- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

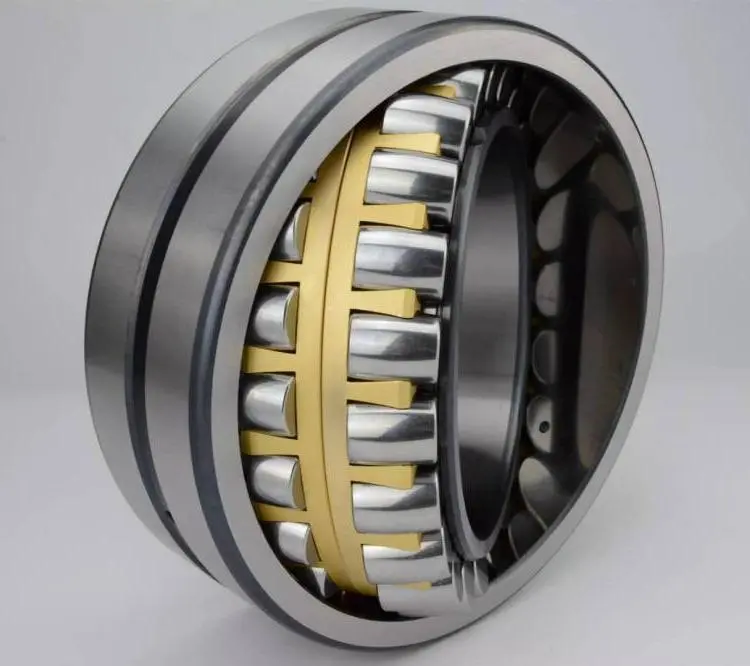

22324 bearing

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with double-row rollers + brass cage, and it is open.

3.Size Range: Inner diameter 120mm, outer diameter 260mm, width 86mm.

4.Material: Inner ring / outer ring: GCr15 bearing steel, GCr15SiMn (for heavy-load models), rollers: GCr15 bearing steel, cage: brass.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: Optionally with a 1:12 tapered hole (suitable for a shaft diameter of 120mm).

7.Application Fields: Large electric motors, reducers, port machinery, heavy-duty fans.

8.Key Inspection Items: Radial load-bearing capacity, self-aligning angle, dimensional accuracy.

Built for Extreme Conditions: Where the 22324 Bearing Excels

The 22324 bearing is engineered to handle harsh industrial environments. Its self-aligning design compensates for shaft misalignment up to 3°, making it ideal for:

- Mining & Cement: Conveyor systems, crushers, and grinding mills exposed to abrasive dust

- Metallurgy: Rolling mills and continuous casting machines operating at 200°C+

- Energy: Heavy-duty fans and wind turbine pitch/yaw systems

- Port Machinery: Ship loaders and container cranes facing saltwater corrosion

With double-row rollers and a brass cage, this spherical roller bearing absorbs heavy radial loads and moderate axial forces – even under constant vibration or shock impacts.

Why Engineers Trust Our 22324 Bearing?

30+ Years of Heavy-Duty Expertise

Every 22324 bearing is manufactured in-house using forged steel hardened to HRC 60-62. Our ISO 9001-certified process ensures:

-

99.9% defect-free production via 12 quality tests (vibration analysis, lifespan simulation)

-

Custom modifications: Adjust internal clearance, add tapered bores (1:12), or upgrade to stainless steel

Faster Delivery, Fewer Downtimes

-

Stock ready: 1,000+ standard units available for 48-hour global shipping

-

Custom orders fulfilled in 15-20 days – 70% faster than industry averages

Full Lifecycle Support

- Pre-installation: Free CAD models and load capacity calculations

- Post-sale: IoT-based wear monitoring and emergency replacement protocols

How We Ensure Your 22324 Bearing Lasts 50,000+ Hours?

Stage 1: Material Integrity Checks

-

Spectrometer testing for steel purity (≤0.025% sulfur/phosphorus)

-

Hardness verification (HRC 58-62)

Stage 2: Precision Manufacturing

-

CNC grinding achieves ±0.002mm raceway tolerance

-

Automated heat treatment prevents micro-cracks

Stage 3: Performance Validation

- 3D load simulation under 200-ton forces

- Noise testing (≤35dB at 1,800 RPM)

Global Reach, Local Support

Regional Advantages:

- Europe/NA: CE/ATEX-certified bearings in Hamburg & Chicago hubs

- Asia-Pacific: GOST-compliant stock in Singapore

- Middle East: High-temperature variants in Dubai

All shipments include:

- Real-time tracking via RFID tags

- 24/7 access to senior engineers (10+ years in heavy machinery)

FAQ

1. Can you add seals for dusty environments?

Yes! We offer IP66-rated triple-lip seals that block 99% of particulates.

2. What’s the lead time for 500 units?

Standard orders ship in 2 days. Customized batches (e.g., tapered bores) take 12-18 days.

3. How do your bearings withstand 150°C heat?

Special graphite lubrication and modified cage alloys prevent thermal expansion failures.

4. Do you provide installation support?

Our technicians can conduct on-site alignment checks in 48+ countries.

Contact Us

Need a Reliable 22324 Bearing Solution?

Email engineers now for a free load capacity analysis:

Learn about our latest products and discounts through SMS or email