- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

22336 bearing

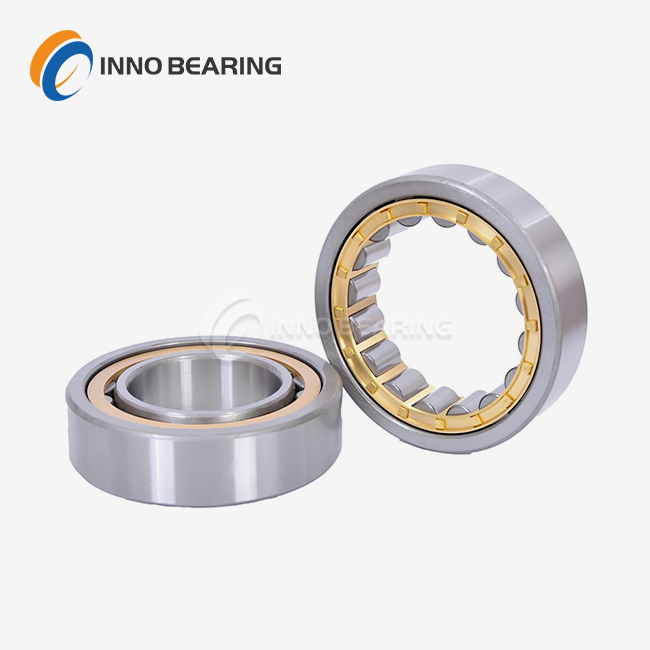

2.Structure Type: The inner ring has a spherical raceway, the outer ring has double ribs, with double-row rollers + steel cage, and it is open.

3.Size Range: Inner diameter 180mm, outer diameter 380mm, width 126mm.

4.Material: Inner ring / outer ring: GCr15SiMn (heavy-load with integral forging), GCr15 bearing steel (conventional), rollers: GCr15 bearing steel, cage: steel.

5.Precision: P0/P6 level.

6.Common Inner Tapered Hole: The standard configuration is a 1:12 tapered 孔 (suitable for a shaft diameter of 180mm).

7.Application Fields: Extra-large rolling mills, port super-heavy-duty cranes, mining machinery spindles.

8.Key Inspection Items: Forging flaw detection by UT/MT, radial load-bearing capacity, self-aligning performance.

22336 Bearing Spherical Roller – Heavy-Duty Solution for Extreme Industrial Demands

When your equipment operates under extreme loads, high temperatures, or harsh environments, the 22336 bearing stands as a reliable workhorse. Designed for heavy industrial applications like metallurgy, mining, and port machinery, this self-aligning roller bearing combines robust construction with precision engineering. At LUOYANG INNO BEARING CO., LTD, we've refined the 22336 model over 30+ years to deliver unmatched durability, even in the most demanding conditions.

Core Advantages of the 22336 Bearing

- Engineered for Extreme Conditions: Withstands dynamic loads up to 1,750kN and temperatures up to 120°C through specialized heat treatment.

- Customizable Design: Modify dimensions (±0.5mm tolerance), add corrosion-resistant coatings (Zn-Ni, PTFE), or integrate triple-lip seals for dusty environments.

- Faster Delivery: Choose from 1,000+ in-stock units (48-hour dispatch) or custom orders completed in 15–20 days – 30% faster than industry averages.

Technical Specifications

| Parameter | Value |

|---|---|

| Dimensions (ID/OD/Width) | 180mm / 380mm / 126mm |

| Dynamic Load Rating | 1,750kN |

| Static Load Rating | 1,240kN |

| Precision | ISO P4 (ABEC 7) |

| Noise Level | <35dB |

| Material | GCr15SiMn (forged) / GCr15 steel |

Where the 22336 Bearing Excels?

1. Metallurgy & Steel Production

-

Challenge: Bearings fail prematurely in rolling mills exposed to 120°C+ heat and heavy slab loads.

-

Solution: Our products use induction-hardened raceways and heat-stable cages to maintain precision under thermal stress.

2. Mining Equipment

-

Challenge: Crushers and conveyors face shock loads >500kN and abrasive dust.

-

Solution: Reinforced roller ends and optional labyrinth seals extend service life by 40% vs. standard bearings.

3. Port Machinery

- Challenge: Crane slewing rings corrode in salty, humid environments.

- Solution: Zinc-nickel coated products reduce rust-related downtime by 60%.

Quality Assurance: Built to Last

Every 22336 bearing undergoes:

1. Material Testing: Ultrasonic (UT) and magnetic particle (MT) inspection for forging defects.

2. Performance Validation: 200,000+ hour lifespan testing at 300 RPM simulated loads.

3. Noise & Vibration Checks: <35dB operation ensures compatibility with high-speed gearboxes.

Supply Chain Efficiency

- Stock Availability: 1,000+ units ready for urgent repairs.

- Custom Orders: Adjust inner ring taper (1:12 standard) or outer diameter (up to φ5000mm).

- Global Logistics: Regional warehouses in EU, North America, and ASEAN support fast delivery.

Why Choose Us?

1. 30+ Years of Heavy-Load Expertise: We've served 1,200+ clients in metallurgy and mining since 1993.

2. End-to-End Customization: Modify material grades, seals, or dimensions without delaying production.

3. Full Compliance: ISO 9001, CE, and ROHS certifications included with every shipment.

4. Lifecycle Support: From bearing selection to IoT-driven predictive maintenance planning.

FAQ

Q: Can you customize the product for a shaft diameter of 185mm?

A: Yes – We adjust inner diameters within ±0.5mm tolerance at no extra cost.

Q: What certifications come with the bearing?

A: Each unit includes ISO 9001, CE, and material traceability reports.

Q: Do you offer on-site installation support?

A: Yes – Our engineers provide global installation guidance within 72 hours of request.

Q: How does your product handle contamination in mining applications?

A: Optional triple-lip seals or PTFE-coated cages block 95% of dust/particles.

Contact Us

Upgrade Your 22336 bearing Equipment's Reliability Today

📞 Contact Us: +86 XXX

📧 Email: sales@inno-bearing.com

🌍 Regional Warehouses: EU (Germany), NA (USA), ASEAN (Singapore)

LUOYANG INNO BEARING CO., LTD – Powering Heavy Industries Since 1993

Learn about our latest products and discounts through SMS or email