25 | 2.5 | 2 | 153.1 | 189.7 | 3200 | 4300 | 30311 | 7311 | 2FB | 65 | 65 | 106 | 114 | 4 | 9 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 163 |

| 120 | 31.5 | 29 | 21 | 2.5 | 2 | 16 | 191 | 3200 | 4300 | 30311R | 65 | 65 | 106 | 114 | 4 | 9 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.69 | |||

| 120 | 45.5 | 43 | 35 | 2.5 | 2 | 202.8 | 274.3 | 3000 | 4000 | 32311 | 7611E | 2FD | 65 | 65 | 106 | 114 | 8 | 14 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 2.33 | |

| 120 | 45.5 | 43 | 35 | 7 | 2 | 203 | 256 | 3000 | 4000 | 32311/YB2 | 66 | 65 | 99 | 111 | 5 | 10.5 | 1.8 | 1.8 | 0.35 | 1.7 | 0.9 | 2.34 | |||

| 125 | 37 | 36 | 25 | 3 | 2 | 158 | 209 | 3000 | 4000 | 31611 | 3DB | 69 | 69 | 107 | 111 | 4 | 11 | 2.5 | 2.5 | 0.73 | 0.8 | 0.4 | 2.11 | ||

| 130 | 36 | 33 | 22 | 3 | 2.5 | 170 | 184 | 2800 | 3800 | 30611 | 2FB | 69 | 69 | 111 | 116 | 4 | 11 | 2.5 | 2.5 | 0.82 | 0.7 | 0.4 | 2.11 | ||

| 60 | 85 | 17.3 | 16 | 14 | 1 | 1 | 56 | 83 | 4000 | 5300 | 32912X2 | 2007912 | 67 | 67 | 78 | 81 | 5 | 1 | 1 | 0.38 | 1.6 | 0.9 | 0.24 | ||

| 95 | 23 | 23 | 17.5 | 1.5 | 1.5 | 79.8 | 125 | 3800 | 5000 | 32012 | 2007112E | 3CE | 67 | 67 | 85 | 91 | A | 5.5 | 1.5 | 1.5 | 0.43 | 1.4 | 0.7 | 0.592 | |

| 110 | 23.75 | 22 | 19 | 2 | 1.5 | 102.9 | 131.5 | 3400 | 4500 | 30212 | 7212E | 69 | 69 | 100 | 104 | 5 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 0.906 | |||

| 110 | 29.75 | 28 | 24 | 2 | 1.5 | 132.2 | 181.5 | 3400 | 4500 | 32212 | 7512E | 3EB | 69 | 69 | 100 | 104 | 4 | 8 | 2 | 1.5 | 04 | 1.5 | 0.8 | 1.18 | |

| 110 | 34.1 | 30 | 20 | 2 | 2 | 82 | 61 | 5810 | 7270 | 3-706 | 70 | 70 | 100 | 104 | 5 | 14 | 2 | 2 | 0.43 | 1.4 | 0.7 | 1.25 | |||

| 130 | 33.5 | 31 | 26 | 3 | 2.5 | 175 | 203 | 3000 | 4000 | 30312 | 7312E | 2FB | 71 | 71 | 116 | 123 | 4 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2 | |

| 130 | 33.5 | 31 | 26 | 3 | 2.5 | 175 | 203 | 3000 | 4000 | 30312R | 71 | 71 | 116 | 123 | 4 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.06 | |||

| 130 | 33.5 | 31 | 22 | 3 | 2.5 | 145.4 | 176.8 | 2600 | 3600 | 31312 | 27312E | 7FB | 71 | 71 | 112 | 123 | 8 | 14 | 2.5 | 2.1 | 0.83 | 0.72 | 0.4 | 2.02 | |

| 130 | 48.5 | 46 | 37 | 3 | 2.5 | 226.3 | 306.1 | 2600 | 3600 | 32312 | 7612E | 7FD | 71 | 71 | 116 | 123 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 2.91 | |

| 62 | 100 | 21.5 | 21 | 16.5 | 1.5 | 1.5 | 70 | 104 | 3900 | 4900 | 306/62 | 7912 | 68 | 71 | 91 | 96.9 | 4 | 6 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.597 | |

| 65 | 100 | 23 | 23 | 17.5 | 1.5 | 1.5 | 84.5 | 131 | 3400 | 4500 | 32013 | 3DC | 72 | 72 | 90 | 97 | 4 | 5.5 | 1.5 | 1.5 | 046 | 1.3 | 0.7 | 0.631 | |

| 110 | 34 | 34 | 26.5 | 1.5 | 1.5 | 125 | 202 | 3200 | 4300 | 33113 | 75 | 75 | 100 | 104 | 4 | 5 | 1.5 | 1.5 | 0.39 | 1.5 | 0.8 | 1.27 | |||

| 120 | 24.75 | 23 | 20 | 2 | 1.5 | 120 | 154.2 | 3000 | 4000 | 30213 | 7213E | 3EB | 74 | 74 | 108 | 114 | 5 | 7 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 1.13 | |

| 120 | 32.75 | 31 | 27 | 2 | 1.5 | 163 | 212 | 3000 | 4000 | 32213 | 7513E | 3EC | 74 | 74 | 108 | 114 | 4 | 8 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 1.54 | |

| 120 | 41 | 41 | 32 | 2 | 1.5 | 184 | 257 | 2800 | 3800 | 33213 | 3007213 | 3EE | 74 | 76 | 104 | 111 | 6 | 12 | 2 | 1.5 | 0.39 | 1.5 | 0.8 | 2.01 | |

| 120 | 41 | 41 | 32 | 2 | 1.5 | 183 | 280 | 2800 | 3800 | 33213TN1 | 74 | 77 | 106 | 114 | 5 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 1.91 | ||||

| 130 | 45 | 43 | 35 | 7 | 2 | 207 | 306 | 2600 | 3600 | 30613 | 70 | 75 | 100 | 104 | 4 | 8 | 3 | 1.5 | 0.33 | 1.5 | 0.8 | 2.64 | |||

| 140 | 36 | 33 | 28 | 3 | 2.5 | 195.7 | 244.4 | 2600 | 3600 | 30313 | 7313E | 7GB | 76 | 76 | 125 | 132 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.45 | |

| 140 | 36 | 33 | 28 | 6 | 2.5 | 206 | 243 | 2600 | 3600 | 30313/YB2 | 76 | 76 | 125 | 132 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.44 | |||

| 140 | 40 | 39 | 26 | 3 | 2.5 | 204 | 246 | 2600 | 3600 | 30313X2B | 76 | 76 | 125 | 132 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.68 | |||

| d 60~80mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 60 | 140 | 36 | 33 | 23 | 3 | 2.5 | 165.7 | 202.6 | 2200 | 3200 | 31313 | 27313E | 7GB | 76 | 76 | 120 | 132 | 10 | 16 | 2.5 | 2.1 | 0.83 | 0.7 | 0.4 | 2.39 |

| 140 | 40 | 38 | 27 | 3 | 2.5 | 187 | 247 | 2600 | 3600 | 31613? | 3DB | 79 | 79 | 122 | 126 | 6 | 13 | 2.5 | 2.5 | 0.73 | 0.8 | 0.4 | 2.74 | ||

| 140 | 51 | 48 | 39 | 3 | 2.5 | 259.3 | 353.6 | 2400 | 3400 | 32313 | 7613E | 2GD | 76 | 76 | 125 | 132 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 3.35 | |

| 140 | 51 | 48 | 39 | 3 | 2.5 | 230 | 206 | 2400 | 3400 | 32313R | 76 | 76 | 125 | 132 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 3.63 | |||

| 70 | 120 | 33 | 33 | 27 | 2 | 2 | 151 | 217 | 3000 | 4000 | 33114X2 | 7814E | 3DE | 77 | 77 | 110 | 115 | 5 | 10 | 2 | 2 | 0.28 | 2.2 | 1.2 | 1.46 |

| 120 | 33 | 33 | 27 | 2 | 2 | 173 | 246 | 3000 | 4000 | 33114X2/YA | 77 | 77 | 110 | 115 | 5 | 10 | 2 | 2 | 0.28 | 2.2 | 1.2 | 1.55 | |||

| 125 | 26.25 | 24 | 21 | 1.5 | 132 | 174.3 | 3000 | 4000 | 30214 | 7214E | 3EB | 79 | 79 | 114 | 119 | 5 | 7 | 2 | 1.5 | 0.42 | 1.4 | 0.8 | 1.26 | ||

| 125 | 33.25 | 31 | 27 | 2 | 1.5 | 168.1 | 238 | 2800 | 3800 | 32214 | 7514E | 3EC | 79 | 79 | 114 | 119 | 4 | 8 | 2 | 1.5 | 42 | 1.4 | 0.8 | 1.65 | |

| 150 | 38 | 35 | 30 | 3 | 2.5 | 218.8 | 274.7 | 2400 | 3400 | 30314 | 7314E | 2GB | 81 | 81 | 135 | 142 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 9 | 2.99 | |

| 150 | 38 | 35 | 30 | 9 | 2.5 | 230 | 275 | 2400 | 3400 | 30314/YB2 | 81 | 81 | 135 | 142 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.97 | |||

| 70 | 150 | 38 | 35 | 25 | 5 | 2.5 | 197 | 232 | 2000 | 3000 | 31314 | 82 | 89 | 130 | 141 | 5 | 8 | 4 | 2.5 | 0.82 | 0.7 | 0.4 | 2.91 | ||

| 150 | 38 | 35 | 25 | 5 | 2.5 | 197 | 232 | 2000 | 3000 | 31314/YB2 | 82 | 89 | 130 | 141 | 5 | 8 | 4 | 2.5 | 0.82 | 0.7 | 0.4 | 2.91 | |||

| 150 | 54 | 51 | 42 | 3 | 2.5 | 298.8 | 413.4 | 2200 | 3200 | 32314 | 7614E | 2GD | 81 | 81 | 135 | 142 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 4.43 | |

| 75 | 130 | 27.25 | 25 | 22 | 2 | 1.5 | 137.7 | 186.9 | 2800 | 3800 | 30215 | 7215E | 4DB | 84 | 84 | 119 | 124 | 5 | 7 | 2 | 1.5 | 0.44 | 1.4 | 0.8 | 1.38 |

