- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

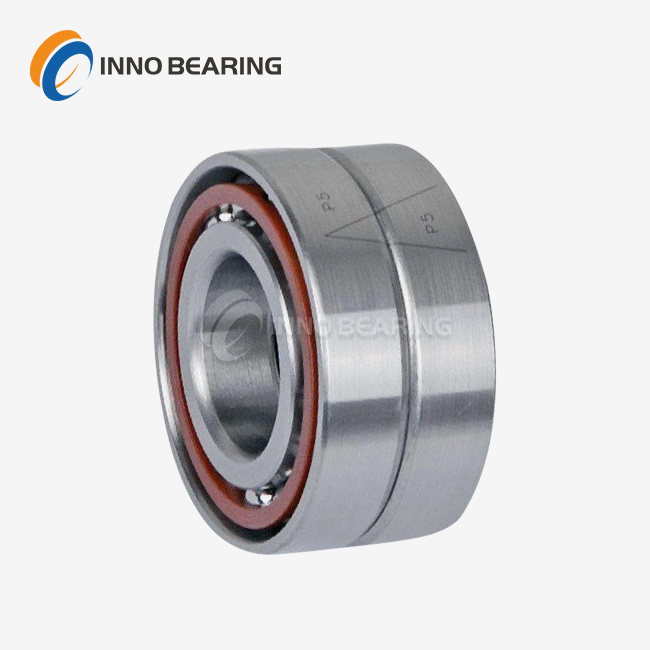

excavator slewing bearing

2.Structure Type: It has a large-diameter annular thick-wall structure. The inner and outer rings are made of 42CrMo steel, with built-in double-row rollers. The gear ring is carburized and quenched, and metal skeleton seals are used to prevent sediment, and the mounting holes have anti-loosening designs.

3.Size Range: Outer ring diameter: 800 - 4000mm, inner ring diameter: 700 - 3800mm, height: 30 - 150mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: 6 - 50 tons of medium and large excavators, mining excavators, heavy-duty backhoe loaders.

6.Key Inspection Items: Tooth surface hardness (HRC58 - 62), anti-impact load performance, sediment-proof performance of seals.

High-Performance Excavator Slewing Bearings Built for Extreme Duty Cycles

Engineered to withstand 500+ ton loads, 150℃ temperatures, and 30+ years of operation. Custom diameters up to φ5000mm with 25 day rapid delivery for non-standard specs.

When your excavator's slewing bearing fails, downtime costs soar. That's why leading OEMs trust LUOYANG INNO BEARING's excavator Slewing Bearings—precision-engineered to endure harsh mining, construction, and demolition environments. Our bearings combine military-grade materials with modular designs, ensuring seamless rotation under extreme axial/radial forces.

Why Our Slewing Bearings Outperform Competitors?

30+ Years of Heavy-Duty Expertise

We specialize in heavy-duty slewing bearings for excavators (6-50 tons), leveraging three decades of R&D to optimize load distribution and fatigue resistance. Our vertical integration—from steel forging to heat treatment—guarantees consistent quality.

Rapid Customization & Production

Need a non-standard slewing ring for excavators? Submit your specs (CAD/blueprints accepted), and we’ll deliver:

-

φ3000mm custom bearings in 25 days (30% faster than industry averages)

-

Diameters up to φ5000mm with ±0.01mm precision

-

Internal/external gear drives, anti-loosening bolt holes

Built to Survive Extreme Conditions

- Material: 42CrMo/50Mn steel with 58-62 HRC hardness (4x wear resistance vs. standard bearings)

- Seals: Triple-lip nitrile rubber + metal shields block abrasive dust and moisture

- Temperature range: -45℃ to +150℃ (ideal for smelting/mining sites)

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Outer Diameter | 800mm - 4000mm |

| Load Capacity | 50kN·m - 50,000kN·m |

| Gear Hardness | HRC58-62 (carburized & quenched) |

| Mounting Holes | Anti-vibration design |

| Certifications | ISO 9001, CE, API 6A, GB/T 307.1 |

Customization Made Simple

1. Share Requirements: Send excavator model, load data, and environmental conditions.

2. Simulate & Optimize: Our engineers run FEM/ANSYS simulations to validate bearing performance.

3. Test Rigorously: Prototypes undergo 12+ stress tests (fatigue, vibration, thermal cycling).

4. Produce & Deliver: Bulk orders ship in 15-30 days with pre-assembly inspection reports.

Quality You Can Trust

Every excavator slewing bearing undergoes:

✅ Ultrasonic flaw detection

✅ Torque tolerance testing (±5%)

✅ 72-hour salt spray corrosion resistance check

✅ Dimensional accuracy verification (ISO 492 Class 5+)

Warranty: 5-year structural integrity guarantee.

Global Support, Local Speed

- 1,000+ bearings in stock: 48-hour dispatch for standard sizes.

- DDP shipping: Doorstep delivery to 50+ countries with customs clearance.

- 24/7 technical support: Multilingual engineers assist with installation, lubrication, and IoT monitoring setup.

Why 100+ Excavator OEMs Choose Us?

- 30% longer lifespan than ISO 7753-1 standards

- 18% lower TCO via reduced maintenance and downtime

- IoT-ready designs: Optional sensors predict failures by tracking vibration and temperature trends.

Get Your Custom Solution Today

“Request Your Custom Bearing Quote in 4 Hours”

📎 Option 1: Upload excavator specs for instant sizing and pricing.

🛠️ Option 2: Schedule a free consultation to optimize bearing lifecycle costs.

FAQs

1. How do your bearings handle compact excavator designs?

We use 3D scanning to retrofit older models, optimizing gear meshing and load paths without blueprints.

2. What materials resist abrasive mining debris?

42CrMo steel with induction-hardened raceways (60 HRC) + fluorocarbon seals.

3. Can φ5000mm bearings handle 50,000 N·m loads?

Yes—double-row roller designs distribute stress evenly, validated via ANSYS simulations.

4. How do you achieve fast lead times?

Modular production with pre-forged components cuts machining time by 40%.

5. Do you support marine environments?

Stocked bearings include zinc-nickel coatings for saltwater corrosion resistance.

Contact Us

Contact Our Engineers for Excavator Slewing Bearing: Email sales@inno-bearing.com for CAD files or emergency replacements.

✅ Certified Quality ✅ Fast Global Shipping ✅ 5-Year Warranty

Learn about our latest products and discounts through SMS or email