- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

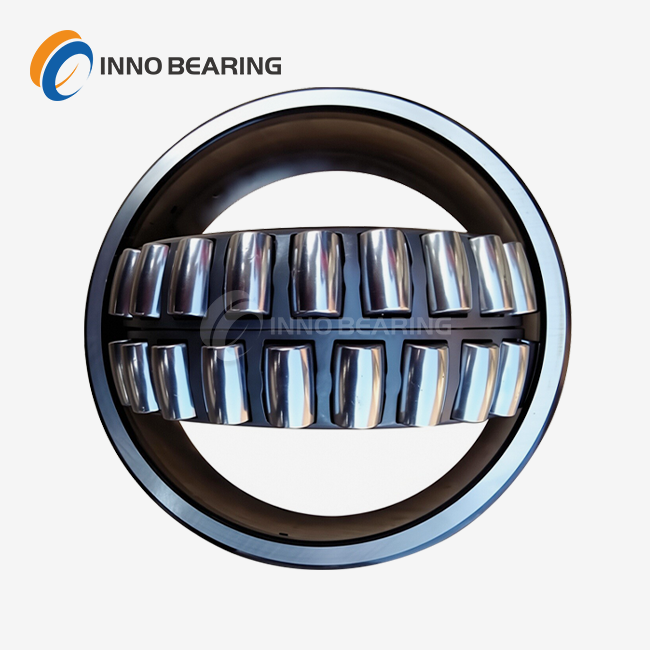

Tapered Rollers

2.Structure Type: Single - ended taper, with a rib at the large end, and the surface is precisely ground.

3.Size Range: Small - end diameter 5 - 200mm, large - end diameter 10 - 300mm, length 8 - 250mm.

4.Material: Rollers: GCr15/GCR15SIMN (no inner ring / outer ring, only spare parts).

5.Precision: P0/P6/P5 level (matched according to bearings).

6.Application Fields: Bearing repair and replacement, customized bearing production.

7.Key Inspection Items: Taper surface angle accuracy, roundness, surface roughness.

Precision Tapered Rollers Built for Extreme Industrial Performance

When your heavy machinery faces relentless demands—500℃ furnace heat, 300-ton crusher loads, or corrosive saltwater exposure—tapered rollers become the linchpin of operational success. At LUOYANG INNO BEARING, we’ve spent 30+ years perfecting these conical workhorses to deliver unmatched durability and precision. Our rollers support radial/axial loads 20% above ISO standards while reducing friction-induced downtime. Whether you need standard replacements (48-hour delivery) or φ5000mm+ custom designs, we engineer Solutions that thrive where others fail.

Key Specifications

- Sizes: φ10mm to φ5000mm (expandable via customization)

- Materials: GCr15/GCR15SIMN steel with SUJ2 hardening

- Load Capacity: 400kN axial load rating for mining crushers

- Precision: P0/P6/P5 grades matched to bearing requirements

- Critical Applications: Steel mill conveyors, port crane slewing rings, medical robotics

Industry-Tailored Engineering

Metallurgy & Steel Production

Our high-temperature products withstand 500–600℃ environments using ceramic coatings and oxidation-resistant alloys. Proven in continuous casting machines, they achieve 35% longer lifespan than standard rollers.

Port Machinery

Saltwater corrosion? Impact shocks? Our heavy-duty tapered rollers feature Zn-Ni plating and 60-64 HRC surface hardening. Ideal for container cranes handling 50-ton loads amid marine conditions.

Mining & Mineral Processing

Reinforced roller ends and double-row designs absorb 300J impact forces in crushers. Tested to endure 200,000+ hours under vibration and abrasive dust.

Zero-Compromise Quality Control

Every precision tapered roller undergoes:

1. Material Spectrometry: Verify steel purity and hardness pre-production.

2. In-Process Checks: Laser-measured taper angles (±0.001° tolerance).

3. 12-Parameter Final Test: Includes micro-crack detection and radial runout analysis.

Result? 99.9% defect-free rollers backed by a 12-month warranty.

Custom Orders Delivered 30% Faster

Need non-standard dimensions or coatings?

- Submit CAD files → Get prototypes in 7 days.

- Full-scale production in 15–20 days (φ3000mm+ rollers).

- Modular manufacturing cuts lead times vs. traditional methods.

Global Availability, Local Speed

- 1,000+ Standard SKUs: Shipped within 48 hours from regional hubs (USA, Germany, UAE, China).

- Bulk Order Savings: 50,000-ton annual capacity ensures volume pricing.

Beyond Delivery

- Free Bearing Health Audits: Our engineers analyze failures and recommend upgrades.

- IoT Integration: Monitor roller wear in real time via smart sensors.

- 24/7 Technical Support: Installation guidance, load optimization, predictive maintenance.

Why Partner With Us?

✅ 30+ Years in Extreme Environments: 200+ successful projects since 1994.

✅ Risk Reduction: Predictive inventory + ISO/IATF 16949-certified production.

✅ Total Cost Savings: 18–25% lower TCO via extended lifespan and maintenance planning.

FAQ

1. How do your rollers handle 500℃ furnace conditions?

We use ceramic-coated GCR15SIMN steel and proprietary heat treatment to prevent deformation and oxidation.

2. Can you make rollers larger than φ5000mm?

Yes—our modular production system accommodates rollers up to φ6000mm for mining mega-machinery.

3. What ensures 99.9% defect-free rates?

Triple inspection protocols, including micro-crack detection and hardness gradient mapping.

4. How fast can you deliver to a mining site?

Standard rollers ship in 48 hours. Expedited air freight available for emergencies.

5. Do you offer impact-resistant designs?

Yes—double-row products with reinforced cages absorb 300J shocks in crushers.

6. What materials boost longevity?

High-purity SAE 52100 steel with carburizing treatment achieves 200,000+ hours in heavy loads.

7. How does modular production accelerate lead times?

Pre-machined components are assembled per your specs, slashing production steps by 40%.

8. Can IoT monitor roller wear?

Yes—ask about our smart sensor kits for predictive replacement scheduling.

Contact Us

Optimize Your Machinery Today with Tapered Rollers

Email sales@inno-bearing.com with your load, speed, and dimension requirements. Receive a same-day quote + free engineering consultation.

LUOYANG INNO BEARING: Where Precision Meets Endurance.

| d 40~50mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 15 | 30 | 13 | 12 | 11 | 1 | 0.3 | 14 | 15 | 9000 | 13000 | 30602-1(TD-CR0529/0256) | 17 | 17 | 25 | 28 | 3 | 7 | 1 | 0.3 | 0.29 | 2.1 | 1.1 | 0.0407 | ||

| 35 | 14.8 | 15 | 11.75 | 1 | 0.3 | 21.8 | 22.4 | 9000 | 13000 | 30602(RV-70FC) | 18 | 18 | 30 | 33 | 3 | 5 | 1 | 0.3 | 0.24 | 2.5 | 1.4 | 0.0716 | |||

| 42 | 14.25 | 13 | 11 | 1 | 1 | 22.9 | 21.7 | 9000 | 13000 | 30302 | 7302E | 2FB | 23 | 23 | 35 | 36 | 3 | 5 | 1 | 1 | 0.28 | 2.1 | 1.1 | 0.0948 | |

| 17 | 40 | 13.25 | 12 | 11 | 1 | 1 | 20.7 | 22.2 | 9000 | 13000 | 30203 | 7203E | 2DB | 22 | 22 | 34 | 35 | 2 | 4 | 1 | 1 | 0.35 | 1.7 | 0.9 | 0.0781 |

| 47 | 15.25 | 14 | 12 | 1 | 1 | 28.3 | 27.4 | 8500 | 12000 | 30303 | 7303E | 2FB | 25 | 25 | 41 | 42 | 3 | 5 | 1 | 1 | 0.28 | 2.1 | 1.1 | 0.13 | |

| 47 | 20.25 | 19 | 16 | 1 | 1 | 35.4 | 36.6 | 8000 | 11000 | 32303 | 7603E | 2FD | 25 | 25 | 41 | 42 | 3 | 6 | 1 | 1 | 0.28 | 2.1 | 1.1 | 0.174 | |

| 20 | 47 | 15.25 | 14 | 12 | 1 | 1 | 28.2 | 30.9 | 8000 | 11000 | 30204 | 7204E | 2DB | 26 | 26 | 42 | 43 | 3 | 5 | 1 | 1 | 0.35 | 1.7 | 0.9 | 0.127 |

| 52 | 16.25 | 15 | 13 | 1.5 | 1.5 | 33.2 | 33.3 | 8000 | 11000 | 30304 | 7304E | 2FB | 28 | 28 | 45 | 47 | 3 | 5 | 1.5 | 1.5 | 03 | 2 | 1.1 | 0.168 | |

| 52 | 22.25 | 21 | 18 | 1.5 | 1.5 | 42.7 | 46.4 | 7500 | 10000 | 32304 | 7604E | 2FD | 28 | 28 | 45 | 47 | 3 | 6 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.231 | |

| 22 | 47 | 20 | 21 | 16 | 1 | 1 | 39.5 | 46 | 7500 | 10000 | 306/22 | 26 | 26 | 42 | 44 | 6.5 | 9 | 1 | 1 | 0.29 | 2.1 | 1.1 | 0.167 | ||

| 25 | 52 | 16.25 | 15 | 13 | 1 | 1 | 33.7 | 39.4 | 7500 | 10000 | 30205 | 7205E | 3CC | 31 | 31 | 46 | 47 | 3 | 5 | 1 | l | 0.37 | 1.6 | 0.9 | 0.157 |

| 52 | 19.25 | 18 | 16 | 1 | 1 | 39 | 48.8 | 7000 | 9500 | 32205 | 2CD | 31 | 31 | 44 | 46 | 3 | 4 | 1 | 1 | 0.36 | 1.7 | 0.9 | 0.184 | ||

| 62 | 18.25 | 17 | 13 | 1.5 | 1.5 | 40.7 | 46 | 5600 | 7500 | 31305 | 27305E | 7FB | 33 | 33 | 52 | 57 | 3 | 7 | 1.5 | 1.5 | 0.83 | 0.7 | 04 | 0.264 | |

| 62 | 18.25 | 17 | 14 | 1.5 | 1.5 | 40.7 | 46 | 5600 | 7500 | 31305X2YB2 | 33 | 33 | 52 | 57 | 3 | 7 | 1.5 | 1.5 | 0.54 | 1.1 | 0.6 | 0.267 | |||

| 62 | 18.25 | 17 | 15 | 1.5 | 1.5 | 47 | 48.3 | 6700 | 9000 | 30305 | 7305E | 2FB | 33 | 33 | 55 | 57 | 3 | 5 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.265 | |

| 62 | 18.25 | 17 | 15 | 1.5 | 1.5 | 49.1 | 48.1 | 5600 | 7500 | 30305/YB | 33 | 33 | 55 | 57 | 3 | 5 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.265 | |||

| 62 | 25.25 | 24 | 20 | 1.5 | 1.5 | 61.7 | 68.9 | 6000 | 8000 | 32305 | 7605E | 2FD | 33 | 33 | 55 | 57 | 3 | 7 | 1.5 | 1.5 | 0.3 | 2 | 1.1 | 0.37 | |

| 30 | 58 | 19.45 | 20 | 15.5 | 1.5 | 0.3 | 45.9 | 57.2 | 6100 | 7700 | 30606(ST3058-1) | 34 | 34 | 52 | 56 | 7 | 9 | 1.5 | 0.3 | 0.32 | 1.9 | 1 | 0.261 | ||

| 62 | 17.25 | 16 | 14 | 1 | 1 | 43.3 | 50.6 | 6300 | 8500 | 30206 | 7206E | 3DB | 36 | 36 | 56 | 57 | 3 | 5 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.232 | |

| 62 | 20 | 20 | 16 | 1 | 1 | 54.3 | 63.6 | 6300 | 8500 | 32206X2 | 36 | 36 | 56 | 59 | 8 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.277 | ||||

| 62 | 21.25 | 20 | 17 | 1 | 1 | 51.8 | 63.9 | 6300 | 8500 | 32206 | 7506E | 3DC | 36 | 36 | 56 | 57 | 3 | 6 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.285 | |

| 72 | 20.75 | 19 | 16 | 1.5 | 1.5 | 59 | 63.9 | 5600 | 7500 | 30306 | 7306E | 2FB | 38 | 38 | 64 | 66 | 3 | 7 | 1.5 | 1.5 | 0.31 | 1.9 | 1 | 0.389 | |

| 72 | 20.75 | 19 | 14 | 1.5 | 1.5 | 51 | 36 | 5000 | 6700 | 31306 | 27306E | 7FB | 38 | 38 | 64 | 66 | 7 | 1.5 | 1.5 | 0.82 | 0.7 | 0.4 | 0.394 | ||

| 72 | 24.5 | 24 | 17.6 | 3 | 1.5 | 53.8 | 65.9 | 5600 | 7500 | 30306X2B | 27706 | 36 | 36 | 60 | 68 | 5 | 9 | 2.5 | 1 | 0.6 | 1 | 0.56 | 0.472 | ||

| d 30~45mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 30 | 72 | 28.75 | 27 | 23 | 1.5 | 1.5 | 66.8 | 83.3 | 5300 | 7000 | 32306 | 7606E | 2FD | 38 | 38 | 64 | 66 | 4 | 8 | 1.5 | 1.5 | 0.31 | 1.9 | 1 | 0.566 |

| 72 | 28.75 | 27 | 23 | 1.5 | 15 | 66.8 | 83.3 | 5300 | 7000 | 32306AN | 37 | 38 | 59 | 66 | 4 | 6 | 1.5 | 1.5 | 31 | 1.9 | 1 | 0.587 | |||