| 130 | 33.25 | 31 | 27 | 2 | 1.5 | 169.5 | 244.1 | 2600 | 3600 | 32215 | 7515 | 4DC | 84 | 84 | 119 | 124 | 4 | 8 | 2 | 1.5 | 44 | 1.4 | 0.8 | 1.74 | |

| 135 | 44 | 45 | 35 | 2 | 2 | 175 | 274 | 3000 | 3800 | 30615/YB2 | 82 | 85 | 119 | 131 | 5 | 11 | 2 | 2 | 0.28 | 2.2 | 1.2 | 2.57 | |||

| 135 | 44.5 | 45 | 36.5 | 2 | 228 | 339 | 3000 | 3800 | 30615 | 82 | 85 | 119 | 131 | 5 | 11 | 2 | 2 | 0.28 | 2.2 | 1.2 | 2.69 | ||||

| 135 | 44.5 | 45 | 36.5 | 2 | 2 | 240 | 370 | 3000 | 3800 | 30615/YA | 86 | 86 | 120 | 125 | 5 | 11 | 2 | 2 | 0.24 | 2.5 | 1.4 | 2.76 | |||

| 160 | 40 | 37 | 26 | 3 | 2.5 | 219 | 259 | 1900 | 2800 | 31315 | 87 | 91 | 127 | 148 | 6 | 14 | 2 | 2 | 0.83 | 0.72 | 0.4 | 3.5 | |||

| 160 | 40 | 37 | 31 | 3 | 2.5 | 250.3 | 318.6 | 2200 | 3200 | 30315 | 7315E | 2GB | 86 | 86 | 143 | 152 | 5 | 11 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 3.58 | |

| 160 | 58 | 55 | 45 | 3 | 2.5 | 358 | 472 | 2000 | 3000 | 32315 | 7615E | 2GD | 86 | 86 | 143 | 152 | 10 | 16 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 5.32 | |

| 170 | 61.5 | 58 | 48 | 3 | 2.5 | 406 | 543 | 1900 | 2800 | T6GD075 | 90 | 90 | 152 | 162 | 10 | 16 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 6.64 | |||

| 80 | 110 | 20 | 20 | 16 | 1 | 1 | 72.8 | 123 | 32916 | 0.538 | |||||||||||||||

| 125 | 29 | 29 | 22 | 1.5 | 1.5 | 136 | 209 | 2600 | 3600 | 32016 | 3EB | 87 | 89 | 112 | 120 | 6 | 7 | 1 | 1 | 0.42 | 1.6 | 0.8 | 1.27 | ||

| 130 | 32 | 31 | 25 | 1 | 3.5 | 140 | 233 | 2500 | 3500 | 30616/YB2 | 86 | 86 | 119 | 124 | 5 | 7 | 1 | 0.38 | 1.6 | 0.8 | 1.56 | ||||

| 140 | 28.25 | 26 | 22 | 2.5 | 2 | 160.1 | 213.6 | 2400 | 3400 | 30216 | 7216E | 3EB | 90 | 90 | 127 | 134 | 5 | 8 | 1 | 2 | 0.42 | 1.4 | 0.8 | 1.84 | |

| d 80~95mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 80 | 140 | 35.25 | 33 | 28 | 2.5 | 2 | 198 | 280.1 | 2400 | 3400 | 32216 | 7516E | 3EC | 90 | 90 | 127 | 134 | 5 | 8 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 2.03 |

| 140 | 35.5 | 33 | 28 | 2 | 2 | 160 | 241 | 2400 | 3400 | 32216/YB2 | 7516 | 90 | 90 | 127 | 134 | 5 | 8 | 2 | 2 | 0.4 | 1.5 | 0.8 | 2.15 | ||

| 140 | 45 | 45 | 36.5 | 2.5 | 2 | 233 | 214 | 2200 | 3200 | 30616 | 87 | 90 | 127 | 136 | 5 | 11 | 2.1 | 2 | 0.28 | 2.2 | 1.2 | 2.81 | |||

| 170 | 42.5 | 39 | 33 | 3 | 2.5 | 286 | 343 | 2000 | 3000 | 30316 | 7316E | 2GB | 92 | 92 | 152 | 162 | 7 | 12 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 4.5 | |

| 170 | 61.5 | 58 | 48 | 3 | 2.5 | 400 | 532 | 1900 | 2800 | 32316 | 7616E | 2GD | 92 | 92 | 152 | 162 | 10 | 16 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 6.39 | |

| 85 | 140 | 77.07 | 38.5 | 69.14 | 2 | 0.6 | B3-748L | 95 | 95 | 130 | 2 | 2 | 0.33 | 1.8 | 1 | 3.32 | |||||||||

| 150 | 30.5 | 28 | 24 | 2.5 | 2 | 180 | 242.5 | 2200 | 3200 | 30217 | 7217E | 3EB | 95 | 95 | 136 | 144 | 5 | 9 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 2.06 | |

| 150 | 38.5 | 36 | 30 | 2.5 | 2 | 220 | 323 | 2200 | 3200 | 32217 | 7517E | 3EC | 95 | 95 | 136 | 144 | 5 | 11 | 2.1 | 2 | 042 | 1.4 | 0.8 | 2.67 | |

| 150 | 49 | 49 | 37 | 2.5 | 2 | 272 | 409 | 2000 | 3000 | 33217 | 3007217 | 3EE | 95 | 95 | 136 | 145 | 7 | 12 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 3.57 | |

| 180 | 44.5 | 41 | 34 | 4 | 3 | 304.5 | 392.4 | 1900 | 2800 | 30317 | 7317E | 3GB | 97 | 97 | 161 | 171 | 8 | 14 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 5.305 | |

| 180 | 44.5 | 41 | 28 | 4 | 3 | 266 | 320 | 1800 | 2600 | 31317 | 99 | 103 | 143 | 169 | 6 | 6.5 | 2.5 | 2.5 | 0.83 | 0.72 | 0.4 | 4.6 | |||

| 180 | 63.5 | 60 | 49 | 4 | 3 | 434 | 580 | 1800 | 2600 | 32317 | 7617E | 2GD | 98 | 98 | 161 | 171 | 12 | 18 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 6.81 | |

| 90 | 140 | 32 | 32 | 24 | 2 | 1.5 | 159 | 245 | 2200 | 3200 | 32018 | 3EB | 99 | 100 | 125 | 134 | 6 | 8 | 2 | 1.5 | 0.42 | 1.4 | 0.8 | 1.7 | |

| 140 | 32.4 | 30 | 26 | 2 | 1.5 | 160 | 257 | 2200 | 3200 | 32018X2/YA | 2007118 | 99 | 99 | 128 | 134 | 5 | 8 | 2 | 1.5 | 0.34 | 1.8 | 1 | 1.66 | ||

| 140 | 32.4 | 30 | 26 | 2 | 1.5 | 130 | 210 | 2200 | 3200 | 32018 RX2 | 99 | 100 | 125 | 134 | 6 | 8 | 2 | 2 | 0.34 | 1.7 | 0.9 | 1.7 | |||

| 150 | 45 | 45 | 35 | 2.5 | 2 | 231 | 396 | 2000 | 3000 | 33118TN1 | 102 | 102 | 134 | 138 | 5 | 10 | 2 | 2 | 0.4 | 1.5 | 0.8 | 2.97 | |||

| 160 | 32.5 | 30 | 26 | 2.5 | 2 | 199.7 | 270.5 | 2000 | 3000 | 30218 | 7218E | 3FB | 100 | 100 | 145 | 153 | 5 | 9 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 2.558 | |

| 160 | 42.5 | 40 | 34 | 2.5 | 2 | 269.1 | 396.9 | 2000 | 3000 | 32218 | 7518E | 3FC | 100 | 100 | 145 | 153 | 5 | 11 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 3.33 | |

| 190 | 46.5 | 43 | 36 | 4 | 3 | 341.7 | 445.7 | 1800 | 2600 | 30318 | 7318E | 2GB | 103 | 103 | 170 | 181 | 8 | 14 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 6.144 | |

| 190 | 67.5 | 64 | 53 | 4 | 3 | 4,777 | 690.8 | 1700 | 2400 | 32318 | 7618E | 2GD | 103 | 103 | 170 | 181 | 12 | 18 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 8.76 | |

| 95 | 145 | 32 | 32 | 24 | 2 | 1.5 | 162 | 255 | 2200 | 3200 | 32019 | 3EB | 104 | 105 | 130 | 140 | 6 | 8 | 2 | 1.5 | 0.45 | 1.3 | 0.7 | 177 | |

| 145 | 32.4 | 30 | 26 | 2 | 1.5 | 226.1 | 310.2 | 2200 | 3200 | 32019X2/YA | 2007119 | 104 | 104 | 133 | 139 | 5 | 8 | 2 | 1.5 | 0.36 | 1.7 | 0.9 | 1.7 | ||

| 160 | 47 | 47 | 38 | 3 | 2.5 | 251 | 420 | 3970 | 4970 | 30619 | 3FB | 109 | 109 | 145 | 146 | 5 | 9 | 2.5 | 2.5 | 0.29 | 2 | 1.1 | 3.7 | ||

| 170 | 34.5 | 32 | 27 | 3 | 2.5 | 226.1 | 310.2 | 1900 | 2800 | 30219 | 7219E | 3FB | 106 | 106 | 157 | 163 | 5 | 10 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 3.269 | |

| 170 | 45.5 | 43 | 37 | 3 | 2.5 | 313 | 443 | 1900 | 2800 | 32219 | 7519E | 3FC | 106 | 106 | 157 | 163 | 5 | 11 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 4.216 | |

| 170 | 58 | 58 | 44 | 3 | 2.5 | 1900 | 2800 | 33219 | 106 | 106 | 157 | 163 | 5 | 11 | 2.5 | 2.1 | |||||||||

| d 95~120mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 95 | 200 | 49.5 | 45 | 38 | 4 | 3 | 368.6 | 483 | 1800 | 2600 | 30319 | 7319E | 2GB | 109 | 109 | 180 | 191 | 8 | 14 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 7.13 |

