- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

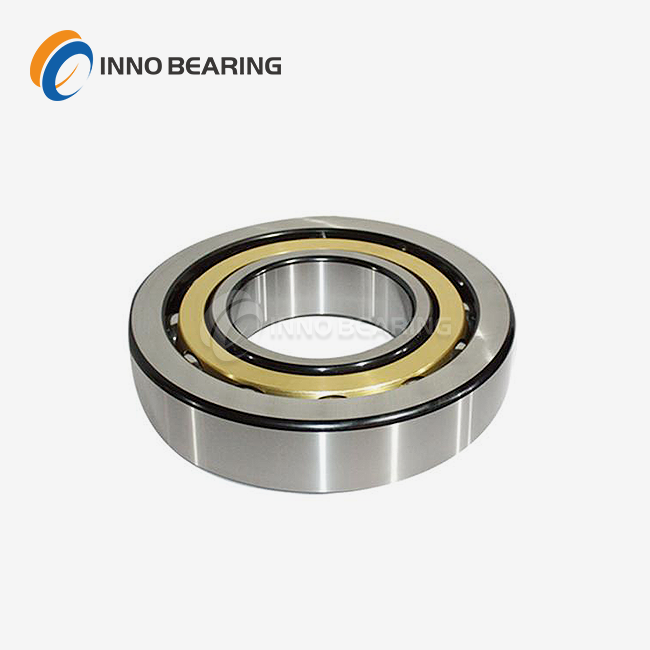

slewing bearing with external gear

2.Structure Type: It has an annular shape. The outer side of the outer ring has straight or helical teeth. The inner and outer rings have double raceways, with steel balls or rollers + cages, and seals on both sides.

3.Size Range: Outer ring diameter: 500 - 3500mm, outer ring gear ring diameter: 520 - 3550mm, height: 30 - 100mm.

4.Material: Inner ring / outer ring: 50Mn, 42CrMo; rolling elements: GCr15 bearing steel, GCr15SiMn (optional for impact resistance); seals: nitrile rubber, fluororubber (optional for oil and high temperature resistance).

5.Application Fields: Tower cranes, large amusement equipment, port portal cranes, wind power yaw systems.

6.Key Inspection Items: External gear pitch error, depth of carburized layer, slewing accuracy.

High-Performance Slewing Bearings with External Gears

Customized for Heavy-Duty Industrial Applications

Engineered for Extreme Loads & Temperatures – 30+ Years of Precision Manufacturing Expertise

Request a Custom Quote Today → (48-Hour Response)

---

Why Choose Slewing Bearings with External Gears?

Slewing Bearings with external gears are engineered to deliver unmatched power transmission efficiency in demanding environments. At LUOYANG INNO BEARING CO., LTD, we specialize in crafting these bearings with high-purity steel and precision-ground gears to ensure smooth rotation, even under loads up to 5,000kN. Whether you’re designing a wind turbine yaw system or a port crane, our Solutions combine AGMA Class 8+ gear accuracy with 500°C heat resistance for long-term reliability.

---

Key Product Highlights

- Wide Size Range: φ500–5,000mm diameters | Up to 100mm height.

- Superior Durability: 42CrMo steel gears with HRC 50–55 hardness.

- Customization Ready: Spur/helical gears, P4-level precision, IP67 sealing.

- Fast Turnaround: 30% faster production for non-standard sizes.

---

Technical Specifications

| Parameter | Standard Range | Custom Options | |

|---|---|---|---|

| Outer Diameter | φ500–3,000mm | Up to φ5,000mm+ | |

| Gear Accuracy | DIN 6–8 | DIN 4 (High-Precision) | |

| Operating Temp | -30°C to 200°C | -50°C to 200°C | |

| Load Capacity | 2,500kN | 10,000kN+ |

Complies with ISO 9001, CE, and AGMA 2001 standards.

---

Industries We Serve

1. Wind Energy

Our external gear slewing bearings withstand 20+ years of harsh offshore conditions. Features include:

- DNV-GL certification for marine environments.

- Fatigue life validated at 2x industry cycles.

2. Port Machinery

Designed for 0.01mm gear backlash control in container cranes:

- Impact-resistant 50Mn steel outer rings.

- Modular assembly for quick retrofitting.

3. Mining & Metallurgy

Built to handle 4,000kN loads and 200°C furnace heat:

- Carburized gear teeth (depth ≥2mm).

- Corrosion-resistant fluororubber seals.

---

Customization Process

1. Submit Requirements: Share gear specs, load data, and environmental needs.

2. 3D Simulation: Gear meshing analysis and FEM stress testing.

3. Prototype Testing: On-site CMM validation (<5μm gear deviation).

4. Bulk Production: Dedicated line for 30-day lead times.

---

Quality Assurance

Every slewing bearing with external gear undergoes:

- 100% Vibration Testing: ≤4.5dB noise at 300 RPM.

- Ultrasonic Inspection: Zero material defects.

- Lifetime Support: IoT-based wear monitoring and predictive maintenance.

99.9% qualification rate across 40+ countries.

---

Why Partner with Us?

- 30+ Years Expertise: Focused solely on slewing bearings with external gears.

- 1,000+ Ready-to-Ship Models: No MOQ for custom orders.

- Global Compliance: CE, API 6A, and GB/T certifications pre-approved.

---

FAQs

Q1: Can you customize helical gears for compact machinery?

Yes! We design helical gears with <0.05mm pitch error for space-constrained applications like medical robotics.

Q2: How do you ensure gear durability in high-heat environments?

Our 42CrMo gears undergo precision heat treatment and carburizing to maintain hardness up to 500°C.

Q3: What’s the lead time for a φ4,000mm custom bearing?

Just 60 days – 50% faster than industry norms.

---

Need a Reliable Slewing Bearing with External Gears?

📧 Email: sales@inno-bearing.com

📥 Download Gear Design Guidelines | 📞 Schedule a Consultation

---

Optimized for heavy machinery OEMs, wind energy integrators, and industrial distributors since 1993.

Learn about our latest products and discounts through SMS or email