| 32 | 75 | 29.75 | 28 | 23 | 1.5 | 1.5 | 76.9 | 60.6 | 5200 | 6900 | 323/32 | 76/32 | 39 | 39 | 68 | 71 | 3 | 6.5 | 1.5 | 1.5 | 0.55 | 1.1 | 0.6 | 0.647 | |

| 35 | 62 | 18 | 18 | 14 | 1 | 1 | 42.3 | 53.7 | 6000 | 8000 | 32007 | 3DC | 40 | 41 | 54 | 59 | 4 | 4 | 1 | 1 | 0.2 | 2.9 | 1.6 | 0.22 | |

| 65 | 18 | 18 | 14 | 3.5 | 3.5 | 41.3 | 59 | 6000 | 8000 | 30607 | 3DB | 50 | 50 | 56 | 50 | 3 | 5 | 3 | 3 | 0.38 | 1.5 | 0.8 | 0.246 | ||

| 72 | 18.25 | 17 | 15 | 1.5 | 1.5 | 54.2 | 63.7 | 5300 | 7000 | 30207 | 7207E | 3DB | 43 | 43 | 64 | 67 | 3 | 5 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.333 | |

| 72 | 24.25 | 23 | 19 | 1.5 | 1.5 | 70.6 | 89.7 | 5300 | 7000 | 32207 | 7507E | 3DC | 43 | 43 | 64 | 67 | 3 | 7 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.447 | |

| 72 | 28 | 28 | 22 | 1.5 | 1.5 | 82.6 | 102 | 5500 | 7000 | 33207 | 40 | 41 | 62 | 71 | 3 | 7 | 1.5 | 1.5 | 0.35 | 1.7 | 0.9 | 0.518 | |||

| 80 | 22.75 | 21 | 18 | 2 | 1.5 | 75.4 | 83.6 | 5000 | 6700 | 30307 | 7307E | 2FB | 44 | 44 | 71 | 75 | 3 | 7 | 2 | 1.5 | 0.31 | 1.9 | 1 | 0.518 | |

| 80 | 22.75 | 21 | 15 | 2 | 1.5 | 63.8 | 45.8 | 4500 | 6000 | 31307 | 27307E | 42 | 44 | 62 | 76 | 4 | 8 | 2 | 1.5 | 0.82 | 0.7 | 0.4 | 0.517 | ||

| 80 | 32.75 | 31 | 25 | 2 | 1.5 | 99.1 | 119.7 | 4800 | 6300 | 32307 | 7607E | 2FE | 44 | 44 | 71 | 75 | 5 | 10 | 2 | 1.5 | 31 | 1.9 | 1 | 0.766 | |

| 80 | 32.75 | 31 | 24 | 2 | 1.5 | 94.7 | 116 | 4800 | 6300 | 32307CN | 43 | 44 | 66 | 74 | 4 | 8 | 2 | 2 | 0.31 | 1.9 | 1 | 0.777 | |||

| 40 | 62 | 15.2 | 14 | 12 | 0.6 | 0.6 | 30 | 50 | 5600 | 7200 | 32908X2 | 2007908 | 46 | 46 | 57 | 58 | 3 | 5 | 0.6 | 6 | 0.28 | 2.1 | 1.1 | 0.139 | |

| 68 | 19 | 19 | 14.5 | 1 | 1 | 52.6 | 72.3 | 5300 | 7000 | 32008 | 3DB | 46 | 46 | 60 | 65 | 4 | 4.5 | 1 | 1 | 0.38 | 1.5 | 0.8 | 0.275 | ||

| 80 | 19.75 | 18 | 16 | 1.5 | 1.5 | 63 | 74.1 | 4800 | 6300 | 30208 | 7208E | 3DB | 48 | 48 | 72 | 75 | 3 | 6 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.423 | |

| 80 | 21.5 | 18 | 17.75 | 1.5 | 1.5 | 66 | 80 | 5300 | 6600 | 30608 | 7808E | 48 | 48 | 72 | 75 | 4 | 7 | 15 | 1.5 | 0.37 | 1.6 | 0.9 | 0.446 | ||

| 80 | 24.75 | 23 | 19 | 1.5 | 1.5 | 77.9 | 97.5 | 4800 | 6300 | 32208 | 7508E | 3DC | 48 | 48 | 72 | 75 | 3 | 8 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.529 | |

| 80 | 24.75 | 23 | 10 | 1.5 | 1.5 | 77.9 | 97.5 | 4800 | 6300 | 32208R | 47 | 48 | 68 | 75 | 3 | 6 | 2 | 1.5 | 0.37 | 1.6 | 0.9 | 0.549 | |||

| 90 | 25.25 | 23 | 20 | 2 | 1.5 | 90.8 | 108.7 | 4500 | 6000 | 30308 | 7308E | 2FB | 49 | 49 | 80 | 85 | 3 | 7 | 2 | 1.5 | 0.35 | 1.7 | 0.9 | 0.748 | |

| 90 | 25.25 | 23 | 17 | 2 | 1.5 | 81.5 | 96.5 | 4000 | 5300 | 31308 | 27308E | 7EB | 49 | 49 | 80 | 85 | 6 | 10 | 2 | 1.5 | 0.83 | 0.7 | 0.4 | 0.729 | |

| 90 | 35.25 | 33 | 27 | 2 | 1.5 | 115.3 | 149 | 4000 | 5300 | 32308 | 7608E | 2FD | 49 | 49 | 80 | 85 | 5 | 10 | 2 | 1.5 | 0.35 | 1.7 | 0.9 | 1 | |

| 90 | 35.25 | 33 | 26 | 2 | 1.5 | 100 | 118 | 4000 | 5300 | 32308CN | 49 | 49 | 73 | 83 | 4 | 8.5 | 2 | 2 | 0.35 | 1.7 | 0.9 | 1.02 | |||

| 45 | 85 | 20.75 | 19 | 16 | 1.5 | 1.5 | 67.6 | 84.4 | 4500 | 6000 | 30209 | 7209E | 3DB | 53 | 53 | 76 | 79 | 3 | 7 | 1.5 | 1.5 | 0.4 | 1.5 | 0.8 | 0.474 |

| 85 | 24.75 | 23 | 19 | 1.5 | 1.5 | 80.3 | 105.1 | 4500 | 6000 | 32209 | 7509E | 3DC | 53 | 53 | 76 | 79 | 3 | 8 | 1.5 | 1.5 | 0.4 | 1.5 | 0.8 | 0.585 | |

| d 45~55mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 45 | 85 | 24.75 | 23 | 19 | 1.5 | 1.5 | 72 | 60 | 4500 | 6000 | 32209R | 53 | 53 | 76 | 79 | 3 | 8 | 1.5 | 1.5 | 0.4 | |||||

| 85 | 25 | 23.5 | 20 | 1.5 | 1.5 | 77 | 93 | 4500 | 6000 | 32209/YB2 | 127509 | 53 | 53 | 76 | 79 | 3 | 8 | 15 | 1.5 | 0.4 | 1.5 | 0.8 | 0.584 | ||

| 85 | 32 | 32 | 25 | 1.5 | 1.5 | 113 | 147 | 4000 | 5300 | 33209 | 52 | 52 | 72 | 78 | 5 | 7 | 1 | 1 | 0.4 | 1.5 | 0.8 | 0.82 | |||

| 100 | 27.25 | 25 | 22 | 2 | 1.5 | 108.7 | 131.2 | 4000 | 5300 | 30309 | 7309E | 2FB | 54 | 54 | 90 | 94 | 4 | 7 | 2 | 1.5 | 0.35 | 1.7 | 0.9 | 988 | |

| 100 | 32 | 29 | 20 | 1.5 | 1.5 | 63 | 83 | 4000 | 5300 | 30309X2B | 27709 | 51 | 51 | 82 | 96 | 6 | 13 | 1.5 | 1.5 | 0.7 | 0.8 | 0.46 | 1.04 | ||

| 47 | 100 | 43 | 43 | 37 | 1.5 | 1 | 108 | 169 | 4000 | 5300 | 30647 | 7909 | 57 | 57 | 86 | 95 | 6 | 8 | 1.5 | 0.3 | 1.9 | 1.1 | 1.66 | ||

| 50 | 80 | 20 | 20 | 15.5 | 1.5 | 1.5 | 54.5 | 85 | 4500 | 6000 | 32010/YB2 | 3DC | 56 | 56 | 72 | 77 | 4 | 4.5 | 1.5 | 1.5 | 0.42 | 14 | 0.8 | 373 | |

| 80 | 20 | 20 | 15.5 | 1 | 1 | 59.1 | 85 | 4500 | 6000 | 32010 | 3DC | 56 | 56 | 72 | 77 | 4 | 4.5 | 1 | 1 | 0.42 | 1.4 | 0.8 | 0.373 | ||

| 90 | 21.75 | 20 | 17 | 1.5 | 1.5 | 76.1 | 97.4 | 4300 | 5600 | 30210 | 7210E | 3DB | 58 | 58 | 82 | 85 | 4 | 7 | 1.5 | 1.5 | 0.43 | 1.4 | 0.8 | 0.539 | |

| 90 | 24.75 | 23 | 19 | 1.5 | 1.5 | 89.4 | 120 | 4300 | 5600 | 32210 | 7510E | 3DC | 58 | 58 | 82 | 85 | 3 | 8 | 1.5 | 1.5 | 43 | 1.4 | 0.8 | 0.645 | |

| 90 | 24.75 | 23 | 19 | 1.5 | 1.5 | 77 | 65 | 4300 | 5600 | 32210R | 57 | 57 | 78 | 86 | 3 | 6 | 1.5 | 1.5 | 0.43 | 1.4 | 0.8 | 0.668 | |||

| 110 | 29.25 | 27 | 23 | 2.5 | 2 | 129.9 | 158.9 | 3600 | 4800 | 30310 | 7310E | 2FB | 60 | 60 | 98 | 103 | 4 | 8 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.3 | |

| 110 | 29.25 | 27 | 19 | 2.5 | 2 | 102 | 128 | 3200 | 4300 | 31310 | 27310E | 58 | 60 | 87 | 105 | 10.5 | 25 | 2 | 0.82 | 0.7 | 4 | 122 | |||

| 110 | 31.75 | 29.5 | 23 | 2.5 | 136 | 157 | 3200 | 4300 | 30310X2 | 60 | 60 | 98 | 103 | 4 | 8 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.35 | ||||

| 110 | 42.25 | 40 | 33 | 2.5 | 2 | 177.3 | 238.7 | 3200 | 4300 | 32310 | 7610E | 2FD | 60 | 60 | 98 | 103 | 6 | 12 | 2.1 | 2 | 0.35 | 1.7 | 9 | 1.9 | |

| 110 | 42.25 | 40.5 | 33 | 2.5 | 190 | 244 | 3200 | 4300 | AK32310 | 60 | 60 | 98 | 103 | 6 | 12 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.91 | ||||

| 50.8 | 100 | 35 | 35 | 27 | 2.5 | 2.5 | 140 | 192 | 3400 | 4500 | 33910/YB2 | 63 | 63 | 90 | 88 | 3 | 5 | 2 | 2 | 0.4 | 1.5 | 0.8 | 1.17 | ||

| 55 | 90 | 23 | 23 | 17.5 | 1.5 | 1.5 | 75.4 | 122 | 4000 | 5300 | 32011 | 2007111E | 3CE | 63 | 62 | 81 | 86 | 4 | 5.5 | 1.5 | 1.5 | 0.4 | 1.5 | 0.8 | 0.561 |

| 95 | 30 | 30 | 23 | 1.5 | 1.5 | 105 | 148 | 3800 | 5000 | 33111 | 3007711 | 3CE | 63 | 63 | 81 | 92 | 5 | 7 | 1.5 | 1.5 | 0.37 | 1.6 | 0.9 | 0.862 | |

| 100 | 22.75 | 21 | 18 | 2 | 1.5 | 90.9 | 115.7 | 3800 | 5000 | 30211 | 7211E | 3DB | 64 | 64 | 90 | 94 | 4 | 7 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 0.719 | |

| 100 | 24.75 | 23 | 18 | 2 | 1.5 | 90.1 | 111 | 3800 | 5000 | 30211 X2 | 64 | 64 | 88 | 95 | 4 | 5 | 2 | 1.5 | 0.55 | 1 | 0.6 | 0.76 | |||

| 100 | 26.75 | 25 | 21 | 2 | 1.5 | 107.5 | 143.8 | 3800 | 5000 | 32211 | 7511E | 3DC | 64 | 64 | 90 | 94 | 4 | 8 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 0.86 | |

| 100 | 35 | 35 | 27 | 2 | 1.5 | 3800 | 5000 | 33211 | 0.4 | 1.5 | 0.8 | 1.22 | |||||||||||||

| 120 | 31.5 | 29 | 21 | 2.5 | 129.9 | 158 | 2800 | 3800 | 31311 | 27311E | 7FB | 65 | 65 | 103 | 114 | 8 | 14 | 2.1 | 2 | 0.83 | 0.7 | 0.4 | 1.56 | ||

| 120 | 31.5 | 29 | 21 | 4 | 3 | 113 | 90 | 2800 | 3800 | 31311/YB2 | 70 | 65 | 104 | 112 | 4 | 6.5 | 1.8 | 1.8 | 0.82 | 0.7 | 0.4 | 1.56 | |||

| d 55~65mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 55 | 120 | 31.5 | 29 | 25 | 2.5 | 2 | 153.1 | 189.7 | 3200 | 4300 | 30311 | 7311 | 2FB | 65 | 65 | 106 | 114 | 4 | 9 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 163 |