| 200 | 71.5 | 67 | 55 | 4 | 3 | 515.5 | 745.8 | 1700 | 2400 | 32319 | 7619E | 2GD | 109 | 109 | 180 | 191 | 14 | 20 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 10.73 | |

| 100 | 130 | 57 | 56 | 35 | 11 | 2 | 238 | 327 | LY-3026 | 2.99 | |||||||||||||||

| 150 | 32 | 32 | 24 | 2 | 1.5 | 165 | 265 | 2000 | 3000 | 32020 | 3EB | 109 | 109 | 134 | 144 | 6 | 8 | 2 | 2 | 0.46 | 1.3 | 0.7 | 1.84 | ||

| 150 | 32.4 | 30 | 26 | 2 | 1.5 | 163 | 266 | 2000 | 3000 | 32020YB2 | 2007120 | 109 | 109 | 138 | 144 | 5 | 8 | 2 | 1.5 | 0.37 | 1.6 | 0.9 | 1.79 | ||

| 150 | 32.4 | 30 | 26 | 2 | 1.5 | 150 | 261 | 2000 | 3000 | 32020 RX2 | 109 | 109 | 134 | 144 | 6 | 8 | 2 | 1.5 | 0.37 | 1.6 | 0.9 | 1.8 | |||

| 165 | 47 | 46 | 39 | 3 | 305 | 486 | 1900 | 2800 | 33120X2 | 111 | 111 | 145 | 160 | 5 | 10 | 2.5 | 2.5 | 0.32 | 1.9 | 1 | 3.93 | ||||

| 180 | 37 | 34 | 29 | 3 | 2.5 | 253.3 | 35L6 | 1900 | 2800 | 30220 | 7220E | 3FB | 111 | 111 | 162 | 172 | 5 | 10 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 3.73 | |

| 180 | 49 | 46 | 39 | 3 | 2.5 | 340.2 | 513.7 | 1800 | 2600 | 32220 | 7520E | 3FC | 111 | 11 | 162 | 172 | 5 | 14 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 5.12 | |

| 180 | 63 | 63 | 48 | 3 | 3 | 1700 | 2400 | 33220/YB2 | 111 | 111 | 162 | 2.5 | 2.5 | ||||||||||||

| 215 | 51.5 | 47 | 39 | 4 | 3 | 406 | 532.3 | 1700 | 2400 | 30320 | 7320E | 2GB | 116 | 116 | 194 | 205 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 8.69 | |

| 215 | 77.5 | 73 | 60 | 4 | 3 | 599.5 | 881.9 | 1600 | 2200 | 32320 | 7620E | 2GD | 116 | 116 | 194 | 205 | 14 | 20 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 12.96 | |

| 105 | 160 | 35 | 35 | 26 | 2.5 | 2 | 194 | 311 | 1900 | 2800 | 32021 | 3EB | 115 | 116 | 143 | 154 | 6 | 9 | 2 | 2 | 0.44 | 1.3 | 0.7 | 2.38 | |

| 160 | 43 | 43 | 34 | 2.5 | 2 | 240 | 398 | 1900 | 2800 | 33021 | 3EB | 115 | 116 | 143 | 154 | 6 | 9 | 2 | 2 | 0.46 | 1.3 | 0.7 | 2.94 | ||

| 190 | 39 | 36 | 30 | 3 | 2.5 | 284.6 | 400 | 1800 | 2600 | 30221 | 7221E | 2FB | 116 | 116 | 172 | 182 | 6 | 11 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 4.936 | |

| 190 | 53 | 50 | 43 | 3 | 2.5 | 380.1 | 581.2 | 1800 | 2600 | 32221 | 7521E | 3FC | 116 | 116 | 172 | 182 | 6 | 12 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 6.495 | |

| 225 | 53.5 | 49 | 41 | 4 | 3 | 432.6 | 568.1 | 1600 | 2200 | 30321 | 7321E | 2GB | 120 | 120 | 202 | 215 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 9.912 | |

| 225 | 81.5 | 77 | 63 | 4 | 3 | 646.4 | 955.6 | 1500 | 2000 | 32321 | 7621E | 2GD | 123 | 123 | 202 | 215 | 14 | 20 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 14.458 | |

| 110 | 170 | 38 | 38 | 29 | 2.5 | 2 | 202 | 354 | 1800 | 2800 | 32022 | 3DC | 120 | 122 | 152 | 163 | 7 | 9 | 2 | 0.43 | 1.4 | 0.7 | 3.01 | ||

| 170 | 47 | 47 | 37 | 2.5 | 266 | 464 | 1800 | 2800 | 33022 | 3EB | 120 | 122 | 152 | 163 | 7 | 9 | 2 | 2 | 0.29 | 2.1 | 1.1 | 3.76 | |||

| 200 | 41 | 38 | 32 | 3 | 2.5 | 314.1 | 445.1 | 1700 | 2400 | 30222 | 7222E | 3FB | 121 | 121 | 181 | 192 | 6 | 11 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 5.422 | |

| 200 | 56 | 53 | 46 | 3 | 2.5 | 430.7 | 668.6 | 1700 | 2400 | 32222 | 7522E | 3FC | 121 | 121 | 181 | 192 | 6 | 12 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 7.86 | |

| 240 | 54.5 | 50 | 42 | 4 | 3 | 471.6 | 619.1 | 1600 | 2200 | 30322 | 7322E | 2GB | 124 | 124 | 215 | 230 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 11.45 | |

| 240 | 84.5 | 80 | 65 | 4 | 3 | 722.8 | 1076 | 1400 | 1900 | 32322 | 7622E | 2GD | 127 | 127 | 215 | 230 | 18 | 25 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 18.78 | |

| 120 | 180 | 38 | 38 | 29 | 2.5 | 2 | 230 | 394 | 1700 | 2400 | 32024/YA | 2007124K | 130 | 131 | 161 | 173 | 7 | 9 | 2 | 2 | 0.37 | 1.6 | 0.9 | 3.07 | |

| d 105~150mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 105 | 180 | 38.4 | 36 | 31 | 2.5 | 2 | 230 | 394 | 1700 | 2400 | 32024X2R | 130 | 131 | 161 | 173 | 7 | 9 | 2 | 2 | 0.37 | 1.6 | 0.9 | 3.14 | ||

| 180 | 38.4 | 36 | 31 | 2.5 | 2 | 230 | 394 | 1700 | 2400 | 32024X2/YA | 2007124 | 130 | 130 | 166 | 174 | 6 | 9 | 2.1 | 2 | 0.37 | 1.6 | 0.9 | 3 | ||

| 215 | 43.5 | 40 | 34 | 3 | 2.5 | 335.8 | 487.2 | 1600 | 2200 | 30224 | 7224E | 4FB | 131 | 131 | 196 | 207 | 7 | 12 | 2.5 | 2.1 | 0.44 | 1.4 | 0.8 | 6.125 | |

| 215 | 61.5 | 58 | 50 | 3 | 2.5 | 492 | 741 | 1600 | 2200 | 32224 | 7524E | 4FD | 131 | 131 | 196 | 207 | 8 | 12 | 2.5 | 2.1 | 0.44 | 1.4 | 0.8 | 9.25 | |

| 260 | 59.5 | 55 | 46 | 4 | 3 | 562 | 754.3 | 1500 | 2000 | 30324 | 7324E | 2GB | 137 | 137 | 235 | 250 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 13.7 | |

| 260 | 90.5 | 86 | 69 | 4 | 3 | 824.8 | 1239 | 1300 | 1800 | 32324 | 7624E | 2GD | 138 | 138 | 235 | 250 | 18 | 25 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 21.7 | |

| 120 | 180 | 48 | 48 | 38 | 2.5 | 2 | 283 | 514 | 1700 | 2400 | 33024 | 130 | 131 | 161 | 173 | 7 | 12 | 2 | 2 | 0.31 | 1.9 | 1 | 4.09 | ||

| 130 | 200 | 45 | 45 | 34 | 2.5 | 2 | 309 | 513 | 1600 | 2200 | 32026 | 3EB | 140 | 144 | 178 | 192 | 8 | 11 | 2 | 2 | 0.43 | 1.3 | 0.7 | 4.9 | |

| 230 | 43.75 | 40 | 34 | 4 | 3 | 364.3 | 525.6 | 1500 | 2000 | 30226 | 7226E | 4FB | 142 | 142 | 208 | 222 | 7 | 12 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 7.24 | |

| 230 | 44.5 | 40 | 34 | 4 | 3 | 351 | 466 | 1500 | 2000 | 30226X2 | 7226 | 4FB | 142 | 142 | 208 | 222 | 7 | 12 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 7.25 | |

| 230 | 67.75 | 64 | 54 | 4 | 3 | 561 | 855 | 1500 | 2000 | 32226 | 7526E | 4FD | 142 | 142 | 208 | 222 | 10 | 16 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 11.37 | |

| 280 | 63.75 | 58 | 49 | 5 | 4 | 639.3 | 864.5 | 1300 | 1800 | 30326 | 7326E | 2GB | 148 | 148 | 250 | 267 | 14 | 18 | 4 | 3 | 0.35 | 1.7 | 0.9 | 17.1 | |

| 140 | 190 | 32 | 32 | 25 | 2 | 1.5 | 207 | 390 | 1600 | 2200 | 32928/YB | 146 | 146 | 177 | 187 | 4 | 8 | 2 | 1.5 | 0.36 | 1.7 | 0.9 | 2.49 | ||

| 210 | 45 | 45 | 34 | 2.5 | 2 | 314 | 533 | 1600 | 2200 | 32028 | 3EB | 150 | 153 | 187 | 202 | 8 | 11 | 2 | 2 | 0.46 | 1.3 | 0.7 | 5.14 | ||

| 210 | 45.5 | 42 | 36 | 2.5 | 2 | 285 | 460 | 1600 | 2200 | 32028X2 | 2007128 | 150 | 153 | 187 | 202 | 8 | 11 | 2 | 2 | 0.37 | 1.6 | 0.9 | 5.1 | ||

