- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

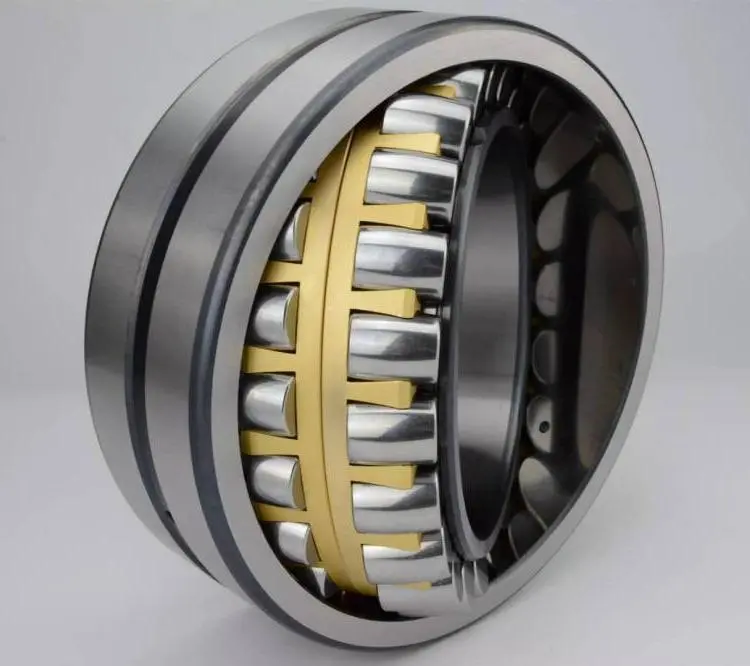

22330 bearing

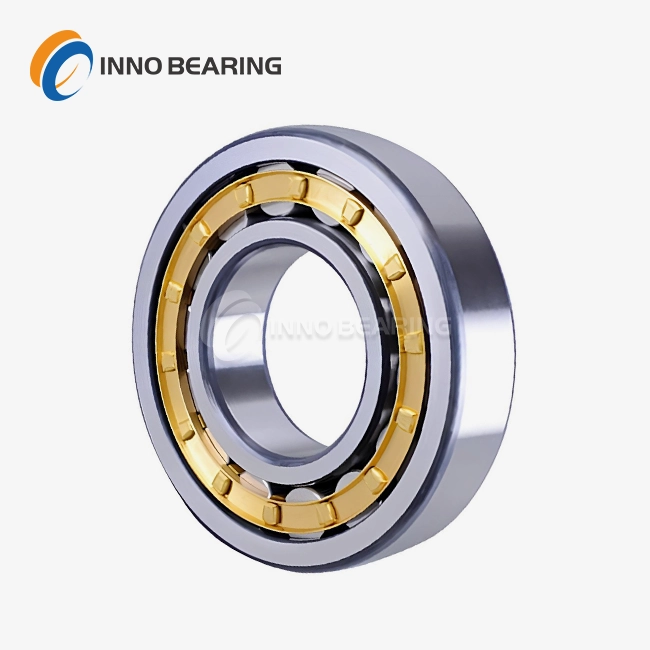

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with double-row rollers + steel cage, and it is open.

3.Size Range: Inner diameter 150mm, outer diameter 320mm, width 108mm.

4.Material: Inner ring / outer ring: GCr15SiMn (heavy-load with integral forging), GCr15 bearing steel (conventional), rollers: GCr15 bearing steel, cage: steel.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: The standard configuration is a 1:12 tapered hole (suitable for a shaft diameter of 150mm).

7.Application Fields: Extra-large electric motors, rolling mill work rolls, port extra-heavy-duty machinery.

8.Key Inspection Items: Forging flaw detection, radial load-bearing capacity, tapered hole precision.

22330 Bearing: Heavy-Duty Performance for Extreme Industrial Applications

The 22330 bearing is a heavy-duty self-aligning roller bearing engineered to withstand extreme loads and harsh operating conditions. With an inner diameter of 150mm and a dynamic load capacity exceeding 850kN, this bearing is ideal for heavy machinery in industries like metallurgy, mining, and port operations. At LUOYANG INNO BEARING CO., LTD, we combine over three decades of manufacturing expertise with advanced materials like GCr15SiMn steel to deliver products that offer unmatched durability and precision in high-stress environments.

Technical Specifications & Performance

- Dimensions: 150mm (inner diameter) × 320mm (outer diameter) × 108mm (width)

- Load Capacity: Dynamic load 850kN | Static load 1,200kN

- Temperature Range: -20℃ to +200℃ (HT Series available for extreme heat)

- Precision: ISO P6 standard (P5/P4 optional for high-speed applications)

- Material: GCr15SiMn forged steel rings, GCr15 rollers, robust steel cage

- Tapered Bore: 1:12 standard ratio for secure shaft fitting

Why Choose Us?

Built for Heavy Industrial Challenges

-

Extreme Load Resilience: Designed for equipment handling ≥300-ton dynamic loads, such as rolling mill work rolls and port cranes.

-

High-Temperature Adaptation: Optional ceramic grease and QPQ nitriding surface treatment ensure stable performance in 200℃+ environments (e.g., cement kilns).

-

Misalignment Compensation: Self-aligning design reduces wear caused by shaft deflection up to 3°.

Precision Manufacturing & Quality Assurance

-

Triple-Layer Quality Checks:

1. Material purity verification via spectral analysis.

2. Real-time monitoring of raceway grinding (≤5μm tolerance).

3. 100% fatigue testing under simulated load conditions.

-

Certifications: ISO 9001, CE, and industry-specific compliance (e.g., GOST for CIS markets).

Customization Without Compromise

- Non-Standard Modifications:

- Bore adjustments (keyways, splines).

- Sealed variants (2RS1/S1) for dusty/wet environments.

- Integrated sensors for IoT-enabled predictive maintenance.

- Rapid Production: 15-20 days for custom orders up to φ3000mm.

Global Availability & Support

- Fast Delivery: 48-hour shipping for standard 22330 bearings (1,000+ units in stock).

- Regional Warehouses: Strategic hubs in Asia, Europe, and North America.

- Technical Services: On-site installation guidance, lifecycle management, and 24/7 emergency support.

FAQ

Q: Can you customize a product for a 200℃ steel plant environment?

A: Yes! Our HT Series uses heat-stabilized steel and ceramic-based grease to maintain performance at extreme temperatures.

Q: What’s the minimum order quantity (MOQ) for custom sizes?

A: MOQ starts at 5 units for non-standard designs, with no upfront tooling fees.

Q: How do you ensure bearing longevity in abrasive mining conditions?

A: We apply QPQ nitriding to achieve ≥0.6mm case depth, enhancing surface hardness to 62 HRC.

Q: Do you provide documentation for customs clearance?

A: Yes, all shipments include commercial invoices, packing lists, and compliance Certificates.

Q: Can you replicate obsolete bearings for legacy machinery?

A: Absolutely. Our reverse engineering team can recreate discontinued models within 3 weeks.

Contact Us

Need a Reliable Partner for Heavy-Duty Bearings?

Email our engineers at sales@inno-bearing.com for personalized Solutions.

Optimized for heavy machinery durability, rapid customization, and global compliance, the 22330 bearing from LUOYANG INNO delivers the reliability your operations demand. With 30+ years of industry-specific expertise, we're your trusted partner for bearings that endure the toughest conditions.

Learn about our latest products and discounts through SMS or email