| 120 | 31.5 | 29 | 21 | 2.5 | 2 | 16 | 191 | 3200 | 4300 | 30311R | 65 | 65 | 106 | 114 | 4 | 9 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 1.69 | |||

| 120 | 45.5 | 43 | 35 | 2.5 | 2 | 202.8 | 274.3 | 3000 | 4000 | 32311 | 7611E | 2FD | 65 | 65 | 106 | 114 | 8 | 14 | 2.1 | 2 | 0.35 | 1.7 | 0.9 | 2.33 | |

| 120 | 45.5 | 43 | 35 | 7 | 2 | 203 | 256 | 3000 | 4000 | 32311/YB2 | 66 | 65 | 99 | 111 | 5 | 10.5 | 1.8 | 1.8 | 0.35 | 1.7 | 0.9 | 2.34 | |||

| 125 | 37 | 36 | 25 | 3 | 2 | 158 | 209 | 3000 | 4000 | 31611 | 3DB | 69 | 69 | 107 | 111 | 4 | 11 | 2.5 | 2.5 | 0.73 | 0.8 | 0.4 | 2.11 | ||

| 130 | 36 | 33 | 22 | 3 | 2.5 | 170 | 184 | 2800 | 3800 | 30611 | 2FB | 69 | 69 | 111 | 116 | 4 | 11 | 2.5 | 2.5 | 0.82 | 0.7 | 0.4 | 2.11 | ||

| 60 | 85 | 17.3 | 16 | 14 | 1 | 1 | 56 | 83 | 4000 | 5300 | 32912X2 | 2007912 | 67 | 67 | 78 | 81 | 5 | 1 | 1 | 0.38 | 1.6 | 0.9 | 0.24 | ||

| 95 | 23 | 23 | 17.5 | 1.5 | 1.5 | 79.8 | 125 | 3800 | 5000 | 32012 | 2007112E | 3CE | 67 | 67 | 85 | 91 | A | 5.5 | 1.5 | 1.5 | 0.43 | 1.4 | 0.7 | 0.592 | |

| 110 | 23.75 | 22 | 19 | 2 | 1.5 | 102.9 | 131.5 | 3400 | 4500 | 30212 | 7212E | 69 | 69 | 100 | 104 | 5 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 0.906 | |||

| 110 | 29.75 | 28 | 24 | 2 | 1.5 | 132.2 | 181.5 | 3400 | 4500 | 32212 | 7512E | 3EB | 69 | 69 | 100 | 104 | 4 | 8 | 2 | 1.5 | 04 | 1.5 | 0.8 | 1.18 | |

| 110 | 34.1 | 30 | 20 | 2 | 2 | 82 | 61 | 5810 | 7270 | 3-706 | 70 | 70 | 100 | 104 | 5 | 14 | 2 | 2 | 0.43 | 1.4 | 0.7 | 1.25 | |||

| 130 | 33.5 | 31 | 26 | 3 | 2.5 | 175 | 203 | 3000 | 4000 | 30312 | 7312E | 2FB | 71 | 71 | 116 | 123 | 4 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2 | |

| 130 | 33.5 | 31 | 26 | 3 | 2.5 | 175 | 203 | 3000 | 4000 | 30312R | 71 | 71 | 116 | 123 | 4 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.06 | |||

| 130 | 33.5 | 31 | 22 | 3 | 2.5 | 145.4 | 176.8 | 2600 | 3600 | 31312 | 27312E | 7FB | 71 | 71 | 112 | 123 | 8 | 14 | 2.5 | 2.1 | 0.83 | 0.72 | 0.4 | 2.02 | |

| 130 | 48.5 | 46 | 37 | 3 | 2.5 | 226.3 | 306.1 | 2600 | 3600 | 32312 | 7612E | 7FD | 71 | 71 | 116 | 123 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 2.91 | |

| 62 | 100 | 21.5 | 21 | 16.5 | 1.5 | 1.5 | 70 | 104 | 3900 | 4900 | 306/62 | 7912 | 68 | 71 | 91 | 96.9 | 4 | 6 | 1 | 1 | 0.37 | 1.6 | 0.9 | 0.597 | |

| 65 | 100 | 23 | 23 | 17.5 | 1.5 | 1.5 | 84.5 | 131 | 3400 | 4500 | 32013 | 3DC | 72 | 72 | 90 | 97 | 4 | 5.5 | 1.5 | 1.5 | 046 | 1.3 | 0.7 | 0.631 | |

| 110 | 34 | 34 | 26.5 | 1.5 | 1.5 | 125 | 202 | 3200 | 4300 | 33113 | 75 | 75 | 100 | 104 | 4 | 5 | 1.5 | 1.5 | 0.39 | 1.5 | 0.8 | 1.27 | |||

| 120 | 24.75 | 23 | 20 | 2 | 1.5 | 120 | 154.2 | 3000 | 4000 | 30213 | 7213E | 3EB | 74 | 74 | 108 | 114 | 5 | 7 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 1.13 | |

| 120 | 32.75 | 31 | 27 | 2 | 1.5 | 163 | 212 | 3000 | 4000 | 32213 | 7513E | 3EC | 74 | 74 | 108 | 114 | 4 | 8 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 1.54 | |

| 120 | 41 | 41 | 32 | 2 | 1.5 | 184 | 257 | 2800 | 3800 | 33213 | 3007213 | 3EE | 74 | 76 | 104 | 111 | 6 | 12 | 2 | 1.5 | 0.39 | 1.5 | 0.8 | 2.01 | |

| 120 | 41 | 41 | 32 | 2 | 1.5 | 183 | 280 | 2800 | 3800 | 33213TN1 | 74 | 77 | 106 | 114 | 5 | 2 | 1.5 | 0.4 | 1.5 | 0.8 | 1.91 | ||||

| 130 | 45 | 43 | 35 | 7 | 2 | 207 | 306 | 2600 | 3600 | 30613 | 70 | 75 | 100 | 104 | 4 | 8 | 3 | 1.5 | 0.33 | 1.5 | 0.8 | 2.64 | |||

| 140 | 36 | 33 | 28 | 3 | 2.5 | 195.7 | 244.4 | 2600 | 3600 | 30313 | 7313E | 7GB | 76 | 76 | 125 | 132 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.45 | |

| 140 | 36 | 33 | 28 | 6 | 2.5 | 206 | 243 | 2600 | 3600 | 30313/YB2 | 76 | 76 | 125 | 132 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.44 | |||

| 140 | 40 | 39 | 26 | 3 | 2.5 | 204 | 246 | 2600 | 3600 | 30313X2B | 76 | 76 | 125 | 132 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.68 | |||

| d 60~80mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 60 | 140 | 36 | 33 | 23 | 3 | 2.5 | 165.7 | 202.6 | 2200 | 3200 | 31313 | 27313E | 7GB | 76 | 76 | 120 | 132 | 10 | 16 | 2.5 | 2.1 | 0.83 | 0.7 | 0.4 | 2.39 |

| 140 | 40 | 38 | 27 | 3 | 2.5 | 187 | 247 | 2600 | 3600 | 31613? | 3DB | 79 | 79 | 122 | 126 | 6 | 13 | 2.5 | 2.5 | 0.73 | 0.8 | 0.4 | 2.74 | ||

| 140 | 51 | 48 | 39 | 3 | 2.5 | 259.3 | 353.6 | 2400 | 3400 | 32313 | 7613E | 2GD | 76 | 76 | 125 | 132 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 3.35 | |

| 140 | 51 | 48 | 39 | 3 | 2.5 | 230 | 206 | 2400 | 3400 | 32313R | 76 | 76 | 125 | 132 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 3.63 | |||

| 70 | 120 | 33 | 33 | 27 | 2 | 2 | 151 | 217 | 3000 | 4000 | 33114X2 | 7814E | 3DE | 77 | 77 | 110 | 115 | 5 | 10 | 2 | 2 | 0.28 | 2.2 | 1.2 | 1.46 |

| 120 | 33 | 33 | 27 | 2 | 2 | 173 | 246 | 3000 | 4000 | 33114X2/YA | 77 | 77 | 110 | 115 | 5 | 10 | 2 | 2 | 0.28 | 2.2 | 1.2 | 1.55 | |||

| 125 | 26.25 | 24 | 21 | 1.5 | 132 | 174.3 | 3000 | 4000 | 30214 | 7214E | 3EB | 79 | 79 | 114 | 119 | 5 | 7 | 2 | 1.5 | 0.42 | 1.4 | 0.8 | 1.26 | ||

| 125 | 33.25 | 31 | 27 | 2 | 1.5 | 168.1 | 238 | 2800 | 3800 | 32214 | 7514E | 3EC | 79 | 79 | 114 | 119 | 4 | 8 | 2 | 1.5 | 42 | 1.4 | 0.8 | 1.65 | |

| 150 | 38 | 35 | 30 | 3 | 2.5 | 218.8 | 274.7 | 2400 | 3400 | 30314 | 7314E | 2GB | 81 | 81 | 135 | 142 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 9 | 2.99 | |

| 150 | 38 | 35 | 30 | 9 | 2.5 | 230 | 275 | 2400 | 3400 | 30314/YB2 | 81 | 81 | 135 | 142 | 5 | 10 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 2.97 | |||

| 70 | 150 | 38 | 35 | 25 | 5 | 2.5 | 197 | 232 | 2000 | 3000 | 31314 | 82 | 89 | 130 | 141 | 5 | 8 | 4 | 2.5 | 0.82 | 0.7 | 0.4 | 2.91 | ||

| 150 | 38 | 35 | 25 | 5 | 2.5 | 197 | 232 | 2000 | 3000 | 31314/YB2 | 82 | 89 | 130 | 141 | 5 | 8 | 4 | 2.5 | 0.82 | 0.7 | 0.4 | 2.91 | |||

| 150 | 54 | 51 | 42 | 3 | 2.5 | 298.8 | 413.4 | 2200 | 3200 | 32314 | 7614E | 2GD | 81 | 81 | 135 | 142 | 8 | 14 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 4.43 | |

| 75 | 130 | 27.25 | 25 | 22 | 2 | 1.5 | 137.7 | 186.9 | 2800 | 3800 | 30215 | 7215E | 4DB | 84 | 84 | 119 | 124 | 5 | 7 | 2 | 1.5 | 0.44 | 1.4 | 0.8 | 1.38 |

| 130 | 33.25 | 31 | 27 | 2 | 1.5 | 169.5 | 244.1 | 2600 | 3600 | 32215 | 7515 | 4DC | 84 | 84 | 119 | 124 | 4 | 8 | 2 | 1.5 | 44 | 1.4 | 0.8 | 1.74 | |

| 135 | 44 | 45 | 35 | 2 | 2 | 175 | 274 | 3000 | 3800 | 30615/YB2 | 82 | 85 | 119 | 131 | 5 | 11 | 2 | 2 | 0.28 | 2.2 | 1.2 | 2.57 | |||

| 135 | 44.5 | 45 | 36.5 | 2 | 228 | 339 | 3000 | 3800 | 30615 | 82 | 85 | 119 | 131 | 5 | 11 | 2 | 2 | 0.28 | 2.2 | 1.2 | 2.69 | ||||

| 135 | 44.5 | 45 | 36.5 | 2 | 2 | 240 | 370 | 3000 | 3800 | 30615/YA | 86 | 86 | 120 | 125 | 5 | 11 | 2 | 2 | 0.24 | 2.5 | 1.4 | 2.76 | |||

| 160 | 40 | 37 | 26 | 3 | 2.5 | 219 | 259 | 1900 | 2800 | 31315 | 87 | 91 | 127 | 148 | 6 | 14 | 2 | 2 | 0.83 | 0.72 | 0.4 | 3.5 | |||

| 160 | 40 | 37 | 31 | 3 | 2.5 | 250.3 | 318.6 | 2200 | 3200 | 30315 | 7315E | 2GB | 86 | 86 | 143 | 152 | 5 | 11 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 3.58 | |

| 160 | 58 | 55 | 45 | 3 | 2.5 | 358 | 472 | 2000 | 3000 | 32315 | 7615E | 2GD | 86 | 86 | 143 | 152 | 10 | 16 | 2.5 | 2.1 | 0.35 | 1.7 | 1 | 5.32 | |

| 170 | 61.5 | 58 | 48 | 3 | 2.5 | 406 | 543 | 1900 | 2800 | T6GD075 | 90 | 90 | 152 | 162 | 10 | 16 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 6.64 | |||

| 80 | 110 | 20 | 20 | 16 | 1 | 1 | 72.8 | 123 | 32916 | 0.538 | |||||||||||||||

| 125 | 29 | 29 | 22 | 1.5 | 1.5 | 136 | 209 | 2600 | 3600 | 32016 | 3EB | 87 | 89 | 112 | 120 | 6 | 7 | 1 | 1 | 0.42 | 1.6 | 0.8 | 1.27 | ||

| 130 | 32 | 31 | 25 | 1 | 3.5 | 140 | 233 | 2500 | 3500 | 30616/YB2 | 86 | 86 | 119 | 124 | 5 | 7 | 1 | 0.38 | 1.6 | 0.8 | 1.56 | ||||

| 140 | 28.25 | 26 | 22 | 2.5 | 2 | 160.1 | 213.6 | 2400 | 3400 | 30216 | 7216E | 3EB | 90 | 90 | 127 | 134 | 5 | 8 | 1 | 2 | 0.42 | 1.4 | 0.8 | 1.84 | |

| d 80~95mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 80 | 140 | 35.25 | 33 | 28 | 2.5 | 2 | 198 | 280.1 | 2400 | 3400 | 32216 | 7516E | 3EC | 90 | 90 | 127 | 134 | 5 | 8 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 2.03 |

