Dedicated R&D in split cylindrical roller bearing technology since 1993.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

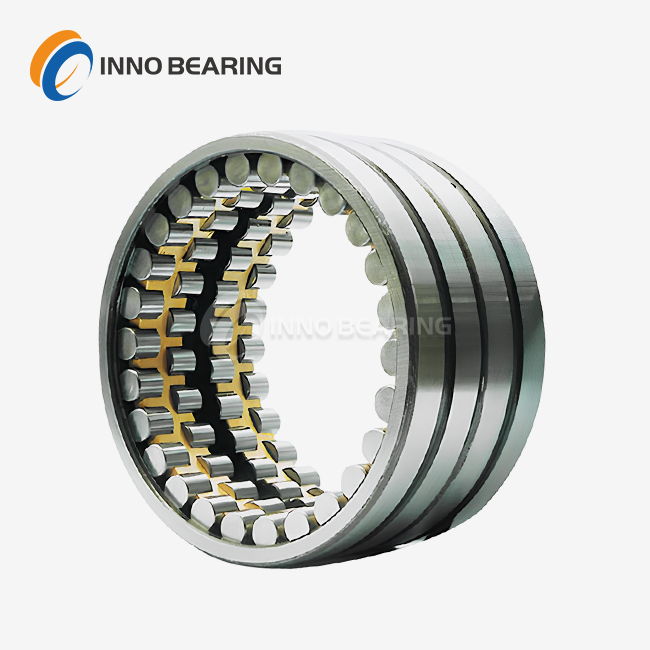

split cylindrical roller bearing

2.Structure Type: The inner ring / outer ring are axially split (with bolt connections), with single-row / double-row rollers + cage, and metal seals.

3.Size Range: Inner diameter 100 - 1500mm, outer diameter 200 - 2000mm, width 50 - 300mm.

4.Material: Inner ring / outer ring / rollers: GCr15/GCR15SIMN/20Cr2Ni4A, cage: stamped steel / brass.

5.Precision: P0/P6 level, P5 level for large precision equipment.

6.Application Fields: Rolling mill roll shafts, large electric motor rotors, mining machinery spindles, port crane large shafts.

7.Key Inspection Items: Split surface fitting degree, bolt

Revolutionizing Maintenance with Split Cylindrical Roller Bearings

Split Cylindrical roller bearings eliminate the need for complete shaft disassembly during installation or replacement—a game-changer for industries like wind energy, mining, and paper production. Engineered for hard-to-access equipment, these bearings combine axial split rings (secured by high-tensile bolts) with optimized roller arrangements. Whether you're maintaining a 5-ton crusher in a Chilean copper mine or retrofitting a legacy paper machine in Brazil, our split design reduces downtime by up to 70%.

Why Our Split Bearings Outperform Competitors?

✅ 48-Hour Delivery Guarantee

1,000+ standard models (OD ≤ φ5000mm) ready for immediate dispatch.

✅ Custom Solutions in 15-20 Days

30% faster prototyping for non-standard sizes like φ3000mm split roller bearings.

✅ Built for Extreme Conditions

- 500℃ heat resistance (metallurgical furnaces)

- 35dB quiet operation (medical imaging systems)

- 300MPa shock load tolerance (mining crushers)

✅ Full Lifecycle Support

From 3D modeling to IoT-driven wear analysis—we're your partners, not just suppliers.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Inner Diameter (ID) | 100mm – 1500mm |

| Outer Diameter (OD) | 200mm – 2000mm |

| Material | GCr15/20Cr2Ni4A steel, brass cages |

| Precision | P0/P6 (standard), P5 for large systems |

| Temperature Range | -50℃ to +150℃ |

| Dynamic Load Capacity | Up to 1,500kN (Wind Series) |

Industry-Specific Solutions

🌬️ Wind Turbine Main Shafts

-

Ceramic-coated split roller bearings withstand salt spray corrosion (1,200+ hours ASTM B117)

-

Dynamic load ratings ≥800kN for offshore turbines

⛏️ Mining Crushers

-

Carburized steel rollers endure abrasive dust & 300MPa impacts

-

6-month replacement cycles slashed to 18+ months

🏭 Paper Mill Dryers

- PTFE seals block steam ingress at 150℃

- Acid-resistant coatings combat chemical exposure

Global Leaders Trust Our Engineering

🔧 30+ Years Expertise

🌍 3 Regional Hubs

Fast-track shipments from EU/NA/Asia warehouses.

📊 12-Stage Quality Control

Every batch undergoes load, noise, and endurance testing.

FAQ

Q: Can you create products for obsolete machinery?

A: Absolutely. 87% of our projects involve reverse-engineering legacy systems.

Q: Do you offer emergency delivery?

A: Yes—critical orders ship within 48 hours, even for φ2000mm split bearings.

Q: What certifications do your bearings have?

A: All bearings meet ISO 9001, CE, and API 6D standards. Wind series are DNV GL-certified.

Contact Us

Ready to Slash Downtime with split cylindrical roller bearing?

Contact our engineers today for:

- Free split bearing design validation

- On-site measurement services

- Custom lubrication plans

📧 Email: sales@inno-bearing.com

⏰ Response Time: <4 hours during business days

Learn about our latest products and discounts through SMS or email