| 210 | 45.5 | 42 | 36 | 2.5 | 2 | 259 | 460 | 1600 | 2200 | 32028X2LYA | 2007128L | 150 | 153 | 187 | 202 | 8 | 11 | 2 | 2 | 0.37 | 1.6 | 0.9 | 5.72 | ||

| 250 | 45.75 | 42 | 36 | 4 | 3 | 407.3 | 589.4 | 1400 | 1900 | 30228 | 7228E | 4FB | 153 | 153 | 226 | 241 | 7 | 12 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 8.892 | |

| 250 | 71.75 | 68 | 58 | 4 | 3 | 657 | 1020 | 1400 | 1900 | 32228 | 7528E | 4FD | 153 | 153 | 226 | 241 | 10 | 16 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 14.68 | |

| 300 | 67.75 | 62 | 53 | 5 | 4 | 721.8 | 985.5 | 1200 | 1700 | 30328 | 7328E | 2GB | 159 | 159 | 270 | 288 | 14 | 18 | 4 | 3 | 0.35 | 1.7 | 0.9 | 21.7 | |

| 150 | 225 | 48 | 48 | 36 | 3 | 2.5 | 361 | 621 | 1500 | 2000 | 32030 | 3EB | 164 | 162 | 200 | 216 | 8 | 12 | 2.5 | 2.5 | 0.46 | 1.3 | 0.7 | 6.38 | |

| 225 | 48 | 48 | 36 | 8 | 2.5 | 365 | 630 | 1500 | 2000 | 32030/YB | 164 | 174 | 200 | 216 | 8 | 12 | 7 | 2.5 | 0.46 | 1.3 | 0.7 | 6.29 | |||

| 270 | 49 | 45 | 38 | 4 | 3 | 495 | 687 | 1300 | 1800 | 30230 | 7230E | 4GB | 164 | 164 | 248 | 260 | 8 | 14 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 10.3 | |

| 270 | 77 | 73 | 60 | 4 | 3 | 718 | 1191 | 1200 | 1700 | 32230 | 7530E | 4GD | 164 | 164 | 248 | 260 | 14 | 20 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 18.2 | |

| 320 | 115 | 108 | 90 | 5 | 4 | 1010 | 1580 | 950 | 1400 | 32330 | 7630 | 172 | 172 | 287 | 305 | 20 | 30 | 4 | 3 | 0.31 | 1.9 | 1.1 | 37.1 | ||

| d 160~220mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 160 | 240 | 51 | 51 | 38 | 3 | 2.5 | 346 | 346 | 1300 | 1800 | 32032/YA4 | 2007132K | 4GD | 172 | 175 | 213 | 231 | 8 | 13 | 2.5 | 2.5 | 0.37 | 1.6 | 0.9 | 7.16 |

| 240 | 51.5 | 48 | 41 | 3 | 2.5 | 380 | 634 | 1300 | 1800 | 32032X2 | 172 | 175 | 213 | 231 | 8 | 13 | 2 | 2 | 0.46 | 1.3 | 0.7 | 7.41 | |||

| 290 | 52 | 48 | 40 | 4 | 3 | 556 | 774 | 1100 | 1600 | 30232 | 7232E | 4GB | 175 | 175 | 265 | 279 | 8 | 14 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 12.9 | |

| 290 | 84 | 80 | 67 | 4 | 3 | 852.6 | 1446 | 1000 | 1400 | 32232 | 7532E | 4GD | 175 | 175 | 265 | 279 | 14 | 20 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 21.1 | |

| 170 | 260 | 57 | 57 | 43 | 3 | 2.5 | 473 | 815 | 1200 | 1700 | 32034 | 3EB | 182 | 187 | 230 | 249 | 10 | 14 | 2.5 | 2.5 | 0.44 | 1.4 | 0.8 | 10.2 | |

| 360 | 127 | 120 | 100 | 5 | 4 | 1280 | 2080 | 850 | 1100 | 32334 | 7634 | 192 | 192 | 326 | 344 | 20 | 30 | 4 | 3 | 0.36 | 1.7 | 0.9 | 58.3 | ||

| 180 | 280 | 64 | 64 | 48 | 3 | 2.5 | 611 | 1070 | 1100 | 1600 | 32036 | 2007136 | 192 | 199 | 247 | 268 | 10 | 16 | 2.5 | 2.5 | 0.28 | 2.1 | 1.2 | 14 | |

| 280 | 64.5 | 60 | 52 | 3 | 2.5 | 550 | 928 | 1100 | 1600 | 32036X2 | 4GD | 192 | 199 | 247 | 267 | 10 | 16 | 2.5 | 2.5 | 0.28 | 2.1 | 1.2 | 13.5 | ||

| 320 | 91 | 86 | 71 | 5 | 4 | 998.1 | 1727 | 950 | 1400 | 32236 | 7536E | 4GD | 196 | 196 | 292 | 308 | 18 | 25 | 4 | 3 | 0.45 | 1.3 | 0.7 | 29.8 | |

| 190 | 260 | 45 | 45 | 34 | 2.5 | 2 | 335 | 699 | 1100 | 1600 | 32938 | 202 | 202 | 231 | 248 | 8 | 11 | 2 | 2 | 0.48 | 1.25 | 0.7 | 6.76 | ||

| 290 | 64 | 64 | 48 | 3 | 2.5 | 605 | 1070 | 1000 | 1500 | 32038 | 202 | 202 | 268 | 282 | 8 | 0.29 | 1.1 | 14.1 | |||||||

| 290 | 64.5 | 60 | 52 | 3 | 2.5 | 511 | 970 | 1000 | 1500 | 32038X2/YA | 2007138 | 14 | 2.5 | 2.1 | 2.1 | ||||||||||

| 290 | 64.5 | 60 | 52 | 3 | 2.5 | 511 | 970 | 1000 | 1500 | 32038X2/HNYA | 2007138N | 202 | 209 | 257 | 279 | 10 | 16 | 2.5 | 2.5 | 0.29 | 2.1 | 1.1 | 14.1 | ||

| 290 | 64.5 | 60 | 52 | 3 | 2.5 | 511 | 970 | 1000 | 1500 | 32038X2NYA | 2007138N | 202 | 209 | 257 | 279 | 10 | 16 | 2.5 | 2.5 | 0.29 | 2.1 | 1.1 | 14.1 | ||

| 340 | 97 | 92 | 75 | 5 | 4 | 1117 | 1920 | 900 | 1300 | 32238 | 7538E | 4GD | 208 | 208 | 309 | 328 | 18 | 25 | 4 | 3 | 0.44 | 1.4 | 0.8 | 36.1 | |

| 200 | 300 | 55 | 51 | 45 | 5 | 4 | 519 | 909 | LY-3023 | 13.8 | |||||||||||||||

| 310 | 70 | 70 | 53 | 3 | 2.5 | 703 | 1240 | 950 | 1400 | 32040 | 222 | 212 | 273 | 297 | 11 | 17 | 2.5 | 2 | 0.43 | 1.4 | 0.8 | 18.6 | |||

| 310 | 70.5 | 70 | 53.5 | 3 | 2.5 | 950 | 1400 | 950 | 1400 | 32040X2 | 222 | 212 | 273 | 297 | 11 | 17 | 2.5 | 2 | 0.43 | 1.4 | 0.8 | 18.7 | |||

| 360 | 104 | 98 | 82 | 5 | 4 | 1309 | 2204 | 900 | 1300 | 32240 | 7540E | 3GD | 231 | 218 | 302 | 340 | 11 | 22 | 4 | 3 | 0.41 | 1.5 | 0.8 | 43.2 | |

| 205 | 485 | 117.5 | 95.2 | 73 | 4 | 4 | 1418 | 1750 | 770 | 960 | 30641 | 7841 | 247 | 279 | 410 | 454 | 20 | 30 | 3 | 3 | 0.87 | 0.7 | 0.4 | 90.8 | |

| 220 | 340 | 76.5 | 72 | 62 | 4 | 3 | 726 | 1380 | 900 | 1300 | 32044X2 | 2007144 | 234 | 234 | 314 | 331 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 22.2 | |

| 400 | 73 | 65 | 54 | 4 | 770 | 1160 | 850 | 1200 | 31244X2 | 35.4 | |||||||||||||||

| 400 | 73 | 65 | 54 | 4 | 3 | 941 | 1330 | 850 | 1200 | 30244X2 | 7244 | 244 | 244 | 367 | 385 | 14 | 20 | 3 | 2.5 | 0.37 | 1.6 | 0.9 | 35.4 | ||

| d 220~300mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 220 | 400 | 115 | 108 | 90 | 4 | 3 | 1530 | 2565 | 800 | 1100 | 32244 | 7544 | 244 | 244 | 367 | 385 | 20 | 30 | 3 | 2.5 | 0.39 | 1.5 | 0.8 | 48.1 | |

| 400 | 115 | 108 | 90 | 4 | 3 | 1230 | 2280 | 800 | 1100 | 32244X2 | 238 | 238 | 381 | 382 | 12 | 24 | 3 | 3 | 0.39 | 1.5 | 0.8 | 48.1 | |||

| 460 | 154 | 145 | 122 | 5 | 5 | 2130 | 3390 | 750 | 1000 | 32344 | 260 | 260 | 408 | 430 | 20 | 35 | 4 | 4 | 0.37 | 1.6 | 0.9 | 40.6 | |||

| 240 | 320 | 51.5 | 48 | 41 | 3 | 2.5 | 407 | 804 | 900 | 1300 | 32948/YB2 | 10.7 | |||||||||||||

| 320 | 52.5 | 52.5 | 39 | 3 | 2.5 | 473 | 975 | 900 | 1300 | 32948X2 | 10.9 | ||||||||||||||

| 360 | 76 | 76 | 57 | 4 | 3 | 709 | 1560 | 850 | 1200 | 32048 | 254 | 261 | 318 | 346 | 12 | 19 | 3 | 3 | 0.36 | 25.8 | |||||

| 440 | 127 | 120 | 100 | 4 | 4 | 1843 | 3183 | 750 | 1000 | 32248 | 7548E | 262 | 262 | 393 | 425 | 20 | 30 | 3 | 3 | 0.44 | 1.4 | 0.8 | 81.3 | ||