| 140 | 35.5 | 33 | 28 | 2 | 2 | 160 | 241 | 2400 | 3400 | 32216/YB2 | 7516 | 90 | 90 | 127 | 134 | 5 | 8 | 2 | 2 | 0.4 | 1.5 | 0.8 | 2.15 | ||

| 140 | 45 | 45 | 36.5 | 2.5 | 2 | 233 | 214 | 2200 | 3200 | 30616 | 87 | 90 | 127 | 136 | 5 | 11 | 2.1 | 2 | 0.28 | 2.2 | 1.2 | 2.81 | |||

| 170 | 42.5 | 39 | 33 | 3 | 2.5 | 286 | 343 | 2000 | 3000 | 30316 | 7316E | 2GB | 92 | 92 | 152 | 162 | 7 | 12 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 4.5 | |

| 170 | 61.5 | 58 | 48 | 3 | 2.5 | 400 | 532 | 1900 | 2800 | 32316 | 7616E | 2GD | 92 | 92 | 152 | 162 | 10 | 16 | 2.5 | 2.1 | 0.35 | 1.7 | 0.9 | 6.39 | |

| 85 | 140 | 77.07 | 38.5 | 69.14 | 2 | 0.6 | B3-748L | 95 | 95 | 130 | 2 | 2 | 0.33 | 1.8 | 1 | 3.32 | |||||||||

| 150 | 30.5 | 28 | 24 | 2.5 | 2 | 180 | 242.5 | 2200 | 3200 | 30217 | 7217E | 3EB | 95 | 95 | 136 | 144 | 5 | 9 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 2.06 | |

| 150 | 38.5 | 36 | 30 | 2.5 | 2 | 220 | 323 | 2200 | 3200 | 32217 | 7517E | 3EC | 95 | 95 | 136 | 144 | 5 | 11 | 2.1 | 2 | 042 | 1.4 | 0.8 | 2.67 | |

| 150 | 49 | 49 | 37 | 2.5 | 2 | 272 | 409 | 2000 | 3000 | 33217 | 3007217 | 3EE | 95 | 95 | 136 | 145 | 7 | 12 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 3.57 | |

| 180 | 44.5 | 41 | 34 | 4 | 3 | 304.5 | 392.4 | 1900 | 2800 | 30317 | 7317E | 3GB | 97 | 97 | 161 | 171 | 8 | 14 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 5.305 | |

| 180 | 44.5 | 41 | 28 | 4 | 3 | 266 | 320 | 1800 | 2600 | 31317 | 99 | 103 | 143 | 169 | 6 | 6.5 | 2.5 | 2.5 | 0.83 | 0.72 | 0.4 | 4.6 | |||

| 180 | 63.5 | 60 | 49 | 4 | 3 | 434 | 580 | 1800 | 2600 | 32317 | 7617E | 2GD | 98 | 98 | 161 | 171 | 12 | 18 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 6.81 | |

| 90 | 140 | 32 | 32 | 24 | 2 | 1.5 | 159 | 245 | 2200 | 3200 | 32018 | 3EB | 99 | 100 | 125 | 134 | 6 | 8 | 2 | 1.5 | 0.42 | 1.4 | 0.8 | 1.7 | |

| 140 | 32.4 | 30 | 26 | 2 | 1.5 | 160 | 257 | 2200 | 3200 | 32018X2/YA | 2007118 | 99 | 99 | 128 | 134 | 5 | 8 | 2 | 1.5 | 0.34 | 1.8 | 1 | 1.66 | ||

| 140 | 32.4 | 30 | 26 | 2 | 1.5 | 130 | 210 | 2200 | 3200 | 32018 RX2 | 99 | 100 | 125 | 134 | 6 | 8 | 2 | 2 | 0.34 | 1.7 | 0.9 | 1.7 | |||

| 150 | 45 | 45 | 35 | 2.5 | 2 | 231 | 396 | 2000 | 3000 | 33118TN1 | 102 | 102 | 134 | 138 | 5 | 10 | 2 | 2 | 0.4 | 1.5 | 0.8 | 2.97 | |||

| 160 | 32.5 | 30 | 26 | 2.5 | 2 | 199.7 | 270.5 | 2000 | 3000 | 30218 | 7218E | 3FB | 100 | 100 | 145 | 153 | 5 | 9 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 2.558 | |

| 160 | 42.5 | 40 | 34 | 2.5 | 2 | 269.1 | 396.9 | 2000 | 3000 | 32218 | 7518E | 3FC | 100 | 100 | 145 | 153 | 5 | 11 | 2.1 | 2 | 0.42 | 1.4 | 0.8 | 3.33 | |

| 190 | 46.5 | 43 | 36 | 4 | 3 | 341.7 | 445.7 | 1800 | 2600 | 30318 | 7318E | 2GB | 103 | 103 | 170 | 181 | 8 | 14 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 6.144 | |

| 190 | 67.5 | 64 | 53 | 4 | 3 | 4,777 | 690.8 | 1700 | 2400 | 32318 | 7618E | 2GD | 103 | 103 | 170 | 181 | 12 | 18 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 8.76 | |

| 95 | 145 | 32 | 32 | 24 | 2 | 1.5 | 162 | 255 | 2200 | 3200 | 32019 | 3EB | 104 | 105 | 130 | 140 | 6 | 8 | 2 | 1.5 | 0.45 | 1.3 | 0.7 | 177 | |

| 145 | 32.4 | 30 | 26 | 2 | 1.5 | 226.1 | 310.2 | 2200 | 3200 | 32019X2/YA | 2007119 | 104 | 104 | 133 | 139 | 5 | 8 | 2 | 1.5 | 0.36 | 1.7 | 0.9 | 1.7 | ||

| 160 | 47 | 47 | 38 | 3 | 2.5 | 251 | 420 | 3970 | 4970 | 30619 | 3FB | 109 | 109 | 145 | 146 | 5 | 9 | 2.5 | 2.5 | 0.29 | 2 | 1.1 | 3.7 | ||

| 170 | 34.5 | 32 | 27 | 3 | 2.5 | 226.1 | 310.2 | 1900 | 2800 | 30219 | 7219E | 3FB | 106 | 106 | 157 | 163 | 5 | 10 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 3.269 | |

| 170 | 45.5 | 43 | 37 | 3 | 2.5 | 313 | 443 | 1900 | 2800 | 32219 | 7519E | 3FC | 106 | 106 | 157 | 163 | 5 | 11 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 4.216 | |

| 170 | 58 | 58 | 44 | 3 | 2.5 | 1900 | 2800 | 33219 | 106 | 106 | 157 | 163 | 5 | 11 | 2.5 | 2.1 | |||||||||

| d 95~120mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 95 | 200 | 49.5 | 45 | 38 | 4 | 3 | 368.6 | 483 | 1800 | 2600 | 30319 | 7319E | 2GB | 109 | 109 | 180 | 191 | 8 | 14 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 7.13 |

| 200 | 71.5 | 67 | 55 | 4 | 3 | 515.5 | 745.8 | 1700 | 2400 | 32319 | 7619E | 2GD | 109 | 109 | 180 | 191 | 14 | 20 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 10.73 | |

| 100 | 130 | 57 | 56 | 35 | 11 | 2 | 238 | 327 | LY-3026 | 2.99 | |||||||||||||||

| 150 | 32 | 32 | 24 | 2 | 1.5 | 165 | 265 | 2000 | 3000 | 32020 | 3EB | 109 | 109 | 134 | 144 | 6 | 8 | 2 | 2 | 0.46 | 1.3 | 0.7 | 1.84 | ||

| 150 | 32.4 | 30 | 26 | 2 | 1.5 | 163 | 266 | 2000 | 3000 | 32020YB2 | 2007120 | 109 | 109 | 138 | 144 | 5 | 8 | 2 | 1.5 | 0.37 | 1.6 | 0.9 | 1.79 | ||

| 150 | 32.4 | 30 | 26 | 2 | 1.5 | 150 | 261 | 2000 | 3000 | 32020 RX2 | 109 | 109 | 134 | 144 | 6 | 8 | 2 | 1.5 | 0.37 | 1.6 | 0.9 | 1.8 | |||

| 165 | 47 | 46 | 39 | 3 | 305 | 486 | 1900 | 2800 | 33120X2 | 111 | 111 | 145 | 160 | 5 | 10 | 2.5 | 2.5 | 0.32 | 1.9 | 1 | 3.93 | ||||

| 180 | 37 | 34 | 29 | 3 | 2.5 | 253.3 | 35L6 | 1900 | 2800 | 30220 | 7220E | 3FB | 111 | 111 | 162 | 172 | 5 | 10 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 3.73 | |

| 180 | 49 | 46 | 39 | 3 | 2.5 | 340.2 | 513.7 | 1800 | 2600 | 32220 | 7520E | 3FC | 111 | 11 | 162 | 172 | 5 | 14 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 5.12 | |

| 180 | 63 | 63 | 48 | 3 | 3 | 1700 | 2400 | 33220/YB2 | 111 | 111 | 162 | 2.5 | 2.5 | ||||||||||||

| 215 | 51.5 | 47 | 39 | 4 | 3 | 406 | 532.3 | 1700 | 2400 | 30320 | 7320E | 2GB | 116 | 116 | 194 | 205 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 8.69 | |

| 215 | 77.5 | 73 | 60 | 4 | 3 | 599.5 | 881.9 | 1600 | 2200 | 32320 | 7620E | 2GD | 116 | 116 | 194 | 205 | 14 | 20 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 12.96 | |

| 105 | 160 | 35 | 35 | 26 | 2.5 | 2 | 194 | 311 | 1900 | 2800 | 32021 | 3EB | 115 | 116 | 143 | 154 | 6 | 9 | 2 | 2 | 0.44 | 1.3 | 0.7 | 2.38 | |

| 160 | 43 | 43 | 34 | 2.5 | 2 | 240 | 398 | 1900 | 2800 | 33021 | 3EB | 115 | 116 | 143 | 154 | 6 | 9 | 2 | 2 | 0.46 | 1.3 | 0.7 | 2.94 | ||

| 190 | 39 | 36 | 30 | 3 | 2.5 | 284.6 | 400 | 1800 | 2600 | 30221 | 7221E | 2FB | 116 | 116 | 172 | 182 | 6 | 11 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 4.936 | |

| 190 | 53 | 50 | 43 | 3 | 2.5 | 380.1 | 581.2 | 1800 | 2600 | 32221 | 7521E | 3FC | 116 | 116 | 172 | 182 | 6 | 12 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 6.495 | |

| 225 | 53.5 | 49 | 41 | 4 | 3 | 432.6 | 568.1 | 1600 | 2200 | 30321 | 7321E | 2GB | 120 | 120 | 202 | 215 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 9.912 | |

| 225 | 81.5 | 77 | 63 | 4 | 3 | 646.4 | 955.6 | 1500 | 2000 | 32321 | 7621E | 2GD | 123 | 123 | 202 | 215 | 14 | 20 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 14.458 | |

| 110 | 170 | 38 | 38 | 29 | 2.5 | 2 | 202 | 354 | 1800 | 2800 | 32022 | 3DC | 120 | 122 | 152 | 163 | 7 | 9 | 2 | 0.43 | 1.4 | 0.7 | 3.01 | ||

| 170 | 47 | 47 | 37 | 2.5 | 266 | 464 | 1800 | 2800 | 33022 | 3EB | 120 | 122 | 152 | 163 | 7 | 9 | 2 | 2 | 0.29 | 2.1 | 1.1 | 3.76 | |||

| 200 | 41 | 38 | 32 | 3 | 2.5 | 314.1 | 445.1 | 1700 | 2400 | 30222 | 7222E | 3FB | 121 | 121 | 181 | 192 | 6 | 11 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 5.422 | |

| 200 | 56 | 53 | 46 | 3 | 2.5 | 430.7 | 668.6 | 1700 | 2400 | 32222 | 7522E | 3FC | 121 | 121 | 181 | 192 | 6 | 12 | 2.5 | 2.1 | 0.42 | 1.4 | 0.8 | 7.86 | |

| 240 | 54.5 | 50 | 42 | 4 | 3 | 471.6 | 619.1 | 1600 | 2200 | 30322 | 7322E | 2GB | 124 | 124 | 215 | 230 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 11.45 | |

| 240 | 84.5 | 80 | 65 | 4 | 3 | 722.8 | 1076 | 1400 | 1900 | 32322 | 7622E | 2GD | 127 | 127 | 215 | 230 | 18 | 25 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 18.78 | |

| 120 | 180 | 38 | 38 | 29 | 2.5 | 2 | 230 | 394 | 1700 | 2400 | 32024/YA | 2007124K | 130 | 131 | 161 | 173 | 7 | 9 | 2 | 2 | 0.37 | 1.6 | 0.9 | 3.07 | |

| d 105~150mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 105 | 180 | 38.4 | 36 | 31 | 2.5 | 2 | 230 | 394 | 1700 | 2400 | 32024X2R | 130 | 131 | 161 | 173 | 7 | 9 | 2 | 2 | 0.37 | 1.6 | 0.9 | 3.14 | ||

| 180 | 38.4 | 36 | 31 | 2.5 | 2 | 230 | 394 | 1700 | 2400 | 32024X2/YA | 2007124 | 130 | 130 | 166 | 174 | 6 | 9 | 2.1 | 2 | 0.37 | 1.6 | 0.9 | 3 | ||

| 215 | 43.5 | 40 | 34 | 3 | 2.5 | 335.8 | 487.2 | 1600 | 2200 | 30224 | 7224E | 4FB | 131 | 131 | 196 | 207 | 7 | 12 | 2.5 | 2.1 | 0.44 | 1.4 | 0.8 | 6.125 | |

