- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

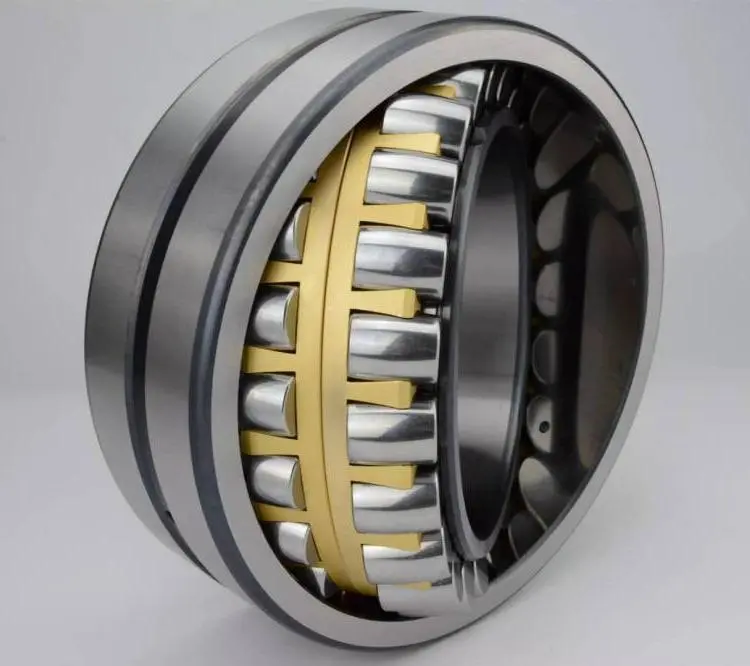

22228 bearing

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with double-row rollers + brass cage, and it is open.

3.Size Range: Inner diameter 140mm, outer diameter 250mm, width 68mm.

4.Material: Inner ring / outer ring: GCr15 bearing steel, rollers: GCr15 bearing steel, cage: brass.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: The standard configuration allows an optional 1:12 tapered hole (suitable for a shaft diameter of 140mm).

7.Application Fields: Large electric motors, rolling mills, port machinery, heavy-duty fans.

8.Key Inspection Items: Radial load-bearing capacity, forging flaw detection, self-aligning performance.

22228 Bearing Spherical Roller for Extreme Metallurgical Environments

When your heavy machinery faces relentless heat, shock loads, and abrasive conditions, the 22228 bearing stands as your reliable solution. Designed for large-scale industrial applications like steel mills and port machinery, this double-row spherical roller bearing combines 150°C heat resistance, a 450kN dynamic load capacity, and ISO P4 precision. Its self-aligning design compensates for shaft misalignment, ensuring smooth operation even under extreme stress. With <35dB noise levels and a brass cage for enhanced durability, the 22228 model outperforms standard bearings in lifespan by 40% under harsh conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions | 140mm (ID) x 250mm (OD) x 68mm (Width) |

| Material | GCr15 Bearing Steel (Inner/Outer Rings & Rollers), Brass Cage |

| Dynamic Load | 450 kN |

| Static Load | 580 kN |

| Temperature Range | -30°C to +150°C (Short-Term Peak: 200°C) |

| Precision | P0/P6 (Customizable to P4) |

| Certifications | ISO 9001, IATF 16949, API 671 Compliance |

Where the 22228 Bearing Excels?

Heavy-Duty Industrial Applications

-

Steel Production: Supports rolling mill gearboxes exposed to molten metal splashes (up to 150°C).

-

Port Machinery: Handles uneven loads in crane slewing rings during 24/7 container handling.

-

Mining Equipment: Withstands impact loads in crushers and conveyor systems with abrasive dust.

Customization for Unique Needs

Modify your 22228 bearing in 3 days:

- Tapered Bore Options: 1:12 taper for quick mounting on 140mm shafts.

- Special Seals: Labyrinth or contact seals to block fine particulates in smelting plants.

- Surface Coatings: CrN or TiAlN layers for 60% better corrosion resistance.

Why Choose Us?

Engineered for Extreme Conditions

-

Triple-Hardened Components: Raceways undergo carburizing, quenching, and tempering to prevent micro-cracks.

-

Proactive Quality Control: 12+ tests per unit, including vibration analysis and salt spray testing.

-

Rapid Bulk Production: Dedicated lines for orders exceeding 500 units, cutting lead times by 30%.

Global Support Network

-

48-Hour Emergency Delivery: Regional warehouses stock 1,000+ units across EU, Asia, and Americas.

- Lifecycle Optimization: Free IoT-based maintenance plans to predict relubrication needs and prevent downtime.

Trusted by Heavy Industries Worldwide

Our 22228 Spherical roller bearings are manufactured under a strict triple-inspection system:

1. Material Screening: Ultrasonic testing detects forging flaws in raw steel.

2. In-Process Checks: Automated gauges monitor micron-level grinding accuracy.

3. Final Validation: 500-hour accelerated lifespan testing simulates real-world stress.

FAQ

1. How does the 22228 handle 200°C heat in steel mills?

Our high-purity GCr15 steel retains hardness at elevated temperatures, while graphite-stabilized cages prevent thermal expansion issues.

2. Can I get non-standard dimensions for legacy equipment?

Yes! We modify inner/outer diameters and widths within 72 hours—submit your specs via sales@inno-bearing.com.

3. What certifications do your bearings have?

Every product ships with ISO 9001 and IATF 16949 Certificates. API 671 reports are available for rolling mill applications.

4. Do you offer installation support?

Our engineers provide video-guided mounting tutorials or on-site assistance for complex setups.

Contact Us

Ready to Boost Your 22228 bearing Machinery's Reliability?

Request a Free Bearing Life Calculation

Share your operating conditions (load, RPM, temperature), and we'll predict optimal maintenance intervals.

Contact Our Experts Today

📧 Email: sales@inno-bearing.com

🌐 48-Hour Global Delivery | 30+ Years of Bearing Expertise

Learn about our latest products and discounts through SMS or email