| 500 | 165 | 155 | 132 | 5 | 5 | 2660 | 4290 | 670 | 900 | 32348 | 272 | 272 | 440 | 470 | 20 | 35 | 4 | 4 | 0.37 | 1.6 | 0.9 | 148 | |||

| 241 | 360 | 76 | 76 | 57 | 4 | 3 | 709 | 1560 | 850 | 1200 | 32048/YA2 | 254 | 261 | 318 | 346 | 12 | 19 | 3 | 3 | 0.36 | 25.6 | ||||

| 255 | 560 | 123.8 | 104.8 | 70 | 6 | 6 | 1816 | 2380 | 620 | 770 | 30651 | 7851 | 300 | 338 | 480 | 523 | 30 | 40 | 5 | 5 | 0.87 | 0.7 | 0.4 | 129 | |

| 260 | 360 | 64.5 | 60 | 52 | 3 | 2.5 | 654 | 1290 | 800 | 1100 | 32952X2 | 18.6 | |||||||||||||

| 400 | 87 | 87 | 65 | 5 | 4 | 1110 | 2120 | 700 | 950 | 32052 | 277 | 277 | 370 | 384 | 10 | 16 | 4 | 3 | 0.43 | 1.4 | 0.8 | 38.3 | |||

| 400 | 87.7 | 82 | 71 | 5 | 4 | 917 | 1849 | 800 | 1100 | 32052X2 | 2007152 | 277 | 277 | 370 | 386 | 12 | 18 | 4 | 3 | 0.3 | 2 | 1.1 | 36.9 | ||

| 540 | 114 | 102 | 85 | 6 | 6 | 2014 | 2898 | 670 | 900 | 30352X2 | 7352 | 301 | 301 | 490 | 506 | 20 | 30 | 5 | 5 | 0.23 | 2.6 | 1.4 | 111 | ||

| 280 | 350 | 36 | 33 | 26 | 2 | 2 | 259 | 614 | 870 | 1100 | 30656 | 1007856 | 295 | 295 | 336 | 342 | 6 | 9 | 2 | 2 | 0.43 | 1.4 | 0.8 | 6.33 | |

| 380 | 63.5 | 63.5 | 48 | 3 | 2.5 | 601 | 1430 | 800 | 1000 | 32956 | 2007956 4EC | 298 | 298 | 348 | 368 | 11 | 16 | 2.5 | 2.1 | 0.43 | 1.4 | 0.8 | 19.8 | ||

| 380 | 64.5 | 60 | 52 | 3 | 2.5 | 601 | 1430 | 800 | 1000 | 32956/YB2 | 2007956K | 300 | 325 | 348 | 368 | 11 | 16 | 2.5 | 2.1 | 0.29 | 2.1 | 1.1 | 19.8 | ||

| 300 | 420 | 76.5 | 72 | 60.5 | 4 | 3 | 998 | 2128 | 700 | 950 | 32960/YB2 | 2007960 | 317 | 317 | 394 | 408 | 10 | 16 | 3 | 2.5 | 0.28 | 2.1 | 1.2 | 28.7 | |

| 460 | 100 | 100 | 74 | 5 | 4 | 1470 | 2840 | 560 | 700 | 32060 | 320 | 320 | 425 | 445 | 20 | 30 | 4 | 3 | 0.43 | 1.4 | 0.8 | 57.2 | |||

| 460 | 100.7 | 95 | 82 | 5 | 4 | 803 | 1722 | 560 | 700 | 32060/YB2 | 2007160 | 320 | 320 | 425 | 445 | 14 | 20 | 4 | 3 | 0.31 | 1.9 | 1.1 | 55.9 | ||

| 440 | 73 | 70 | 55 | 4 | 3 | 959 | 2062 | 570 | 600 | 30660 | 7860 | 318 | 318 | 406 | 426 | 14 | 20 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 30.7 | ||

| 500 | 95 | 90 | 70 | 4 | 4 | 1225 | 2207 | 530 | 670 | 31160X2 | 1007760 | 327 | 327 | 460 | 480 | 20 | 30 | 3 | 3 | 0.32 | 1.9 | 1 | 67.7 | ||

| 540 | 149 | 140 | 115 | 6 | 5 | 2740 | 4780 | 530 | 670 | 32260/HC YA | 330 | 330 | 485 | 515 | 20 | 35 | 5 | 4 | 0.43 | 1.4 | 0.8 | 143 | |||

| d 304.8~460mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 304.8 | 546.1 | 171.1 | 171.1 | 140.1 | 8 | 8 | 2660 | 3020 | 530 | 670 | 306/304.8/HC | 316 | 316 | 534 | 8 | 8 | 0.34 | 175 | |||||||

| 320 | 440 | 76.5 | 72 | 62 | 4 | 3 | 607 | 1375 | 650 | 870 | 32964 | 2007964 | 335 | 335 | 412 | 427 | 10 | 16 | 3 | 2.5 | 0.3 | 2 | 1.1 | 44.7 | |

| 480 | 100.7 | 95 | 82 | 5 | 4 | 1463 | 2945 | 630 | 850 | 32064/YB2 | 2007164 | 340 | 340 | 440 | 468 | 14 | 20 | 4 | 3 | 0.42 | 1.4 | 0.8 | 59 | ||

| 330.2 | 482.64 | 87 | 75 | 68 | 3 | 3 | 863 | 1526 | 530 | 670 | 306/330.2 | 7766 | 351 | 351 | 449 | 462 | 20 | 30 | 2.5 | 2.5 | 0.31 | 1.9 | 1.1 | 37.2 | |

| 340 | 460 | 76.5 | 72 | 62 | 4 | 3 | 611 | 1428 | 530 | 670 | 32968/YB2 | 2007968 | 356 | 356 | 432 | 448 | 10 | 16 | 3 | 2.5 | 0.31 | 1.9 | 1.1 | 34.3 | |

| 520 | 86 | 82 | 64 | 4 | 3 | 807 | 1540 | 500 | 630 | 32068X2 | 7168 | 360 | 360 | 486 | 501 | 18 | 25 | 3 | 3 | 0.29 | 2.1 | 1.1 | 57 | ||

| 520 | 100 | 95 | 75 | 5 | 5 | 1510 | 2940 | 30668 | 73.4 | ||||||||||||||||

| 360 | 480 | 76.5 | 72 | 62 | 4 | 3 | 634 | 1526 | 500 | 630 | 32972/YB2 | 2007972 | 376 | 376 | 452 | 468 | 10 | 16 | 3 | 2.5 | 0.33 | 1.8 | 1 | 35.9 | |

| 540 | 86 | 82 | 64 | 4 | 4 | 919 | 1848 | 480 | 600 | 31072X2 | 7172 | 380 | 380 | 504 | 522 | 18 | 25 | 3 | 3 | 0.3 | 2 | 1.1 | 60.5 | ||

| 380 | 520 | 66.5 | 65 | 46.5 | 3 | 3 | 529 | 1138 | 480 | 600 | 31976X2 | 1007976 | 402 | 402 | 486 | 505 | 15 | 20 | 2.5 | 2.5 | 0.42 | 1.4 | 0.8 | 37.5 | |

| 620 | 112 | 106 | 76 | 4 | 4 | 909 | 1708 | 400 | 500 | 31176X2 | 1007776 | 420 | 420 | 534 | 560 | 10 | 40 | 3 | 3 | 0.46 | 1.3 | 0.7 | 114 | ||

| 400 | 540 | 70 | 65 | 48 | 5 | 4 | 811 | 1658 | 980 | 1220 | 31980 | 422 | 422 | 499 | 518 | 16 | 16 | 4 | 4 | 0.44 | 1.3 | 0.7 | 40.6 | ||

| 600 | 95 | 90 | 67 | 4 | 4 | 1040 | 2128 | 400 | 500 | 31080X2 | 7180 | 420 | 420 | 560 | 580 | 20 | 30 | 3 | 3 | 0.39 | 1.5 | 0.8 | 84 | ||

| 420 | 560 | 70 | 65 | 51 | 3 | 3 | 630 | 1383 | 400 | 500 | 31984X2 | 1007984 | 440 | 440 | 532 | 546 | 15 | 20 | 2.5 | 2.5 | 0.3 | 1.9 | 1.1 | 42.4 | |

| 620 | 95 | 90 | 70 | 4 | 4 | 1132 | 2422 | 380 | 480 | 31084X2 | 7184 | 448 | 448 | 579 | 601 | 20 | 30 | 3 | 3 | 0.4 | 1.5 | 0.8 | 88 | ||

| 700 | 130 | 122 | 92 | 6 | 6 | 1620 | 2800 | 310 | 420 | 31184X2 | 107784 | 490 | 490 | 606 | 646 | 15 | 40 | 5 | 5 | 0.32 | 19 | 1 | 183 | ||

| 440 | 620 | 95 | 90 | 67 | 2.3 | 5 | 1440 | 2930 | 340 | 650 | 32988 XI/P5 | 465 | 465 | 585 | 592 | 20 | 30 | 2 | 4 | 0.41 | 1.5 | 0.8 | 79.4 | ||

| 650 | 96.4 | 94 | 67 | 6 | 4 | 1193 | 2422 | 360 | 450 | 31088X2 | 7188 | 469 | 469 | 606 | 629 | 20 | 30 | 5 | 3 | 0.43 | 1.4 | 0.8 | 99 | ||

| 460 | 620 | 80 | 74 | 58 | 3 | 3 | 836 | 1843 | 380 | 480 | 31992X2 | 1007992 | 480 | 480 | 590 | 605 | 18 | 25 | 2.5 | 2.5 | 0.4 | 1.5 | 0.8 | 59.8 | |

| 660 | 115 | 110 | 90 | 5 | 4 | 1960 | 4650 | 32996X3 | |||||||||||||||||

| d 460~1800mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 460 | 680 | 105 | 100 | 78 | 6 | 6 | 1680 | 3550 | 330 | 450 | 31092X2 | 7192 | 516 | 516 | 610 | 640 | 8 | 34 | 5 | 5 | 0.3 | 1.9 | 1.1 | 118 | |