| 215 | 61.5 | 58 | 50 | 3 | 2.5 | 492 | 741 | 1600 | 2200 | 32224 | 7524E | 4FD | 131 | 131 | 196 | 207 | 8 | 12 | 2.5 | 2.1 | 0.44 | 1.4 | 0.8 | 9.25 | |

| 260 | 59.5 | 55 | 46 | 4 | 3 | 562 | 754.3 | 1500 | 2000 | 30324 | 7324E | 2GB | 137 | 137 | 235 | 250 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 13.7 | |

| 260 | 90.5 | 86 | 69 | 4 | 3 | 824.8 | 1239 | 1300 | 1800 | 32324 | 7624E | 2GD | 138 | 138 | 235 | 250 | 18 | 25 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 21.7 | |

| 120 | 180 | 48 | 48 | 38 | 2.5 | 2 | 283 | 514 | 1700 | 2400 | 33024 | 130 | 131 | 161 | 173 | 7 | 12 | 2 | 2 | 0.31 | 1.9 | 1 | 4.09 | ||

| 130 | 200 | 45 | 45 | 34 | 2.5 | 2 | 309 | 513 | 1600 | 2200 | 32026 | 3EB | 140 | 144 | 178 | 192 | 8 | 11 | 2 | 2 | 0.43 | 1.3 | 0.7 | 4.9 | |

| 230 | 43.75 | 40 | 34 | 4 | 3 | 364.3 | 525.6 | 1500 | 2000 | 30226 | 7226E | 4FB | 142 | 142 | 208 | 222 | 7 | 12 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 7.24 | |

| 230 | 44.5 | 40 | 34 | 4 | 3 | 351 | 466 | 1500 | 2000 | 30226X2 | 7226 | 4FB | 142 | 142 | 208 | 222 | 7 | 12 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 7.25 | |

| 230 | 67.75 | 64 | 54 | 4 | 3 | 561 | 855 | 1500 | 2000 | 32226 | 7526E | 4FD | 142 | 142 | 208 | 222 | 10 | 16 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 11.37 | |

| 280 | 63.75 | 58 | 49 | 5 | 4 | 639.3 | 864.5 | 1300 | 1800 | 30326 | 7326E | 2GB | 148 | 148 | 250 | 267 | 14 | 18 | 4 | 3 | 0.35 | 1.7 | 0.9 | 17.1 | |

| 140 | 190 | 32 | 32 | 25 | 2 | 1.5 | 207 | 390 | 1600 | 2200 | 32928/YB | 146 | 146 | 177 | 187 | 4 | 8 | 2 | 1.5 | 0.36 | 1.7 | 0.9 | 2.49 | ||

| 210 | 45 | 45 | 34 | 2.5 | 2 | 314 | 533 | 1600 | 2200 | 32028 | 3EB | 150 | 153 | 187 | 202 | 8 | 11 | 2 | 2 | 0.46 | 1.3 | 0.7 | 5.14 | ||

| 210 | 45.5 | 42 | 36 | 2.5 | 2 | 285 | 460 | 1600 | 2200 | 32028X2 | 2007128 | 150 | 153 | 187 | 202 | 8 | 11 | 2 | 2 | 0.37 | 1.6 | 0.9 | 5.1 | ||

| 210 | 45.5 | 42 | 36 | 2.5 | 2 | 259 | 460 | 1600 | 2200 | 32028X2LYA | 2007128L | 150 | 153 | 187 | 202 | 8 | 11 | 2 | 2 | 0.37 | 1.6 | 0.9 | 5.72 | ||

| 250 | 45.75 | 42 | 36 | 4 | 3 | 407.3 | 589.4 | 1400 | 1900 | 30228 | 7228E | 4FB | 153 | 153 | 226 | 241 | 7 | 12 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 8.892 | |

| 250 | 71.75 | 68 | 58 | 4 | 3 | 657 | 1020 | 1400 | 1900 | 32228 | 7528E | 4FD | 153 | 153 | 226 | 241 | 10 | 16 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 14.68 | |

| 300 | 67.75 | 62 | 53 | 5 | 4 | 721.8 | 985.5 | 1200 | 1700 | 30328 | 7328E | 2GB | 159 | 159 | 270 | 288 | 14 | 18 | 4 | 3 | 0.35 | 1.7 | 0.9 | 21.7 | |

| 150 | 225 | 48 | 48 | 36 | 3 | 2.5 | 361 | 621 | 1500 | 2000 | 32030 | 3EB | 164 | 162 | 200 | 216 | 8 | 12 | 2.5 | 2.5 | 0.46 | 1.3 | 0.7 | 6.38 | |

| 225 | 48 | 48 | 36 | 8 | 2.5 | 365 | 630 | 1500 | 2000 | 32030/YB | 164 | 174 | 200 | 216 | 8 | 12 | 7 | 2.5 | 0.46 | 1.3 | 0.7 | 6.29 | |||

| 270 | 49 | 45 | 38 | 4 | 3 | 495 | 687 | 1300 | 1800 | 30230 | 7230E | 4GB | 164 | 164 | 248 | 260 | 8 | 14 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 10.3 | |

| 270 | 77 | 73 | 60 | 4 | 3 | 718 | 1191 | 1200 | 1700 | 32230 | 7530E | 4GD | 164 | 164 | 248 | 260 | 14 | 20 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 18.2 | |

| 320 | 115 | 108 | 90 | 5 | 4 | 1010 | 1580 | 950 | 1400 | 32330 | 7630 | 172 | 172 | 287 | 305 | 20 | 30 | 4 | 3 | 0.31 | 1.9 | 1.1 | 37.1 | ||

| d 160~220mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 160 | 240 | 51 | 51 | 38 | 3 | 2.5 | 346 | 346 | 1300 | 1800 | 32032/YA4 | 2007132K | 4GD | 172 | 175 | 213 | 231 | 8 | 13 | 2.5 | 2.5 | 0.37 | 1.6 | 0.9 | 7.16 |

| 240 | 51.5 | 48 | 41 | 3 | 2.5 | 380 | 634 | 1300 | 1800 | 32032X2 | 172 | 175 | 213 | 231 | 8 | 13 | 2 | 2 | 0.46 | 1.3 | 0.7 | 7.41 | |||

| 290 | 52 | 48 | 40 | 4 | 3 | 556 | 774 | 1100 | 1600 | 30232 | 7232E | 4GB | 175 | 175 | 265 | 279 | 8 | 14 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 12.9 | |

| 290 | 84 | 80 | 67 | 4 | 3 | 852.6 | 1446 | 1000 | 1400 | 32232 | 7532E | 4GD | 175 | 175 | 265 | 279 | 14 | 20 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 21.1 | |

| 170 | 260 | 57 | 57 | 43 | 3 | 2.5 | 473 | 815 | 1200 | 1700 | 32034 | 3EB | 182 | 187 | 230 | 249 | 10 | 14 | 2.5 | 2.5 | 0.44 | 1.4 | 0.8 | 10.2 | |

| 360 | 127 | 120 | 100 | 5 | 4 | 1280 | 2080 | 850 | 1100 | 32334 | 7634 | 192 | 192 | 326 | 344 | 20 | 30 | 4 | 3 | 0.36 | 1.7 | 0.9 | 58.3 | ||

| 180 | 280 | 64 | 64 | 48 | 3 | 2.5 | 611 | 1070 | 1100 | 1600 | 32036 | 2007136 | 192 | 199 | 247 | 268 | 10 | 16 | 2.5 | 2.5 | 0.28 | 2.1 | 1.2 | 14 | |

| 280 | 64.5 | 60 | 52 | 3 | 2.5 | 550 | 928 | 1100 | 1600 | 32036X2 | 4GD | 192 | 199 | 247 | 267 | 10 | 16 | 2.5 | 2.5 | 0.28 | 2.1 | 1.2 | 13.5 | ||

| 320 | 91 | 86 | 71 | 5 | 4 | 998.1 | 1727 | 950 | 1400 | 32236 | 7536E | 4GD | 196 | 196 | 292 | 308 | 18 | 25 | 4 | 3 | 0.45 | 1.3 | 0.7 | 29.8 | |

| 190 | 260 | 45 | 45 | 34 | 2.5 | 2 | 335 | 699 | 1100 | 1600 | 32938 | 202 | 202 | 231 | 248 | 8 | 11 | 2 | 2 | 0.48 | 1.25 | 0.7 | 6.76 | ||

| 290 | 64 | 64 | 48 | 3 | 2.5 | 605 | 1070 | 1000 | 1500 | 32038 | 202 | 202 | 268 | 282 | 8 | 0.29 | 1.1 | 14.1 | |||||||

| 290 | 64.5 | 60 | 52 | 3 | 2.5 | 511 | 970 | 1000 | 1500 | 32038X2/YA | 2007138 | 14 | 2.5 | 2.1 | 2.1 | ||||||||||

| 290 | 64.5 | 60 | 52 | 3 | 2.5 | 511 | 970 | 1000 | 1500 | 32038X2/HNYA | 2007138N | 202 | 209 | 257 | 279 | 10 | 16 | 2.5 | 2.5 | 0.29 | 2.1 | 1.1 | 14.1 | ||

| 290 | 64.5 | 60 | 52 | 3 | 2.5 | 511 | 970 | 1000 | 1500 | 32038X2NYA | 2007138N | 202 | 209 | 257 | 279 | 10 | 16 | 2.5 | 2.5 | 0.29 | 2.1 | 1.1 | 14.1 | ||

| 340 | 97 | 92 | 75 | 5 | 4 | 1117 | 1920 | 900 | 1300 | 32238 | 7538E | 4GD | 208 | 208 | 309 | 328 | 18 | 25 | 4 | 3 | 0.44 | 1.4 | 0.8 | 36.1 | |

| 200 | 300 | 55 | 51 | 45 | 5 | 4 | 519 | 909 | LY-3023 | 13.8 | |||||||||||||||

| 310 | 70 | 70 | 53 | 3 | 2.5 | 703 | 1240 | 950 | 1400 | 32040 | 222 | 212 | 273 | 297 | 11 | 17 | 2.5 | 2 | 0.43 | 1.4 | 0.8 | 18.6 | |||

| 310 | 70.5 | 70 | 53.5 | 3 | 2.5 | 950 | 1400 | 950 | 1400 | 32040X2 | 222 | 212 | 273 | 297 | 11 | 17 | 2.5 | 2 | 0.43 | 1.4 | 0.8 | 18.7 | |||

| 360 | 104 | 98 | 82 | 5 | 4 | 1309 | 2204 | 900 | 1300 | 32240 | 7540E | 3GD | 231 | 218 | 302 | 340 | 11 | 22 | 4 | 3 | 0.41 | 1.5 | 0.8 | 43.2 | |

| 205 | 485 | 117.5 | 95.2 | 73 | 4 | 4 | 1418 | 1750 | 770 | 960 | 30641 | 7841 | 247 | 279 | 410 | 454 | 20 | 30 | 3 | 3 | 0.87 | 0.7 | 0.4 | 90.8 | |

| 220 | 340 | 76.5 | 72 | 62 | 4 | 3 | 726 | 1380 | 900 | 1300 | 32044X2 | 2007144 | 234 | 234 | 314 | 331 | 10 | 16 | 3 | 2.5 | 0.35 | 1.7 | 0.9 | 22.2 | |

| 400 | 73 | 65 | 54 | 4 | 770 | 1160 | 850 | 1200 | 31244X2 | 35.4 | |||||||||||||||

| 400 | 73 | 65 | 54 | 4 | 3 | 941 | 1330 | 850 | 1200 | 30244X2 | 7244 | 244 | 244 | 367 | 385 | 14 | 20 | 3 | 2.5 | 0.37 | 1.6 | 0.9 | 35.4 | ||

| d 220~300mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 220 | 400 | 115 | 108 | 90 | 4 | 3 | 1530 | 2565 | 800 | 1100 | 32244 | 7544 | 244 | 244 | 367 | 385 | 20 | 30 | 3 | 2.5 | 0.39 | 1.5 | 0.8 | 48.1 | |

| 400 | 115 | 108 | 90 | 4 | 3 | 1230 | 2280 | 800 | 1100 | 32244X2 | 238 | 238 | 381 | 382 | 12 | 24 | 3 | 3 | 0.39 | 1.5 | 0.8 | 48.1 | |||

| 460 | 154 | 145 | 122 | 5 | 5 | 2130 | 3390 | 750 | 1000 | 32344 | 260 | 260 | 408 | 430 | 20 | 35 | 4 | 4 | 0.37 | 1.6 | 0.9 | 40.6 | |||

| 240 | 320 | 51.5 | 48 | 41 | 3 | 2.5 | 407 | 804 | 900 | 1300 | 32948/YB2 | 10.7 | |||||||||||||

| 320 | 52.5 | 52.5 | 39 | 3 | 2.5 | 473 | 975 | 900 | 1300 | 32948X2 | 10.9 | ||||||||||||||

| 360 | 76 | 76 | 57 | 4 | 3 | 709 | 1560 | 850 | 1200 | 32048 | 254 | 261 | 318 | 346 | 12 | 19 | 3 | 3 | 0.36 | 25.8 | |||||

| 440 | 127 | 120 | 100 | 4 | 4 | 1843 | 3183 | 750 | 1000 | 32248 | 7548E | 262 | 262 | 393 | 425 | 20 | 30 | 3 | 3 | 0.44 | 1.4 | 0.8 | 81.3 | ||

| 500 | 165 | 155 | 132 | 5 | 5 | 2660 | 4290 | 670 | 900 | 32348 | 272 | 272 | 440 | 470 | 20 | 35 | 4 | 4 | 0.37 | 1.6 | 0.9 | 148 | |||

