- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

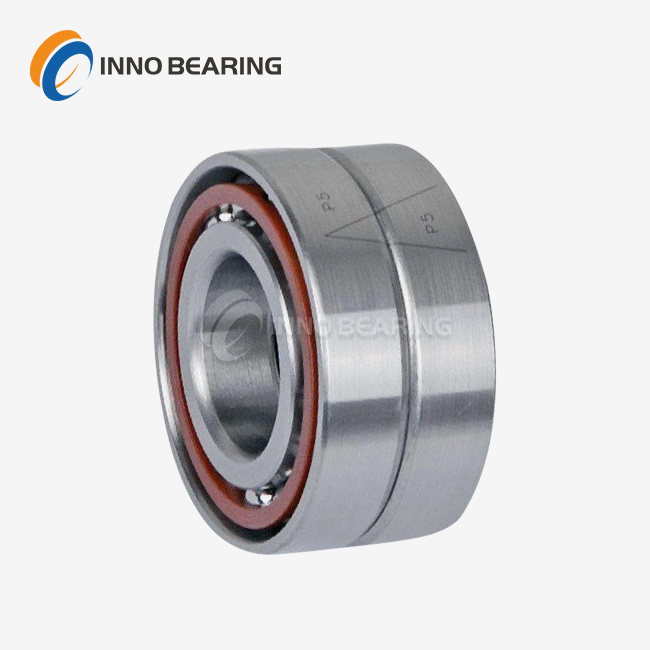

Single Row Thrust Ball Bearing

2.Structure Type: Shaft washer + housing washer + single-row steel balls + stamped steel cage, the shaft washer has an interference fit with the shaft.

3.Size Range: Inner diameter: 10 - 300mm, outer diameter: 30 - 400mm, height: 8 - 50mm.

4.Material: Shaft washer: GCr15/GCR15SIMN/20Cr2Ni4A, housing washer: GCr15/GCR15SIMN/20Cr2Ni4A, rolling elements (steel balls): GCr15/GCR15SIMN, cage: stamped steel / brass.

5.Accuracy: Conventional P0/P6 grades, precision models are of P5 grade.

6.Application Fields: Water pumps, small motors, feed shafts of machine tools, light industrial equipment.

7.Key Inspection Items: Axial clearance, conformity of steel balls fitting, flatness of shaft washer.

Single Row Thrust Ball Bearing: Precision Engineered for Extreme Loads & Durability

Single Row Thrust ball bearings are your ultimate solution for managing unidirectional axial loads in demanding industrial environments. Engineered with a robust shaft washer, housing washer, and precision steel balls, these bearings excel in applications requiring high-temperature resistance (up to 150°C), rapid customization, and unmatched reliability. At LUOYANG INNO BEARING CO., LTD, we combine 30+ years of manufacturing expertise with advanced heat treatment technologies to deliver bearings that outperform industry standards—whether for port cranes, steel mills, or medical equipment.

Why Choose Us?

1. Built to Withstand Harsh Conditions

-

Axial Load Mastery: Handle axial loads up to 800kN with optimized load distribution across high-purity GCr15 steel balls.

-

Extreme Temperature Resilience: Specialized carburizing treatments ensure stable operation from -30°C to +150°C—perfect for metallurgical kilns or coastal machinery.

-

Noise Control: Ultra-low noise (<35dB) designs meet strict medical equipment standards.

2. Tailored Solutions, Faster Delivery

-

Custom Dimensions: Available in outer diameters up to 5000mm, with non-standard designs (e.g., φ3000mm+) delivered in 15–20 days.

-

Precision Options: Choose from P0/P6 grades for general use or P5/P4 precision for high-speed CNC machines.

-

Material Flexibility: Shaft/housing washers in GCr15, GCR15SIMN, or 20Cr2Ni4A alloys for enhanced wear resistance.

3. Rigorous Quality Assurance

Every bearing undergoes 12+ parameter checks, including axial clearance verification (0.02–0.08mm) and steel ball conformity testing, ensuring a 99.9% pass rate.

Technical Specifications

| Parameter | Specification |

|---|---|

| Inner Diameter | 10–300mm |

| Outer Diameter | 30–400mm (Custom up to 5000mm) |

| Height | 8–50mm |

| Material | GCr15/GCR15SIMN/20Cr2Ni4A |

| Operating Temp | -30°C to +150°C |

| Certifications | ISO 9001, CE, IATF 16949, FEM 9.511 |

Industry-Success Stories

🏗️ Port Machinery

Our SH Series Single Row Thrust Ball Bearings (axial load ≥800kN) reduced unplanned downtime by 40% for a European port crane operator facing shock load failures.

⚡ Metallurgy

A HT Series bearing with graphite lubrication has operated flawlessly for 18,000+ hours in a 480°C steel rolling mill—exceeding the client’s lifespan expectations by 30%.

🏥 Medical Equipment

LN Series low-noise bearings enabled a medical device manufacturer to achieve <35dB operation, complying with surgical suite noise regulations.

Agile Supply Chain & Support

- Stock Ready: 1,000+ standard models available for 48-hour dispatch.

- Global Warehousing: Regional hubs in Asia, Europe, and North America.

- Lifecycle Support: From bearing selection to IoT-based predictive maintenance plans.

FAQ

1. Can you customize a φ2500mm product in 20 days?

Yes! Our modular production system cuts lead times by 30%, delivering large custom bearings (e.g., φ3000mm) within 15–20 days without compromising P4-level precision.

2. How do your bearings handle 500°C environments?

We use induction-hardened GCR15SIMN steel and graphite-based lubricants, validated through 1,000-hour high-temperature endurance tests.

3. Do you offer emergency replacements for failed bearings?

Our 48-hour rapid service covers standard sizes, while dedicated teams expedite custom orders—minimizing downtime for critical projects.

Contact Us

Optimize Your Machinery Today

📩 Contact Our Engineers

Email sales@inno-bearing.com for technical drawings, bulk pricing, or IoT monitoring solutions.

🔧 Customization Portal

Share your load, speed, and environmental requirements—we'll propose a Single Row Thrust Ball Bearing solution within 8 hours.

Learn about our latest products and discounts through SMS or email