| 480 | 650 | 84.2 | 78 | 60 | 4 | 4 | 854 | 1918 | 340 | 430 | 31996X2 | 1007996 | 502 | 502 | 613 | 633 | 18 | 25 | 3 | 3 | 0.42 | 1.4 | 0.8 | 71 | |

| 500 | 720 | 110 | 100 | 82 | 6 | 6 | 1459 | 3192 | 280 | 360 | 310/500X2 | 71/500 | 530 | 530 | 674 | 700 | 20 | 30 | 5 | 5 | 0.33 | 1.8 | 1 | 135 | |

| 530 | 670 | 100.5 | 95 | 82 | 5 | 3 | 1850 | 4800 | 329/530X2 | 552 | 552 | 637 | 658 | 20 | 30 | 4 | 3 | 0.38 | 81.3 | ||||||

| 710 | 88 | 82 | 62 | 4 | 4 | 1001 | 2380 | 280 | 360 | 319/530X2 | 10079/530 | 554 | 554 | 672 | 693 | 20 | 30 | 3 | 3 | 0.41 | 1.5 | 0.8 | 94.8 | ||

| 560 | 750 | 92.5 | 85 | 64 | 4 | 4 | 1001 | 2576 | 240 | 320 | 319/560X2 | 10079/560 | 586 | 586 | 708 | 731 | 20 | 30 | 3 | 3 | 0.44 | 1.4 | 0.8 | 104 | |

| 820 | 121 | 115 | 84 | 6 | 6 | 1887 | 4046 | 220 | 300 | 310/560X2 | 71/560 | 594 | 594 | 768 | 795 | 30 | 40 | 5 | 5 | 0.39 | 1.5 | 0.8 | 191 | ||

| 600 | 870 | 124 | 118 | 89 | 6 | 6 | 2020 | 4438 | 180 | 240 | 310/600X2 | 71/600 | 630 | 630 | 821 | 845 | 30 | 40 | 5 | 5 | 0.41 | 1.5 | 1.6 | 235 | |

| 630 | 920 | 135 | 128 | 94 | 7.5 | 7.5 | 2315 | 5222 | 170 | 220 | 310/630X2 | 71/630 | 669 | 669 | 858 | 891 | 30 | 40 | 6 | 6 | 0.42 | 1.4 | 0.8 | 278 | |

| 710 | 950 | 114 | 106 | 80 | 6 | 6 | 1765 | 4494 | 150 | 190 | 319710X2 | 10079710 | 743 | 743 | 895 | 925 | 25 | 35 | 5 | 5 | 0.46 | 1.3 | 0.7 | 210.24 | |

| 800 | 990 | 57 | 55 | 45 | 5 | 5 | 907 | 2644 | 150 | 190 | 308800 RYB2P6 | 822 | 822 | 930 | 968 | 25 | 35 | 4 | 4 | 0.39 | 1.5 | 0.8 | 96.3 | ||

| 1060 | 122 | 115 | 89 | 6 | 6 | 2132 | 5530 | 130 | 170 | 319/800 X2 | 10079/800 | 838 | 838 | 1005 | 1031 | 25 | 35 | 5 | 5 | 0.35 | 1.7 | 0.9 | 275 | ||

| 900 | 1180 | 124 | 122 | 87 | 6 | 6 | 2173 | 5782 | 95 | 130 | 319/900X2 | 10079900 | 940 | 940 | 1117 | 1146 | 30 | 40 | 5 | 5 | 0.39 | 1.5 | 0.8 | 330 | |

| 1280 | 190 | 170 | 135 | 7.5 | 7.5 | 5615 | 13913 | 95 | 130 | 320900X2 | 71/900 | 944 | 944 | 1194 | 1246 | 45 | 60 | 6 | 6 | 0.54 | 1.1 | 0.6 | 703 | ||

| 950 1800 |

1250 | 140 | 132 | 100 | 7.5 | 7.5 | 3930 | 10427 | 80 | 100 | 319950X2 | 10079950 | 994 | 994 | 1191 | 1220 | 30 | 40 | 6 | 6 | 0.33 | 1.8 | 1 | 428 | |

| 2300 | 260 | 218 | 180 | 15 | 15 | 10810 | 34000 | 306/1800 | 1824 | 1824 | 2191 | 2276 | 30 | 40 | 15 | 15 | 0.67 | 0.9 | 0.5 | 2339 | |||||

| d 17.462~31.75mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 17.462 | 39.878 | 13.84 | 14.61 | 10.67 | 1.3 | 1.3 | 21.2 | 20.8 | 9000 | 13000 | LMI1749LMI1710 | LM1749LMII710 | 21.5 | 23 | 34 | 37 | 2 | 3 | 1 | 1.3 | 0.29 | 2.1 | 1.15 | 0.083 | |

| 19.05 | 45.237 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 27.5 | 27.5 | 8500 | 12000 | LMI⁹49LMI910 | LM1949LMII910 | 23.5 | 25 | 39.5 | 41.5 | 2 | 4 | 1 | 1.3 | 0.3 | 2 | 1.I | 0.124 | |

| 21.43 | 50.005 | 17.53 | 18.29 | 13.97 | 1.3 | 1.3 | 36.9 | 38 | 8000 | 11000 | M12649M12610 | MI2M649MI2610 | 25.4 | 27.5 | 44 | 46 | 2 | 4 | 1 | 1.3 | 0.28 | 2.16 | 1.19 | 0.169 | |

| 21.986 | 45.237 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 26.9 | 33.6 | 9270 | 11590 | LMI2749LM12710 | 26 | 27.5 | 39.5 | 42 | 3 | 4 | 1 | 1.3 | 0.31 | 2 | 1.1 | 0.115 | ||

| 45.974 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 27.5 | 31 | 8000 | 11000 | LM12749LMI2711 | LMZ749LMI27I1 | 26 | 27.5 | 40 | 42.5 | 3 | 4 | 1 | 1.3 | 0.3 | 2.02 | 1.11 | 0.12 | ||

| 22 | 45.237 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 27.5 | 31 | 8000 | 11000 | LMIZ749LMI12710 | LMLZ749LM12710 | 26 | 28 | 39.5 | 41.5 | 2 | 4 | 1 | 1.3 | 0.3 | 2.02 | 1.11 | 0.115 | |

| 49.225 | 11 | 1 | 16.4 | 18.4 | LR306302 | (内组件) | 0.071 | ||||||||||||||||||

| 25.4 | 50.005 | 13.5 | 14.26 | 9.525 | 1 | 1 | 27 | 29 | 7500 | 10000 | 710007196 | 71000197 | 29.5 | 30.5 | 44.5 | 47 | 3 | 5 | 1 | 1 | 0.4 | 149 | 0.82 | 0.119 | |

| 50.292 | 14.22 | 14.73 | 10.67 | 1.3 | 1.3 | 26 | 30 | 7500 | 10000 | L4643L44610 | 14643L4610 | 29.5 | 31.5 | 44.5 | 47 | 3 | 5 | 1 | 1.3 | 0.37 | 1.6 | 0.88 | 0.127 | ||

| 26.988 | 50.292 | 14.22 | 14.73 | 10.67 | 3.5 | 1.3 | 26 | 32.2 | 7500 | 10000 | L44649L44610 | 14649L4610 | 31 | 37.5 | 44.5 | 47 | 3 | 5 | 3 | 1.3 | 0.37 | 1.6 | 0.88 | 0.12 | |

| 29 | 50.292 | 14.22 | 14.73 | 10.67 | 3.5 | 1.3 | 26 | 33 | 7000 | 9500 | L4549L45410 | 14549L45410 | 33 | 39.5 | 44.5 | 48 | 3 | 5 | 3 | 1.3 | 0.37 | 1.62 | 0.89 | 0.113 | |

| 58 | 17 | 4 | 16.4 | 18.4 | LR3063302YB | (内组件) | 0.248 | ||||||||||||||||||

| 30.162 | 64.292 | 21.43 | 21.43 | 16.67 | 1.5 | 1.5 | 48 | 66.5 | 6750 | 8430 | M86649M86610 | 38.2 | 41 | 54 | 61 | 3 | 5 | 3 | 1.3 | 0.55 | 1.1 | 0.6 | 0.331 | ||

| 31.75 | 59.131 | 15.88 | 16.76 | 11.81 | 3.6 | 1.3 | 34.7 | 43 | 6300 | 7500 | LM67048LM67010 | LM6748LM67H0 | 36 | 42.5 | 52 | 56 | 3 | 5 | 3 | 1.3 | 0.41 | 1.46 | 0.8 | 0.18 | |

| 59.131 | 15.88 | 16.76 | 11.81 | 3.6 | 1.3 | 32.8 | 43 | 10410 | 13010 | LM67048LM67010 | 36 | 42.5 | 52 | 56 | 3.5 | S | 3 | 1.3 | 0.41 | 1.46 | 0.8 | 0.18 | |||

| 62 | 18.16 | 19.05 | 14.29 | 3.5 | 1.3 | 45.8 | 60.1 | 6300 | 8500 | 1512315245 | 36 | 42.5 | 52 | 56 | 3.5 | 5 | 3.5 | 1.3 | 0.35 | 1.71 | 0.94 | 0.244 | |||

| 68.262 | 22.23 | 22.23 | 17.46 | 3.5 | 1.5 | 53.1 | 64.8 | 247502420 | 38.5 | 39 | 59 | 63 | 5.5 | 3 | 3.5 | 1.5 | 0.42 | 1.44 | 0.382 | ||||||

| 69.012 | 19.85 | 19.58 | 15.88 | 3.5 | 1.3 | 51.2 | 65.4 | 9060 | 11320 | 14125A/14276 | 37.5 | 44 | 60 | 63 | 3 | 5 | 3.5 | 1.3 | 0.38 | 1.57 | 0.86 | 0.353 | |||

| d 34.925~50.8mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 34.925 | 65.088 | 18.03 | 18.29 | 13.97 | 3.6 | 1.3 | 47.3 | 58.2 | 5600 | 7500 | LM48548LM4510 | LM48548LM48510 | 40 | 46 | 58 | 61 | 3 | 5 | 3 | 1.3 | 0.38 | 1.59 | 0.88 | 0.252 | |