| 241 | 360 | 76 | 76 | 57 | 4 | 3 | 709 | 1560 | 850 | 1200 | 32048/YA2 | 254 | 261 | 318 | 346 | 12 | 19 | 3 | 3 | 0.36 | 25.6 | ||||

| 255 | 560 | 123.8 | 104.8 | 70 | 6 | 6 | 1816 | 2380 | 620 | 770 | 30651 | 7851 | 300 | 338 | 480 | 523 | 30 | 40 | 5 | 5 | 0.87 | 0.7 | 0.4 | 129 | |

| 260 | 360 | 64.5 | 60 | 52 | 3 | 2.5 | 654 | 1290 | 800 | 1100 | 32952X2 | 18.6 | |||||||||||||

| 400 | 87 | 87 | 65 | 5 | 4 | 1110 | 2120 | 700 | 950 | 32052 | 277 | 277 | 370 | 384 | 10 | 16 | 4 | 3 | 0.43 | 1.4 | 0.8 | 38.3 | |||

| 400 | 87.7 | 82 | 71 | 5 | 4 | 917 | 1849 | 800 | 1100 | 32052X2 | 2007152 | 277 | 277 | 370 | 386 | 12 | 18 | 4 | 3 | 0.3 | 2 | 1.1 | 36.9 | ||

| 540 | 114 | 102 | 85 | 6 | 6 | 2014 | 2898 | 670 | 900 | 30352X2 | 7352 | 301 | 301 | 490 | 506 | 20 | 30 | 5 | 5 | 0.23 | 2.6 | 1.4 | 111 | ||

| 280 | 350 | 36 | 33 | 26 | 2 | 2 | 259 | 614 | 870 | 1100 | 30656 | 1007856 | 295 | 295 | 336 | 342 | 6 | 9 | 2 | 2 | 0.43 | 1.4 | 0.8 | 6.33 | |

| 380 | 63.5 | 63.5 | 48 | 3 | 2.5 | 601 | 1430 | 800 | 1000 | 32956 | 2007956 4EC | 298 | 298 | 348 | 368 | 11 | 16 | 2.5 | 2.1 | 0.43 | 1.4 | 0.8 | 19.8 | ||

| 380 | 64.5 | 60 | 52 | 3 | 2.5 | 601 | 1430 | 800 | 1000 | 32956/YB2 | 2007956K | 300 | 325 | 348 | 368 | 11 | 16 | 2.5 | 2.1 | 0.29 | 2.1 | 1.1 | 19.8 | ||

| 300 | 420 | 76.5 | 72 | 60.5 | 4 | 3 | 998 | 2128 | 700 | 950 | 32960/YB2 | 2007960 | 317 | 317 | 394 | 408 | 10 | 16 | 3 | 2.5 | 0.28 | 2.1 | 1.2 | 28.7 | |

| 460 | 100 | 100 | 74 | 5 | 4 | 1470 | 2840 | 560 | 700 | 32060 | 320 | 320 | 425 | 445 | 20 | 30 | 4 | 3 | 0.43 | 1.4 | 0.8 | 57.2 | |||

| 460 | 100.7 | 95 | 82 | 5 | 4 | 803 | 1722 | 560 | 700 | 32060/YB2 | 2007160 | 320 | 320 | 425 | 445 | 14 | 20 | 4 | 3 | 0.31 | 1.9 | 1.1 | 55.9 | ||

| 440 | 73 | 70 | 55 | 4 | 3 | 959 | 2062 | 570 | 600 | 30660 | 7860 | 318 | 318 | 406 | 426 | 14 | 20 | 3 | 2.5 | 0.44 | 1.4 | 0.8 | 30.7 | ||

| 500 | 95 | 90 | 70 | 4 | 4 | 1225 | 2207 | 530 | 670 | 31160X2 | 1007760 | 327 | 327 | 460 | 480 | 20 | 30 | 3 | 3 | 0.32 | 1.9 | 1 | 67.7 | ||

| 540 | 149 | 140 | 115 | 6 | 5 | 2740 | 4780 | 530 | 670 | 32260/HC YA | 330 | 330 | 485 | 515 | 20 | 35 | 5 | 4 | 0.43 | 1.4 | 0.8 | 143 | |||

| d 304.8~460mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 304.8 | 546.1 | 171.1 | 171.1 | 140.1 | 8 | 8 | 2660 | 3020 | 530 | 670 | 306/304.8/HC | 316 | 316 | 534 | 8 | 8 | 0.34 | 175 | |||||||

| 320 | 440 | 76.5 | 72 | 62 | 4 | 3 | 607 | 1375 | 650 | 870 | 32964 | 2007964 | 335 | 335 | 412 | 427 | 10 | 16 | 3 | 2.5 | 0.3 | 2 | 1.1 | 44.7 | |

| 480 | 100.7 | 95 | 82 | 5 | 4 | 1463 | 2945 | 630 | 850 | 32064/YB2 | 2007164 | 340 | 340 | 440 | 468 | 14 | 20 | 4 | 3 | 0.42 | 1.4 | 0.8 | 59 | ||

| 330.2 | 482.64 | 87 | 75 | 68 | 3 | 3 | 863 | 1526 | 530 | 670 | 306/330.2 | 7766 | 351 | 351 | 449 | 462 | 20 | 30 | 2.5 | 2.5 | 0.31 | 1.9 | 1.1 | 37.2 | |

| 340 | 460 | 76.5 | 72 | 62 | 4 | 3 | 611 | 1428 | 530 | 670 | 32968/YB2 | 2007968 | 356 | 356 | 432 | 448 | 10 | 16 | 3 | 2.5 | 0.31 | 1.9 | 1.1 | 34.3 | |

| 520 | 86 | 82 | 64 | 4 | 3 | 807 | 1540 | 500 | 630 | 32068X2 | 7168 | 360 | 360 | 486 | 501 | 18 | 25 | 3 | 3 | 0.29 | 2.1 | 1.1 | 57 | ||

| 520 | 100 | 95 | 75 | 5 | 5 | 1510 | 2940 | 30668 | 73.4 | ||||||||||||||||

| 360 | 480 | 76.5 | 72 | 62 | 4 | 3 | 634 | 1526 | 500 | 630 | 32972/YB2 | 2007972 | 376 | 376 | 452 | 468 | 10 | 16 | 3 | 2.5 | 0.33 | 1.8 | 1 | 35.9 | |

| 540 | 86 | 82 | 64 | 4 | 4 | 919 | 1848 | 480 | 600 | 31072X2 | 7172 | 380 | 380 | 504 | 522 | 18 | 25 | 3 | 3 | 0.3 | 2 | 1.1 | 60.5 | ||

| 380 | 520 | 66.5 | 65 | 46.5 | 3 | 3 | 529 | 1138 | 480 | 600 | 31976X2 | 1007976 | 402 | 402 | 486 | 505 | 15 | 20 | 2.5 | 2.5 | 0.42 | 1.4 | 0.8 | 37.5 | |

| 620 | 112 | 106 | 76 | 4 | 4 | 909 | 1708 | 400 | 500 | 31176X2 | 1007776 | 420 | 420 | 534 | 560 | 10 | 40 | 3 | 3 | 0.46 | 1.3 | 0.7 | 114 | ||

| 400 | 540 | 70 | 65 | 48 | 5 | 4 | 811 | 1658 | 980 | 1220 | 31980 | 422 | 422 | 499 | 518 | 16 | 16 | 4 | 4 | 0.44 | 1.3 | 0.7 | 40.6 | ||

| 600 | 95 | 90 | 67 | 4 | 4 | 1040 | 2128 | 400 | 500 | 31080X2 | 7180 | 420 | 420 | 560 | 580 | 20 | 30 | 3 | 3 | 0.39 | 1.5 | 0.8 | 84 | ||

| 420 | 560 | 70 | 65 | 51 | 3 | 3 | 630 | 1383 | 400 | 500 | 31984X2 | 1007984 | 440 | 440 | 532 | 546 | 15 | 20 | 2.5 | 2.5 | 0.3 | 1.9 | 1.1 | 42.4 | |

| 620 | 95 | 90 | 70 | 4 | 4 | 1132 | 2422 | 380 | 480 | 31084X2 | 7184 | 448 | 448 | 579 | 601 | 20 | 30 | 3 | 3 | 0.4 | 1.5 | 0.8 | 88 | ||

| 700 | 130 | 122 | 92 | 6 | 6 | 1620 | 2800 | 310 | 420 | 31184X2 | 107784 | 490 | 490 | 606 | 646 | 15 | 40 | 5 | 5 | 0.32 | 19 | 1 | 183 | ||

| 440 | 620 | 95 | 90 | 67 | 2.3 | 5 | 1440 | 2930 | 340 | 650 | 32988 XI/P5 | 465 | 465 | 585 | 592 | 20 | 30 | 2 | 4 | 0.41 | 1.5 | 0.8 | 79.4 | ||

| 650 | 96.4 | 94 | 67 | 6 | 4 | 1193 | 2422 | 360 | 450 | 31088X2 | 7188 | 469 | 469 | 606 | 629 | 20 | 30 | 5 | 3 | 0.43 | 1.4 | 0.8 | 99 | ||

| 460 | 620 | 80 | 74 | 58 | 3 | 3 | 836 | 1843 | 380 | 480 | 31992X2 | 1007992 | 480 | 480 | 590 | 605 | 18 | 25 | 2.5 | 2.5 | 0.4 | 1.5 | 0.8 | 59.8 | |

| 660 | 115 | 110 | 90 | 5 | 4 | 1960 | 4650 | 32996X3 | |||||||||||||||||

| d 460~1800mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | IS0355 Series Designation |

damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 460 | 680 | 105 | 100 | 78 | 6 | 6 | 1680 | 3550 | 330 | 450 | 31092X2 | 7192 | 516 | 516 | 610 | 640 | 8 | 34 | 5 | 5 | 0.3 | 1.9 | 1.1 | 118 | |

| 480 | 650 | 84.2 | 78 | 60 | 4 | 4 | 854 | 1918 | 340 | 430 | 31996X2 | 1007996 | 502 | 502 | 613 | 633 | 18 | 25 | 3 | 3 | 0.42 | 1.4 | 0.8 | 71 | |

| 500 | 720 | 110 | 100 | 82 | 6 | 6 | 1459 | 3192 | 280 | 360 | 310/500X2 | 71/500 | 530 | 530 | 674 | 700 | 20 | 30 | 5 | 5 | 0.33 | 1.8 | 1 | 135 | |

| 530 | 670 | 100.5 | 95 | 82 | 5 | 3 | 1850 | 4800 | 329/530X2 | 552 | 552 | 637 | 658 | 20 | 30 | 4 | 3 | 0.38 | 81.3 | ||||||

| 710 | 88 | 82 | 62 | 4 | 4 | 1001 | 2380 | 280 | 360 | 319/530X2 | 10079/530 | 554 | 554 | 672 | 693 | 20 | 30 | 3 | 3 | 0.41 | 1.5 | 0.8 | 94.8 | ||

| 560 | 750 | 92.5 | 85 | 64 | 4 | 4 | 1001 | 2576 | 240 | 320 | 319/560X2 | 10079/560 | 586 | 586 | 708 | 731 | 20 | 30 | 3 | 3 | 0.44 | 1.4 | 0.8 | 104 | |

| 820 | 121 | 115 | 84 | 6 | 6 | 1887 | 4046 | 220 | 300 | 310/560X2 | 71/560 | 594 | 594 | 768 | 795 | 30 | 40 | 5 | 5 | 0.39 | 1.5 | 0.8 | 191 | ||

| 600 | 870 | 124 | 118 | 89 | 6 | 6 | 2020 | 4438 | 180 | 240 | 310/600X2 | 71/600 | 630 | 630 | 821 | 845 | 30 | 40 | 5 | 5 | 0.41 | 1.5 | 1.6 | 235 | |

| 630 | 920 | 135 | 128 | 94 | 7.5 | 7.5 | 2315 | 5222 | 170 | 220 | 310/630X2 | 71/630 | 669 | 669 | 858 | 891 | 30 | 40 | 6 | 6 | 0.42 | 1.4 | 0.8 | 278 | |

| 710 | 950 | 114 | 106 | 80 | 6 | 6 | 1765 | 4494 | 150 | 190 | 319710X2 | 10079710 | 743 | 743 | 895 | 925 | 25 | 35 | 5 | 5 | 0.46 | 1.3 | 0.7 | 210.24 | |

| 800 | 990 | 57 | 55 | 45 | 5 | 5 | 907 | 2644 | 150 | 190 | 308800 RYB2P6 | 822 | 822 | 930 | 968 | 25 | 35 | 4 | 4 | 0.39 | 1.5 | 0.8 | 96.3 | ||

| 1060 | 122 | 115 | 89 | 6 | 6 | 2132 | 5530 | 130 | 170 | 319/800 X2 | 10079/800 | 838 | 838 | 1005 | 1031 | 25 | 35 | 5 | 5 | 0.35 | 1.7 | 0.9 | 275 | ||

| 900 | 1180 | 124 | 122 | 87 | 6 | 6 | 2173 | 5782 | 95 | 130 | 319/900X2 | 10079900 | 940 | 940 | 1117 | 1146 | 30 | 40 | 5 | 5 | 0.39 | 1.5 | 0.8 | 330 | |

| 1280 | 190 | 170 | 135 | 7.5 | 7.5 | 5615 | 13913 | 95 | 130 | 320900X2 | 71/900 | 944 | 944 | 1194 | 1246 | 45 | 60 | 6 | 6 | 0.54 | 1.1 | 0.6 | 703 | ||

| 950 1800 |

1250 | 140 | 132 | 100 | 7.5 | 7.5 | 3930 | 10427 | 80 | 100 | 319950X2 | 10079950 | 994 | 994 | 1191 | 1220 | 30 | 40 | 6 | 6 | 0.33 | 1.8 | 1 | 428 | |

| 2300 | 260 | 218 | 180 | 15 | 15 | 10810 | 34000 | 306/1800 | 1824 | 1824 | 2191 | 2276 | 30 | 40 | 15 | 15 | 0.67 | 0.9 | 0.5 | 2339 | |||||

| d 17.462~31.75mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 17.462 | 39.878 | 13.84 | 14.61 | 10.67 | 1.3 | 1.3 | 21.2 | 20.8 | 9000 | 13000 | LMI1749LMI1710 | LM1749LMII710 | 21.5 | 23 | 34 | 37 | 2 | 3 | 1 | 1.3 | 0.29 | 2.1 | 1.15 | 0.083 | |

| 19.05 | 45.237 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 27.5 | 27.5 | 8500 | 12000 | LMI⁹49LMI910 | LM1949LMII910 | 23.5 | 25 | 39.5 | 41.5 | 2 | 4 | 1 | 1.3 | 0.3 | 2 | 1.I | 0.124 | |

| 21.43 | 50.005 | 17.53 | 18.29 | 13.97 | 1.3 | 1.3 | 36.9 | 38 | 8000 | 11000 | M12649M12610 | MI2M649MI2610 | 25.4 | 27.5 | 44 | 46 | 2 | 4 | 1 | 1.3 | 0.28 | 2.16 | 1.19 | 0.169 | |

| 21.986 | 45.237 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 26.9 | 33.6 | 9270 | 11590 | LMI2749LM12710 | 26 | 27.5 | 39.5 | 42 | 3 | 4 | 1 | 1.3 | 0.31 | 2 | 1.1 | 0.115 | ||

| 45.974 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 27.5 | 31 | 8000 | 11000 | LM12749LMI2711 | LMZ749LMI27I1 | 26 | 27.5 | 40 | 42.5 | 3 | 4 | 1 | 1.3 | 0.3 | 2.02 | 1.11 | 0.12 | ||

| 22 | 45.237 | 15.49 | 16.64 | 12.07 | 1.3 | 1.3 | 27.5 | 31 | 8000 | 11000 | LMIZ749LMI12710 | LMLZ749LM12710 | 26 | 28 | 39.5 | 41.5 | 2 | 4 | 1 | 1.3 | 0.3 | 2.02 | 1.11 | 0.115 | |

| 49.225 | 11 | 1 | 16.4 | 18.4 | LR306302 | (内组件) | 0.071 | ||||||||||||||||||

| 25.4 | 50.005 | 13.5 | 14.26 | 9.525 | 1 | 1 | 27 | 29 | 7500 | 10000 | 710007196 | 71000197 | 29.5 | 30.5 | 44.5 | 47 | 3 | 5 | 1 | 1 | 0.4 | 149 | 0.82 | 0.119 | |

| 50.292 | 14.22 | 14.73 | 10.67 | 1.3 | 1.3 | 26 | 30 | 7500 | 10000 | L4643L44610 | 14643L4610 | 29.5 | 31.5 | 44.5 | 47 | 3 | 5 | 1 | 1.3 | 0.37 | 1.6 | 0.88 | 0.127 | ||

| 26.988 | 50.292 | 14.22 | 14.73 | 10.67 | 3.5 | 1.3 | 26 | 32.2 | 7500 | 10000 | L44649L44610 | 14649L4610 | 31 | 37.5 | 44.5 | 47 | 3 | 5 | 3 | 1.3 | 0.37 | 1.6 | 0.88 | 0.12 | |

| 29 | 50.292 | 14.22 | 14.73 | 10.67 | 3.5 | 1.3 | 26 | 33 | 7000 | 9500 | L4549L45410 | 14549L45410 | 33 | 39.5 | 44.5 | 48 | 3 | 5 | 3 | 1.3 | 0.37 | 1.62 | 0.89 | 0.113 | |

| 58 | 17 | 4 | 16.4 | 18.4 | LR3063302YB | (内组件) | 0.248 | ||||||||||||||||||

| 30.162 | 64.292 | 21.43 | 21.43 | 16.67 | 1.5 | 1.5 | 48 | 66.5 | 6750 | 8430 | M86649M86610 | 38.2 | 41 | 54 | 61 | 3 | 5 | 3 | 1.3 | 0.55 | 1.1 | 0.6 | 0.331 | ||

| 31.75 | 59.131 | 15.88 | 16.76 | 11.81 | 3.6 | 1.3 | 34.7 | 43 | 6300 | 7500 | LM67048LM67010 | LM6748LM67H0 | 36 | 42.5 | 52 | 56 | 3 | 5 | 3 | 1.3 | 0.41 | 1.46 | 0.8 | 0.18 | |

| 59.131 | 15.88 | 16.76 | 11.81 | 3.6 | 1.3 | 32.8 | 43 | 10410 | 13010 | LM67048LM67010 | 36 | 42.5 | 52 | 56 | 3.5 | S | 3 | 1.3 | 0.41 | 1.46 | 0.8 | 0.18 | |||

| 62 | 18.16 | 19.05 | 14.29 | 3.5 | 1.3 | 45.8 | 60.1 | 6300 | 8500 | 1512315245 | 36 | 42.5 | 52 | 56 | 3.5 | 5 | 3.5 | 1.3 | 0.35 | 1.71 | 0.94 | 0.244 | |||

| 68.262 | 22.23 | 22.23 | 17.46 | 3.5 | 1.5 | 53.1 | 64.8 | 247502420 | 38.5 | 39 | 59 | 63 | 5.5 | 3 | 3.5 | 1.5 | 0.42 | 1.44 | 0.382 | ||||||

| 69.012 | 19.85 | 19.58 | 15.88 | 3.5 | 1.3 | 51.2 | 65.4 | 9060 | 11320 | 14125A/14276 | 37.5 | 44 | 60 | 63 | 3 | 5 | 3.5 | 1.3 | 0.38 | 1.57 | 0.86 | 0.353 | |||

| d 34.925~50.8mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | |||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 34.925 | 65.088 | 18.03 | 18.29 | 13.97 | 3.6 | 1.3 | 47.3 | 58.2 | 5600 | 7500 | LM48548LM4510 | LM48548LM48510 | 40 | 46 | 58 | 61 | 3 | 5 | 3 | 1.3 | 0.38 | 1.59 | 0.88 | 0.252 | |

| 80.167 | 29.37 | 30.39 | 23.81 | 3.5 | 3.2 | 91.9 | 106 | 5000 | 6700 | 35793320 | 3793320 | 41.5 | 48 | 70 | 74.8 | 3 | 5 | 3 | 2.5 | 0.27 | 2.19 | 1.21 | 0.742 | ||

| 34.987 | 59.131 | 15.88 | 16.76 | 11.94 | 3.6 | 1.3 | 32.2 | 47.3 | L68149L68110 | 39 | 45.5 | 52 | 56 | 3 | 4 | 3 | 1.3 | 0.42 | 1.44 | 0.79 | 0.169 | ||||

| 59.975 | 15.88 | 16.76 | 11.94 | 3.6 | 1.3 | 32.2 | 47.3 | 6710 | 8390 | L68149L68I1 | 39 | 45.5 | 53 | 56 | 3 | 4 | 3 | 1.3 | 0.42 | 1.44 | 0.79 | 0.177 | |||

| 37.987 | 62.975 | 17 | 17 | 13.5 | 3.6 | 1.3 | 40 | 55 | 5600 | 7500 | JL69349JL69310 | JL693416310 | 41 | 47 | 56 | 60 | 4 | 6 | 3 | 1.3 | 0.42 | 1.44 | 0.79 | 0.186 | |

| 38.1 | 76.2 | 23.81 | 25.65 | 19.05 | 3.5 | 3.2 | 74.8 | 93 | 5000 | 6700 | 2788R2720 | 278R2720 | 43 | 50 | 65 | 72 | 4 | 6 | 3 | 2.5 | 0.3 | 2.03 | 1.12 | 0.501 | |

| 39.688 | 73.025 | 25.65 | 22.1 | 21.34 | 0.8 | 2.3 | 66 | 86.5 | 5000 | 6700 | M201047M291011 | M201047M2DH011 | 44 | 51 | 66 | 70 | 4 | 6 | 0.8 | 2.1 | 0.32 | 1.85 | 1.02 | 0.432 | |

| 41.275 | 73.431 | 19.56 | 19.81 | 14.73 | 3.5 | 0.8 | 55 | 73.9 | 4800 | 6300 | LM501349LMS901310 | LM601349LMS0138 | 46.5 | 53 | 67 | 70 | 3.5 | 6 | 3.5 | 0.8 | 0.4 | 1.5 | 0.8 | 0.336 | |

| 82.55 | 26.54 | 25.65 | 20.19 | 3.5 | 3.3 | 76.3 | 105 | MS02048M82011F | 51 | 57 | 70 | 79 | 3 | 6 | 3.5 | 3.3 | 0.55 | 1.1 | 0.617 | ||||||

| 88.9 | 30.16 | 29.37 | 23.02 | 3.5 | 3.3 | 95.2 | 127 | 4300 | 5600 | FHDMS13146FH8B19 | FHM906146FH895LI0 | 53 | 53.5 | 70 | 84 | 4 | 7 | 3 | 2.5 | 0.54 | 1.1 | 0.6 | 0.882 | ||

| 44.45 | 82.931 | 23.81 | 25.4 | 19.05 | 3.5 | 0.8 | 80.9 | 106 | 4500 | 6000 | 25882550 | 258025) | 50 | 56 | 72 | 78 | 4 | 6 | 3 | 0.8 | 0.32 | 1.85 | 1.02 | 0.57 | |

| 45.23 | 79.985 | 19.84 | 20.64 | 15.08 | 2 | 1.3 | 55.1 | 70.8 | 4800 | 6300 | 1788717831 | 178717831 | 50 | 56 | 72 | 78 | 4 | 6 | 2 | 1.3 | 0.37 | 1.64 | 0.9 | 0.402 | |

| 45.242 | 73.431 | 19.56 | 19.81 | 15.75 | 3.5 | 0.8 | 53.9 | 69.5 | 4800 | 6300 | LM02949LMI02910 | LMI299LM102910 | 50 | 57 | 68 | 70 | 3 | 5 | 3 | 0.8 | 0.31 | 1.97 | 1.08 | 0.3 | |

| 77.788 | 21.43 | 19.84 | 16.67 | 3.5 | 0.8 | 52.2 | 73.7 | 8110 | 10140 | LM1603049LM6L3012 | 50 | 57 | 70 | 74 | 3.5 | 5 | 3.5 | 0.8 | 0.43 | 141 | 0.77 | 0.385 | |||

| 45.618 | 82.931 | 23.81 | 25.4 | 19.05 | 3.5 | 0.8 | 80.9 | 106 | 4500 | 6000 | 2559025520 | 259025530 | 50 | 56 | 72 | 78 | 4 | 6 | 3 | 8 | 0.33 | 1.8 | 1 | 0.554 | |

| 82.931 | 26.99 | 25.4 | 22.23 | 3.5 | 2.3 | 80.9 | 106 | 4500 | 6000 | 2559025523 | 25902524 | 50 | 56 | 72 | 78 | 4 | 6 | 3 | 2.1 | 0.33 | 1.8 | 1 | 0.603 | ||

| 50 | 82 | 21.5 | 21.5 | 17 | 3 | 0.6 | 66.9 | 94.1 | 4840 | 6060 | JLM10948JLM109 | 0 | 55 | 60 | 76 | 78 | 4 | 6 | 3 | 0.6 | 0.31 | 1.97 | 1.08 | 0.429 | |

| 50.8 | 82.55 | 21.59 | 22.23 | 16.51 | 3.5 | 1.3 | 60.8 | 94.1 | 4790 | 5990 | LM104949LM10491 | 55 | 62 | 75 | 78 | 4 | 6 | 3.5 | 1.3 | 0.31 | 1.97 | 1.08 | 0.426 | ||

| d 52.388~89.975mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 52.388 | 92.075 | 24.61 | 25.4 | 19.85 | 3.5 | 0.8 | 82 | 108 | 4000 | 5300 | 2858428521 | 28842821 | 59 | 69 | 83 | 87 | 4 | 7 | 0.8 | 38 | 159 | 0.87 | 0.695 | ||

| 54.488 | 104.78 | 36.51 | 36.51 | 28.58 | 2 | 3.3 | 139 | 192 | HM8/748HMS0010 | 63 | 73 | 89 | 100 | 4 | 7 | 2 | 3.3 | 49 | 1.23 | 1.38 | |||||

| 54.5 | 104.78 | 36.51 | 36.51 | 28.58 | 2 | 3.3 | 139 | 192 | LY-3035 | 1.38 | |||||||||||||||

| 55 | 90 | 23 | 26 | 18.5 | 3.5 | 0.5 | 84 | 110 | 3800 | 5000 | IMSAEJLAE9M89 | ANS0648ELMS5W680 | 61 | 69 | 78 | 87 | 7 | 8 | 3 | 0.5 | 4 | 149 | 0.82 | 0.586 | |

| 55.562 | 97.63 | 24.61 | 24.61 | 19.45 | 3.5 | 0.8 | 80.9 | 71 | 4160 | 5200 | 2868028622 | 62 | 68 | 88 | 92 | 4 | 5 | 3.5 | 0.8 | 4 | 149 | 0.82 | 0.754 | ||