| 80.167 | 29.37 | 30.39 | 23.81 | 3.5 | 3.2 | 91.9 | 106 | 5000 | 6700 | 35793320 | 3793320 | 41.5 | 48 | 70 | 74.8 | 3 | 5 | 3 | 2.5 | 0.27 | 2.19 | 1.21 | 0.742 | ||

| 34.987 | 59.131 | 15.88 | 16.76 | 11.94 | 3.6 | 1.3 | 32.2 | 47.3 | L68149L68110 | 39 | 45.5 | 52 | 56 | 3 | 4 | 3 | 1.3 | 0.42 | 1.44 | 0.79 | 0.169 | ||||

| 59.975 | 15.88 | 16.76 | 11.94 | 3.6 | 1.3 | 32.2 | 47.3 | 6710 | 8390 | L68149L68I1 | 39 | 45.5 | 53 | 56 | 3 | 4 | 3 | 1.3 | 0.42 | 1.44 | 0.79 | 0.177 | |||

| 37.987 | 62.975 | 17 | 17 | 13.5 | 3.6 | 1.3 | 40 | 55 | 5600 | 7500 | JL69349JL69310 | JL693416310 | 41 | 47 | 56 | 60 | 4 | 6 | 3 | 1.3 | 0.42 | 1.44 | 0.79 | 0.186 | |

| 38.1 | 76.2 | 23.81 | 25.65 | 19.05 | 3.5 | 3.2 | 74.8 | 93 | 5000 | 6700 | 2788R2720 | 278R2720 | 43 | 50 | 65 | 72 | 4 | 6 | 3 | 2.5 | 0.3 | 2.03 | 1.12 | 0.501 | |

| 39.688 | 73.025 | 25.65 | 22.1 | 21.34 | 0.8 | 2.3 | 66 | 86.5 | 5000 | 6700 | M201047M291011 | M201047M2DH011 | 44 | 51 | 66 | 70 | 4 | 6 | 0.8 | 2.1 | 0.32 | 1.85 | 1.02 | 0.432 | |

| 41.275 | 73.431 | 19.56 | 19.81 | 14.73 | 3.5 | 0.8 | 55 | 73.9 | 4800 | 6300 | LM501349LMS901310 | LM601349LMS0138 | 46.5 | 53 | 67 | 70 | 3.5 | 6 | 3.5 | 0.8 | 0.4 | 1.5 | 0.8 | 0.336 | |

| 82.55 | 26.54 | 25.65 | 20.19 | 3.5 | 3.3 | 76.3 | 105 | MS02048M82011F | 51 | 57 | 70 | 79 | 3 | 6 | 3.5 | 3.3 | 0.55 | 1.1 | 0.617 | ||||||

| 88.9 | 30.16 | 29.37 | 23.02 | 3.5 | 3.3 | 95.2 | 127 | 4300 | 5600 | FHDMS13146FH8B19 | FHM906146FH895LI0 | 53 | 53.5 | 70 | 84 | 4 | 7 | 3 | 2.5 | 0.54 | 1.1 | 0.6 | 0.882 | ||

| 44.45 | 82.931 | 23.81 | 25.4 | 19.05 | 3.5 | 0.8 | 80.9 | 106 | 4500 | 6000 | 25882550 | 258025) | 50 | 56 | 72 | 78 | 4 | 6 | 3 | 0.8 | 0.32 | 1.85 | 1.02 | 0.57 | |

| 45.23 | 79.985 | 19.84 | 20.64 | 15.08 | 2 | 1.3 | 55.1 | 70.8 | 4800 | 6300 | 1788717831 | 178717831 | 50 | 56 | 72 | 78 | 4 | 6 | 2 | 1.3 | 0.37 | 1.64 | 0.9 | 0.402 | |

| 45.242 | 73.431 | 19.56 | 19.81 | 15.75 | 3.5 | 0.8 | 53.9 | 69.5 | 4800 | 6300 | LM02949LMI02910 | LMI299LM102910 | 50 | 57 | 68 | 70 | 3 | 5 | 3 | 0.8 | 0.31 | 1.97 | 1.08 | 0.3 | |

| 77.788 | 21.43 | 19.84 | 16.67 | 3.5 | 0.8 | 52.2 | 73.7 | 8110 | 10140 | LM1603049LM6L3012 | 50 | 57 | 70 | 74 | 3.5 | 5 | 3.5 | 0.8 | 0.43 | 141 | 0.77 | 0.385 | |||

| 45.618 | 82.931 | 23.81 | 25.4 | 19.05 | 3.5 | 0.8 | 80.9 | 106 | 4500 | 6000 | 2559025520 | 259025530 | 50 | 56 | 72 | 78 | 4 | 6 | 3 | 8 | 0.33 | 1.8 | 1 | 0.554 | |

| 82.931 | 26.99 | 25.4 | 22.23 | 3.5 | 2.3 | 80.9 | 106 | 4500 | 6000 | 2559025523 | 25902524 | 50 | 56 | 72 | 78 | 4 | 6 | 3 | 2.1 | 0.33 | 1.8 | 1 | 0.603 | ||

| 50 | 82 | 21.5 | 21.5 | 17 | 3 | 0.6 | 66.9 | 94.1 | 4840 | 6060 | JLM10948JLM109 | 0 | 55 | 60 | 76 | 78 | 4 | 6 | 3 | 0.6 | 0.31 | 1.97 | 1.08 | 0.429 | |

| 50.8 | 82.55 | 21.59 | 22.23 | 16.51 | 3.5 | 1.3 | 60.8 | 94.1 | 4790 | 5990 | LM104949LM10491 | 55 | 62 | 75 | 78 | 4 | 6 | 3.5 | 1.3 | 0.31 | 1.97 | 1.08 | 0.426 | ||

| d 52.388~89.975mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 52.388 | 92.075 | 24.61 | 25.4 | 19.85 | 3.5 | 0.8 | 82 | 108 | 4000 | 5300 | 2858428521 | 28842821 | 59 | 69 | 83 | 87 | 4 | 7 | 0.8 | 38 | 159 | 0.87 | 0.695 | ||

| 54.488 | 104.78 | 36.51 | 36.51 | 28.58 | 2 | 3.3 | 139 | 192 | HM8/748HMS0010 | 63 | 73 | 89 | 100 | 4 | 7 | 2 | 3.3 | 49 | 1.23 | 1.38 | |||||

| 54.5 | 104.78 | 36.51 | 36.51 | 28.58 | 2 | 3.3 | 139 | 192 | LY-3035 | 1.38 | |||||||||||||||

| 55 | 90 | 23 | 26 | 18.5 | 3.5 | 0.5 | 84 | 110 | 3800 | 5000 | IMSAEJLAE9M89 | ANS0648ELMS5W680 | 61 | 69 | 78 | 87 | 7 | 8 | 3 | 0.5 | 4 | 149 | 0.82 | 0.586 | |

| 55.562 | 97.63 | 24.61 | 24.61 | 19.45 | 3.5 | 0.8 | 80.9 | 71 | 4160 | 5200 | 2868028622 | 62 | 68 | 88 | 92 | 4 | 5 | 3.5 | 0.8 | 4 | 149 | 0.82 | 0.754 | ||

| 60.325 | 101.6 | 25.4 | 25.4 | 1985 | 5 | 3.3 | 85.8 | 125 | 3600 | 4800 | 289852893 | 29K52901 | 68 | 80 | 88 | 97 | 5 | 9 | 3 | 2.5 | 43 | 14 | 0.78 | 0.798 | |

| 63.5 | 107.95 | 25.4 | 25.4 | 19.05 | 1.5 | 3.3 | 83.5 | 76.4 | 295862950 | 915 | |||||||||||||||

| 12224 | 38.1 | 38.35 | 29.72 | 7 | 1.5 | 172 | 245 | 3400 | 4300 | FN212047HM212010 | HBCID4THNZ1200 | 73 | 80 | 110 | 116 | A | 6 | 6 | 1.5 | 0.34 | 178 | 0.98 | 1.94 | ||

| 122.24 | 38.1 | 38.35 | 29.72 | 1 | 3.3 | 172 | 245 | 3400 | 4300 | HNI212N47HM21201 | HMCI3N4THM213I1 | 73 | 80 | 110 | 116 | 4 | 6 | 6 | 2.5 | 0.34 | 178 | 0.98 | 1.93 | ||

| 66.675 | 107.95 | 25.4 | 25.4 | 19.05 | 3.5 | 0.8 | 85.8 | 125 | 3600 | 4800 | 295029522 | H29902622 | 75 | 87 | 94 | 103 | 4 | 10 | 3 | 0.8 | 0.46 | 13 | 0.72 | 0.854 | |

| 122.24 | 38.1 | 38.35 | 29.72 | 3.5 | 1.5 | 159 | 146 | 3400 | 4200 | HN212049HN212010 | HBCI3M49HM212010 | 75.5 | 82 | 110 | 116 | 4 | 6 | 3 | 1.5 | 0.34 | 178 | 0.98 | 1.85 | ||

| 122.24 | 38.1 | 38.35 | 29.72 | 3.5 | 3.3 | 159 | 146 | 3400 | 4200 | HNI212049HM21201 | HMCI12049EDNL12011 | 75.5 | 82 | 110 | 116 | 4 | 5 | 3 | 3 | 0.34 | 178 | 0.98 | 1.85 | ||

| 68.262 | 161.93 | 49.21 | 46.04 | 31.75 | 3.5 | 3.3 | 256 | 304 | 2690 | 3360 | 9278922 | 904 | 97 | 138 | 153 | 4.5 | 12 | 3.5 | 3 | 71 | 85 | 0.46 | 4.46 | ||

| 69.85 | 146.05 | 41.28 | 39.69 | 25.4 | 3.6 | 3.4 | 192 | 239 | 2880 | 3610 | H9189H9L810 | 82 | 95 | 124 | 138 | 5.5 | 11 | 3.5 | 3 | 78 | 77 | 0.42 | 2.92 | ||

| 84.976 | 125.41 | 25.4 | 25.4 | 19.85 | 5 | 1.5 | 110 | 183 | 2970 | 3710 | 276527620 | 91 | 100 | 115 | 120 | 5 | 6 | 5 | 1.5 | 42 | 144 | 0.79 | 1 | ||