| 60.325 | 101.6 | 25.4 | 25.4 | 1985 | 5 | 3.3 | 85.8 | 125 | 3600 | 4800 | 289852893 | 29K52901 | 68 | 80 | 88 | 97 | 5 | 9 | 3 | 2.5 | 43 | 14 | 0.78 | 0.798 | |

| 63.5 | 107.95 | 25.4 | 25.4 | 19.05 | 1.5 | 3.3 | 83.5 | 76.4 | 295862950 | 915 | |||||||||||||||

| 12224 | 38.1 | 38.35 | 29.72 | 7 | 1.5 | 172 | 245 | 3400 | 4300 | FN212047HM212010 | HBCID4THNZ1200 | 73 | 80 | 110 | 116 | A | 6 | 6 | 1.5 | 0.34 | 178 | 0.98 | 1.94 | ||

| 122.24 | 38.1 | 38.35 | 29.72 | 1 | 3.3 | 172 | 245 | 3400 | 4300 | HNI212N47HM21201 | HMCI3N4THM213I1 | 73 | 80 | 110 | 116 | 4 | 6 | 6 | 2.5 | 0.34 | 178 | 0.98 | 1.93 | ||

| 66.675 | 107.95 | 25.4 | 25.4 | 19.05 | 3.5 | 0.8 | 85.8 | 125 | 3600 | 4800 | 295029522 | H29902622 | 75 | 87 | 94 | 103 | 4 | 10 | 3 | 0.8 | 0.46 | 13 | 0.72 | 0.854 | |

| 122.24 | 38.1 | 38.35 | 29.72 | 3.5 | 1.5 | 159 | 146 | 3400 | 4200 | HN212049HN212010 | HBCI3M49HM212010 | 75.5 | 82 | 110 | 116 | 4 | 6 | 3 | 1.5 | 0.34 | 178 | 0.98 | 1.85 | ||

| 122.24 | 38.1 | 38.35 | 29.72 | 3.5 | 3.3 | 159 | 146 | 3400 | 4200 | HNI212049HM21201 | HMCI12049EDNL12011 | 75.5 | 82 | 110 | 116 | 4 | 5 | 3 | 3 | 0.34 | 178 | 0.98 | 1.85 | ||

| 68.262 | 161.93 | 49.21 | 46.04 | 31.75 | 3.5 | 3.3 | 256 | 304 | 2690 | 3360 | 9278922 | 904 | 97 | 138 | 153 | 4.5 | 12 | 3.5 | 3 | 71 | 85 | 0.46 | 4.46 | ||

| 69.85 | 146.05 | 41.28 | 39.69 | 25.4 | 3.6 | 3.4 | 192 | 239 | 2880 | 3610 | H9189H9L810 | 82 | 95 | 124 | 138 | 5.5 | 11 | 3.5 | 3 | 78 | 77 | 0.42 | 2.92 | ||

| 84.976 | 125.41 | 25.4 | 25.4 | 19.85 | 5 | 1.5 | 110 | 183 | 2970 | 3710 | 276527620 | 91 | 100 | 115 | 120 | 5 | 6 | 5 | 1.5 | 42 | 144 | 0.79 | 1 | ||

| 88.9 | 152.4 | 39.69 | 39.69 | 30.16 | 6 | 3.51 | 229 | 362 | 2550 | 3190 | HD51845HM518410 | 102 | 109 | 135 | 139 | 6 | 10 | 5 | 3.5 | 4 | 149 | 0.82 | 2.9 | ||

| 89.975 | 146.98 | 40 | 40 | 32.5 | 7 | 3.5 | 229 | 355 | 2200 | 3200 | HM218248HM218210 | HB2I8248HMI820 | 95 | 111 | 132 | 140 | 5 | 7 | 6 | 2.5 | 0.33 | 18 | 1 | 2.52 | |

| d 95.25~146.05mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 95.25 | 152.4 | 39.69 | 36.32 | 30.16 | 5 | 3.3 | 185.3 | 289.7 | 2480 | 3100 | 594A/592A | 104 | 113 | 135 | 144 | 4 | 10 | 5 | 3 | 0.44 | 1.36 | 0.75 | 2.55 | ||

| 99.974 | 156.98 | 42 | 42 | 34 | 8 | 3.5 | 243 | 391 | 2380 | 2970 | HM220149/HM220110 | 109 | 123 | 142 | 151 | 5.5 | 9 | 7 | 3.5 | 0.33 | 1.9 | 0.99 | 2.92 | ||

| 99.975 | 212.73 | 66.68 | 66.68 | 53.98 | 3.5 | 3.3 | 556 | 783 | 1900 | 2380 | HH224334/HH224310 | 120 | 124 | 192 | 202 | 7 | 12 | 3 | 3 | 0.33 | 1.84 | 0.99 | 11.3 | ||

| 101.6 | 180.98 | 47.63 | 48.01 | 38.1 | 3.5 | 3.3 | 288 | 436 | 780772 | 113 | 119 | 161 | 168 | 5 | 10 | 3.5 | 3 | 0.39 | 1.56 | 5.02 | |||||

| 104.78 | 180.98 | 47.63 | 48.01 | 38.1 | 7 | 3.3 | 258 | 375 | 2000 | 2600 | 7872 | 116 | 129 | 161 | 168 | 5 | 10 | 7 | 3.3 | 0.39 | 1.56 | 0.86 | 4.66 | ||

| 107.95 | 161.93 | 34.93 | 34.93 | 26.99 | 3.5 | 3.3 | 164 | 280 | 2000 | 2800 | 48190/48120 | 116 | 122 | 146 | 156 | 3.5 | 8 | 3.5 | 3.3 | 0.51 | 1.2 | 0.65 | 2.42 | ||

| 109.54 | 158.75 | 23.02 | 21.44 | 15.88 | 5 | 3.3 | 103 | 167 | 37431A/37625 | 116 | 126 | 143 | 152 | 3.5 | 7 | 5 | 3.3 | 0.61 | 0.99 | 1.31 | |||||

| 114.3 | 152.4 | 21.43 | 21.43 | 16.67 | 1.5 | 1.5 | 89 | 178 | 2000 | 2800 | L623149/L623110 | 120 | 123 | 143 | 147 | 3.5 | 6 | 15 | 1.5 | 0.41 | 1.5 | 0.8 | 1.05 | ||

| 212.73 | 66.68 | 66.68 | 53.98 | 7 | 3.3 | 570 | 810 | 1700 | 2200 | HH224346/HH224310 | 131 | 143 | 192 | 202 | 7 | 12 | 7 | 3.3 | 0.33 | 1.84 | 1 | 10 | |||

| 117.48 | 180.98 | 34.93 | 31.75 | 25.4 | 3.5 | 3.3 | 174 | 254 | 1800 | 2400 | 68462/68712 | 125 | 132 | 163 | 172 | 2 | 8 | 3.5 | 3.3 | 0.5 | 1.21 | 0.66 | 2.78 | ||

| 120 | 174.63 | 35.72 | 36.51 | 27.78 | 3.5 | 1.5 | 212 | 385 | 1900 | 2600 | M224748/M224710 | 129 | 135 | 163 | 168 | 3.5 | 15 | 0.33 | 1.8 | 0.99 | 2.78 | ||||

| 123.83 | 182.56 | 39.69 | 38.1 | 33.34 | 3.5 | 3.3 | 228 | 445 | 1800 | 2400 | 48286/48220 | 133 | 139 | 168 | 176 | 4.5 | 7 | 3.5 | 3.3 | 0.31 | 1.97 | 1.1 | 3.51 | ||

| 130.18 | 203.2 | 46.04 | 46.04 | 38.1 | 3.5 | 3.3 | 315 | 560 | 1700 | 2200 | 67389/67320 | 141 | 146 | 183 | 191 | 3.5 | 3.3 | 0.34 | 1.7 | 0.96 | 5.57 | ||||

| 142.88 | 200.03 | 41.28 | 39.69 | 34.13 | 3.5 | 3.3 | 242 | 500 | 1710 | 2130 | 4868548620 | 151 | 158 | 185 | 193 | 3.5 | 7 | 35 | 3.3 | 0.34 | 1.78 | 0.97 | 3.84 | ||

| 146.05 | 254 | 66.68 | 6668 | 47.63 | 7 | 3.3 | 530 | 867 | 99575199100 | 162 | 175 | 227 | 238 | 8 | 135 | 7 | 3.3 | 0.41 | 1.47 | 13.2 | |||||

| d 152.4~762mm | |||||||||||||||||||||||||

| Overall Dimensions | Rated Load | Limiting Rotational Speed | Bearing Designation | Mounting Dimensions | Calculation Coefficient | Weight | |||||||||||||||||||

| d | D | T | B | C | r1,2min | r3,4min | Dynamic Load C |

Static Load C₀ |

Grease | Oil | Current Model | Original Model | damax | dbmax | Damin | Dbmin | a1 | a2 | ramax | rbmax | e | Y | Y。 | ||

| mm | kN | r/min | mm | kg | |||||||||||||||||||||

| 152.4 | 254 | 66.68 | 66.68 | 47.63 | 7 | 3.3 | 515 | 830 | 1300 | 1800 | 9960099100 | 9960091600 | 170 | 181 | 227 | 238 | 8 | 13.5 | 7 | 3.3 | 0.41 | 1.47 | 0.81 | 12.29 | |

| 165.1 | 247.65 | 47.63 | 47.63 | 38.1 | 3.5 | 3.3 | 345 | 705 | 1300 | 1700 | 67786720 | 179 | 185 | 229 | 240 | 5 | 8 | 3.5 | 3.3 | 0.44 | 1.36 | 0.75 | 8.16 | ||

| 174.63 | 24765 | 47.63 | 47.63 | 38.1 | 3.5 | 3.3 | 345 | 705 | 1300 | 1700 | 6778767720 | 185 | 192 | 229 | 240 | 5 | 8 | 3.5 | 3.3 | 0.44 | 1.4 | 0.75 | 7.21 | ||

| 180 | 250 | 47 | 45 | 37 | 3 | 2.5 | 338 | 682 | 1300 | 1630 | JM736149JM736110 | 190 | 196 | 232 | 243 | 5.5 | 10 | 3 | 2.5 | 0.48 | 1.25 | 0.69 | 6.72 | ||

| 190 | 260 | 46 | 44 | 36.5 | 3 | 2.5 | 370 | 730 | 1100 | 1600 | JM738249JM738210 | 200 | 206 | 242 | 252 | 5.5 | 9.5 | 3 | 2.5 | 0.48 | 1.3 | 0.69 | 6.93 | ||

| 206.38 | 282.58 | 46.04 | 46.04 | 36.51 | 3.5 | 3.3 | 365 | 800 | 100 | 1400 | 6798567920 | 219 | 224 | 260 | 275 | 5 | 8 | 3.5 | 3.3 | 0.51 | 1.2 | 65 | 8.48 | ||

| 254 | 358.78 | 71.44 | 71.44 | 53.98 | 3.5 | 3.3 | 694 | 1550 | 830 | 1040 | M249749M249710 | 270 | 274 | 335 | 343 | 75 | 135 | 35 | 3.3 | 0.33 | 1.8 | 1 | 21.7 | ||

| 304.8 | 444.5 | 63.5 | 61.91 | 39.69 | 6 | 1.1 | 685 | 1140 | 510 | 640 | EE291201291749 | 3-736 | 340 | 370 | 403 | 422 | 8 | 28 | 2 | 1 | 0.38 | 1.6 | 0.87 | 25.1 | |

| 546.1 | 171.1 | 171.1 | 140.1 | 6 | 6 | 2800 | 5800 | 490 | 600 | 3063048 | 7961 | 355 | 400 | 500 | 515 | 8 | 28 | 5 | 0.34 | 1.8 | 17.5 | ||||

| 393.7 | 546.1 | 76.2 | 61.12 | 55.56 | 6 | 6 | 860 | 1343 | 500 | 630 | EE234154234215 | 7979 | 416 | 437 | 508 | 532 | 18 | 25 | 6 | 5 | 0.48 | 1.2 | 0.7 | 44.8 | |

| 431.8 | 571.5 | 52.38 | 874.612 | 74.612 | 3.3 | 3.3 | 1080 | 2470 | 380 | 480 | LM869448J/LM869410J | 453 | 457 | 537 | 549 | 5 | 16 | 3.3 | 3.3 | 0.55 | 1.1 | 0.6 | 48.2 | ||

| 609.6 | 787.4 | 93.66 | 93.66 | 69.85 | 6 | 6 | 2010 | 5060 | 340 | 450 | EE649240649310 | 3-734 | 655 | 690 | 725 | 760 | 10 | 25 | 6 | 5 | 0.37 | 1.6 | 0.9 | 110 | |

| 685.8 | 876.3 | 93.66 | 92.08 | 69.85 | 6.4 | 6.4 | 1980 | 5150 | 300 | 400 | EE65527065345 | EF655270655345 | 714 | 723 | 831 | 843 | 13 | 25 | 5 | 5 | 0.42 | 1.4 | 0.8 | 133 | |

| 759.93 | 889 | 88.9 | 88.9 | 72 | 3.3 | 3.3 | 1910 | 6130 | LI8448L183410 | 780 | 783 | 864 | 873 | 12.5 | 19 | 3.3 | 3.3 | 0.31 | 1.97 | 89.9 | |||||

| 762 | 889 | 88.9 | 88.9 | 72 | 3.3 | 3.3 | 1910 | 6130 | LI83449L183410 | 780 | 783 | 864 | 872 | 12.5 | 19 | 3.3 | 3.3 | 0.31 | 1.97 | 88.2 | |||||

Learn about our latest products and discounts through SMS or email