| 88.9 | 152.4 | 39.69 | 39.69 | 30.16 | 6 | 3.51 | 229 | 362 | 2550 | 3190 | HD51845HM518410 | 102 | 109 | 135 | 139 | 6 | 10 | 5 | 3.5 | 4 | 149 | 0.82 | 2.9 | ||

| 89.975 | 146.98 | 40 | 40 | 32.5 | 7 | 3.5 | 229 | 355 | 2200 | 3200 | HM218248HM218210 | HB2I8248HMI820 | 95 | 111 | 132 | 140 | 5 | 7 | 6 | 2.5 | 0.33 | 18 | 1 | 2.52 | |

| d 95.25~146.05mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 95.25 | 152.4 | 39.69 | 36.32 | 30.16 | 5 | 3.3 | 185.3 | 289.7 | 2480 | 3100 | 594A/592A | 104 | 113 | 135 | 144 | 4 | 10 | 5 | 3 | 0.44 | 1.36 | 0.75 | 2.55 | ||

| 99.974 | 156.98 | 42 | 42 | 34 | 8 | 3.5 | 243 | 391 | 2380 | 2970 | HM220149/HM220110 | 109 | 123 | 142 | 151 | 5.5 | 9 | 7 | 3.5 | 0.33 | 1.9 | 0.99 | 2.92 | ||

| 99.975 | 212.73 | 66.68 | 66.68 | 53.98 | 3.5 | 3.3 | 556 | 783 | 1900 | 2380 | HH224334/HH224310 | 120 | 124 | 192 | 202 | 7 | 12 | 3 | 3 | 0.33 | 1.84 | 0.99 | 11.3 | ||

| 101.6 | 180.98 | 47.63 | 48.01 | 38.1 | 3.5 | 3.3 | 288 | 436 | 780772 | 113 | 119 | 161 | 168 | 5 | 10 | 3.5 | 3 | 0.39 | 1.56 | 5.02 | |||||

| 104.78 | 180.98 | 47.63 | 48.01 | 38.1 | 7 | 3.3 | 258 | 375 | 2000 | 2600 | 7872 | 116 | 129 | 161 | 168 | 5 | 10 | 7 | 3.3 | 0.39 | 1.56 | 0.86 | 4.66 | ||

| 107.95 | 161.93 | 34.93 | 34.93 | 26.99 | 3.5 | 3.3 | 164 | 280 | 2000 | 2800 | 48190/48120 | 116 | 122 | 146 | 156 | 3.5 | 8 | 3.5 | 3.3 | 0.51 | 1.2 | 0.65 | 2.42 | ||

| 109.54 | 158.75 | 23.02 | 21.44 | 15.88 | 5 | 3.3 | 103 | 167 | 37431A/37625 | 116 | 126 | 143 | 152 | 3.5 | 7 | 5 | 3.3 | 0.61 | 0.99 | 1.31 | |||||

| 114.3 | 152.4 | 21.43 | 21.43 | 16.67 | 1.5 | 1.5 | 89 | 178 | 2000 | 2800 | L623149/L623110 | 120 | 123 | 143 | 147 | 3.5 | 6 | 15 | 1.5 | 0.41 | 1.5 | 0.8 | 1.05 | ||

| 212.73 | 66.68 | 66.68 | 53.98 | 7 | 3.3 | 570 | 810 | 1700 | 2200 | HH224346/HH224310 | 131 | 143 | 192 | 202 | 7 | 12 | 7 | 3.3 | 0.33 | 1.84 | 1 | 10 | |||

| 117.48 | 180.98 | 34.93 | 31.75 | 25.4 | 3.5 | 3.3 | 174 | 254 | 1800 | 2400 | 68462/68712 | 125 | 132 | 163 | 172 | 2 | 8 | 3.5 | 3.3 | 0.5 | 1.21 | 0.66 | 2.78 | ||

| 120 | 174.63 | 35.72 | 36.51 | 27.78 | 3.5 | 1.5 | 212 | 385 | 1900 | 2600 | M224748/M224710 | 129 | 135 | 163 | 168 | 3.5 | 15 | 0.33 | 1.8 | 0.99 | 2.78 | ||||

| 123.83 | 182.56 | 39.69 | 38.1 | 33.34 | 3.5 | 3.3 | 228 | 445 | 1800 | 2400 | 48286/48220 | 133 | 139 | 168 | 176 | 4.5 | 7 | 3.5 | 3.3 | 0.31 | 1.97 | 1.1 | 3.51 | ||

| 130.18 | 203.2 | 46.04 | 46.04 | 38.1 | 3.5 | 3.3 | 315 | 560 | 1700 | 2200 | 67389/67320 | 141 | 146 | 183 | 191 | 3.5 | 3.3 | 0.34 | 1.7 | 0.96 | 5.57 | ||||

| 142.88 | 200.03 | 41.28 | 39.69 | 34.13 | 3.5 | 3.3 | 242 | 500 | 1710 | 2130 | 4868548620 | 151 | 158 | 185 | 193 | 3.5 | 7 | 35 | 3.3 | 0.34 | 1.78 | 0.97 | 3.84 | ||

| 146.05 | 254 | 66.68 | 6668 | 47.63 | 7 | 3.3 | 530 | 867 | 99575199100 | 162 | 175 | 227 | 238 | 8 | 135 | 7 | 3.3 | 0.41 | 1.47 | 13.2 | |||||

| d 152.4~762mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 152.4 | 254 | 66.68 | 66.68 | 47.63 | 7 | 3.3 | 515 | 830 | 1300 | 1800 | 9960099100 | 9960091600 | 170 | 181 | 227 | 238 | 8 | 13.5 | 7 | 3.3 | 0.41 | 1.47 | 0.81 | 12.29 | |

| 165.1 | 247.65 | 47.63 | 47.63 | 38.1 | 3.5 | 3.3 | 345 | 705 | 1300 | 1700 | 67786720 | 179 | 185 | 229 | 240 | 5 | 8 | 3.5 | 3.3 | 0.44 | 1.36 | 0.75 | 8.16 | ||

| 174.63 | 24765 | 47.63 | 47.63 | 38.1 | 3.5 | 3.3 | 345 | 705 | 1300 | 1700 | 6778767720 | 185 | 192 | 229 | 240 | 5 | 8 | 3.5 | 3.3 | 0.44 | 1.4 | 0.75 | 7.21 | ||

| 180 | 250 | 47 | 45 | 37 | 3 | 2.5 | 338 | 682 | 1300 | 1630 | JM736149JM736110 | 190 | 196 | 232 | 243 | 5.5 | 10 | 3 | 2.5 | 0.48 | 1.25 | 0.69 | 6.72 | ||

| 190 | 260 | 46 | 44 | 36.5 | 3 | 2.5 | 370 | 730 | 1100 | 1600 | JM738249JM738210 | 200 | 206 | 242 | 252 | 5.5 | 9.5 | 3 | 2.5 | 0.48 | 1.3 | 0.69 | 6.93 | ||

| 206.38 | 282.58 | 46.04 | 46.04 | 36.51 | 3.5 | 3.3 | 365 | 800 | 100 | 1400 | 6798567920 | 219 | 224 | 260 | 275 | 5 | 8 | 3.5 | 3.3 | 0.51 | 1.2 | 65 | 8.48 | ||

| 254 | 358.78 | 71.44 | 71.44 | 53.98 | 3.5 | 3.3 | 694 | 1550 | 830 | 1040 | M249749M249710 | 270 | 274 | 335 | 343 | 75 | 135 | 35 | 3.3 | 0.33 | 1.8 | 1 | 21.7 | ||

| 304.8 | 444.5 | 63.5 | 61.91 | 39.69 | 6 | 1.1 | 685 | 1140 | 510 | 640 | EE291201291749 | 3-736 | 340 | 370 | 403 | 422 | 8 | 28 | 2 | 1 | 0.38 | 1.6 | 0.87 | 25.1 | |

| 546.1 | 171.1 | 171.1 | 140.1 | 6 | 6 | 2800 | 5800 | 490 | 600 | 3063048 | 7961 | 355 | 400 | 500 | 515 | 8 | 28 | 5 | 0.34 | 1.8 | 17.5 | ||||

| 393.7 | 546.1 | 76.2 | 61.12 | 55.56 | 6 | 6 | 860 | 1343 | 500 | 630 | EE234154234215 | 7979 | 416 | 437 | 508 | 532 | 18 | 25 | 6 | 5 | 0.48 | 1.2 | 0.7 | 44.8 | |

| 431.8 | 571.5 | 52.38 | 874.612 | 74.612 | 3.3 | 3.3 | 1080 | 2470 | 380 | 480 | LM869448J/LM869410J | 453 | 457 | 537 | 549 | 5 | 16 | 3.3 | 3.3 | 0.55 | 1.1 | 0.6 | 48.2 | ||

| 609.6 | 787.4 | 93.66 | 93.66 | 69.85 | 6 | 6 | 2010 | 5060 | 340 | 450 | EE649240649310 | 3-734 | 655 | 690 | 725 | 760 | 10 | 25 | 6 | 5 | 0.37 | 1.6 | 0.9 | 110 | |

| 685.8 | 876.3 | 93.66 | 92.08 | 69.85 | 6.4 | 6.4 | 1980 | 5150 | 300 | 400 | EE65527065345 | EF655270655345 | 714 | 723 | 831 | 843 | 13 | 25 | 5 | 5 | 0.42 | 1.4 | 0.8 | 133 | |

| 759.93 | 889 | 88.9 | 88.9 | 72 | 3.3 | 3.3 | 1910 | 6130 | LI8448L183410 | 780 | 783 | 864 | 873 | 12.5 | 19 | 3.3 | 3.3 | 0.31 | 1.97 | 89.9 | |||||

| 762 | 889 | 88.9 | 88.9 | 72 | 3.3 | 3.3 | 1910 | 6130 | LI83449L183410 | 780 | 783 | 864 | 872 | 12.5 | 19 | 3.3 | 3.3 | 0.31 | 1.97 | 88.2 | |||||

Learn about our latest products and discounts through SMS or email